Hot plate mold for automobile lamp housing manufacturing equipment

A technology for manufacturing equipment and shells, applied in the field of hot plate molds, can solve the problems of affecting the welding effect of the edge of the lamp shell, uneven heating of the welding ribs, inconvenient mold replacement, etc., to reduce weight and cost, easy operation, and energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

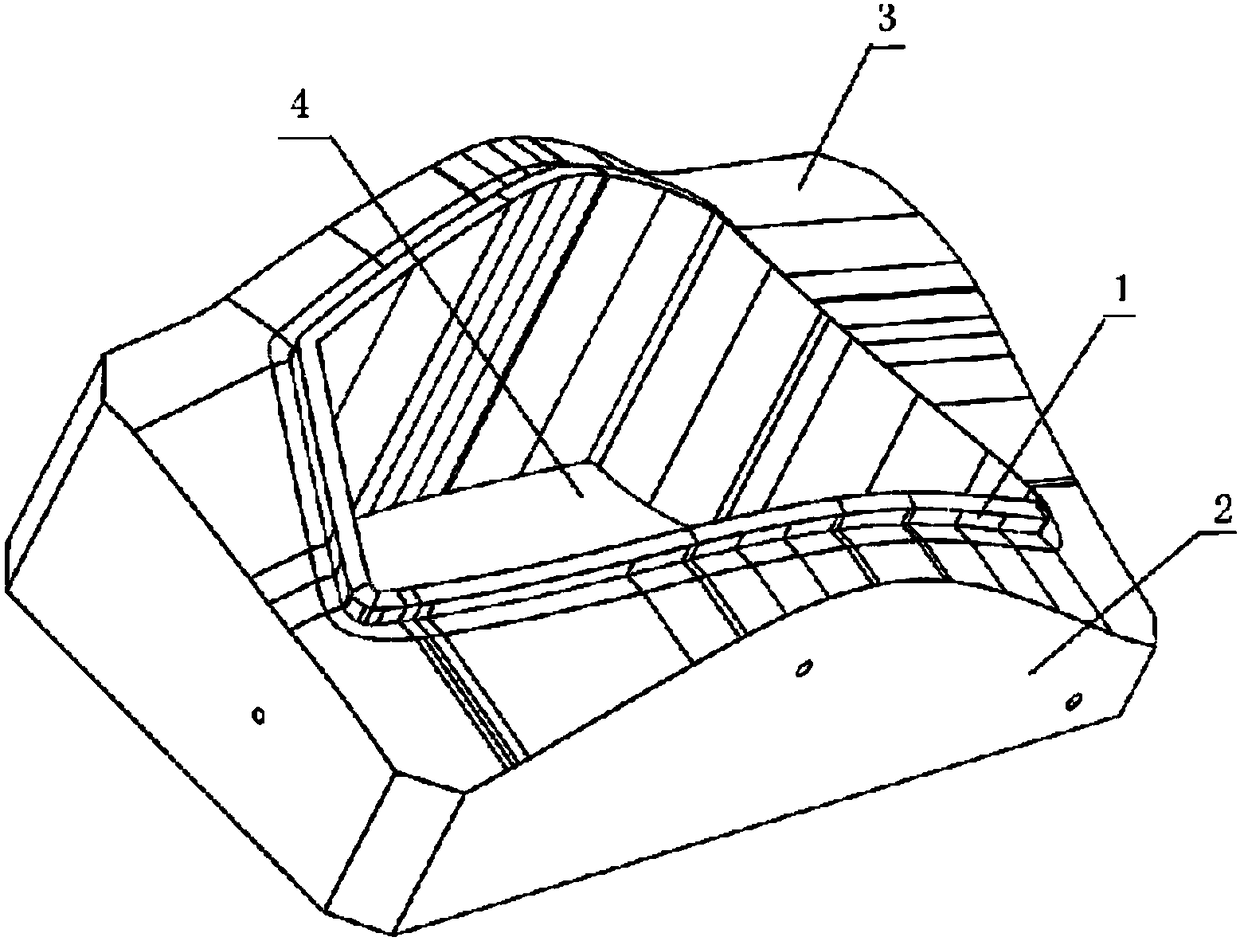

