Dyeing technology of chemical fibers

A chemical fiber and process technology, applied in the field of chemical fiber dyeing process, can solve the problems of low dye uptake, more waste water, poor uniformity, etc., and achieve the effects of reducing treatment costs, reducing costs, and reducing consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

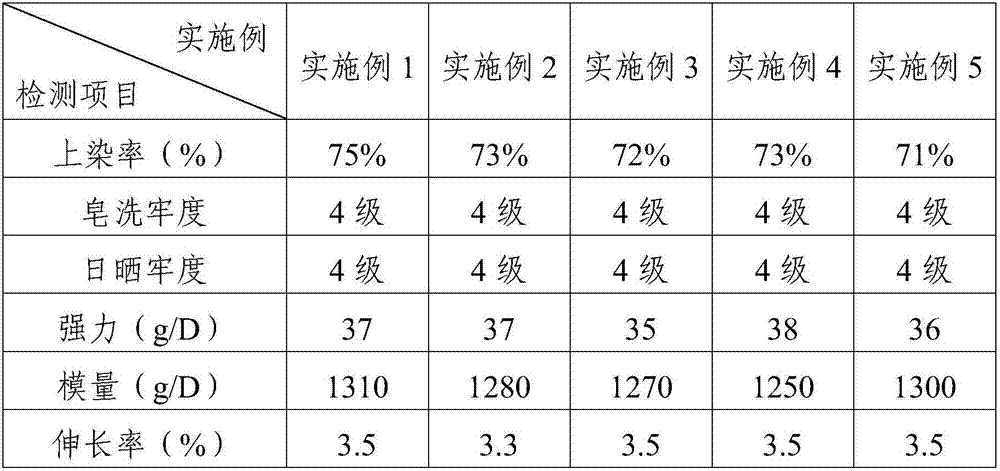

Examples

Embodiment 1

[0030] A kind of chemical fiber dyeing process, comprises the following steps:

[0031] (1) Pretreatment: Add chemical fiber, D8-808 degreaser, urea, 30% H to the dyeing machine 2 o 2 , sodium lauryl alcohol polyoxyethylene ether sulfate, ethylene glycol monobutyl ether, 122 defoamer and EDTA tetrasodium salt, heat up to 100°C and keep stirring for 1 hour, then cool down to 45°C, discharge the waste solution, and then Add water, stir and wash twice, then discharge;

[0032] (2) Purification treatment: add 10% sodium hydroxide solution to the system, heat up to 90°C and stir for 40 minutes, drain the waste liquid, add water to wash until the discharged waste liquid is neutral;

[0033] (3) Pre-setting: the pre-treated chemical fiber is pre-formed in low-temperature water, the temperature is controlled at 155 ° C, and the overfeed is 25%;

[0034] (4) Dyeing: Add softened clear water, sodium sulfate, fatty alcohol polyoxyethylene ether, penetrant JFC, disperse dyes in the dye...

Embodiment 2

[0040] A kind of chemical fiber dyeing process, comprises the following steps:

[0041] (1) Pretreatment: Add chemical fiber, D8-808 degreaser, urea, 35% H to the dyeing machine 2 o 2 , sodium lauryl alcohol polyoxyethylene ether sulfate, ethylene glycol monobutyl ether, 122 defoamer and EDTA tetrasodium salt, heat up to 110°C and keep stirring for 1 hour, then cool down to 45°C, discharge the waste solution, and then Add water, stir and wash twice, then discharge;

[0042] (2) Purification treatment: add 10% sodium hydroxide solution to the system, heat up to 95°C and stir for 20 minutes, drain the waste liquid, add water to wash until the discharged waste liquid is neutral;

[0043] (3) Pre-setting: Pre-setting the pre-treated chemical fiber in low-temperature water, controlling the temperature at 160°C, and overfeeding by 20%;

[0044](4) Dyeing: add softened clear water, sodium sulfate, fatty alcohol polyoxyethylene ether, penetrant JFC, disperse dyes in the dyeing mach...

Embodiment 3

[0050] A kind of chemical fiber dyeing process, comprises the following steps:

[0051] (1) Pretreatment: Add chemical fiber, D8-808 degreaser, urea, 25% H to the dyeing machine 2 o 2 , sodium lauryl alcohol polyoxyethylene ether sulfate, ethylene glycol monobutyl ether, 122 defoamer and EDTA tetrasodium salt, heat up to 90°C and keep stirring for 1 hour, then cool down to 45°C, discharge the waste solution, and then Add water, stir and wash twice, then discharge;

[0052] (2) Purification treatment: add 10% sodium hydroxide solution to the system, heat up to 80°C and stir for 40 minutes, drain the waste liquid, add water to wash until the discharged waste liquid is neutral;

[0053] (3) Pre-forming: the pre-treated chemical fiber is pre-formed in low-temperature water, the temperature is controlled at 150°C, and the overfeed is 30%;

[0054] (4) Dyeing: Add softened clear water, sodium sulfate, fatty alcohol polyoxyethylene ether, penetrant JFC, disperse dyes in the dyeing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com