Thixotropic agent for curable compositions

A thixotropic agent and composition technology, applied in the fields of sealants or coatings, elastic adhesives, can solve problems such as unfavorable processability and viscosity increase, and achieve the effects of easy processing, high thixotropy and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

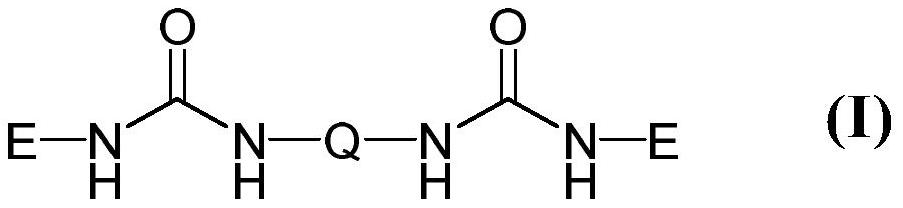

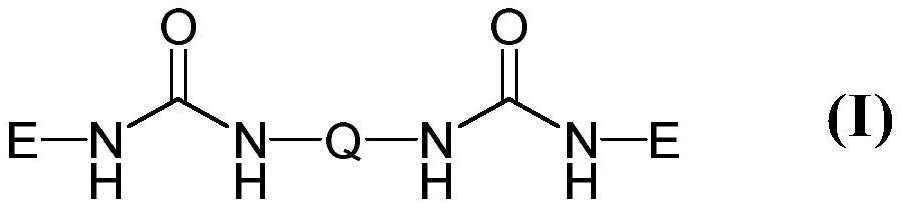

[0045] The preparation of the urea compounds is preferably carried out in a continuous process, in which the amines and / or isocyanates are used optionally diluted with polyethers having blocked hydroxyl groups.

[0046] The preparation is preferably carried out with the exclusion of moisture. Preferably no further additives are present during the preparation, in particular no solvent and no catalyst.

[0047] Preferably, the thixotropic agent is present in the form of a spreadable paste that resists sagging at room temperature.

[0048] The thixotropic agent preferably comprises 5 to 25% by weight of urea compounds and 50 to 95% by weight of polyethers with blocked hydroxyl groups. The thixotropic agent particularly preferably comprises 10 to 25% by weight of urea compounds and 75 to 90% by weight of polyethers with blocked hydroxyl groups.

[0049] Polyethers with blocked hydroxyl groups are substantially free of unblocked hydroxyl groups. "Essentially free" here means tha...

Embodiment

[0246] Examples are described below, which explain the present invention in more detail. The invention is of course not limited to the described embodiments.

[0247] "Normal climate" ("NK") means a temperature of 23±1° C. and a relative air humidity of 50±5%.

[0248] Chemicals used were from Sigma-Aldrich Chemie GmbH if not stated otherwise.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com