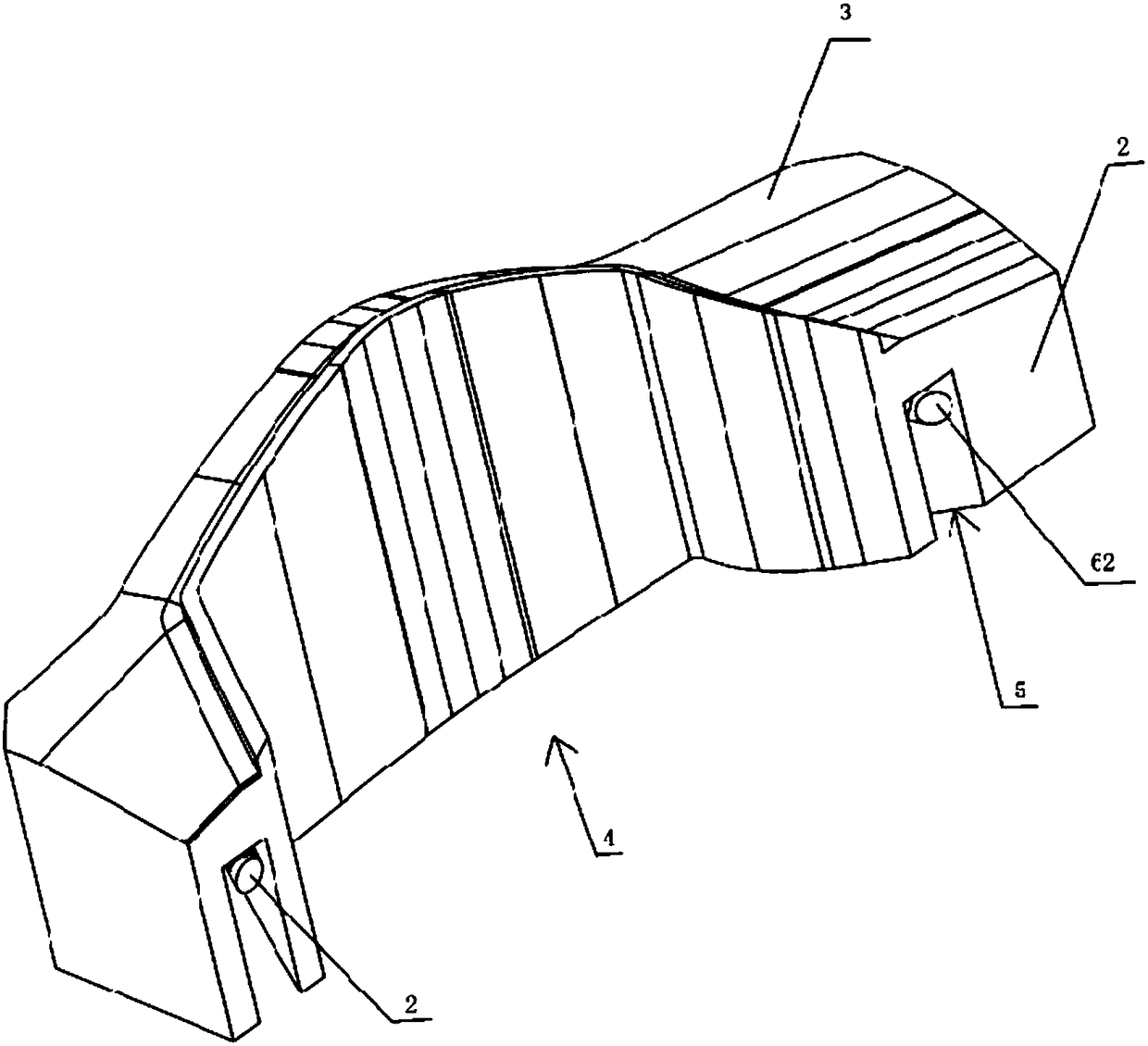

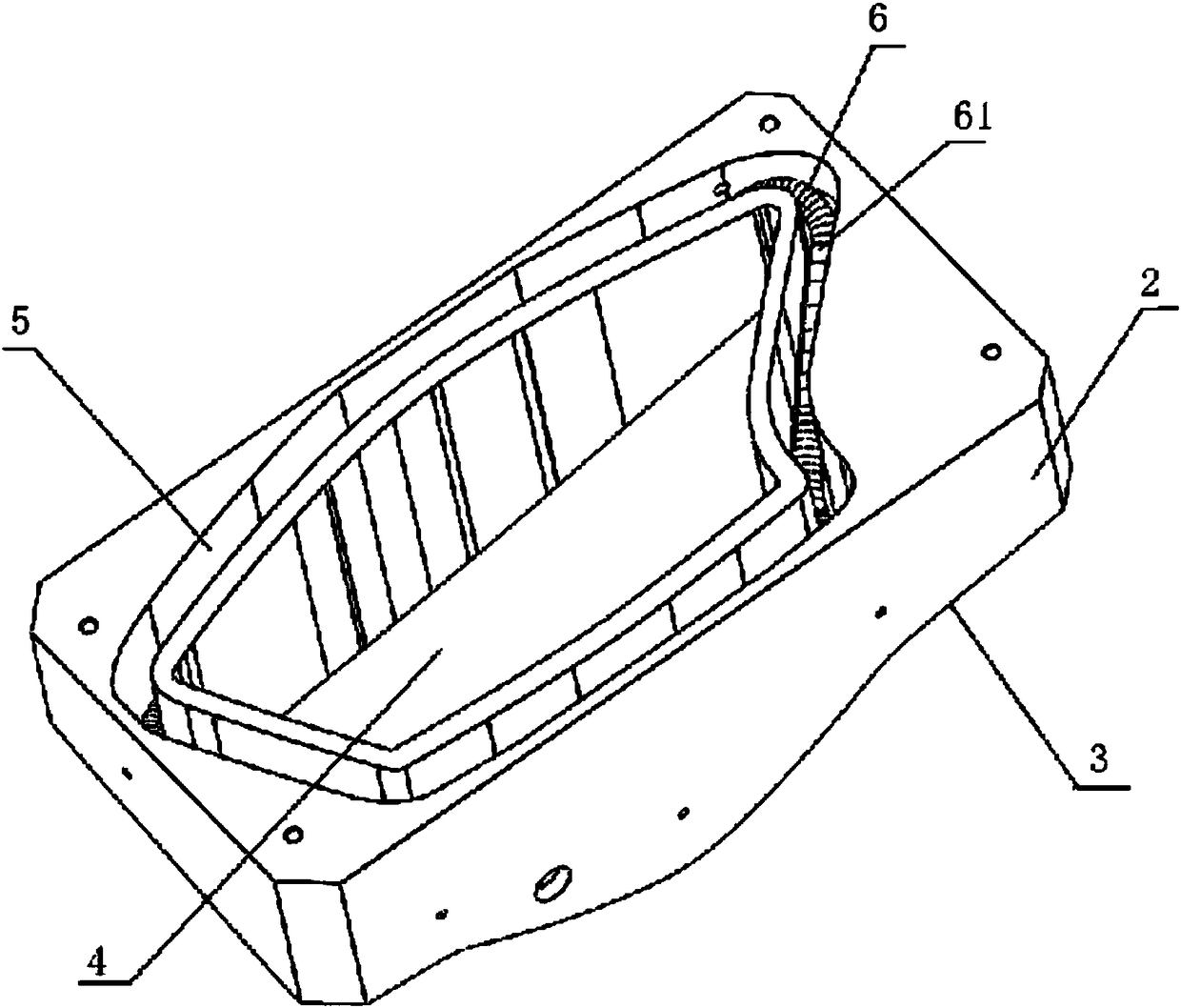

[0014] Such as figure 1 , 2 As shown in , 3, the hot plate mold for the manufacturing equipment of the car lamp shell includes an upper surface as a working surface 3 corresponding to the shape of the workpiece to be processed, and a mold seat 2 whose lower surface is the mounting surface, and a heating wire tube 6 is arranged in the mold seat 2 The heating wire tube 6 is composed of a whole heating wire 61 wound on an insulating support rod 6 made of prefabricated ceramic material, and the mounting surface of the mold base 2 is provided with a heating groove 5 for placing the heating wire tube 6 , The heating groove 5 corresponds to the outer contour of the welding rib 1 used when processing the workpiece, and the middle part of the mold holder 2 corresponds to a hollow cavity 4 within the contour range of the heating groove 5 to make the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com