Bactericide for medical instruments

A technology of medical devices and fungicides, applied in the direction of fungicides, biocides, biocides, etc., can solve the problems of corrosion, rust and fogging of medical devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

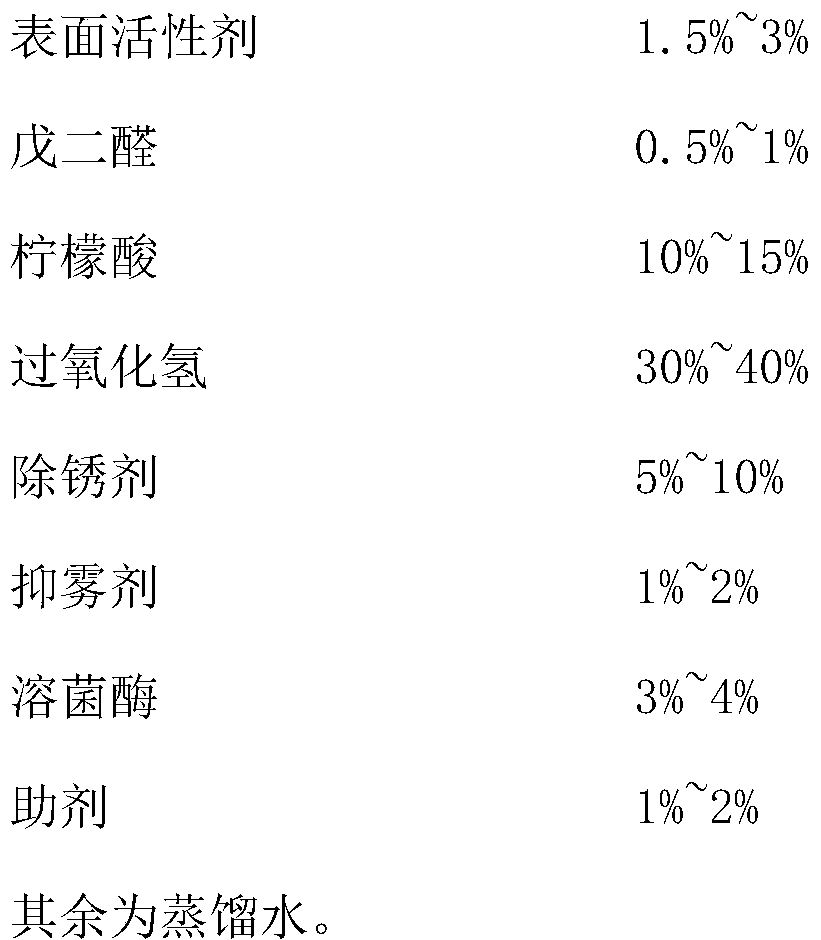

[0047] A bactericide for medical devices, made of the following components by weight percentage,

[0048] Surfactant 1.5%, glutaraldehyde 0.5%, citric acid 10%, hydrogen peroxide 30%, rust remover 5%, fog suppressant 1%, lysozyme 3%, additive 1%, and the rest is distilled water.

[0049] The above-mentioned degradable fungicide preparation method for sewage comprises the following steps:

[0050]Step 1: Dilute the cationic surfactant and water in a ratio of 1:50, dilute the nonionic surfactant coconut acid diethanolamide and water in a ratio of 1:55, and dilute the diluted cationic surfactant solution with The nonionic surfactant solution was mixed in a ratio of 1:0.5, stirred for 1 and left to stand for 30 minutes;

[0051] Step 2: Add glutaraldehyde solution to the above-mentioned surfactant mixed solution, mix and stir for 0.5h, and let stand for 20 minutes;

[0052] Step 3: Dilute hydrogen peroxide and water into aqueous hydrogen peroxide in a ratio of 1:30, add aqueous ...

