Weight clump manufacturing method

A counterweight and casing technology, which is applied in the field of counterweight manufacturing, can solve the problems of increased manufacturing cost, power consumption, and unsatisfactory effects, and achieve the effects of saving energy consumption, improving work efficiency, and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

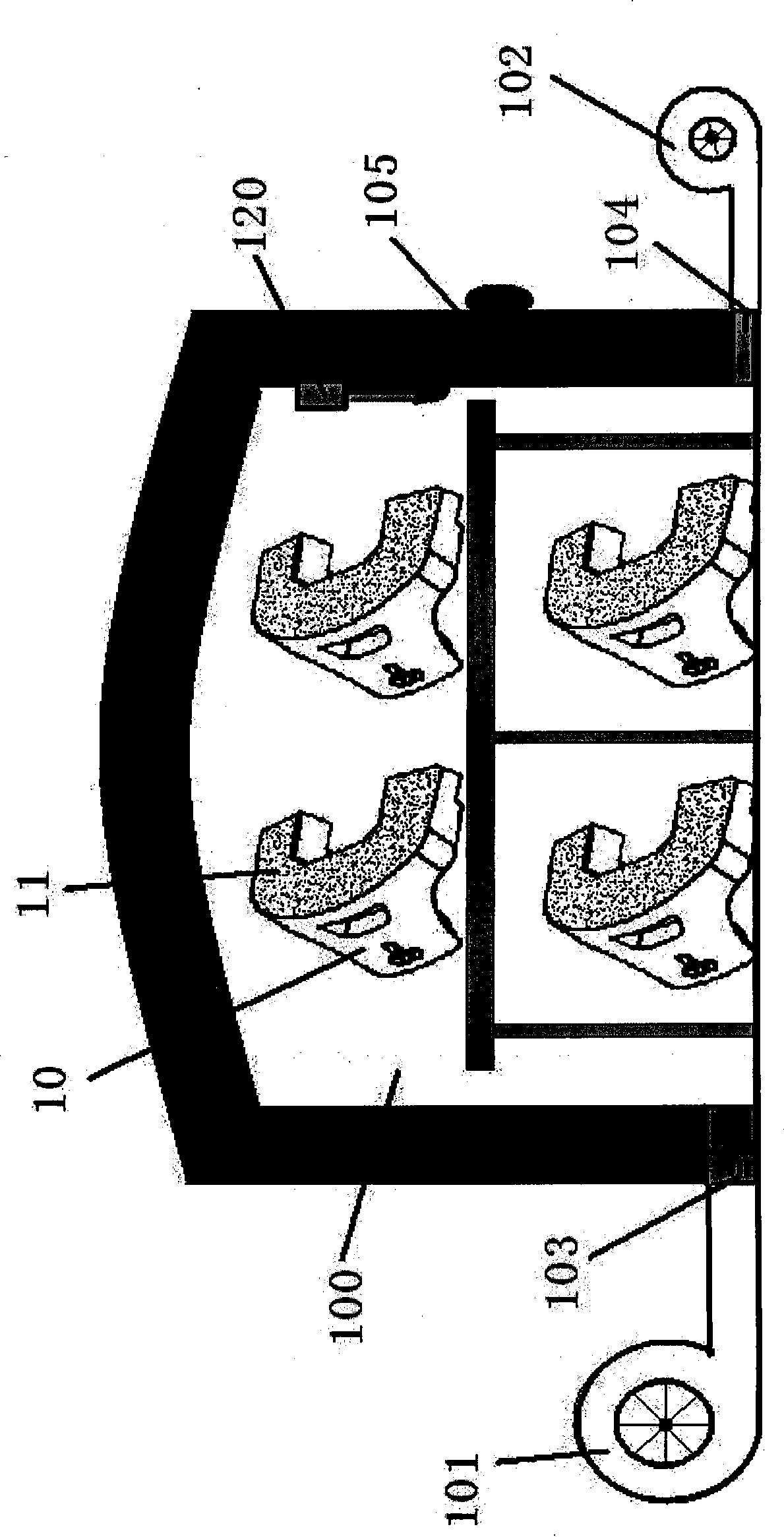

[0056] The present invention discloses two methods for manufacturing counterweights. The difference between the two methods and the prior art is that they both include negative pressure and blown dry air in the manufacturing process to balance the counterweights. The steps in which drying is carried out; however, the exact manner in which drying is carried out varies.

