Excimer lamp device

A technology for excimer lamps and lampshades, applied in lighting devices, discharge lamps, lighting applications, etc., can solve problems such as difficult substrate processing, and achieve the effects of avoiding electrode oxidation, stabilizing cleaning effects, and suppressing excessive attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

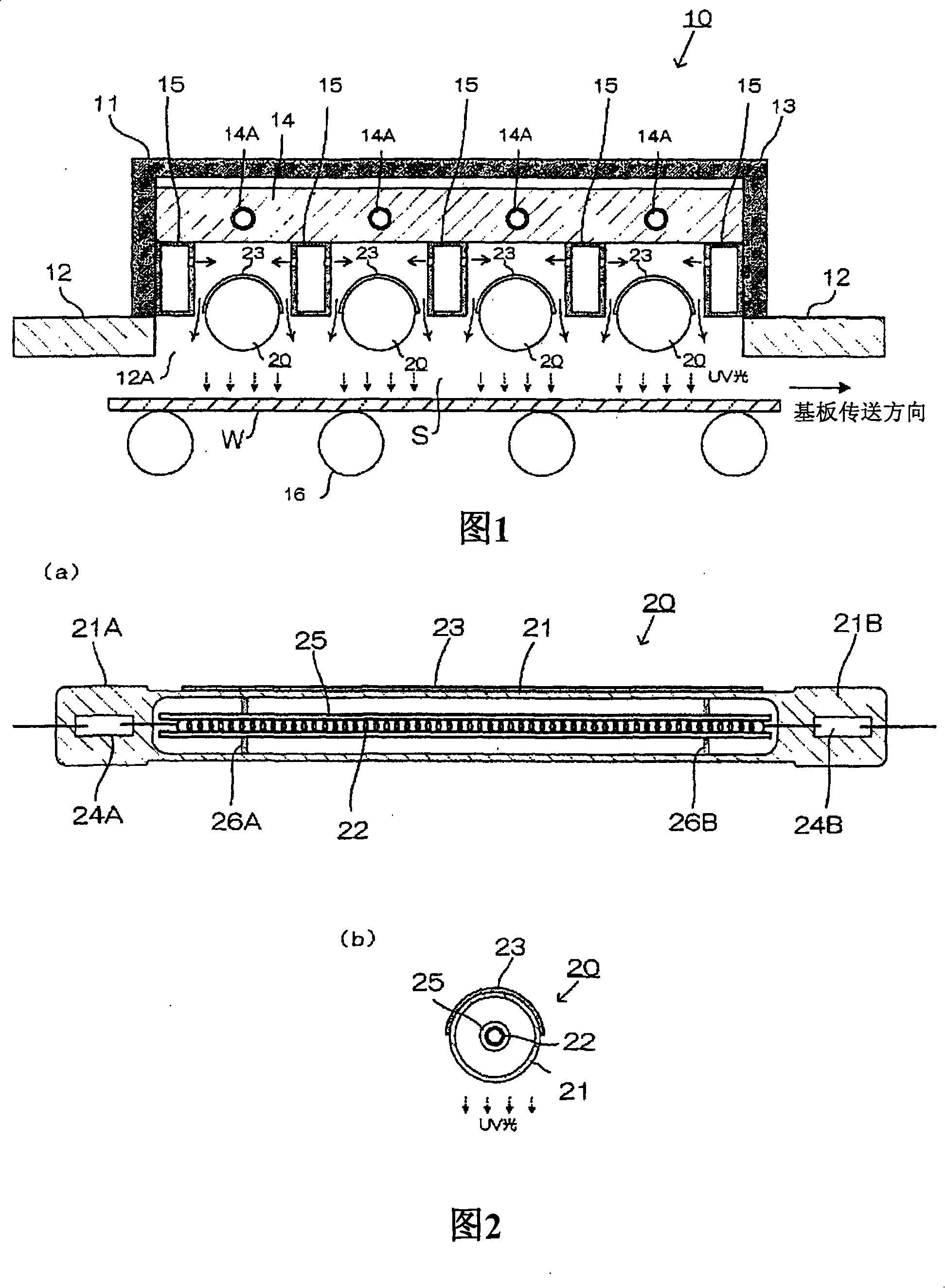

[0104] According to the structure of Fig. 1, the experimental machine of the excimer lamp device (10) was made. The specific structure of the excimer lamp device (10) is as follows.

