Lead-free conducting resin and manufacture method thereof

A manufacturing method and conductive adhesive technology, applied in the field of conductive adhesive, can solve the problems of loose packing factor of bulk density, unable to actually solve silicon chips, inspection specifications, etc., and achieve the effect of solving silicon chip warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

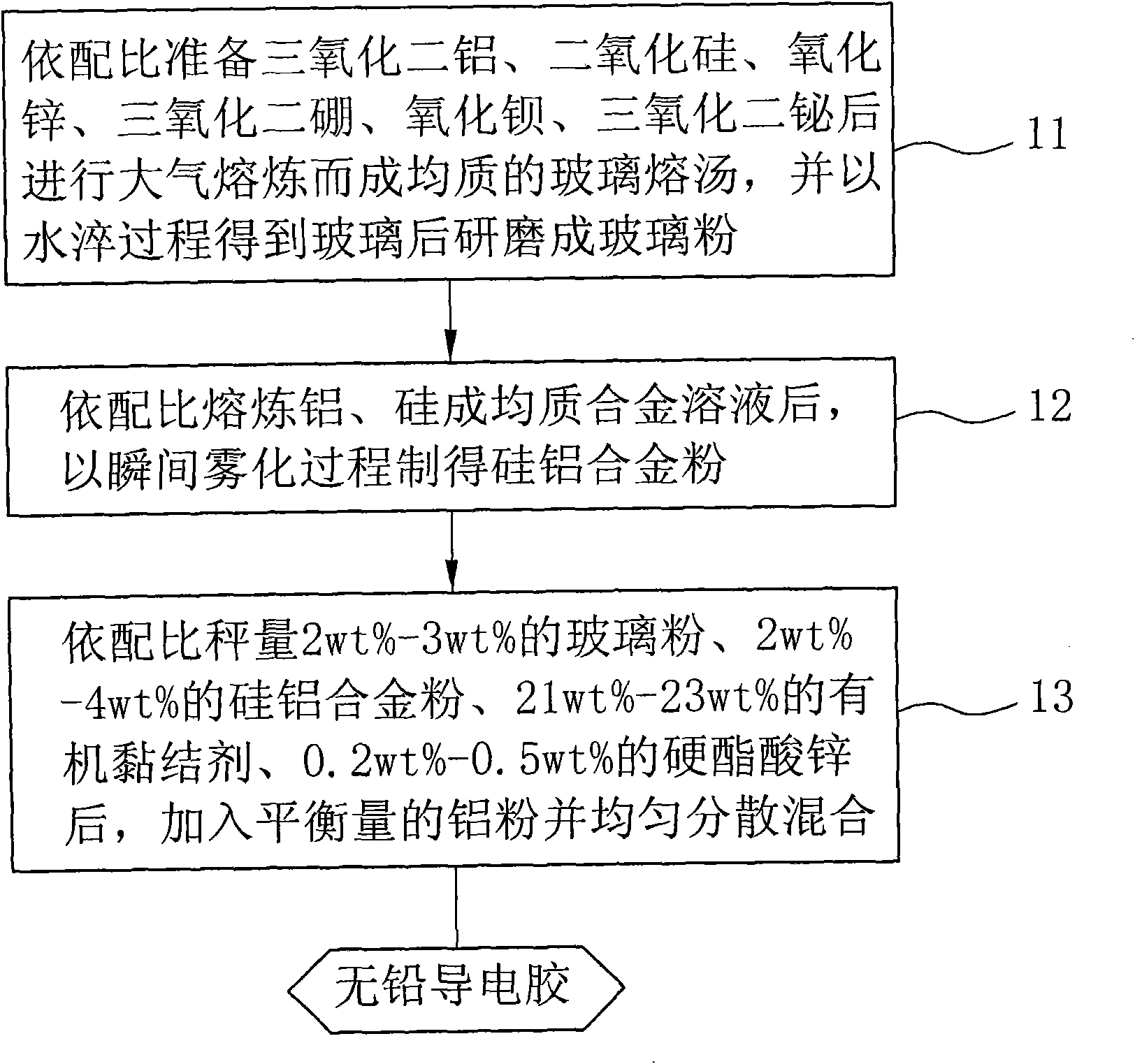

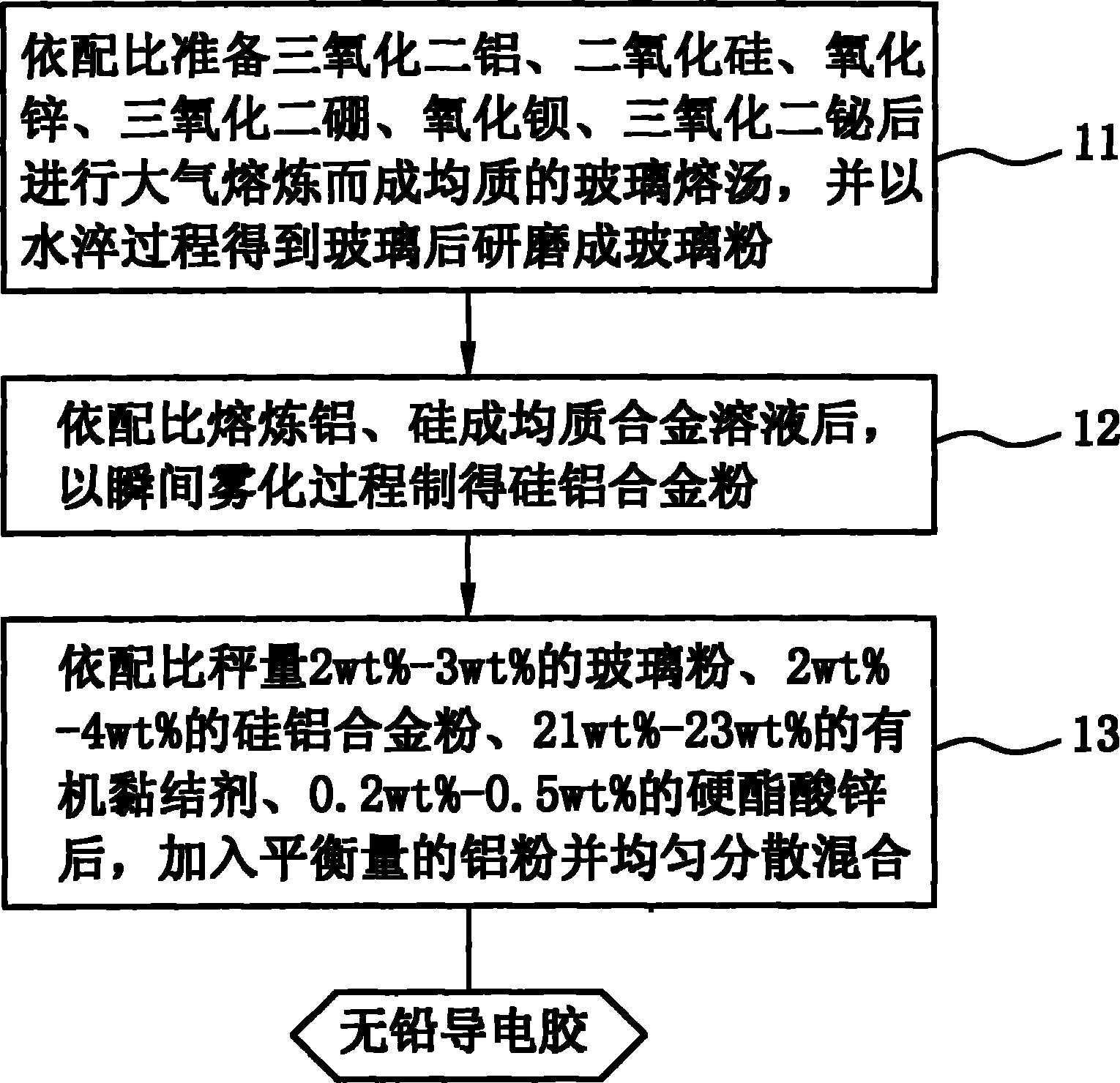

Method used

Image

Examples

experiment example 1

[0027] Based on the total weight of the glass powder to be made as 100wt%, weigh 2wt% aluminum oxide, 9wt% silicon dioxide, 13% zinc oxide, 8wt% boron trioxide, 1wt% barium oxide , and a balanced amount of bismuth trioxide, mixed evenly with a mixer, poured into a platinum crucible and placed in a high-temperature furnace at 950°C, and kept at the temperature for 10 minutes after all the oxides were completely melted to ensure the formation of a homogeneous glass Melt the soup, then pour the glass melt into water to carry out the water quenching process, after making the glass, grind the glass into glass powder below 10 microns.

[0028] Based on the total weight of the silicon-aluminum alloy powder to be produced as 100wt%, in the silicon block and aluminum block with a purity of 99.99% or more, weigh 75wt% silicon and 25wt% aluminum, and put it into the crucible of the vacuum induction melting furnace and evacuate to 10 -3 Above torr, raise the temperature of the vacuum ind...

experiment example 2

[0035] Based on the total weight of the glass powder to be made as 100wt%, weigh 1wt% aluminum oxide, 4wt% silicon dioxide, 14% zinc oxide, 9wt% boron trioxide, 2wt% barium oxide , and a balanced amount of bismuth trioxide, mixed evenly with a mixer, poured into a platinum crucible and placed in a high-temperature furnace at 1000°C, and kept at the temperature for 10 minutes after all the oxides were completely melted to ensure the formation of a homogeneous glass The molten soup is then poured into water for a water quenching process. After the glass is made, the glass is ground to below 10 microns.

[0036] Based on the total weight of the silicon-aluminum alloy powder to be produced as 100wt%, with a silicon block and an aluminum block with a purity of more than 99.99%, weigh 55wt% silicon and 45wt% aluminum, and put them into the crucible of the vacuum induction melting furnace and evacuated to 10 -3 Above torr, raise the temperature of the vacuum induction furnace to 160...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curvature | aaaaa | aaaaa |

| Curvature | aaaaa | aaaaa |

| Curvature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com