Non-chromium passivation technology for zinc coating

A chromium-free passivation and galvanized layer technology, applied in the coating process of metal materials, etc., can solve the problems of restricting the use and discharge of chromate, human and environmental hazards, toxicity, etc., and achieve good decorative effects and low environmental pollution , Bright and even color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 Influence of each component content on the quality of passivation film in the chromium-free passivation solution of galvanized layer of the present invention

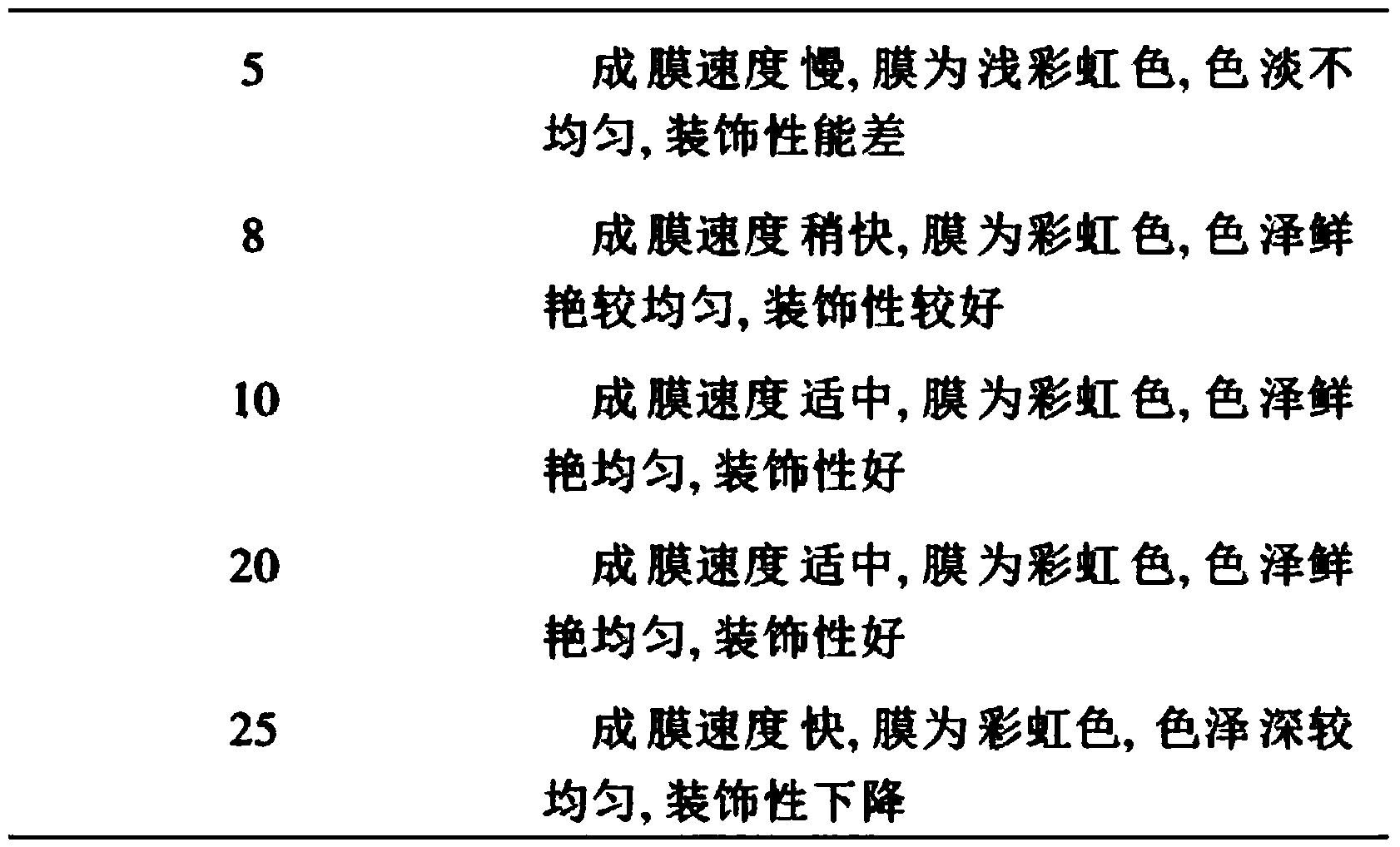

[0026] (1) Effect of ammonium molybdate content on the quality of passivation film

[0027] Ammonium molybdate is the main salt of the passivation solution and provides the main component of the passivation film. Its dosage has a great influence on the molybdate process, as shown in Table 1.

[0028] Table 1, the effect of ammonium molybdate content on the quality of passivation film

[0029]

[0030] It can be seen from Table 1 that the content of ammonium molybdate should be controlled at 10-20g / L; if the content is too low, the passivation film will be thin and light in color, and it will be difficult or impossible to form a film; Uniform, poor decoration, there are microscopic cracks on the surface of the film layer, and the corrosion resistance is reduced.

