Liquid-state metal magnetic fluid and preparation method thereof

A liquid metal and liquid metal alloy technology, applied in the field of magnetic fluid, can solve the problems of complex preparation process, poor uniformity, magnetic particle segregation of magnetic fluid, etc., and achieve the effect of uniform physical properties, high thermal conductivity and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

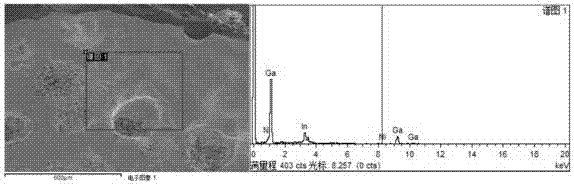

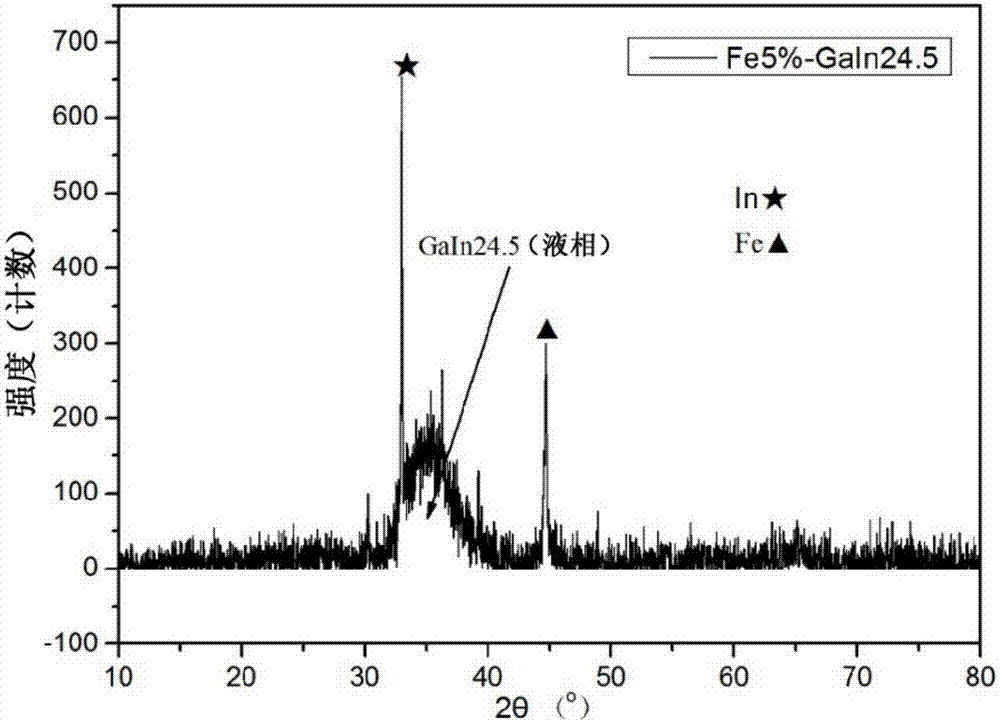

[0027] 75.5 wt% of Ga, 24.5 wt% of In, and less than 0.01 wt% of other impurity elements are configured into 100 parts of liquid metal fluid. The D90 particle diameter is 50nm, and the Fe content with a purity of 99.99% is adopted, and the addition amount of Fe powder is 5 parts. The ball milling process adopts a 304 stainless steel ball mill tank and is filled with nitrogen, the nitrogen purity is 99.99%, and agate balls are used. The volume ratio of the sum of the volumes of the liquid metal alloy and the magnetic metal to the balls is 2:1, and the ball milling time is 2:1. 2h, speed 600r / min. Cut off the power supply, and after the ball mill tank is at normal temperature, take out the liquid metal magnetic fluid and test its phase. like figure 1 As shown, the XRD spectrum shows that the magnetic fluid is composed of elemental Fe and liquid Ga and In liquid metals.

Embodiment 2

[0029] Ga 66wt%, In21wt%, Sn13wt%, Zn1wt%, and other impurity elements less than 0.01wt% are configured into 100 parts of liquid metal fluid. The Fe powder with D90 particle size of 1 μm and purity of 99.99% is used, and the addition amount of Fe powder is 2 parts. The Ni powder with D90 particle size of 50 nm and purity of 99.99% is used, and the addition amount of Ni powder is 1 part. A planetary ball mill is used for ball milling. The ball milling process uses a 304 stainless steel ball mill tank and is filled with nitrogen. The nitrogen purity is 99.99%. Agate balls are used. The volume ratio of the sum of the volumes of the liquid metal alloy and the magnetic metal to the balls is 3 : 1, ball milling time 4h, rotating speed 500r / min. Cut off the power supply, and after the temperature of the ball mill tank is at normal temperature, take out the liquid metal magnetic fluid, and observe its appearance photos (such as figure 2 shown). According to the test results, the av...

Embodiment 3

[0031] 90 wt% of Ga, 10 wt% of In, and less than 0.01 wt% of other impurity elements are configured into 100 parts of liquid metal fluid. Ni powder with a D90 particle size of 50nm and a purity of 99.99% was used, and the amount of Ni powder added was 3 parts. A planetary ball mill is used for ball milling. The ball milling process uses a 304 stainless steel ball mill tank and is filled with nitrogen. The nitrogen purity is 99.99%. Agate balls are used. The volume ratio of the sum of the volumes of the liquid metal alloy and the magnetic metal to the ball is 2 : 1, ball milling time 6h, rotating speed 400r / min. Cut off the power supply, and after the temperature of the ball mill tank is at normal temperature, take out the liquid metal magnetic fluid, observe its SEM and its energy spectrum (such as image 3 shown). SEM observation and energy spectrum results show that the magnetic material particles are uniformly dispersed in the liquid metal without agglomeration.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com