[0057] refer to figure 1 , figure 2 , image 3 and Figure 4 , shows the manufacturing process of the first method for manufacturing the counterweight disclosed in the present invention.

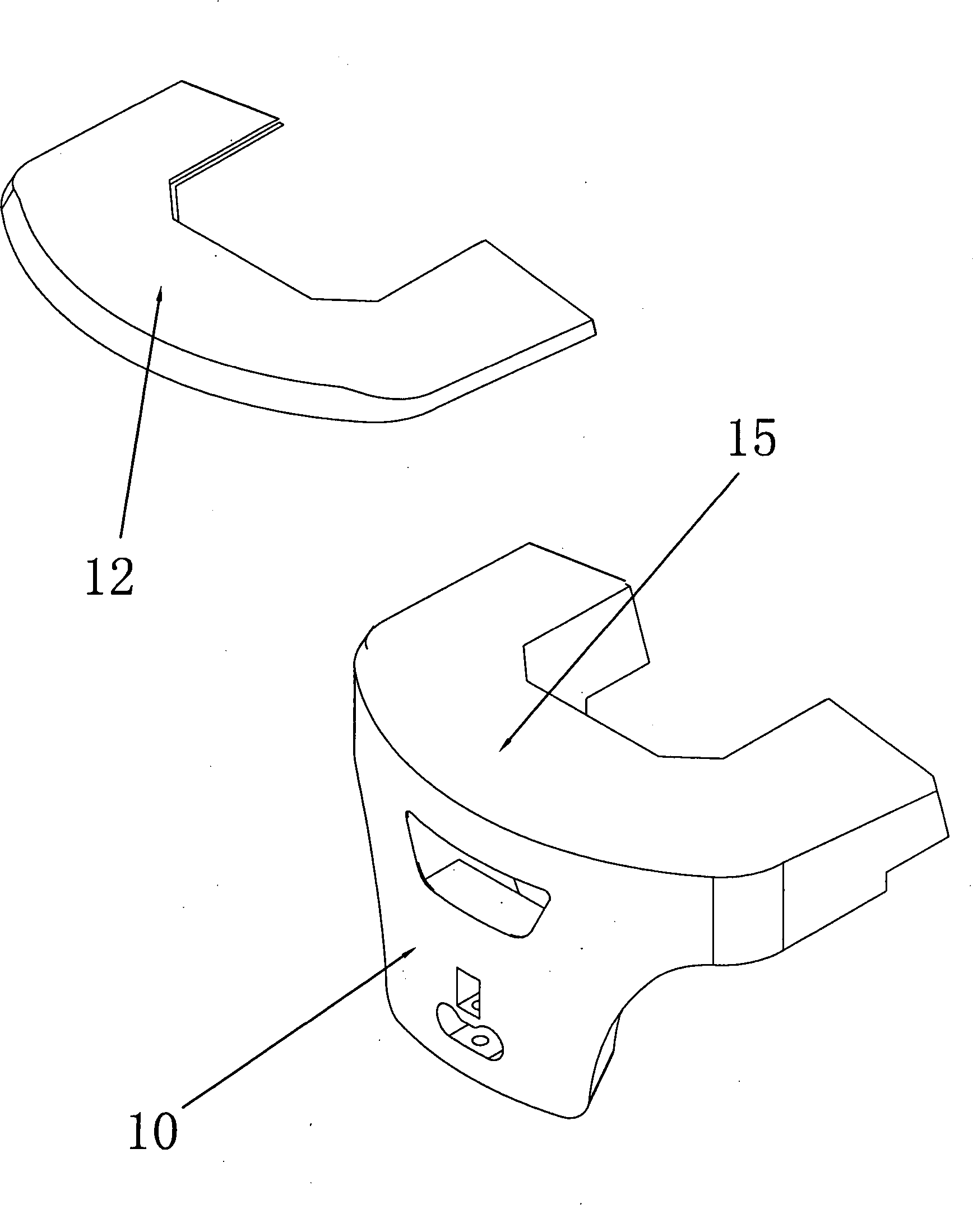

[0058] first reference figure 1 , according to the pre-designed shape, weld the shell 10 of the counterweight with a plurality of metal plates; 10 has a filler port 15 for filling the core material; in addition, the top cover 12 matching the profile of the filler port 15 is processed for subsequent use.

