Molded surface detection method for non-rigid irregular composite material component

A composite material component, non-rigid technology, applied in the field of parts processing, manufacturing and testing, can solve problems such as non-conformity with the use state, no testing benchmark, out of tolerance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

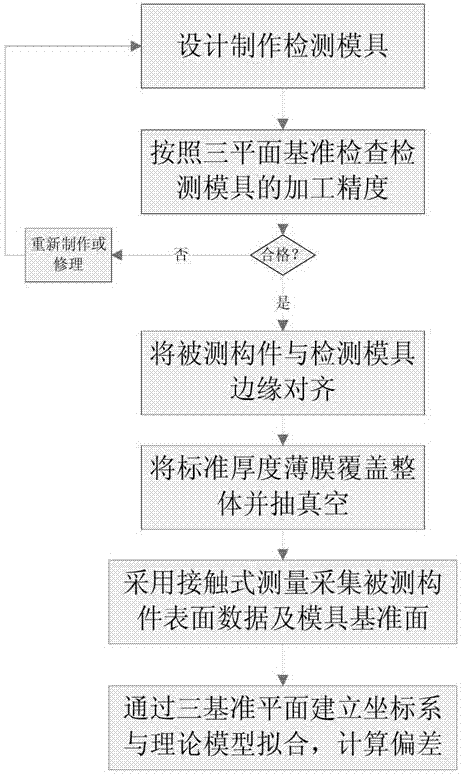

[0026] A method for detecting the surface of a non-rigid special-shaped composite material member according to the present invention, the process is as follows figure 1 As shown, the method includes the following steps:

[0027] Step 1: Process a set of inspection molds with three-plane datums according to the mold design for component processing:

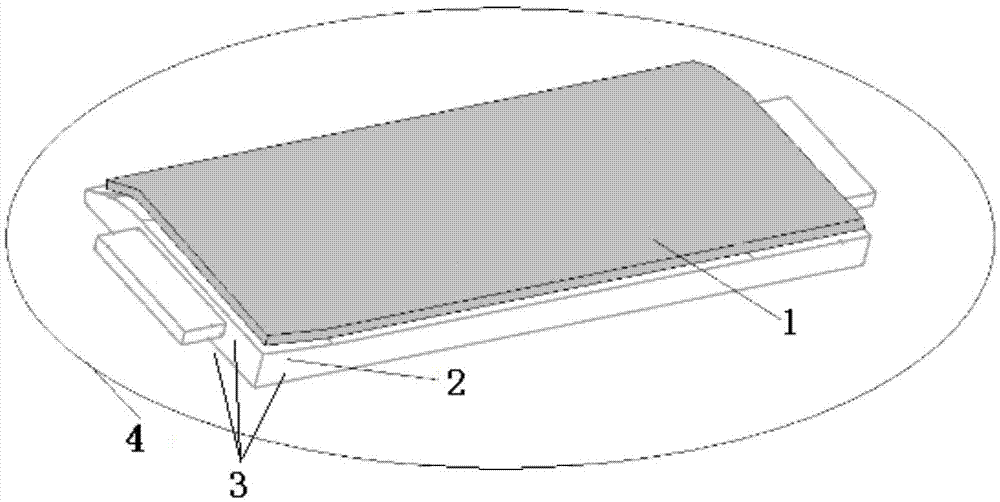

[0028] The upper surface of the detection mold and the bonding surface of the processing mold (the bonding surface of the processing mold and the component to be tested) have the same profile and reference, and the detection mold has three reference planes, namely the bottom surface of the detection mold in the horizontal direction, one The side end face of the side, and the side perpendicular to the side end face are three reference planes; the three reference planes are used to fit the actual coordinate system ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com