Electronic ceramic continuous sputtering coating equipment

A technology for sputtering coating and electronic ceramics, which is applied in the field of electronic ceramics continuous sputtering coating equipment, can solve the problems of poor bonding force, high production cost, low yield, etc., and achieves improved work efficiency, good consistency and tensile strength. The effect of strong strength and high temperature erosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

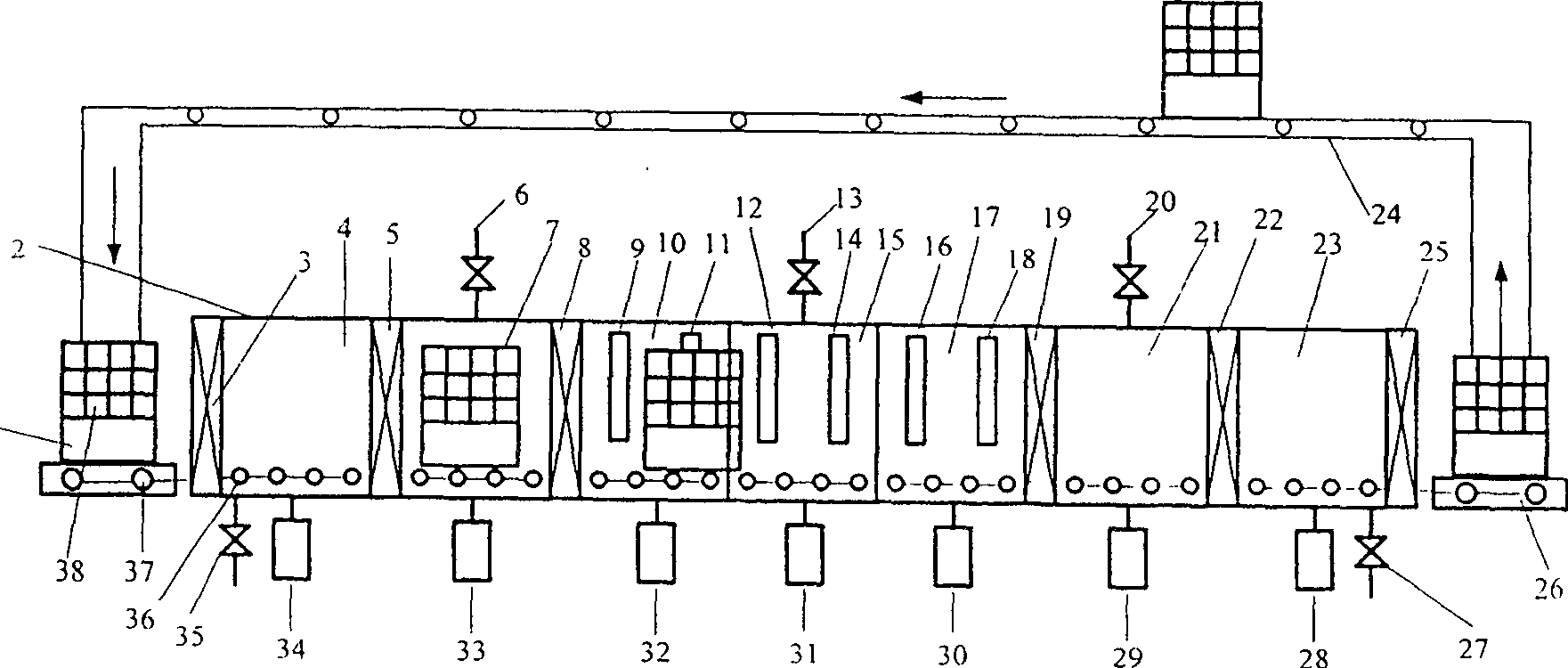

[0020]A vertical continuous sputtering coating equipment for ceramic substrates, each workpiece frame 1 can be loaded with a ceramic substrate of one square meter, and the technology of the present invention is used to sputter-plate nickel-copper-silver film on both sides thereof, It takes about 5 minutes to plate one frame, and the annual output can be plated to 120,000 square meters. Sampling inspection of the film layer shows that the error of its uniformity is within 3%, the average tensile strength is greater than 5KPa, and no corrosion is found when soldering in a lead-free tin bath at 260 °C. However, the average tensile strength of the same kind of ceramic coating film evaporated by single-furnace vacuum evaporation is below 2KPa, the uniformity error is greater than 10%, and the proportion of scrapping due to erosion when welding in a tin bath at 260°C is more than 8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com