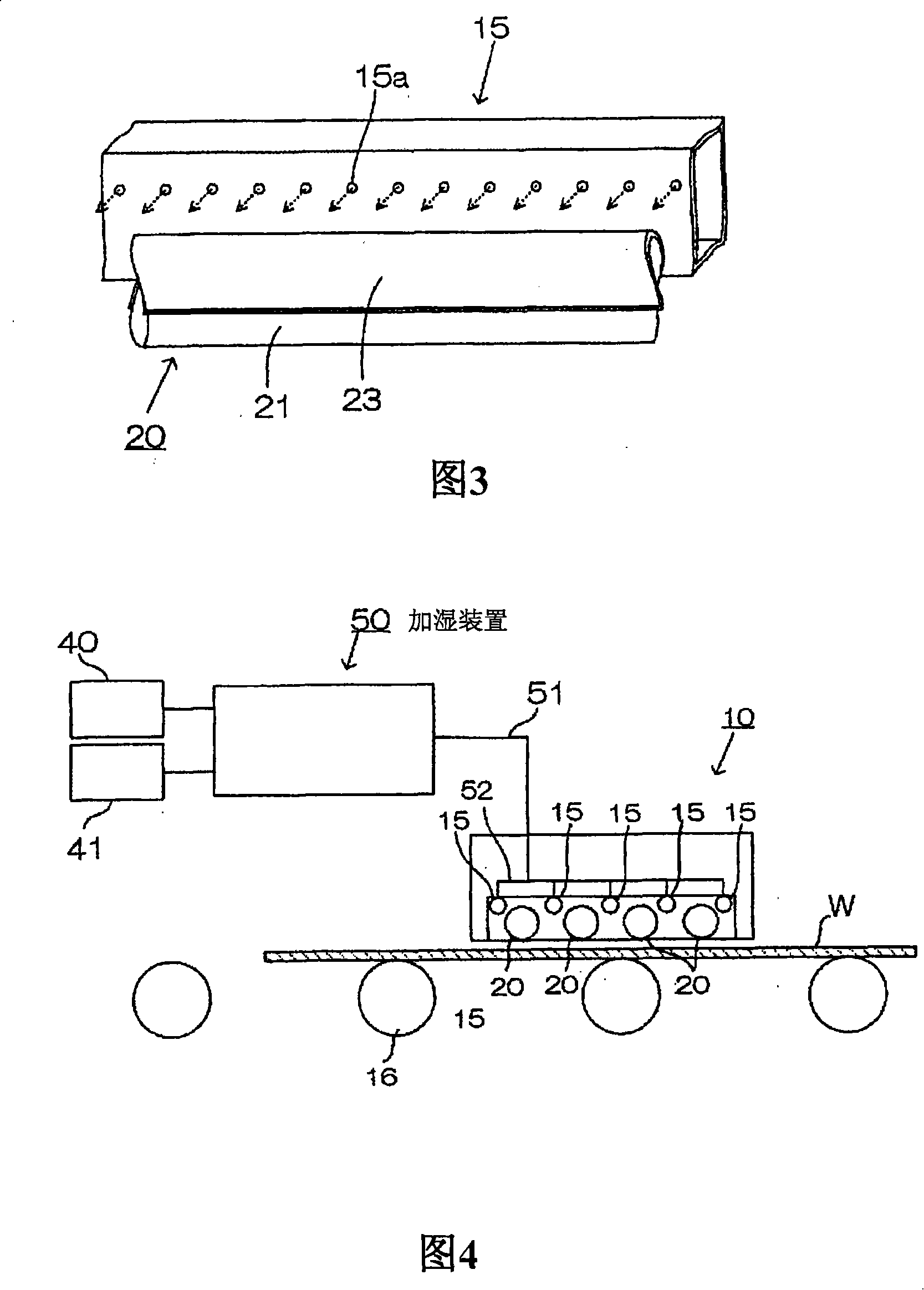

[0105] The excimer lamp (20) has the structure shown in Fig. 2, has an outer diameter of 18.5 mm, an inner diameter of 16.5 mm, and a cylindrical discharge vessel (21) made of quartz glass with a total length of 2470 mm, and is arranged in the center of the tube. One electrode (22), and another electrode (23) in a semi-cylindrical shape is provided on the outer surface of the discharge vessel (21). Moreover, excimer generation gas with a pressure of 60 kPa was sealed inside this discharge vessel (21), and the excimer lamp whose rated power consumption was 600 W was produced.

[0106] Four excimer lamps ( 20 ) fabricated in this way were used and mounted on the excimer lamp device according to the structure of FIG. 1 .

[0107] The gas supply piping provided adjacent to the excimer lamp (20) is ...

