Three-dimensional integration method for tile TR component subarray element

A three-dimensional integrated, tiled technology, applied in the direction of electrical components, antenna components, electrical components to assemble printed circuits, etc., can solve problems such as the impact of chip reliability, and achieve good electromagnetic shielding effect, thin body and light weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

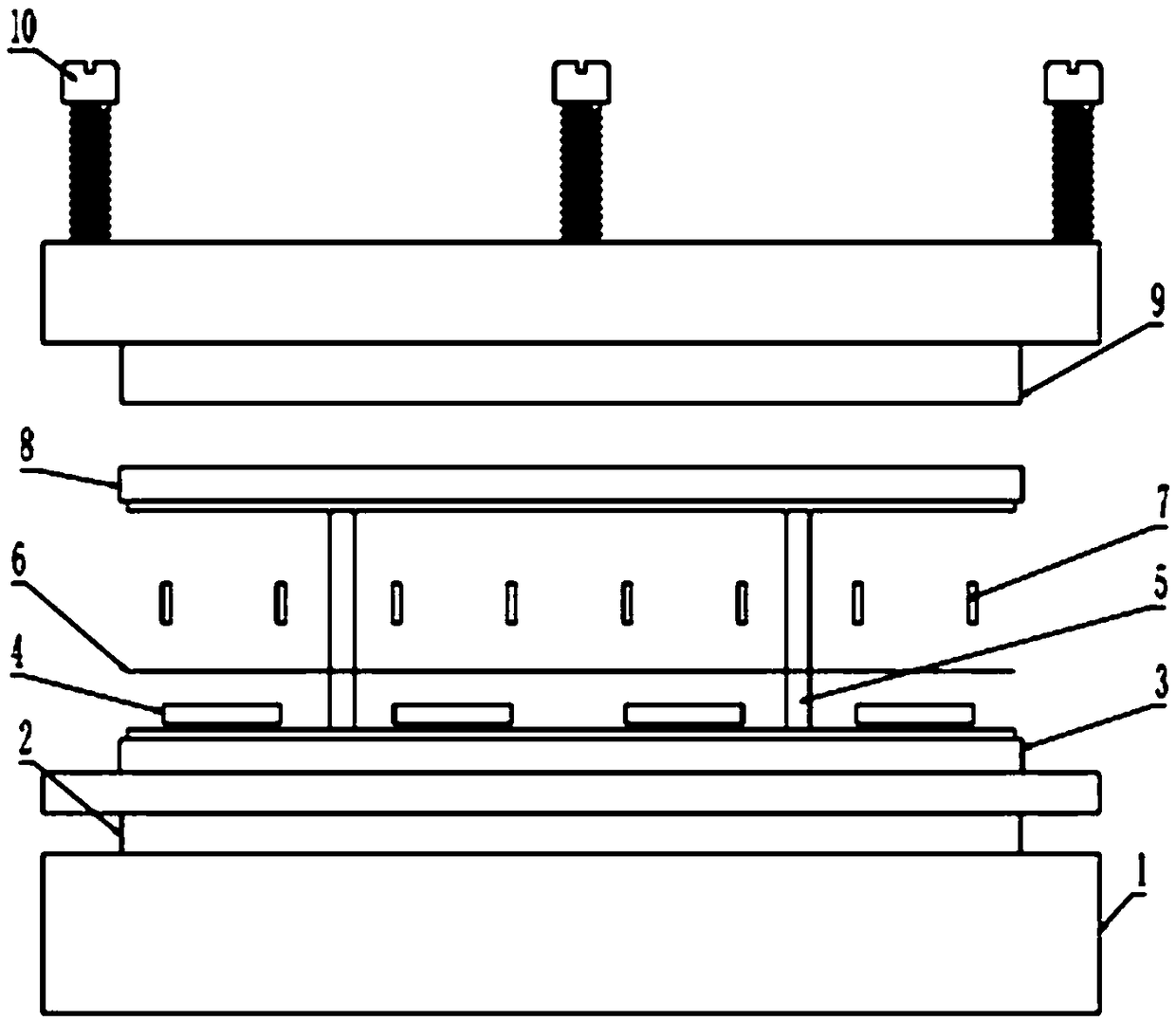

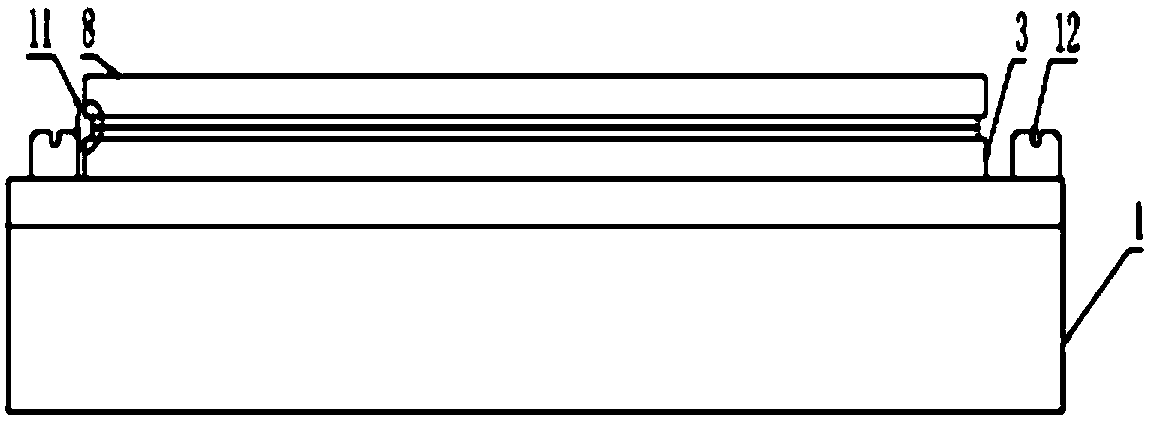

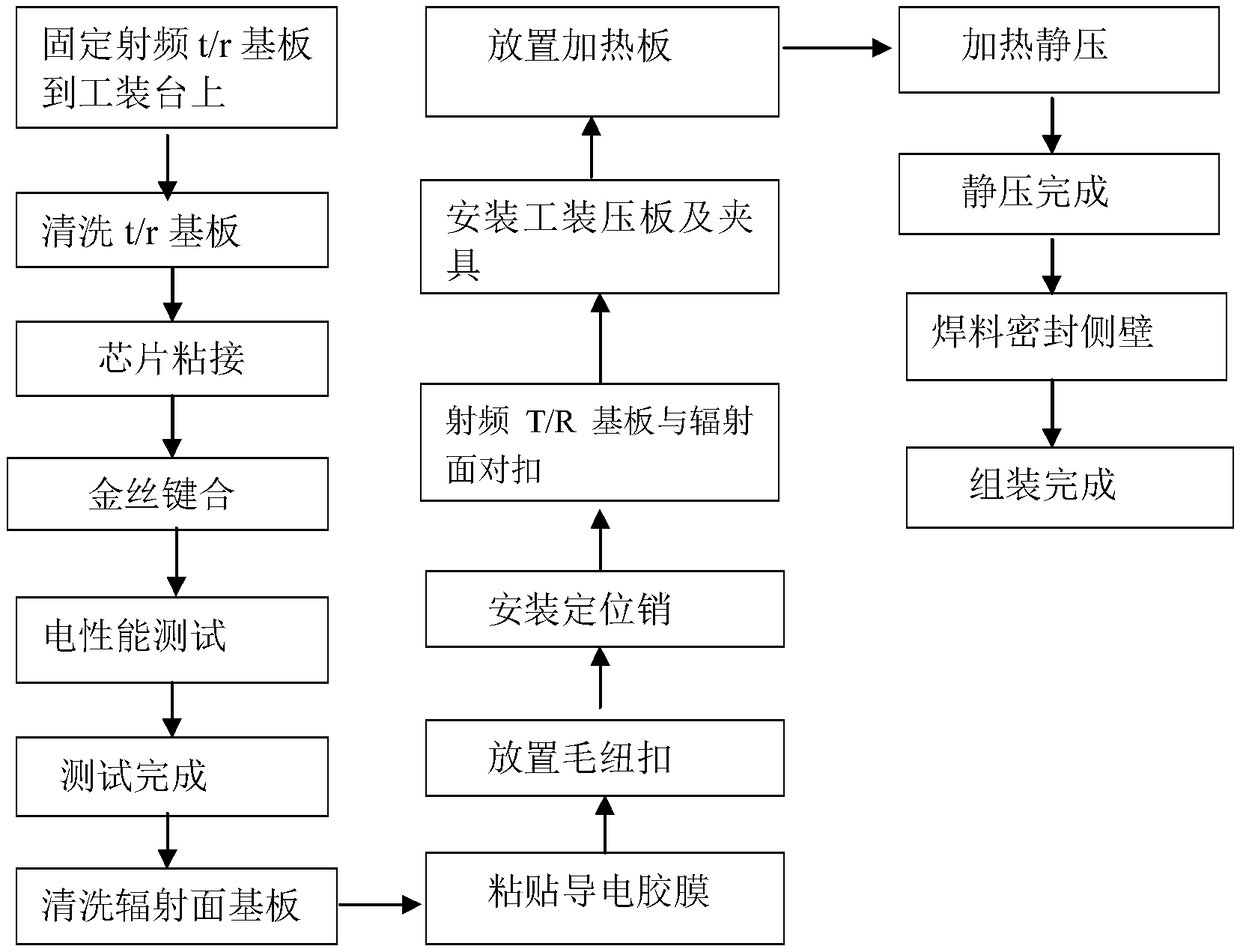

[0020] refer to figure 1 , figure 2 . According to the present invention, prepare an embedded tooling base 1 consistent with the shape of the radio frequency TR printed board 3, which is used to fix the radio frequency TR printed board 3 and the 8-piece printed board of the radiating surface, and place the radio frequency TR printed board 3 The low-frequency and wave control unit 2 is embedded in the tooling base 1, and the RF TR printed board 3 is fixed to the tooling base 1 with screws 12, so that it does not affect the assembly of the MMIC chip 4 on the RF side of the RF TR printed board 3; Assemble the MMIC chip 4 into the T-shaped cavity on the RF TR printed board 3, and then use gold wire bonding to electrically interconnect the MMIC chip 4 and the microstrip circuit to make it electrically conductive; The adhesive film 6 is pasted on the outer conductor of the printed board 8 on the radiating surface, so that it is closely attached to the outer conductor of the print...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com