Solution casting method and apparatus

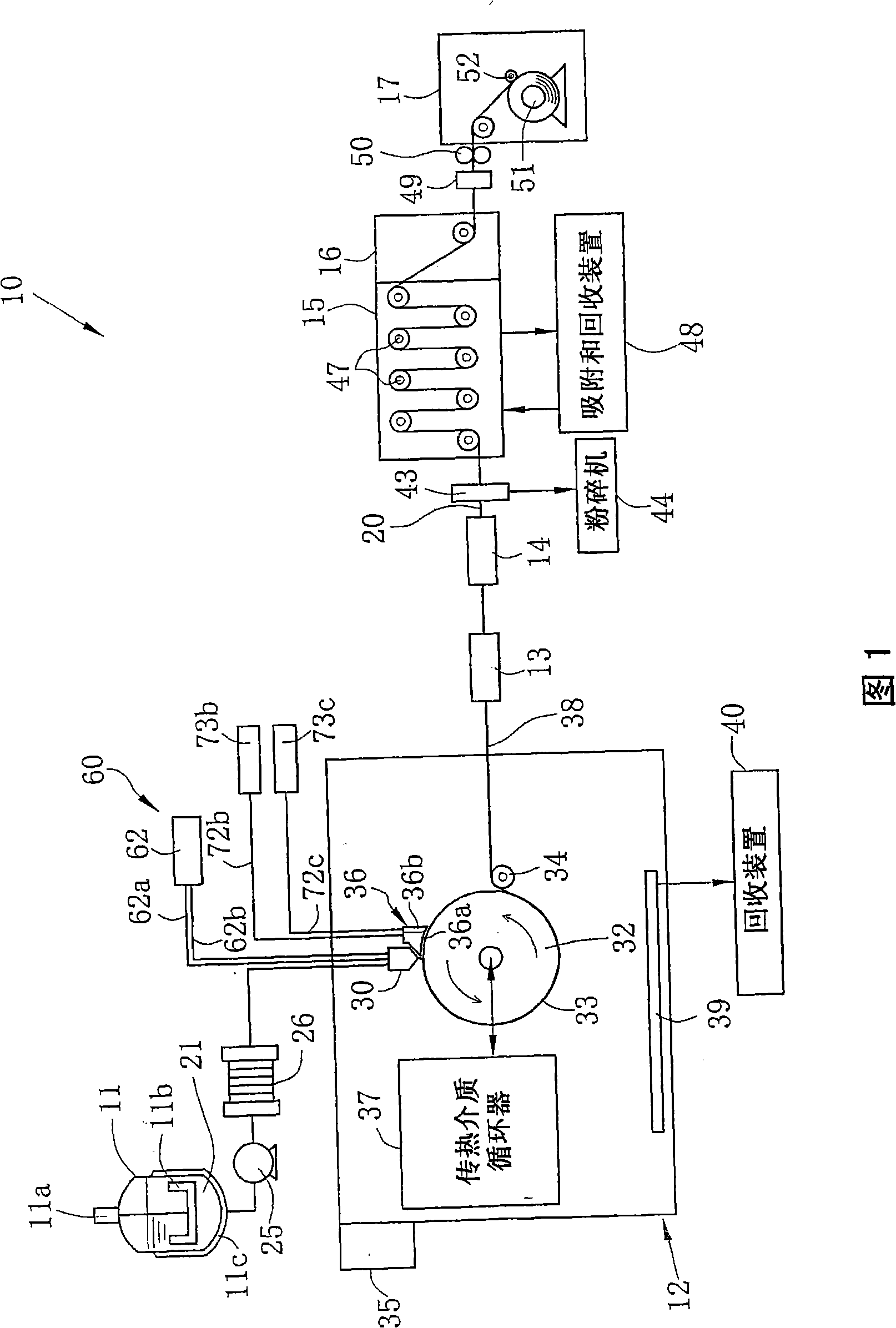

一种溶液、流延的技术,应用在应用、涂层、家里用具等方向,能够解决厚度不均匀性的质量允许程度变高等问题,达到降低厚度不均匀性、高质量、抑制振动的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

