Double-layer structured yarn-dyeing tube with certain elastic deformability in surface

An elastic deformation, double-layer structure technology, applied in the processing of textile materials, textiles and papermaking, processing of textile material carriers, etc. , achieve the effect of reducing density difference, solving large color difference and inconsistency in elasticity, and solving technical problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

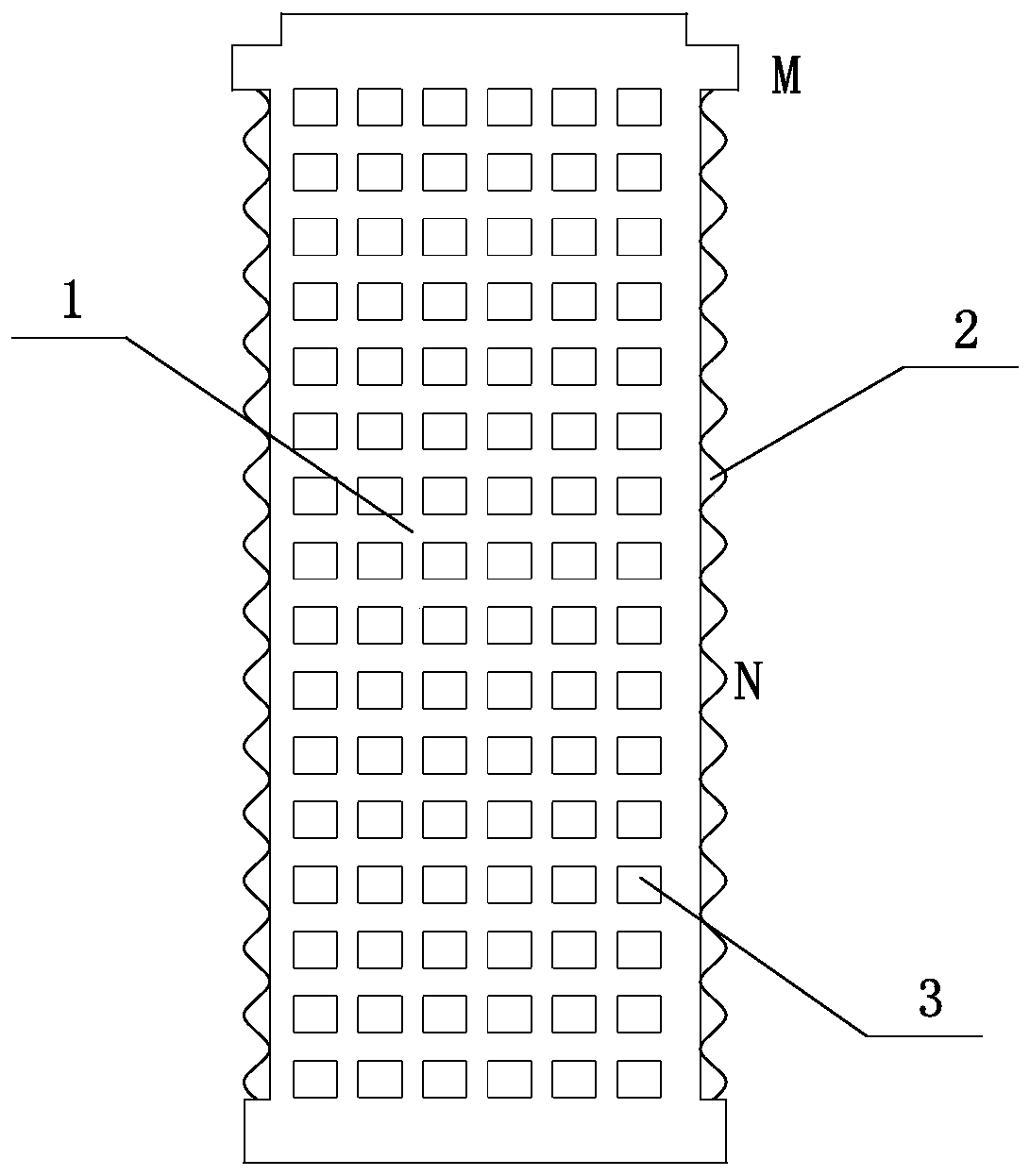

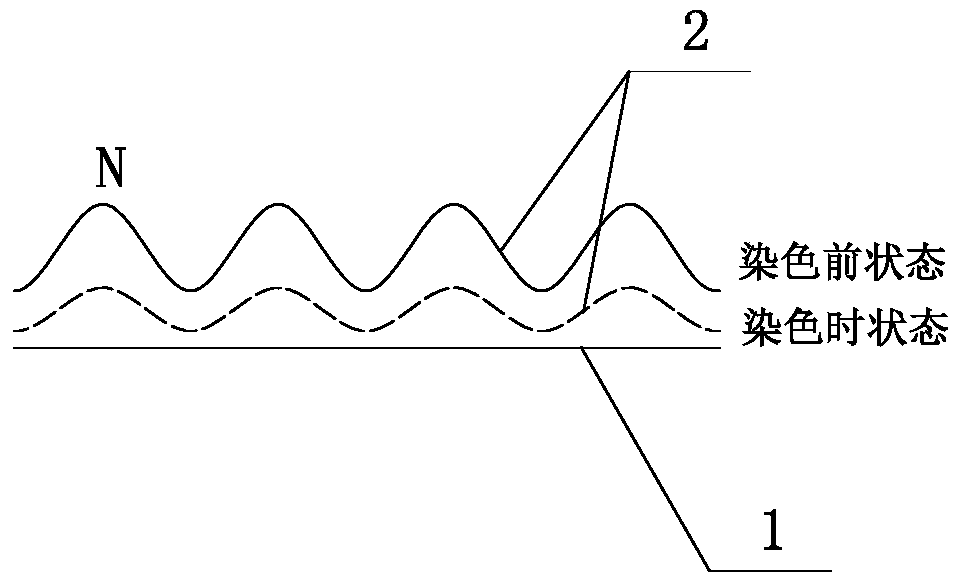

[0020] Such as Figure 1-2 As shown, the double-layer structure yarn dyeing tube with a certain elastic deformation ability on the surface of the present invention is divided into an inner layer 1 and an outer layer 2 arranged concentrically, and the inner layer 1 is a cylindrical hollow cheese with a through hole 3 Dyeing tube, the outer layer 2 is a wave-shaped embossed mesh with elastic deformation capability, the upper and lower parts of the inner layer 1 are provided with semi-arc-shaped grooves, and the upper and lower parts of the outer layer 2 are provided with semi-arc-shaped protrusions for assembly. The outer layer 2 closely contacts and completely covers the yarn winding area of the inner layer 1 . Because the pH value of the cheese dyeing solution is 2-14, hydrogen peroxide and other oxidizing agents need to be added during the dyeing process. Therefore, the outer layer 2 is a wavy roll with a plain weave structure interwoven with acid-resistant, alkali-resistan...

Embodiment 2

