Sandwich structure for ultrathin laminated board processing and laminated board manufacturing method

A multi-layer board and sandwich technology, which is applied in the direction of multi-layer circuit manufacturing, printed circuit manufacturing, and simultaneous processing of multiple printed circuits. Difficulty and other problems, to achieve the effect of good symmetry, reducing process difficulty and simplifying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0056] This embodiment introduces the sandwich structure for processing ultra-thin multilayer boards, and the method for making multilayer boards by using the sandwich structure for processing ultra-thin multilayer boards;

[0057] A method for making a multilayer board, comprising the steps of:

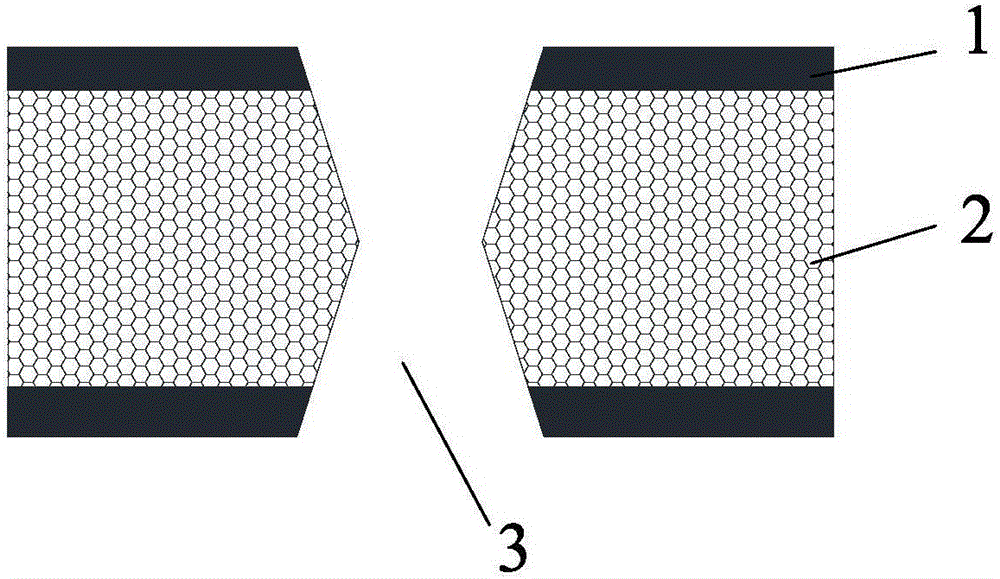

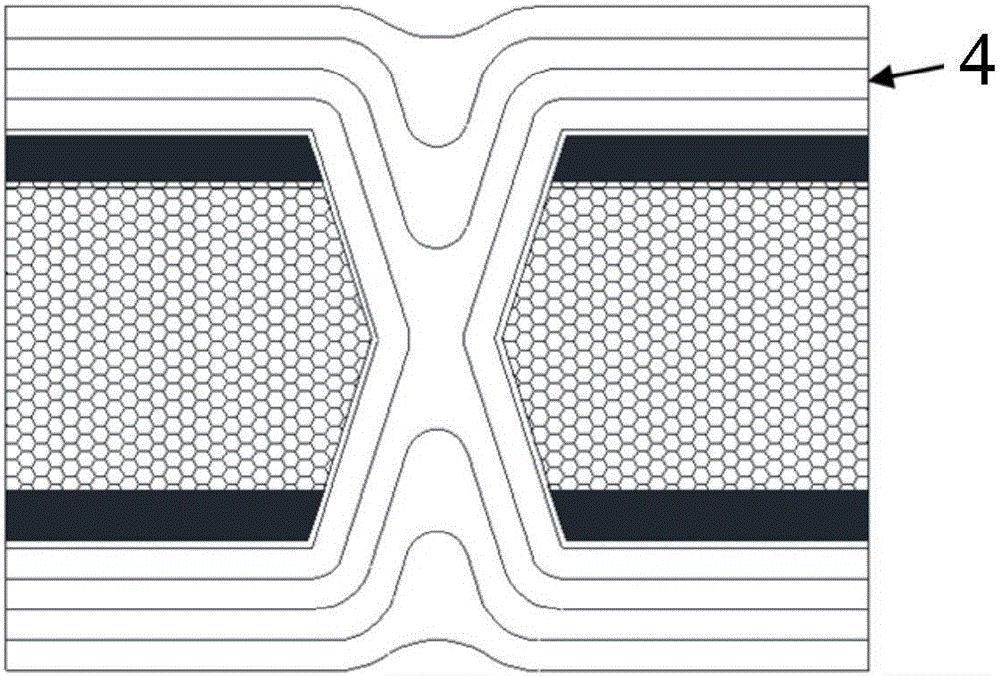

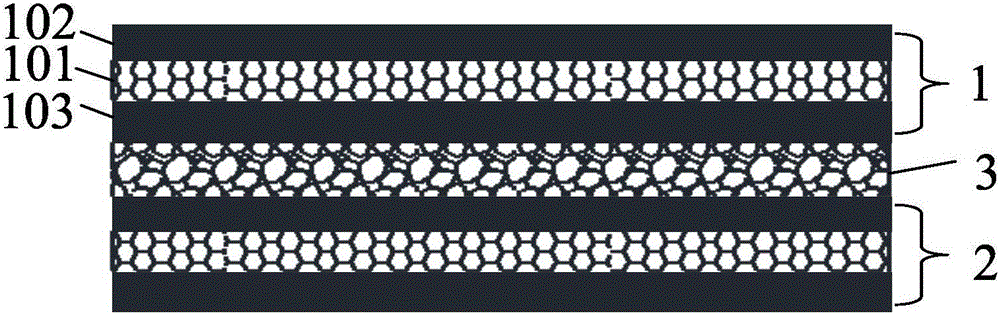

[0058] Step S1, providing two ultra-thin double-sided copper-clad laminates 1 and 2; placing the first prepreg 3 between the two double-sided copper-clad laminates 1 and 2, and pressing at low temperature to form a three-layer temporary bonding structure, wherein the first prepreg 3 is not Curing; the temperature of low temperature lamination is 80℃~140℃; image 3 shown;

[0059] Ultra-thin double-sided copper-clad laminates in this example refer to double-sided copper-clad laminates below 80 μm;

[0060] The prepreg used in the present invention can be the prepreg o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com