Wood flooring with carbonized solid wood using symmetric structure and process for preparing the same

A symmetrical structure, wood floor technology, applied in chemical instruments and methods, wood layered products, building structures, etc., can solve problems such as poor dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The carbonized solid wood layer 20 , the base layer 30 and the carbonized solid wood layer 20 are integrated into a symmetrical structure from top to bottom by pressing. Then, the surface treatment layer 10 is formed thereon. The resulting structures were cut in the form of tongues and tongues to prepare symmetrically structured wood floors with layers of carbonized solid wood.

[0044] As the carbonized solid wood layer 20 applied on the top and bottom layers of the base layer, a wood layer with a thickness of about 3.0mm and a moisture content of 5-7% is used, which is heat-treated at a temperature of 180-200°C. As the base layer 30, a Finnish Birch plywood having a thickness of 4.0 mm and a moisture content of 5% was used. As an adhesive, an aqueous emulsion containing vinyl urethane as a main component was mixed with 10% of a curing agent. Both room temperature compressible and room temperature curing resins are used.

[0045] Hereinafter, the manufacturing metho...

Embodiment 2

[0048] A wooden floor was prepared in the same manner as in Example 1 except that a core board composed of Burmese teak was stacked on the base layer 30 of Example 1.

experiment Embodiment 1

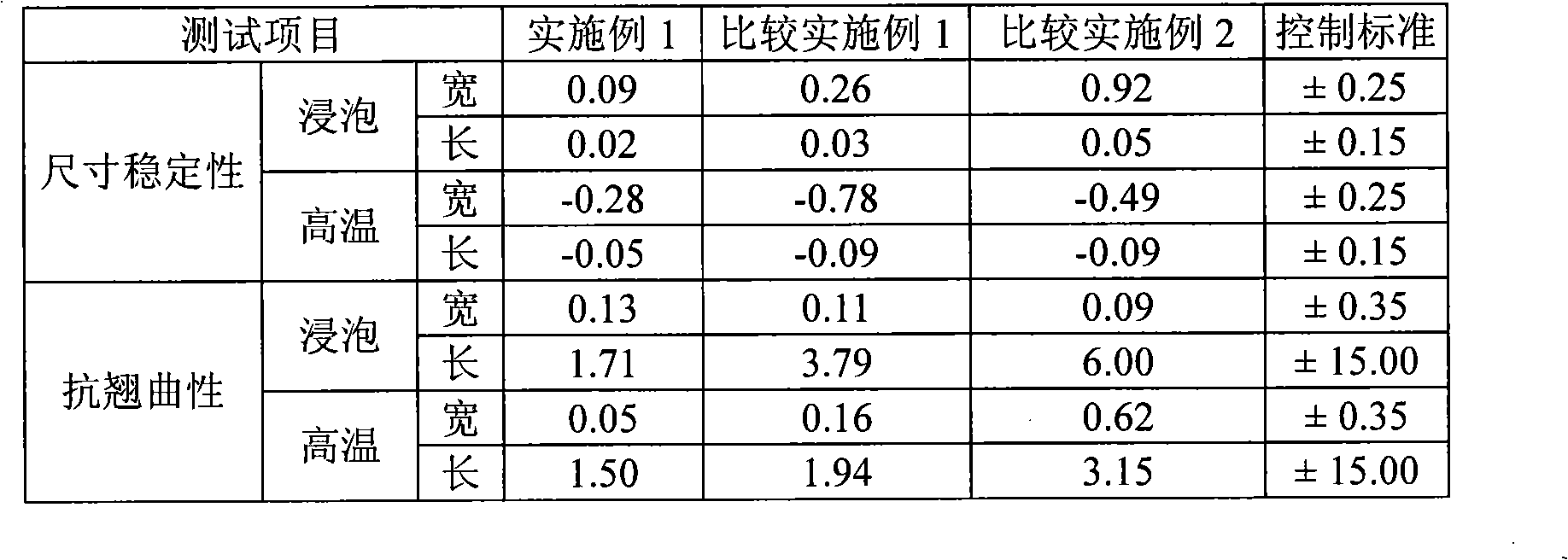

[0054] The physical properties of a wood floor having a symmetrical structure by applying a carbonized solid wood layer to the top and bottom of a base layer prepared in Examples of the present invention were compared with a non-heat-treated wood floor and a conventional commercially available wood floor having the same structure. The results thus obtained are given in Table 1 below. It could be confirmed that the wooden floor prepared in Example 1 showed superior dimensional stability and warping resistance compared to the wooden floor of Comparative Examples 1 and 2.

[0055] For the tests performed under high temperature conditions, the product samples were dried in a dryer at 80°C for 6 hours. For the soak treatment test, the samples were immersed in room temperature water for 6 hours. Then, the sample size and the degree of warpage in the width and length directions were measured using a caliper and a thickness gauge, respectively.

[0056] [Table 1]

[0057]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com