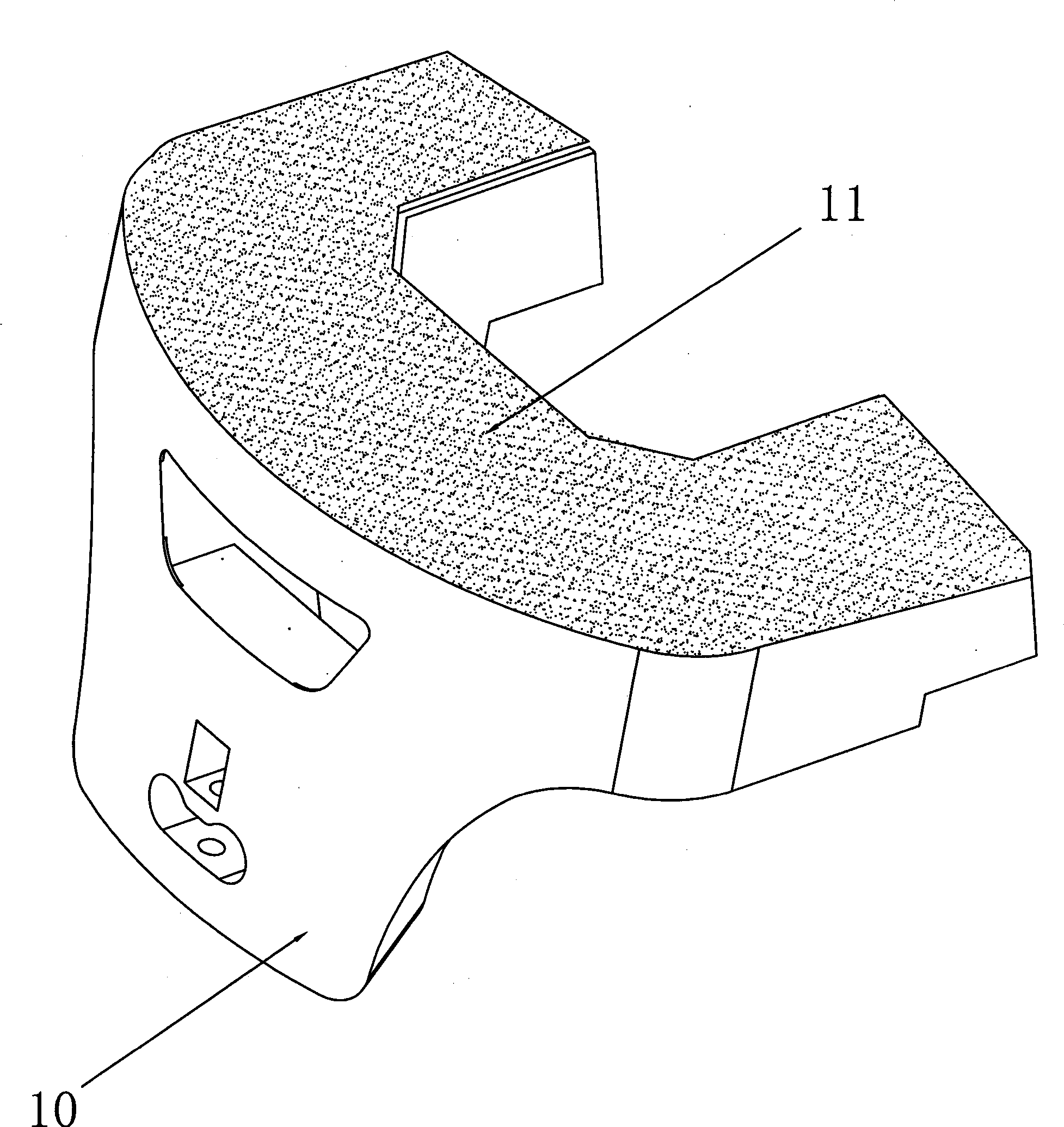

[0059] Refer again figure 2 Fill the core material 11 into the counterweight shell 10; the core material 11 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com