High-performance PBAT plant fiber composite wire material applied to 3D printing and preparation method thereof

A plant fiber and 3D printing technology, applied in the field of 3D printing, can solve problems such as heat shrinkage of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

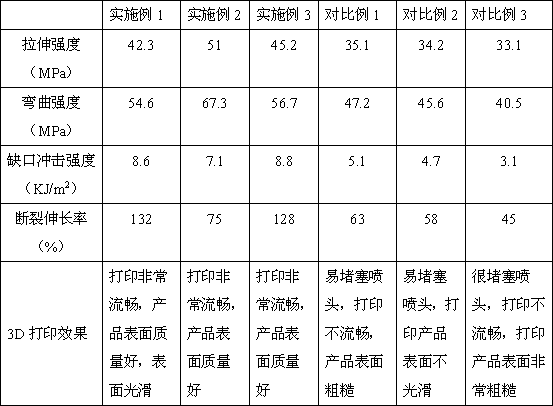

Examples

Embodiment 1

[0014] Example 1 of the present invention: a high-performance PBAT plant fiber composite wire for 3D printing, calculated in parts by mass, including 69.5 parts of PBAT raw material, 15 parts of wood powder (with a particle size of about 300 mesh), and 5 parts of nano-talc powder , 10 parts of polylactic acid, 0.5 parts of chain extender.

[0015] The preparation process is as follows:

[0016] Surface treatment method of plant fiber: Pour 400g wood flour into 1000ml deionized water, add 8g silane coupling agent KH550 into the deionized water, treat it under centrifugal speed of 1000 r / min for 20-40min, then suction filter and dry , to prepare the wood powder that the surface of the coupling agent has been treated for subsequent use.

[0017] Preparation of high-performance PBAT plant fiber composite wires for 3D printing: dry PBAT, wood powder treated with coupling agent, nano-talc powder, and polylactic acid in a vacuum oven at 80°C for 7-8 hours; The components are placed...

Embodiment 2

[0018] Example 2 of the present invention: a high-performance PBAT plant fiber composite wire for 3D printing, calculated in parts by mass, including 59.3 parts of PBAT raw materials, 15 parts of wood powder (with a particle size of about 300 mesh), and 10 parts of bamboo powder ( The particle size is about 300 mesh), 3 parts of nano-talc powder, 2 parts of nano-glass microspheres, 10 parts of polylactic acid, and 0.7 parts of chain extender.

[0019] The preparation process is as follows:

[0020] The surface treatment method of plant fibers: pour 240g wood powder and 160g bamboo powder into 1000ml deionized water, add 6g silane coupling agent KH550 and 4g silane coupling agent KH560 to the deionized water, stir at a centrifugal speed of 1000 r / min Treat for 20 to 40 minutes, then suction filter and dry to obtain wood powder and bamboo powder with the surface treated by the coupling agent, and set aside.

[0021] Preparation of high-performance PBAT plant fiber composite wir...

Embodiment 3

[0022] Example 3 of the present invention: a high-performance PBAT plant fiber composite wire for 3D printing, calculated in parts by mass, including 72.4 parts of PBAT raw materials, 10 parts of wood flour (with a particle size of about 500 mesh), 5 parts of straw (grain diameter of about 500 mesh), 5 parts of nano-talc powder, 2 parts of nano-calcium carbonate, 5 parts of polylactic acid, and 0.6 parts of chain extender.

[0023] The preparation process is as follows:

[0024] Surface treatment method of plant fibers: Pour 240g wood flour and 160g straw into 1000ml deionized water, add 6g silane coupling agent KH550 and 4g silane coupling agent KH560 to the deionized water, and treat under 1000 r / min centrifugal speed stirring 20 to 40 minutes, then suction filtered and dried to obtain the wood powder treated with the coupling agent surface and set aside.

[0025] Preparation of high-performance PBAT plant fiber composite wire for 3D printing: dry PBAT, wood powder and stra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com