Embodiment 2

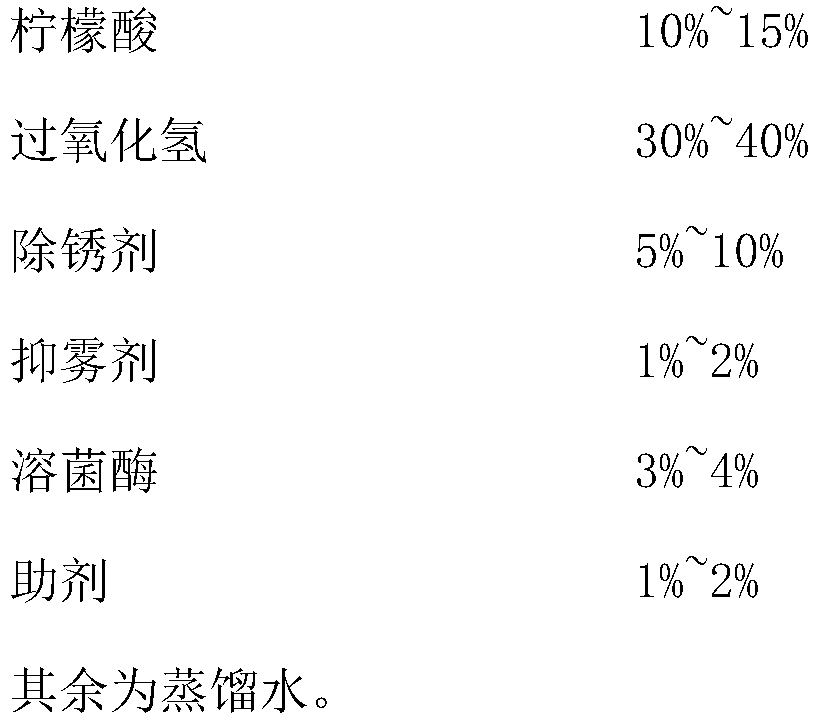

[0057] A bactericide for medical devices, made of the following components by weight percentage,

[0058] 2.25% surfactant, 0.75% glutaraldehyde, 12.5% citric acid, 35% hydrogen peroxide, 7.5% rust remover, 1.5% fog suppressant, 3.5% lysozyme, 1.5% auxiliary agent, and the rest is distilled water.

[0059] The above-mentioned degradable fungicide preparation method for sewage comprises the following steps:

[0060] Step 1: Dilute the cationic surfactant and water in a ratio of 1:52.5, dilute the nonionic surfactant coconut acid diethanolamide and water in a ratio of 1:57.5, and dilute the diluted cationic surfactant solution with The non-ionic surfactant solution was mixed in a ratio of 1:0.65, stirred for 1.5 hours and left to stand for 35 minutes;

[0061] Step 2: Add glutaraldehyde solution to the above-mentioned surfactant mixed solution, mix and stir for 0.75h, and let stand for 25 minutes;

[0062] Step 3: Dilute hydrogen peroxide and water into an aqueous hydrogen p...

Embodiment 3

[0067] A bactericide for medical devices, made of the following components by weight percentage,

[0068] 2% surfactant, 0.5% glutaraldehyde, 15% citric acid, 35% hydrogen peroxide, 8% rust remover, 1% fog suppressant, 3% lysozyme, 1% additive, and the rest is distilled water.

[0069] The above-mentioned degradable fungicide preparation method for sewage comprises the following steps:

[0070] Step 1: Dilute the cationic surfactant and water in a ratio of 1:55, dilute the nonionic surfactant coconut acid diethanolamide and water in a ratio of 1:55, and dilute the cationic surfactant solution after dilution with The non-ionic surfactant solution was mixed in a ratio of 1:0.5, stirred for 1.5 hours and left to stand for 35 minutes;

[0071] Step 2: Add glutaraldehyde solution to the above-mentioned surfactant mixed solution, mix and stir for 0.5h, and let stand for 20 minutes;

[0072] Step 3: Dilute hydrogen peroxide and water into aqueous hydrogen peroxide in a ratio of 1:3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com