Infiltrating micro-irrigation system

A technology of micro-irrigation and capillary infiltration, which is applied in the fields of application, horticulture, and botanical equipment and methods. It can solve the problems of poor water seepage effect, high overall production cost, and low production efficiency, and achieve the effect of uniform and balanced irrigation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

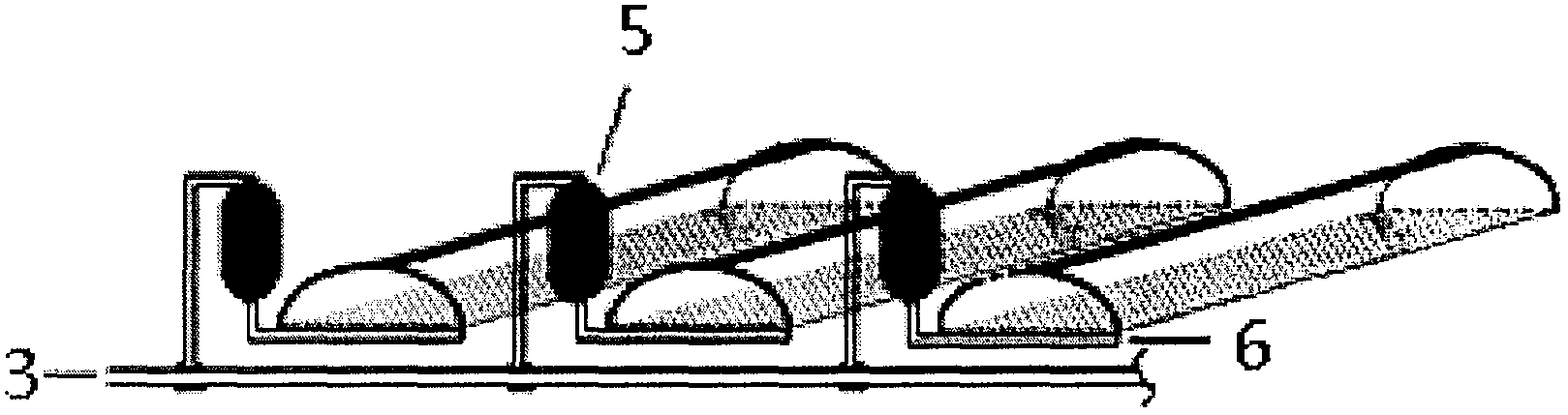

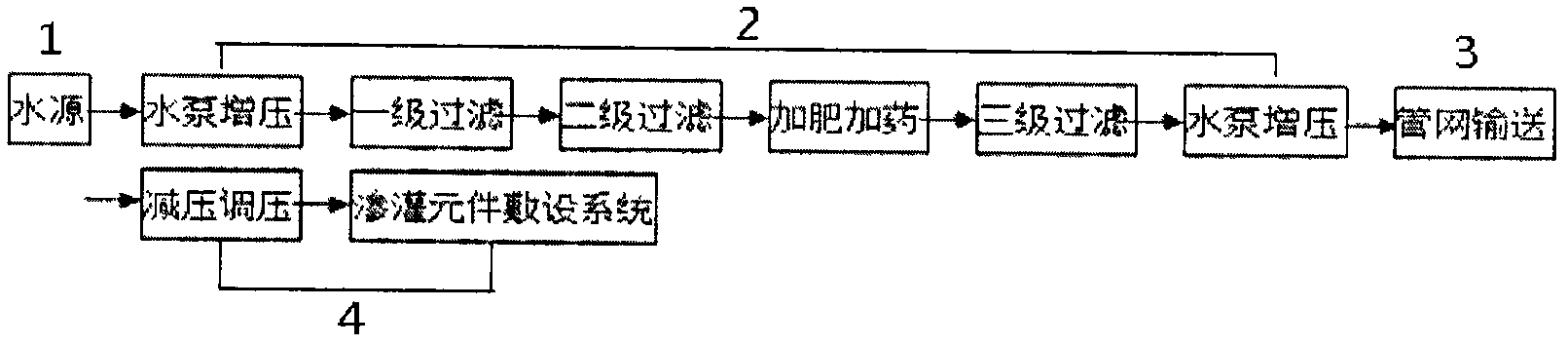

[0183] A flowchart of an irrigation system designed according to the national standard GB / T 50485-2009 "Technical Specifications for Micro-irrigation Engineering" is as follows figure 1 shown. Including water source 1, head hub 2, transmission and distribution network 3, irrigation department 4 four parts. As an irrigation system, due to different water sources, the structure and function of the head hub used are different, and the structure or connection form and shape of the transmission and distribution pipeline network are different, which will form different irrigation systems. This difference is nothing more than water treatment (filtering, adding fertilizers and pesticides, etc.), control (flow control, liquid level control, pressure control, etc.), delivery method (channel or pipe, pipe material, channel / pipe layout) ) are different, and can be traded off or increased according to needs. However, the functions of the water source 1, the head hub 2 (the part between t...

Embodiment 2

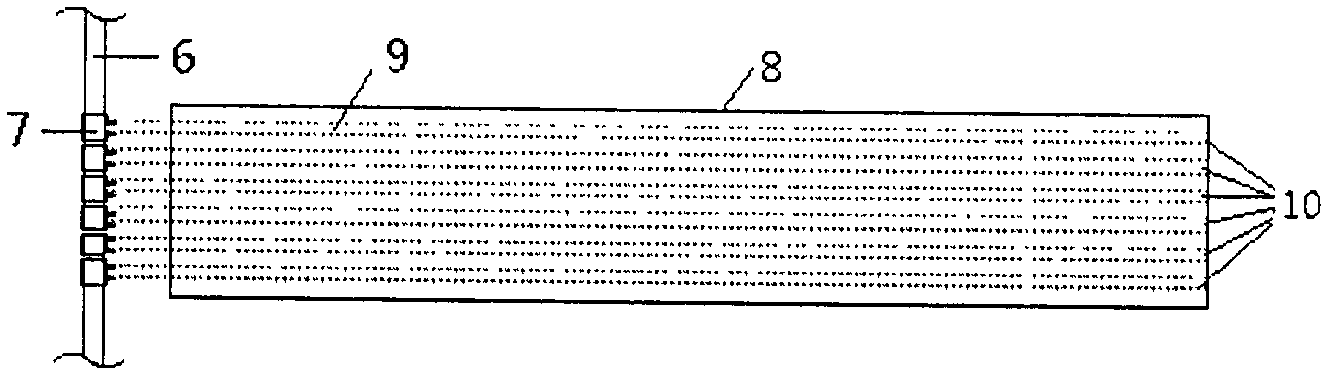

