Dyed foaming particle and preparation method and application thereof

A technology of foamed particles and dyed foam, which is applied in the field of dyed foamed particles and its preparation, which can solve the problems of affecting performance, difficulty in uniform dyeing, single color, etc., and achieve the effect of solving large color difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

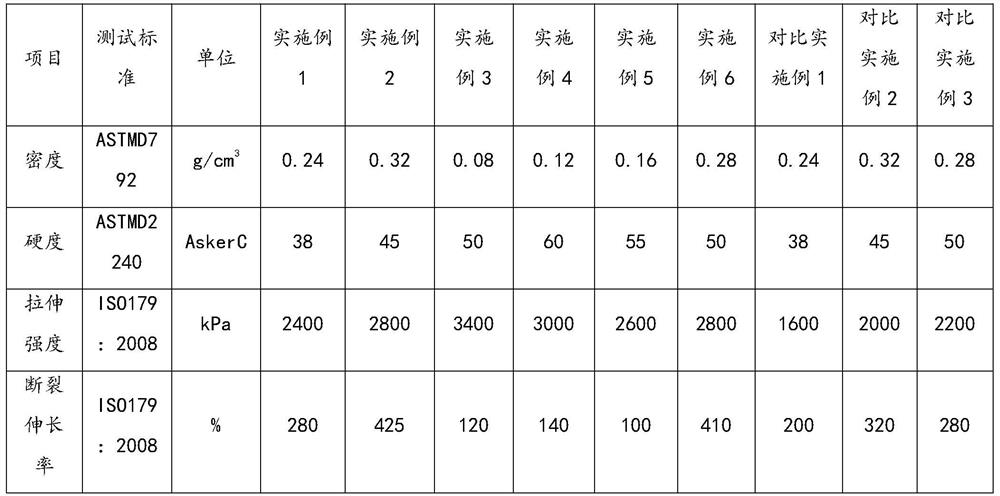

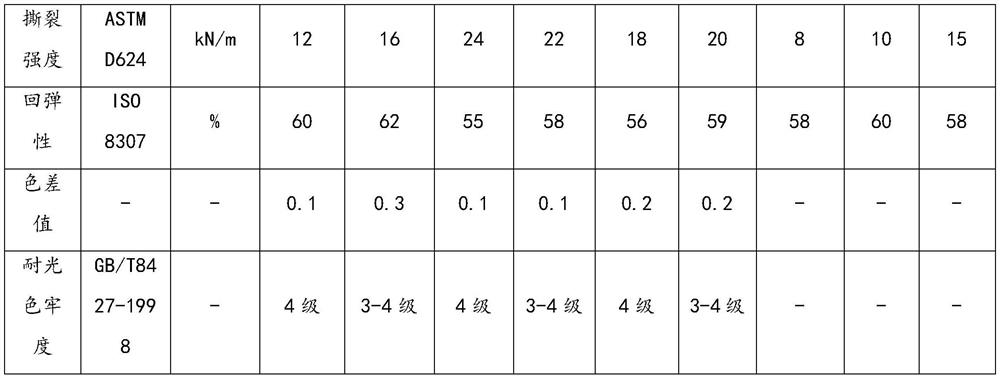

Examples

Embodiment 1

[0032] A kind of preparation method of black thermoplastic polyurethane elastomer (TPU) expanded particle, comprises the steps:

[0033] (1) Weigh 90g of density 0.16g / cm 3 , The TPU expanded particles with a long diameter of 1cm are put into the high mixer for preheating treatment, the preheating temperature is 20°C, and the preheating time is 10min;

[0034] (2) Weigh 10 g of black one-component polyurethane reactive hot melt adhesive containing 10% Cabot 9A32 carbon black and put it in an oven for preheating treatment. The preheating temperature is 120° C. and the preheating time is 60 minutes;

[0035] (3) the one-component polyurethane reactive hot-melt adhesive of black coloring in step (2) is joined in the high mixer in step (1) and carries out stirring dyeing;

[0036] (4) The one-component polyurethane reactive hot-melt adhesive to be black colored is cured after the surface dry part of the particle surface is cured, and the high mixer is turned on to obtain black TPU ...

Embodiment 2

[0039] A kind of preparation method of red thermoplastic polyester elastomer (TPEE) expanded particle, comprises the steps:

[0040] (1) Weigh 80g of density 0.25g / cm 3 , TPEE foam particles with a long diameter of 6 mm are put into the high-mixer without preheating;

[0041] (2) Weigh 20g of solvent-free two-component polyurethane glue containing 15% Klein 247# red pigment;

[0042] (3) Add the red colored solvent-free two-component polyurethane glue in the step (2) to the double-helix stirring feed bin in the step (1) to carry out stirring and dyeing;

[0043] (4) Open the double-helix mixing silo after the surface-dry part of the surface-dry part of the particle surface is cured by the red-colored solvent-free two-component polyurethane glue to obtain red TPEE foamed particles, and the thickness of the polymer dyed layer is 800 μm.

[0044] Fill the red TPEE expanded particles obtained above into a mold with a length of 300mm×a width of 250mm×a thickness of 50mm. Use ele...

Embodiment 3

[0046] A kind of preparation method of yellow polypropylene (PP) expanded particle, comprises the steps:

[0047] (1) Weigh 85g of density 0.03g / cm 3 , PP foam particles with a long diameter of 2 mm are put into the high-mixer without preheating;

[0048] (2) Weigh 15g of liquid silica gel containing 1% BASF 191# yellow pigment;

[0049] (3) adding the yellow colored liquid silica gel in the step (2) to the double-helix stirring silo in the step (1) for stirring and dyeing;

[0050] (4) After the yellow colored liquid silica gel is solidified on the surface dry part of the particle surface, the double-helix stirring silo is opened to obtain yellow PP foamed particles, and the thickness of the polymer dyed layer is 20 μm.

[0051] The yellow PP expanded particles obtained above were filled into a mold having a length of 300 mm x a width of 250 mm x a thickness of 50 mm. Use electromagnetic induction to compress 10% along the thickness direction of the mold to make the partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com