Printing ink circulating car

An ink circulation and ink technology, applied in printing, printing machines, general parts of printing machinery, etc., can solve problems such as loss of due proportion and color difference of printed products, and achieve the effect of solving color difference, improving quality and improving printing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

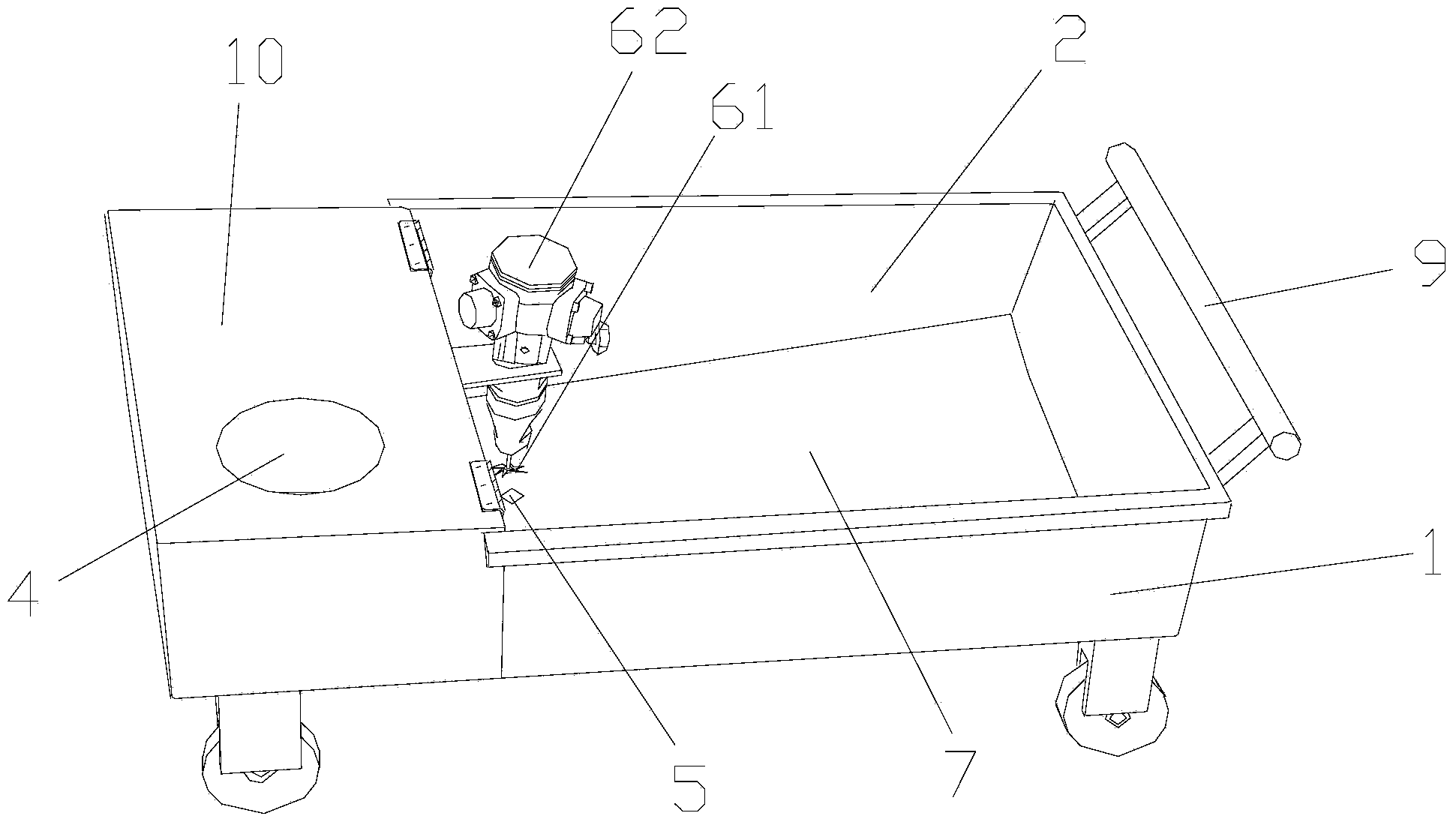

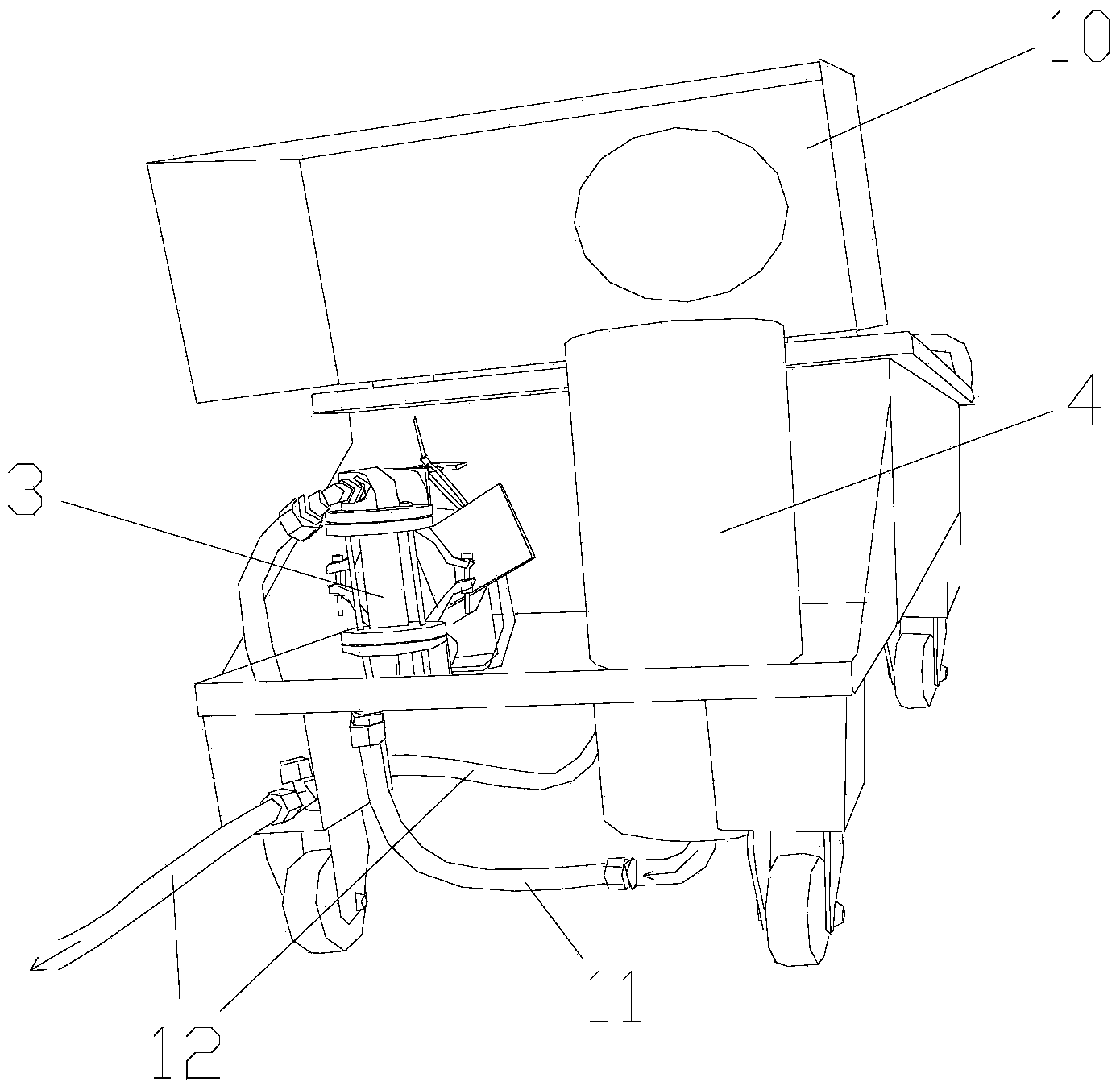

[0013] Examples, please refer to Figure 1 to 2 , An ink circulation vehicle, comprising a vehicle body 1, a first ink tank 2 arranged on the vehicle body 1, and a stirring device installed on the side wall of the first ink tank 2, passing through the ink channel 5 and the first ink tank 2 The communicating second ink tank 4, and the feed pump 3. Specifically, the stirring device includes a paddle 61 to prevent ink precipitation, and a pneumatic agitator 62 for driving the paddle; the feed pump 3 is a diaphragm pump, the inlet of which is connected to the bottom of the second ink tank 4 through the oil inlet pipe 11, and the outlet The three links are connected, and the two ports are respectively connected to the feeding tube 12 and the ink storage tank (not shown in the figure) of the printing press, so as to realize double-tube ink filling.

[0014] In order to prevent the ink in the ink storage tank from overflowing, the second ink tank 4 is provided with a return pipe (not s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com