Double-mesh reticulate ceramic roller and its laser carving process

A technology of laser engraving and ceramic mesh, which is applied in laser welding equipment, rotary printing machines, printing, etc., can solve the problems of large ink consumption, easy printing white spots, and affecting the quality of printed products, so as to save ink and achieve uniform color Vividness, the effect of reducing the number of white spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

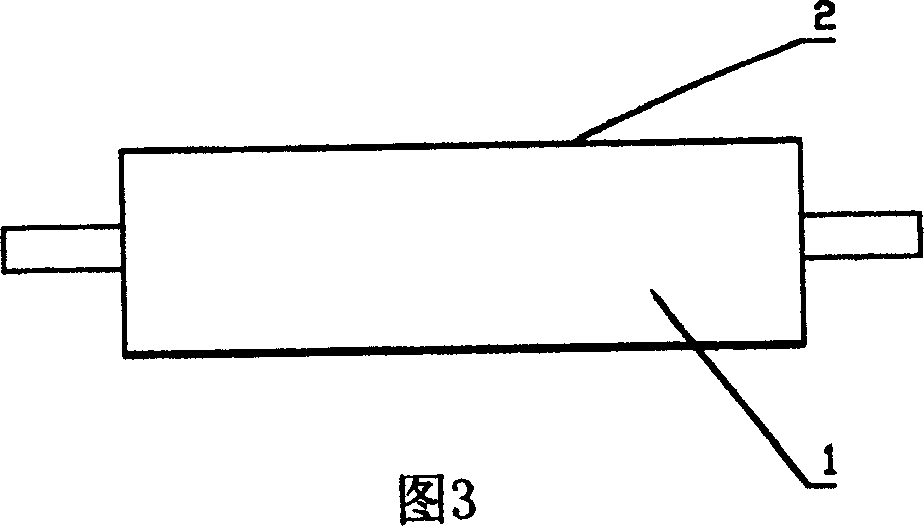

[0018] Example one: such as Figure 4 As shown, the present invention proposes a method for engraving a double-mesh ceramic anilox roller by using a single original laser beam. The original laser beam 10 is generated by laser A, and the original laser beam 10 is divided into A laser beam by a beam splitter 17 11 and B laser beam 12;

[0019] The A laser beam 11 after passing through the beam splitter 17 continues to advance in the direction of the original laser beam 10, passes through the A hole mold 14 to change the size and shape, and then passes through the full transmission part of the full transmission and reflection combination mirror 133, and is directed to the focusing mirror 16;

[0020] The B laser beam 12 that changes its direction through the beam splitter 17 changes its direction through the total mirror 131, changes its size and shape through the B-hole mold 15, and then passes through the total reflection part of the total reflection mirror 132 and the total transm...

Embodiment 2

[0022] Embodiment two: such as Figure 5 As shown, a method for engraving a double-mesh ceramic anilox roller with two original laser beams is proposed. The two original laser beams can be generated by two lasers or one laser.

[0023] The A laser beam 11 generated by the A laser passes through the A hole mold 14 to shape the shape of the hole to be engraved, and then passes through the 45° total mirror 134 to change the direction, and then shoots to the focusing mirror 16.

[0024] The B laser beam 12 generated by the B laser passes through the B hole mold 15 to shape the shape of the hole to be engraved, and then changes the direction through the 45° total mirror 131 and shoots to the focusing mirror 16.

[0025] The A laser beam 11 and the B laser beam 12 are focused on the ceramic layer 2 of the roller body 1 through the same focusing lens 16, and two points are carved at the same time to respectively engrave meshes with their own characteristics.

[0026] Through automatic con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com