Polycarbonate composition for 3D printing technology and preparation method thereof

A polycarbonate, 3D printing technology, applied in the field of polymer materials, can solve problems such as wide melting range, limited application, warpage, etc., to achieve the effect of solving warpage and improving heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

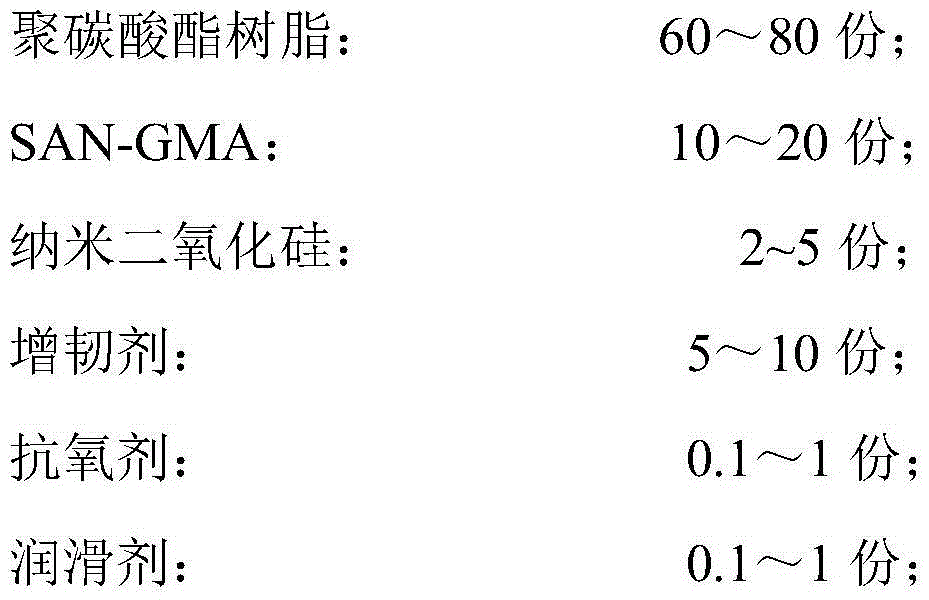

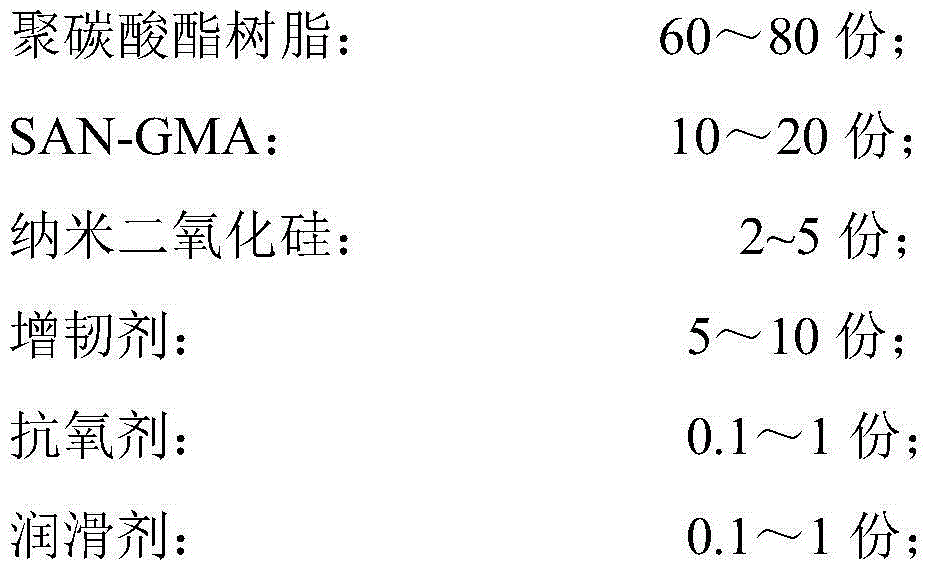

Method used

Image

Examples

Embodiment 1

[0033] (1) Weigh each component by weight: PC: 70, SAN-GMA: 20, nano-silica: 5, toughening agent EXL-2691A: 5, antioxidant 10100.1, antioxidant 1680.1, lubricant PETS 0.3.

[0034] (2) Feed the raw materials from the feeding port, melt and extrude at 200-280°C, the screw extruder rotates at 500rpm, and the pressure is 2MPa, melts and extrudes, and granulates to obtain the product.

[0035] (3) The screw diameter of the extruder is 58 mm, and the aspect ratio is 60.

Embodiment 2

[0037] (1) Weigh each component by weight: PC: 80, SAN-GMA: 10, nano-silica: 2, toughening agent EXL-2691A: 8, antioxidant 10100.1, antioxidant 1680.1, lubricant PETS 0.3.

[0038] (2) Feed the raw materials from the feeding port, melt and extrude at 200-280°C, the screw extruder rotates at 500rpm, and the pressure is 2MPa, melts and extrudes, and granulates to obtain the product.

[0039] (3) The screw diameter of the extruder is 58 mm, and the aspect ratio is 60.

Embodiment 3

[0041] (1) Weigh each component by weight: PC: 75, SAN-GMA: 15, nano-silica: 2, toughening agent EXL-2691A: 8, antioxidant 10100.1, antioxidant 1680.1, lubricant PETS 0.3.

[0042] (2) Feed the raw materials from the feeding port, melt and extrude at 200-280°C, the screw extruder rotates at 500rpm, and the pressure is 2MPa, melts and extrudes, and granulates to obtain the product.

[0043] (3) The screw diameter of the extruder is 58 mm, and the aspect ratio is 60.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com