Cleaning driver of self-cleaning mechanical type filter

A mechanical and driver technology, applied in the field of filters, can solve the problems of easy breakage, unsuitability, large pressure difference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

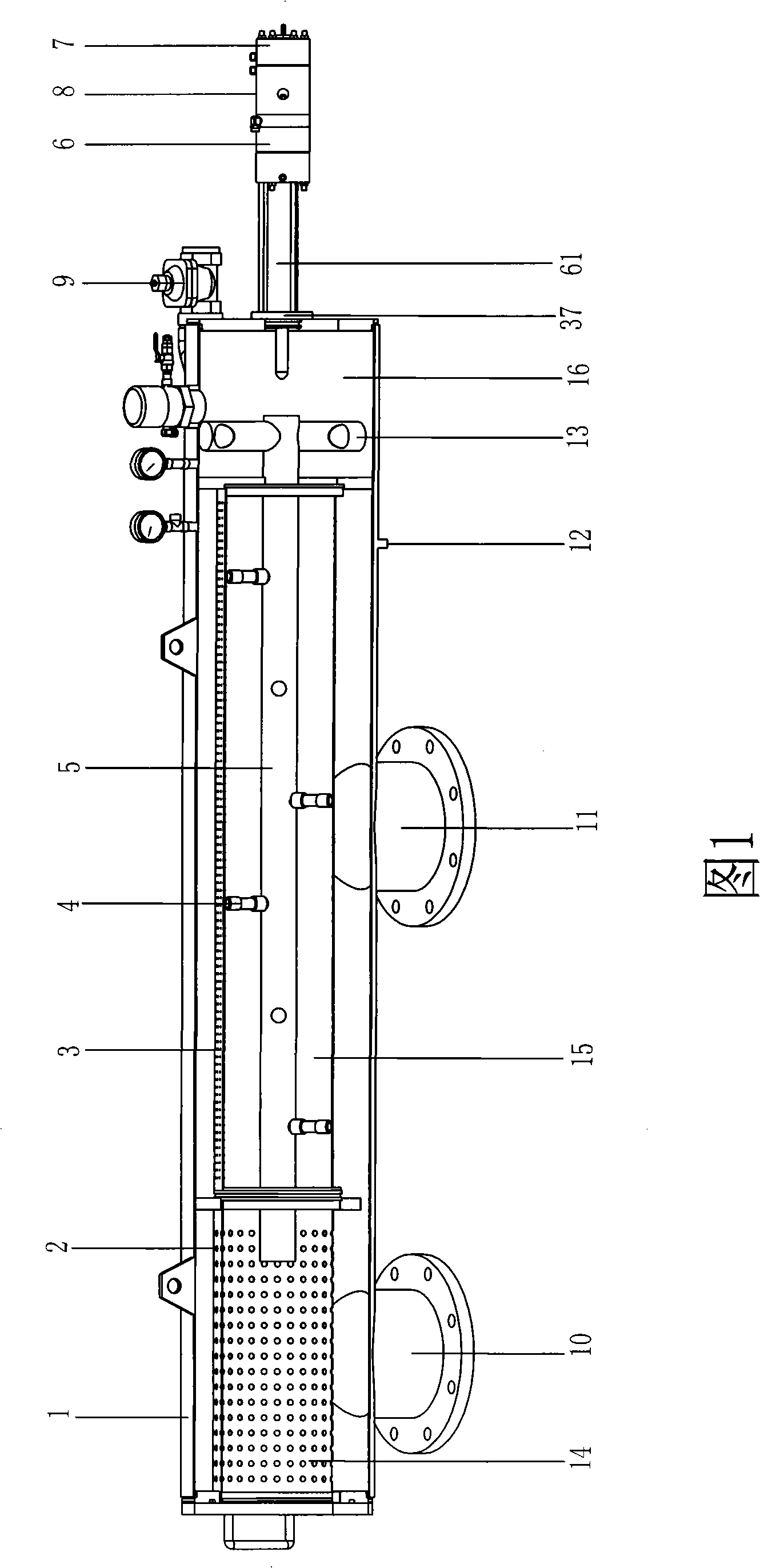

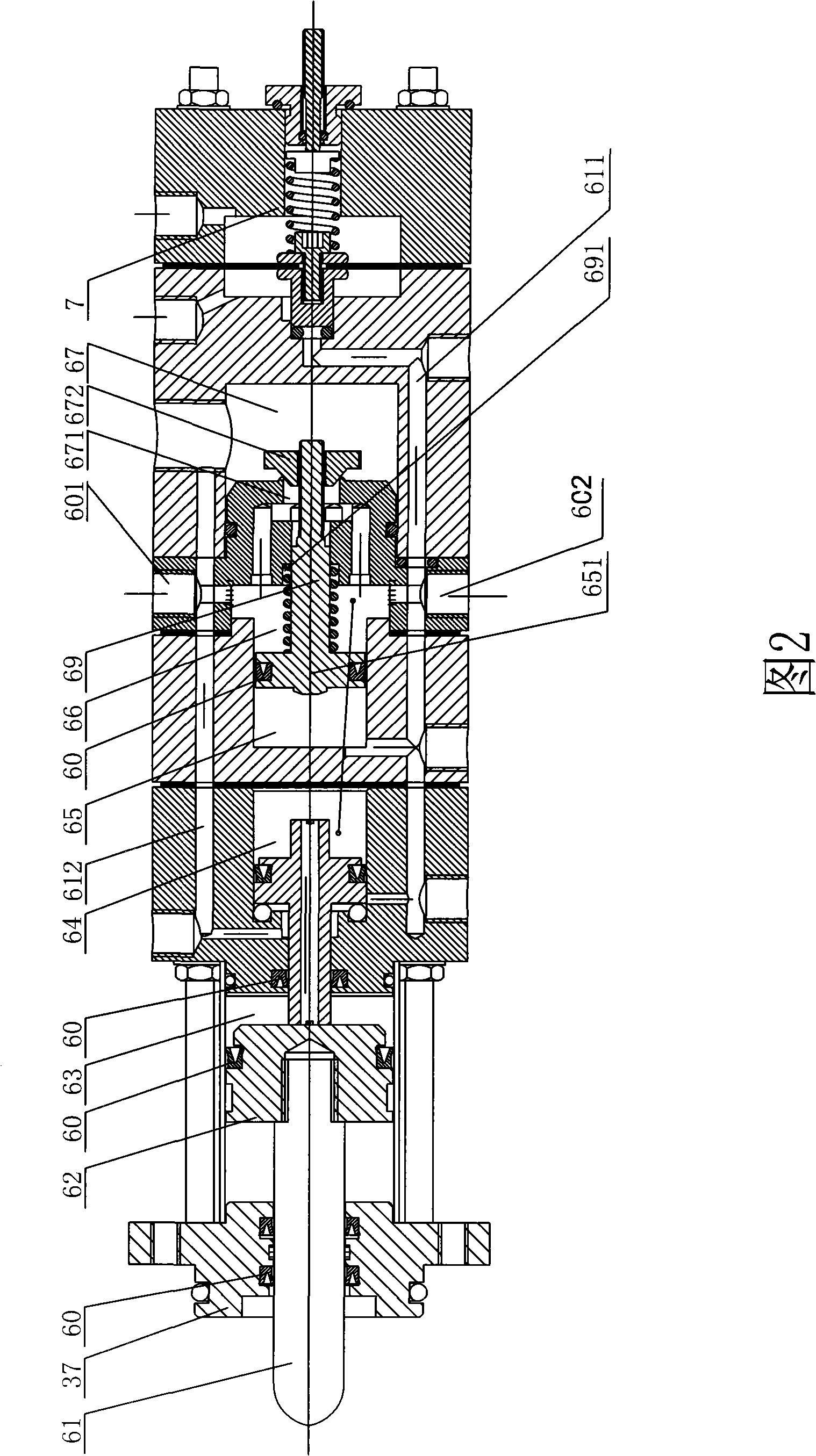

[0011] Referring to accompanying drawing 2, in this embodiment of the cleaning driver of the self-cleaning filter according to the present invention, it includes a piston rod 61 and a piston 62 that are axially linked with the dirt suction assembly and, in the piston cavity The back pressure chamber 64, the trigger chamber 65, the driving chamber 66, and the pressure relief chamber 67 are arranged in parallel on the outside of the chamber 63 from the inside to the outside, wherein the back pressure chamber 64 communicates with the piston chamber 63 and the driving chamber 66 respectively. , there are also two outlets on the driving chamber 66, one of which can communicate with raw water or clean water, the driving chamber water inlet 601, and the other can communicate with the control chamber of the blowdown valve 602, the trigger chamber 65 and the driving chamber The chamber 66 is liquid-tightly closed, and the drive chamber 66 and the pressure relief chamber 67 are controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com