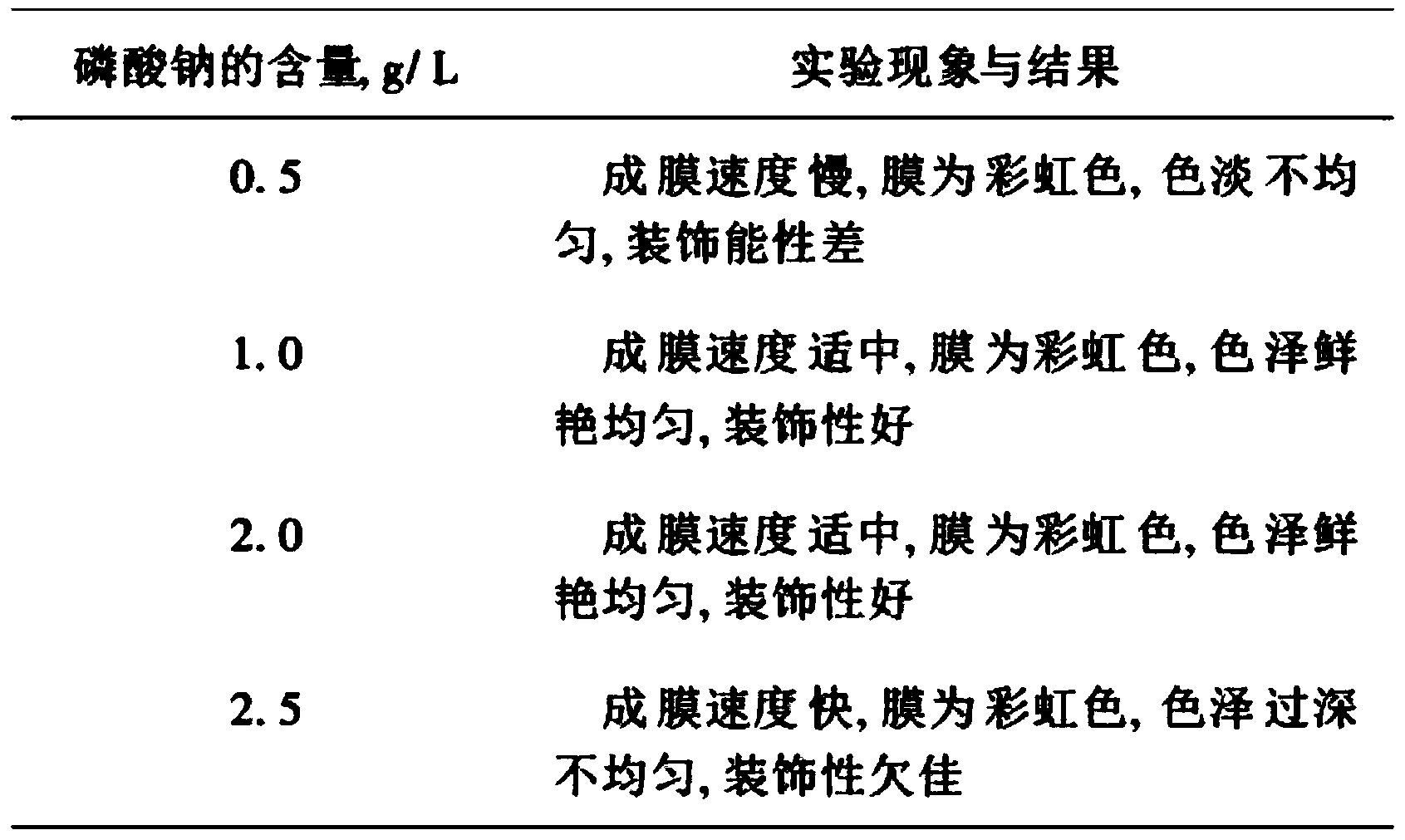

[0031] (2) Effect of sodium pho...

Embodiment 2

[0040] The influence of embodiment 2 passivation conditions on passivation film quality

[0041] (1) Influence of the pH value of the passivation solution on the quality of the passivation film

[0042] The pH value of the passivation solution has a great influence on the film formation and corrosion resistance of the passivation film, as shown in Table 3.

[0043] Table 3. Influence of passivation solution pH on passivation film quality

[0044]

[0045] It can be seen from Table 3 that the pH value of the process should be controlled at 3-4.5. The formation process of the passivation film is accompanied by the dissolution of the metal, and the metal ions react with the passivating agent in the passivation solution to form a passivation film. Therefore, the zinc in the passivation solution should be in the region where the E-pH diagram corrodes moderately and produces zinc ions. According to the E-pH diagram of zinc in aqueous solution, zinc is in this region in the pas...