Embodiment 2

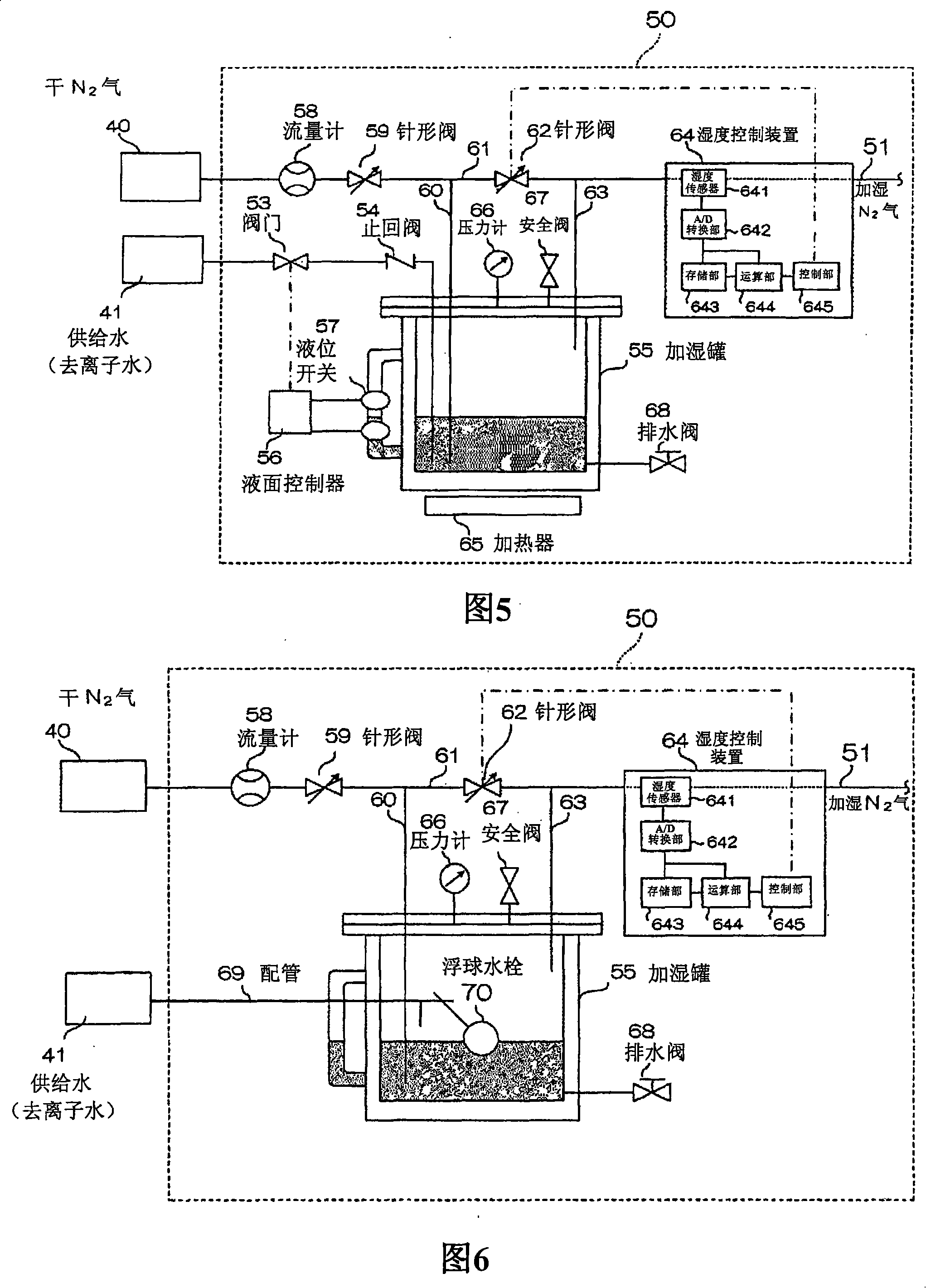

[0129] The gas supply device shown in FIGS. 4 and 5 was installed on the excimer lamp device used in the above-mentioned Example 1 to constitute an experimental device. As the object to be processed, a substrate having the same structure as the substrate used in the above-mentioned Example 1 was used, and the absolute humidity (weight absolute humidity) in the inert gas was changed between 0 and 8.0 g / kg to perform cleaning, and the The contact angle of pure water on the substrate surface was measured. In addition, the driving conditions of the device are also the same as those in the above-mentioned embodiments.

[0130] Fig. 10 shows the results of Example 2.

[0131] The contact angle of pure water on the substrate decreases as the water vapor increases from the weight absolute humidity of 0 g / kg, and the lowest contact angle is obtained around 3.0 to 3.5 g / kg. If the weight absolute humidity is greater than this, the contact angle will gradually increase, and if the weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com