Light-absorption heating denim and production method thereof

A technology that absorbs light and generates heat, and is used in the continuous processing of textiles, textile materials, fabrics, etc., can solve the problems of difficult coloring, poor color fastness, and large flower degree, and achieves reduced flower degree, bright and uniform color. , the effect of high color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

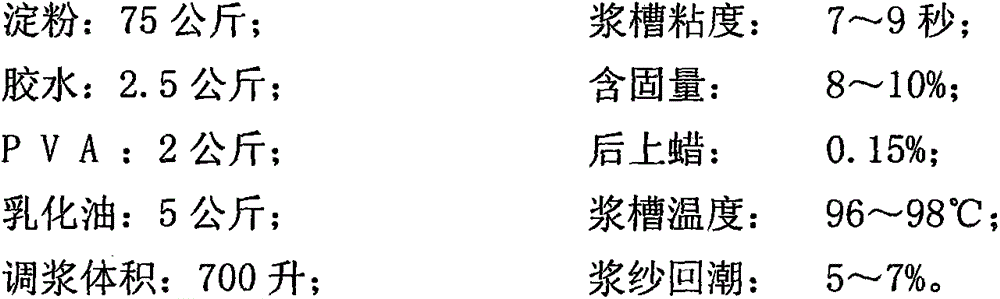

[0016] A method for producing light-absorbing and heat-generating denim, the production steps of which are: a. weaving yarn; b. ball warping; c. dividing warp; d. dyeing;

[0017] In order to obtain better light-absorbing and heat-generating properties, cotton and light-absorbing acrylic fiber blends and three kinds of plain yarns are used as warp yarns, and cotton and hollow polyester yarns wrapped with spandex are used as weft yarns. Good heat preservation effect; in terms of the draft ratio of spandex yarn, choose a draft ratio between 2.5 and 3.0 times, use Siro compact spinning for the warp yarn, and use Siro spinning for the weft yarn.

[0018] The ball warp process always maintains a stable temperature and humidity. Before the ball warp, the yarn that is about to be ball warped is pulled 24 hours in advance to the ball warp process to regain moisture in advance, so that the light-absorbing and heat-absorbing acrylic fibers in the yarn can get enough free creep to ensure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com