High-surface gloss glass fiber reinforced flame retardant polycarbonate composition and preparation method thereof

A glass fiber and polycarbonate technology, applied in the field of polycarbonate composition and preparation, can solve the problems of welding line and fogging, increase material cost, and a small amount of fiber separation, and achieve no welding line, high rigidity and high surface. glossy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

[0034] A preparation method of high surface gloss glass fiber reinforced flame retardant polycarbonate composition, the method comprises the following steps:

[0035] (1) prepare materials according to the following components:

[0036] Polycarbonate: PC-1, LG-DOW Caliber 200-10, PC-2, LG-DOW Caliber 201-30, PC-3, LG-DOW Caliber 1080DVD;

[0037] Glass fiber: GF-1;

[0038] Surface modifier: W-1, Honeywell A-C540A, W-2, Honeywell A-C400A, W-3, Honeywell A-C573A, W-4, PETS;

[0039] Flame retardant: FR-1, 3M FR2025;

[0040] Anti-dripping agent: PTFE-1, MITSUBISHI RAYON Metablen A-3000;

[0041] Other additives Additive: Antioxidant 1010: Antioxidant 168=2:3 (weight ratio) compound mixture; the content of each component is shown in Table 1.

[0042] (2) Put polycarbonate, surface modifier, flame retardant, anti-dripping agent and other additives in the high-speed mixer according to the above ratio, stir and mix evenly, and send it into the twin-screw extruder from the main ...

Embodiment 9

[0060] A preparation method of high surface gloss glass fiber reinforced flame retardant polycarbonate composition, the method comprises the following steps:

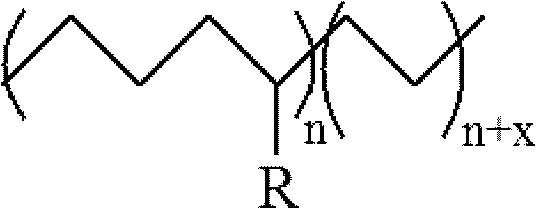

[0061] (1) Prepare materials according to the following components and parts by weight: 50kg polycarbonate, 20kg glass fiber, 0.2kg surface modifier, 0.03kg flame retardant, 0.1kg anti-dripping agent, wherein the M of polycarbonate W It is 20000, according to ASTM D1234 standard, the melt index at 300°C is 70g / 10min, the glass fiber diameter is 10μm, and the glass fiber length is 10cm. The structure of the surface modifier is as follows:

[0062]

[0063] Where n is 10, x is 50, the number average molecular weight of the surface modifier is 1000, the R group is an epoxy group, the flame retardant is potassium perfluorobutane sulfonate (KFPBS), and the anti-dripping agent is poly Tetrafluoroethylene (PTFE), in addition, also includes 0.1kg light stabilizer 292, 0.1kg antioxidant-264 as heat stabilizer and 0.3kg polyvi...

Embodiment 10

[0066] A preparation method of high surface gloss glass fiber reinforced flame retardant polycarbonate composition, the method comprises the following steps:

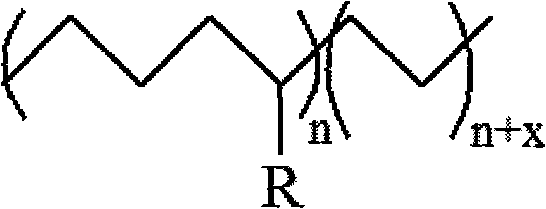

[0067] (1) Prepare materials according to the following components and parts by weight: 70kg polycarbonate, 30kg glass fiber, 0.3kg surface modifier, 0.05kg flame retardant, 0.2kg anti-dripping agent, wherein the M of polycarbonate W According to the ASTM D1234 standard, the melt index measured at 300°C is 1g / 10min, the glass fiber diameter is 8μm, and the glass fiber length is 10cm. The structure of the surface modifier is as follows:

[0068]

[0069] Among them, n150, x is 345, the number average molecular weight of the surface modifier is 10000, the R group is ethylene acetate group, the flame retardant is potassium perfluorobutane sulfonate (KFPBS), and the anti-dripping agent is polytetrafluoroethylene (PTFE), in addition, also includes 0.2kg impact modifier AE1303, 0.2kg carbon black.

[0070] (2) Put polycar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com