[0025] On the basis of Example 1, the surface has a double-layer structure dyeing tube with a certain elastic deformation capacity. The mesh of the wave-shaped embossed net is a square, the side length is 3mm, and the diameter of the steel wire is 0.5mm. 33% of the mesh area, the number of outer layer 2 coating layers is 1 layer.

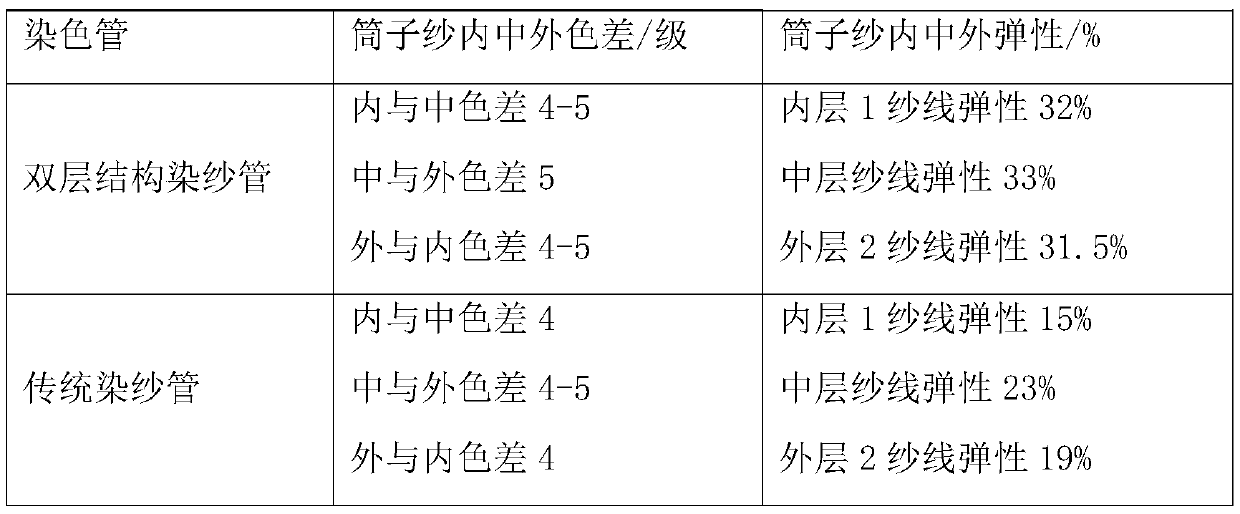

[0026] Use the double-layer structure dyeing bobbin in Example 2 and the traditional cheese dyeing bobbin to dye the 40S / 1FFT elastic yarn in the same dyeing vat, and the cheese density is 3.9g / cm 3 , The color difference and elasticity comparison data of the inner and outer layers of the yarn after dyeing are shown in Table 1:

[0027] Table 1 Dyeing comparison data of FFT elastic yarn double-layer structure dyeing bobbin and traditional dyeing bobbin

[0028]

Embodiment 3

[0030] On the basis of Example 1, the surface of this example has a double-layer structure dyeing tube with a certain elastic deformation capacity. The mesh of the wave-shaped embossed net is square, the side length is 15mm, and the diameter of the steel wire is 0.8mm. Accounting for 11% of the area of the crimped wire mesh, the number of outer layer 2 cladding layers is 3.

[0031] Use the double-layer structure dyeing bobbin in Example 3 and the traditional cheese dyeing bobbin to dye 50S / 1 Lycra yarn in the same dyeing vat, and the cheese density is 4.2g / cm 3 , The color difference and elasticity comparison data of the inner and outer layers of the yarn after dyeing are shown in Table 2:

[0032] Table 2 Dyeing comparison data of 50S / 1 Lycra yarn double-layer structure dyed bobbin and traditional dyed bobbin

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com