Embodiment 3

[0053] Embodiment 3 The performance detection of passivation film made by passivation solution and passivation process of the present invention

[0054] (1) The routine performance test results of the passivation film are shown in Table 5.

[0055] Table 5. Test results of routine performance of passivation film

[0056]

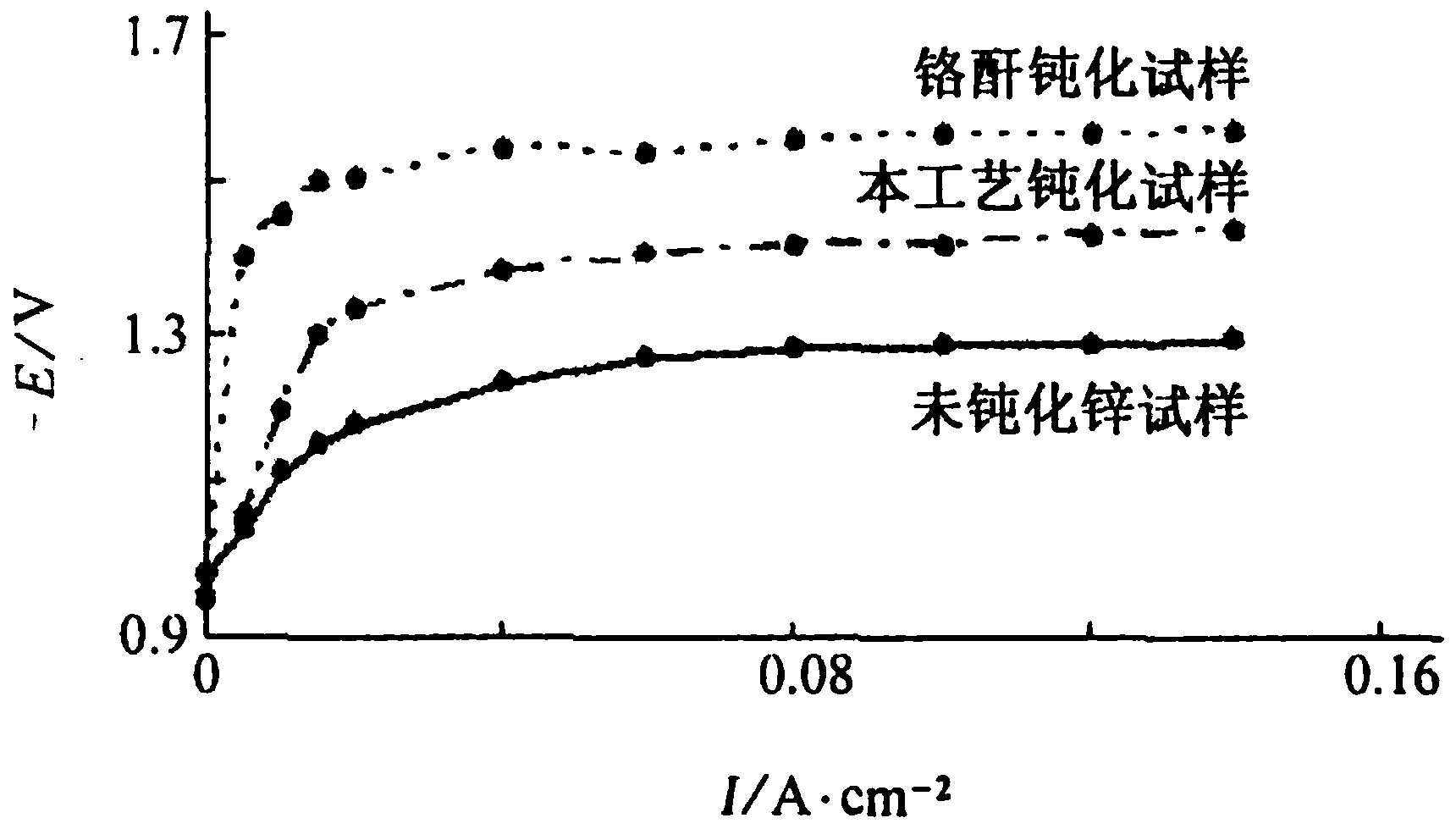

[0057] (2) Polarization curve of passivation film

[0058] The cathode electrochemical behavior of passivation film, non-passivation and chromate passivation film in 5% sodium chloride solution of this process was measured by galvanostatic method. The reference electrode is a saturated calomel electrode, and the auxiliary electrode is 1 cm 2 Platinum electrode, the sample is the research electrode (the exposed area is 1cm 2 ), the natural corrosion potential of the research electrode was measured first, and after 10 min the natural corrosion potential was stabilized, and the constant current polarization measurement was started. Adjust the current to a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com