Packaging body capable of repeatedly stacking

An encapsulation body and encapsulation colloid technology, applied in semiconductor devices, electric solid state devices, semiconductor/solid state device parts, etc., can solve problems such as cracking, alignment, poor connection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific implementation of the present invention is described in detail as follows, and the preferred embodiments are only for illustration, and are not intended to limit the present invention.

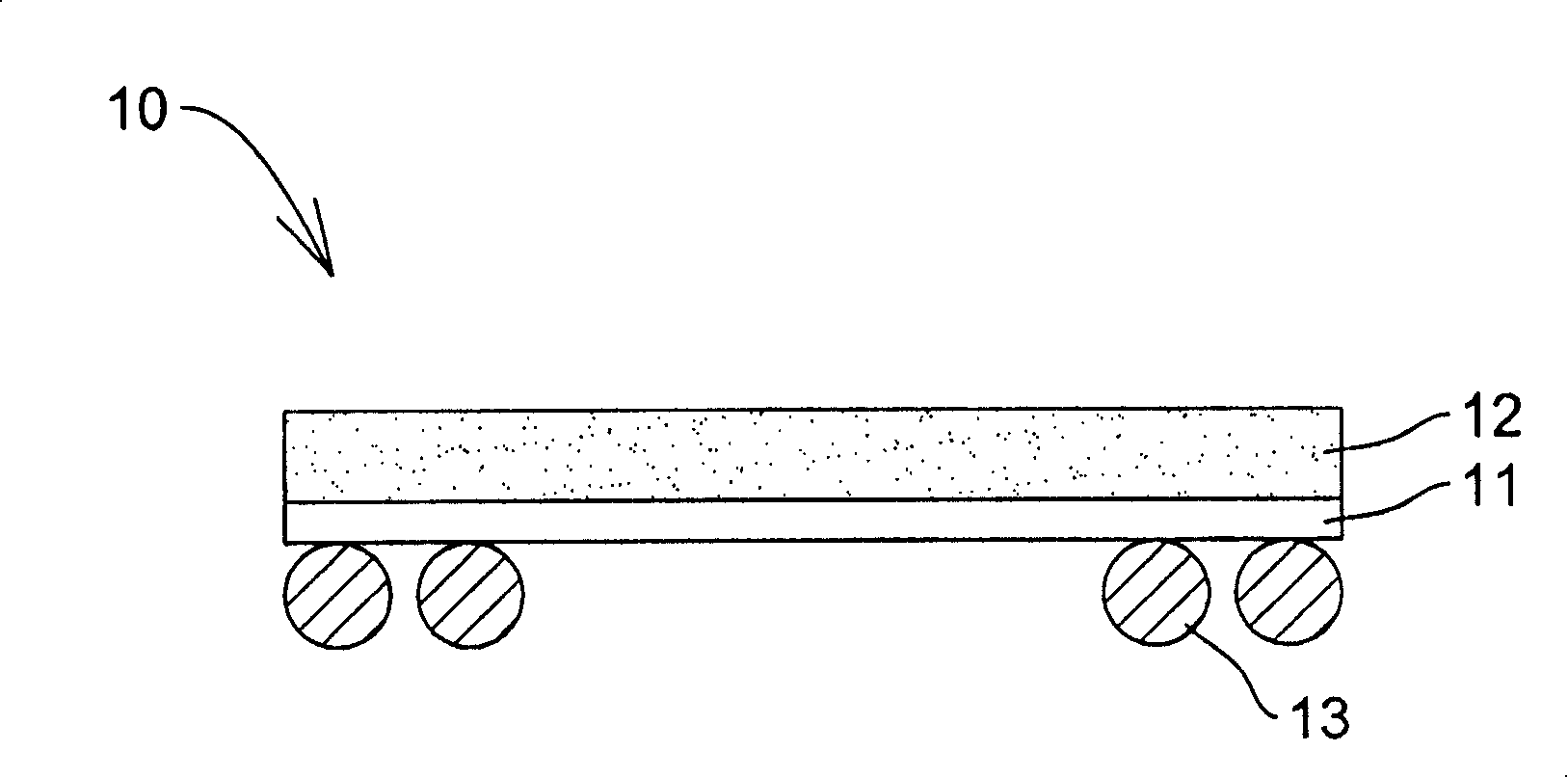

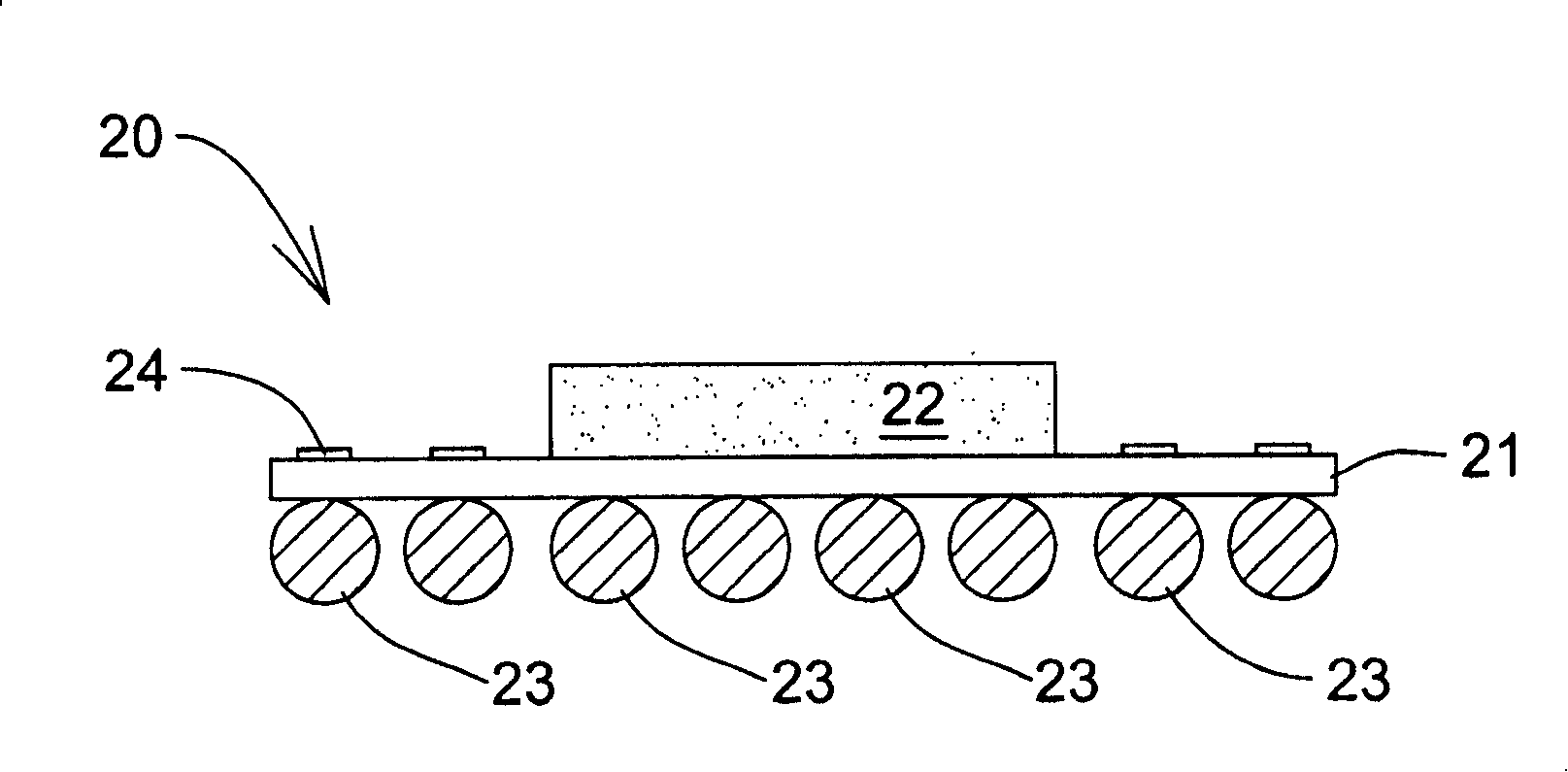

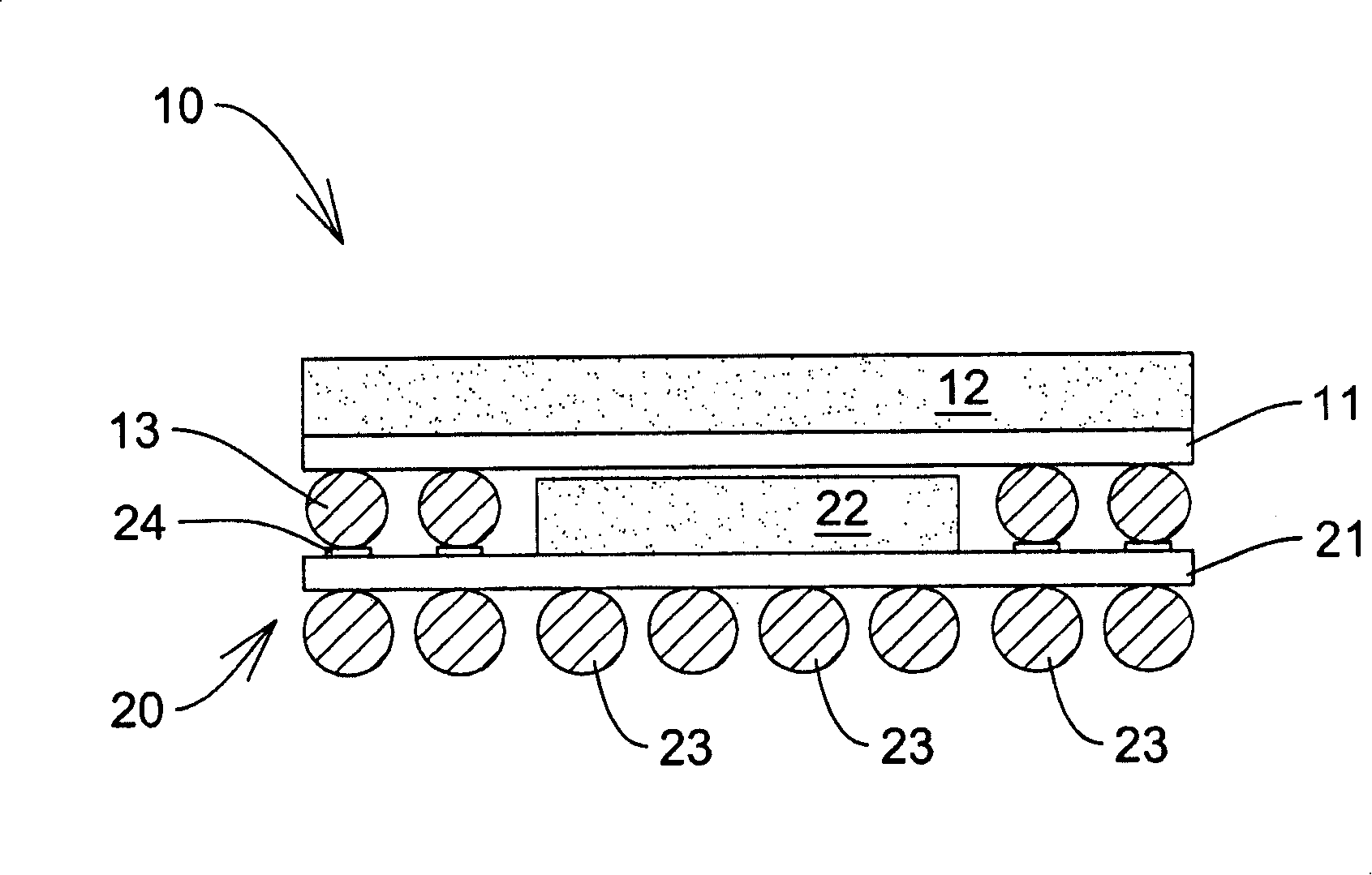

[0041] First of all, please refer to FIG. 2A and FIG. 2B . FIG. 2A and FIG. 2B are a structural cross-sectional view and a stacking diagram of a first embodiment of a repeatable stackable package according to the present invention. As shown in the figure, the repeatable stackable package 100 includes a substrate 110, a plurality of first bonding pads, such as bonding pads 120, a chip 130, a plurality of second bonding pads, such as bonding pads 122, and an encapsulant 140. , which are described below. The substrate 110 has a first surface 112 and a second surface 114 , and the second surface 114 is disposed opposite to the first surface 112 . In addition, a chip carrying area 116 can be defined on the first surface 112 for subsequent chip placement. A plurality of first so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com