Backlight module

A technology of backlight module and light guide plate, which is applied in the field of backlight module, can solve the problems such as difficult adhesive tape and tape coverage, and achieve the effect of enhancing mechanical strength, preventing light leakage, and solving warping problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

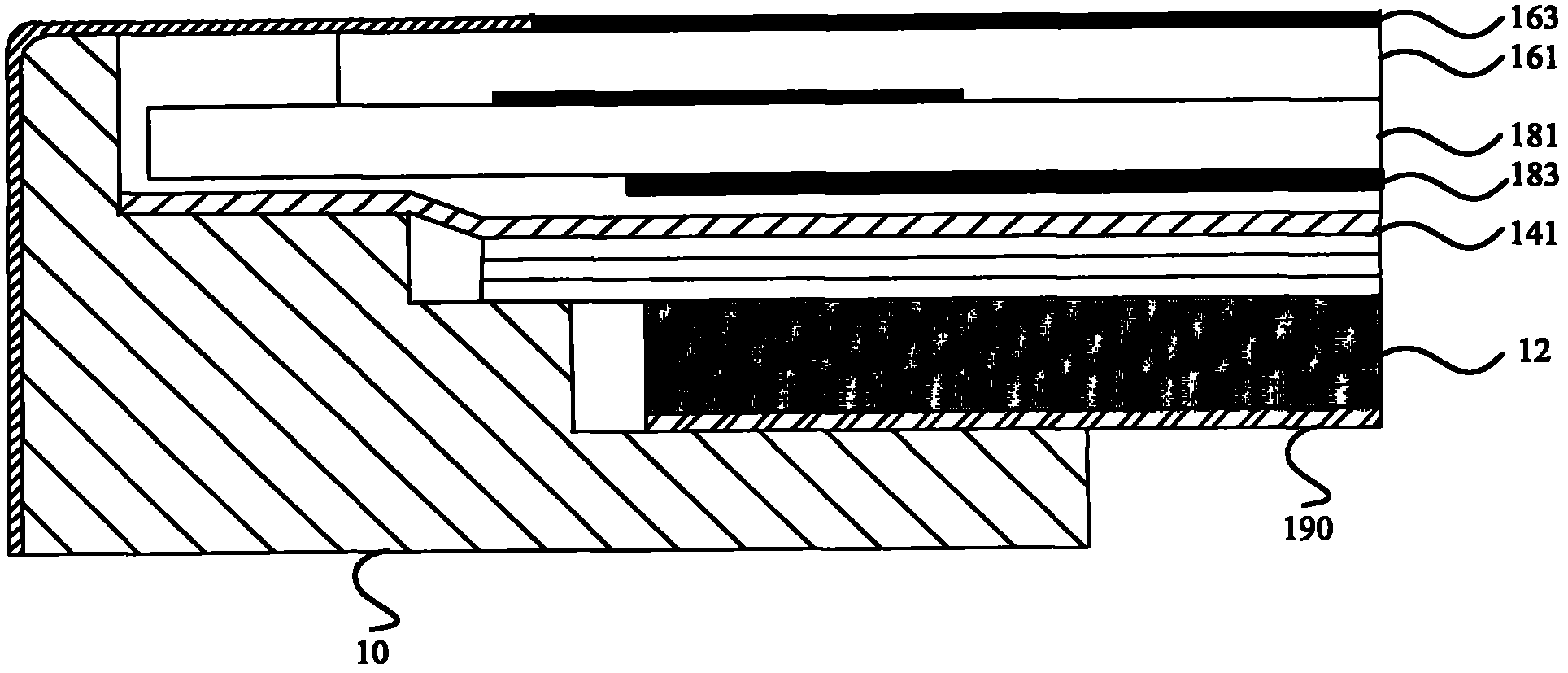

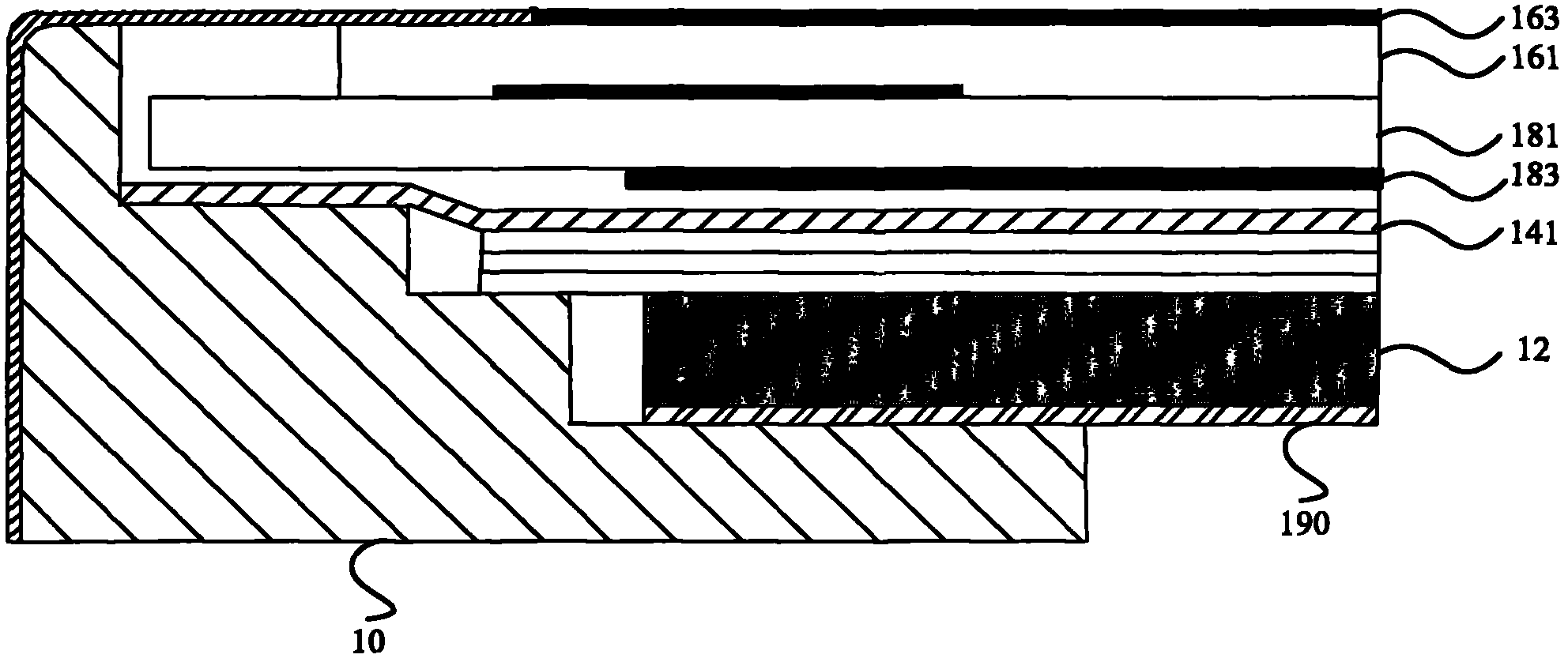

[0020] In order to make the technical content disclosed in this application more detailed and complete, reference may be made to the drawings and the following various specific embodiments of the present invention, and the same symbols in the drawings represent the same or similar components. However, those skilled in the art should understand that the examples provided below are not intended to limit the scope of the present invention. In addition, the drawings are only for schematic illustration and are not drawn according to their original scale.

[0021] The specific implementation manners of various aspects of the present invention will be further described in detail below with reference to the accompanying drawings.

[0022] As mentioned above, after the existing liquid crystal display panel is stored in a high-temperature and high-humidity environment, the optical film in the panel will warp to a large extent, resulting in moiré (mura), which is not conducive to image d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com