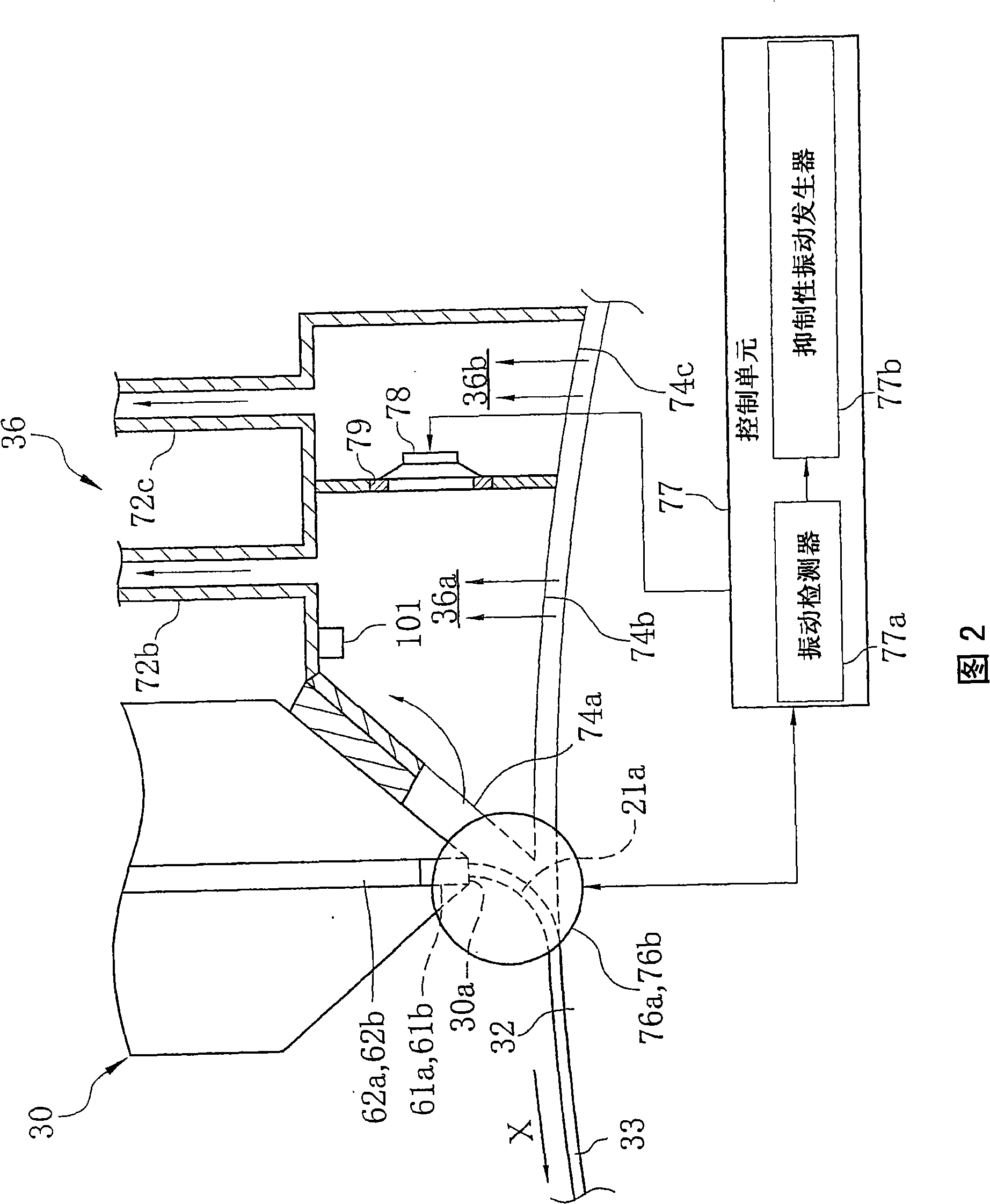

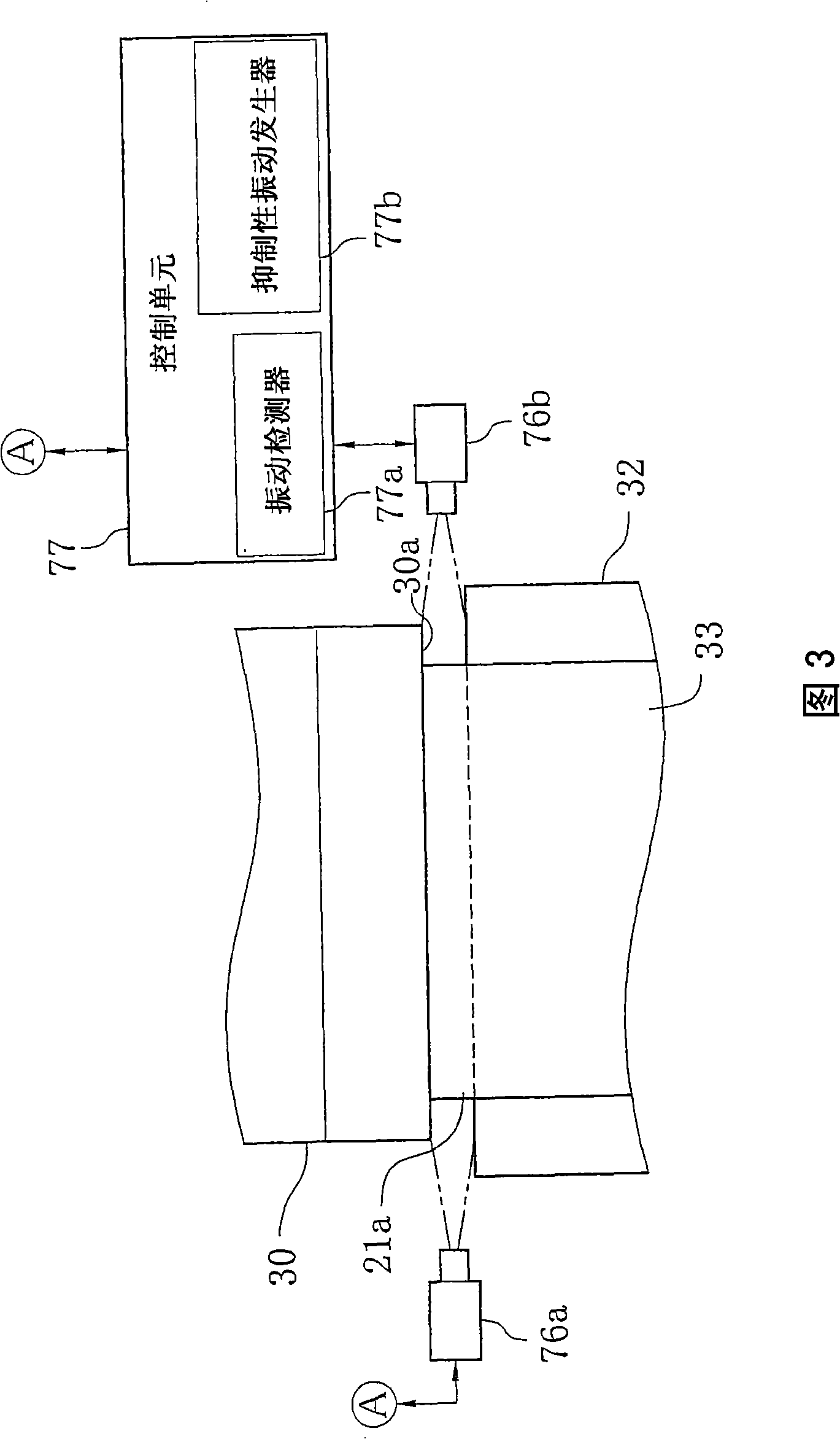

[0090] A decompression chamber 36 shown in FIG. 6 is installed in the film production line 10 . Based on the air pressure information from the air gauge 101 , suppressive vibration is applied to the casting bead 21 a. Films were formed under the following conditions. The distance "h" between the casting die 30 and the casting drum 32 is 3.5mm, the decompression degree "p" of the decompression chamber 36 is -40Pa, the viscosity of the coating is 45Pa·s for the "μ", and the die lip The gap "c1" was 0.9 mm, the casting speed "v" was 50 m / min, and the thickness "t" of the base was 80 μm. At this time, it was detected that the static pressure fluctuation range (amplitude) ΔP of the decompression chamber 36 was 2.4 Pa when the tape length (the length of the casting bead) thereof was 19 mm. A suppressive vibration having an amplitude ΔP of 1.5 Pa, the phase of which is opposite to that of the vibration of the casting bead was applied to and, as a result, was periodically generated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com