Production process of plastic bowl

A production process and technology for plastic bowls, applied in the field of plastic production and manufacturing, can solve the problems of general gloss and transparency, complex production process, large environmental pollution, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

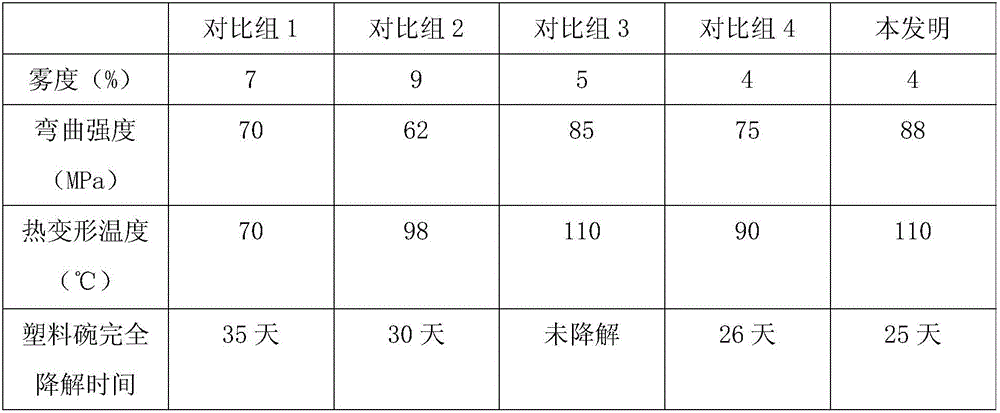

Examples

Embodiment 1

[0045] A plastic bowl, mainly made of the following raw materials in parts by weight: 50 parts of PBAT, 10 parts of cornstarch, 70 parts of high-density polypropylene particles, 11 parts of functional additives, 4 parts of nano-talcum powder, and 5 parts of modified materials; , the functional additive is composed of the following raw materials by weight: 1 part of anti-aging agent MB, 4 parts of toughening agent SBS, 2 parts of clearing agent xylene, 2 parts of curing agent diethylenetriamine; the weight ratio of modified materials is 1:1 : 2 mixture of polyamine polyphosphate, nanometer calcium carbonate and talcum powder;

[0046] The high-density polypropylene particles are mainly prepared from the following raw materials in parts by weight: 30 parts of polypropylene, 4 parts of glass fiber, 15 parts of polyoxymethylene, 5 parts of thermoplastic polyester elastomer, 20 parts of deionized water, 20 parts of isopropanol 2 parts, 2 parts of antioxidant 1010, 2 parts of plasti...

Embodiment 2

[0064] A plastic bowl, mainly made from the following raw materials in parts by weight: 65 parts of PBAT, 18 parts of cornstarch, 80 parts of high-density polypropylene particles, 13 parts of functional additives, 6 parts of nano-talcum powder, and 8 parts of modified materials; , functional auxiliary agent is made up of the raw material mixing of following parts by weight: 3 parts of antioxidant MB, 8 parts of toughening agent ABS, 7 parts of transparent agent chloroform, 7 parts of curing agent dipropylenetriamine; Modified material is that weight ratio is 1:1: A mixture of amine polyphosphate, nanometer calcium carbonate and talcum powder;

[0065] The high-density polypropylene particles are mainly prepared from the following raw materials in parts by weight: 40 parts of polypropylene, 8 parts of glass fiber, 25 parts of polyoxymethylene, 7 parts of thermoplastic polyester elastomer, 30 parts of deionized water, 30 parts of isopropanol 4 parts, antioxidant 168 dosage 4 par...

Embodiment 3

[0083] A plastic bowl, mainly made from the following raw materials in parts by weight: 80 parts of PBAT, 25 parts of cornstarch, 90 parts of high-density polypropylene granules, 15 parts of functional additives, 9 parts of nano-talcum powder, and 12 parts of modified materials; , the functional auxiliary agent is composed of the following raw materials by weight: 5 parts of anti-aging agent MB, 13 parts of toughening agent CPE, 10 parts of clearing agent xylene, 10 parts of curing agent triethylenetetramine; the weight ratio of the modified material is 2:2 : 3 mixtures of amine polyphosphate, nanometer calcium carbonate and talcum powder;

[0084] The high-density polypropylene particles are mainly prepared from the following raw materials in parts by weight: 50 parts of polypropylene, 10 parts of glass fiber, 40 parts of polyoxymethylene, 10 parts of thermoplastic polyester elastomer, 35 parts of deionized water, 40 parts of isopropanol parts, 6 parts of antioxidant 1076, 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com