[0190] Irrigation system is consistent with embodiment 1, but the infiltration micro-irrigation pipe 9 wherein uses sectional view such as Figure 5 A "anti-clogging osmotic micro-irrigation tube" with unpowered, self-adaptive, continuous, and balanced osmotic functions is shown. Prepared by the following method:

[0191] Sprinkle the high water retention resin powder on the loose non-woven fabric of the specified width, slightly vibrate the non-woven fabric, so that the high water retention resin powder evenly falls into the pores of the non-woven fabric and place it in a water vapor environment for 15 minutes to make the high water retention Resin powder absorbs water and swells. The amount of sprinkled high water-retaining resin powder is based on 0.5% of the volume ratio of the non-woven fabric. The high water-retaining resin powder particles after water absorption are tightly "stuck" in the high-strength polymer skeleton network composed of non-woven fabrics, and the no...

Embodiment 3

[0193] Irrigation system is consistent with embodiment 1, but the infiltration micro-irrigation pipe 9 adopts such as Image 6 Shown is an "external pressure-resistant, anti-clogging osmotic micro-irrigation tube" with unpowered, self-adaptive, continuous, and balanced osmotic functions. Prepared by the following method:

[0194] like Image 6 shown. The processed non-woven fabric containing high water retention resin powder is used to sew a tubular gel protective layer 13, which is placed outside the "anti-external pressure micro-irrigation tube" of Example 1, so that the middle layer is a capillary permeable tube 11 , the inner layer is a perforated threaded pipe 12, and the outer layer is a gel protective layer 13 "anti-external pressure, anti-clogging permeation micro-irrigation tube".

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com