High precision manufacturing method and injection mold for plastic injection mold for complex curved surface

An injection mold, complex curved surface technology, applied in the field of mold manufacturing, can solve the problems of reduced product accuracy, complex structure, low mold manufacturing accuracy, etc., to improve processing accuracy, solve warpage and shrinkage problems, and avoid cost and time. effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

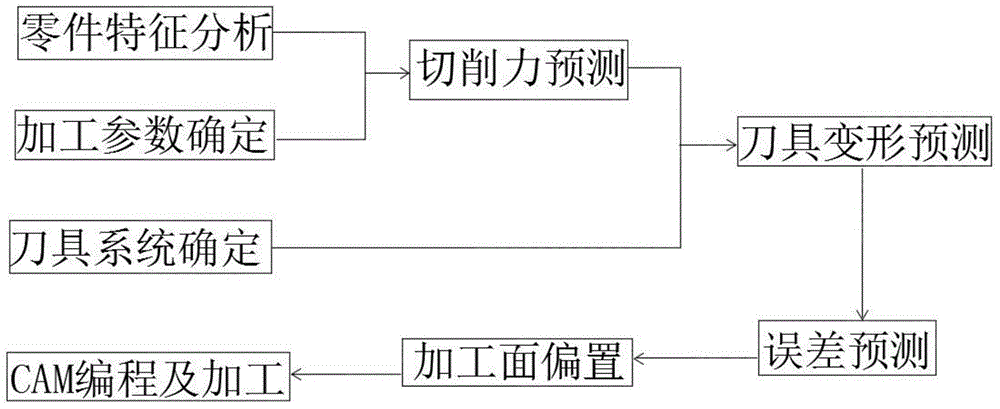

[0043] Examples, see figure 1 , the high-precision manufacturing method of the complex surface automobile injection mold provided by the present embodiment, the numerical control machining center, the computer and the AutoCAD software, HyperMesh software, Autodesk Moldflow simulation software, ANSYS software built in the computer, the processing code generation software of the numerical control machining center,

[0044] The manufacturing method includes the following steps:

[0045] (1) Modeling and deformation analysis of plastic parts:

[0046] Establish the 3D model of automobile injection molded parts in the AutoCAD software of the computer, generate the mid-plane model through the 3D model through HyperMesh software, and then generate high-quality R-trias triangular mesh through the finite element mesh of HyperMesh software, and the generated R- The trias triangular mesh is imported into the Moldflow simulation software for mold flow analysis and modeling, and the compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com