Anti-fog urethane acrylate coating as well as preparation method and use method thereof

A technology of urethane acrylate and acrylic resin, which is applied in the field of anti-fog urethane acrylate coatings. It can solve the problems of coating anti-fog effect, migration and floating of graphite oxide, etc., and achieve the retention of hydrophilicity and adhesion, and excellent film-forming performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

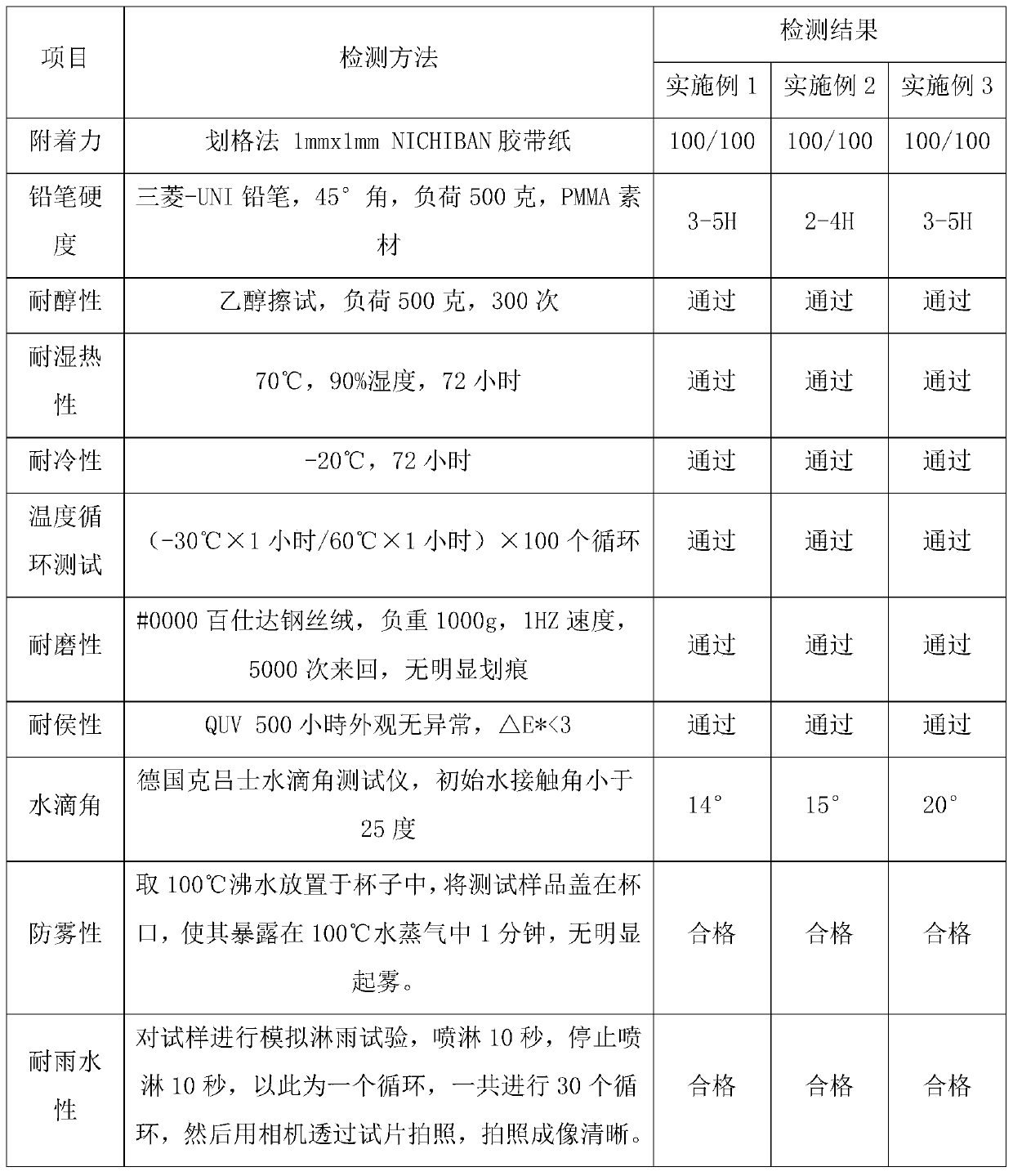

Examples

Embodiment 1

[0028] A kind of anti-fog polyurethane acrylate paint, comprises following raw materials in parts by weight:

[0029] 40 parts of polyurethane acrylate, 30 parts of acrylic resin, 13 parts of carboxylated graphene dispersion liquid with sheet diameter less than 500nm, 50 parts of water, 3 parts of 1-hydroxycyclohexyl phenyl ketone and 0.5 part of germanium dioxide.

[0030] The carboxylated graphene dispersion with sheet diameter less than 500nm was purchased from Nanjing Xianfeng Nano Material Technology Co., Ltd., number / CAS number: XF004L 7440-44-0; other raw materials are commercially available products.

[0031] A preparation method for anti-fog polyurethane acrylate paint, comprising the steps of:

[0032] (a) Disperse the carboxylated graphene dispersion in water, stir and disperse evenly to obtain the first mixture for use;

[0033] (b) adding urethane acrylate and acrylic resin into the container, adding 1-hydroxycyclohexyl phenyl ketone and germanium dioxide under t...

Embodiment 2

[0043] A kind of anti-fog polyurethane acrylate paint, comprises following raw materials in parts by weight:

[0044] 30 parts of polyurethane acrylate, 15 parts of acrylic resin, 10 parts of carboxylated graphene dispersion with a sheet diameter less than 500nm, 40 parts of ethanol, 2-hydroxy-2-methyl-1-[4-(2-hydroxyethoxy ) phenyl]-1-propanone and 2,4,6-trimethylbenzoylphenyl phosphonic acid ethyl ester mixture 1 part and antimony trioxide 0.1 part.

[0045] A preparation method for anti-fog polyurethane acrylate paint, comprising the steps of:

[0046] (a) dispersing the carboxylated graphene dispersion in ethanol, stirring and dispersing to obtain the first mixture for use;

[0047] (b) Add urethane acrylate and acrylic resin in the container, add 2-hydroxyl-2-methyl-1-[4-(2-hydroxyethoxy)phenyl]-1-acetone and 2,4,6-trimethylbenzoylphenylphosphonic acid ethyl ester mixture and antimony trioxide, heated to 40°C and stirred evenly to obtain the second mixture;

[0048] (c...

Embodiment 3

[0057] A kind of anti-fog polyurethane acrylate paint, comprises following raw materials in parts by weight:

[0058]50 parts of polyurethane acrylate, 40 parts of acrylic resin, 15 parts of carboxylated graphene dispersion, 60 parts of water and ethanol mixture, 1-hydroxycyclohexyl phenyl ketone and 2,4,6-trimethylbenzoyl- 5 parts of a mixture of diphenylphosphine oxide and 1 part of a mixture of germanium dioxide and antimony trioxide.

[0059] A preparation method for anti-fog polyurethane acrylate paint, comprising the steps of:

[0060] (a) dispersing the carboxylated graphene dispersion in water and ethanol mixture, stirring and dispersing to obtain the first mixture for use;

[0061] (b) Add urethane acrylate and acrylic resin in the container, add 1-hydroxycyclohexyl phenyl ketone and 2,4,6-trimethylbenzoyl-diphenylphosphine oxide mixture and The mixture of germanium dioxide and antimony trioxide is heated up to 60°C and stirred evenly to obtain the second mixture; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com