Steam explosion straw material collection and energy utilization technology

A technology of steam-exploding straw and materials, which is applied in the field of steam-explosion pretreatment of fiber ethanol production process, can solve problems such as unproposed process methods, and achieve the effect of simple operation, good effect and reasonable process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

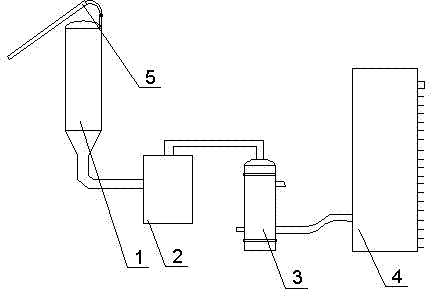

[0035] Such as figure 1 Shown, the present invention adopts following technical scheme to realize above-mentioned purpose, and its concrete steps are as follows:

[0036] (1) The straw crushed to 40-80 mm is sent into the blasting container 1 by the loader;

[0037] (2) High-pressure steam with a pressure of 1.2-4.0 MPa is introduced into the blasting container 1;

[0038] (3) Keep the pressure on the blasting vessel 1 for 10-120 minutes;

[0039] (4) Open the blasting container 1 to eject the material to realize the separation of material and steam;

[0040] (5) Enter the steam obtained in step (4) into the decompression chamber 2, and the steam containing organic molecules is discharged from the top of the decompression chamber 2 and enters the condenser 3;

[0041] (6) The steam obtained in step (5) passes through the condenser 3 and becomes liquid, and the liquid is sent to the sewage treatment process, and the tail gas generated enters the absorption tower 4;

[...

specific Embodiment 3

[0046] Such as figure 1 Shown, the present invention adopts following technical scheme to realize above-mentioned purpose, and its concrete steps are as follows:

[0047] (1) The straw that has been crushed to 20-100 mm is sent into the blasting container 1 by the loader;

[0048] (2) High-pressure steam with a pressure of 2.2-3.0 MPa is introduced into the blasting container 1;

[0049] (3) Keep the pressure on the blasting vessel 1 for 60-70 minutes;

[0050] (4) Open the blasting container 1 to eject the material to realize the separation of material and steam;

[0051] (5) Enter the steam obtained in step (4) into the decompression chamber 2, and the steam containing organic molecules is discharged from the top of the decompression chamber 2 and enters the condenser 3;

[0052] (6) The steam obtained in step (5) passes through the condenser 3 and becomes liquid, and the liquid is sent to the sewage treatment process, and the tail gas generated enters the absorption...

specific Embodiment 4

[0057] Such as figure 1Shown, the present invention adopts following technical scheme to realize above-mentioned purpose, and its concrete steps are as follows:

[0058] (1) The straw that has been crushed to 40-80 mm is sent to the blasting container 1 through the belt conveyor 5;

[0059] (2) High-pressure steam with a pressure of 1.2-4.0 MPa is introduced into the blasting container 1;

[0060] (3) Keep the pressure on the blasting vessel 1 for 40-90 minutes;

[0061] (4) Open the blasting container 1 to eject the material to realize the separation of material and steam;

[0062] (5) Enter the steam obtained in step (4) into the decompression chamber 2, and the steam containing organic molecules is discharged from the top of the decompression chamber 2 and enters the condenser 3;

[0063] (6) The steam obtained in step (5) passes through the condenser 3 and becomes liquid, and the liquid is sent to the sewage treatment process, and the tail gas generated enters the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com