Damping type flow control forming process and die for aluminium-alloy rib-plate forging

A flow control, damping technology, applied in manufacturing tools, metal processing equipment, forging/pressing/hammering machinery, etc., can solve the problems of large friction resistance, large equipment tonnage, large deformation resistance of rib members, etc. Die forging force, long service life, and the effect of reducing pre-forging force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

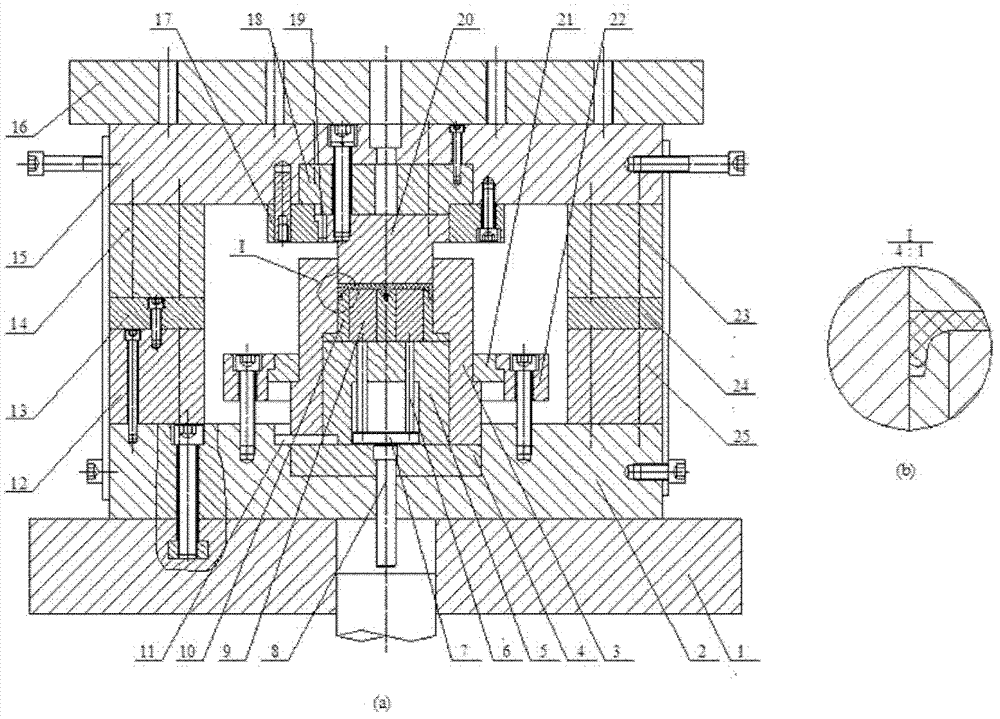

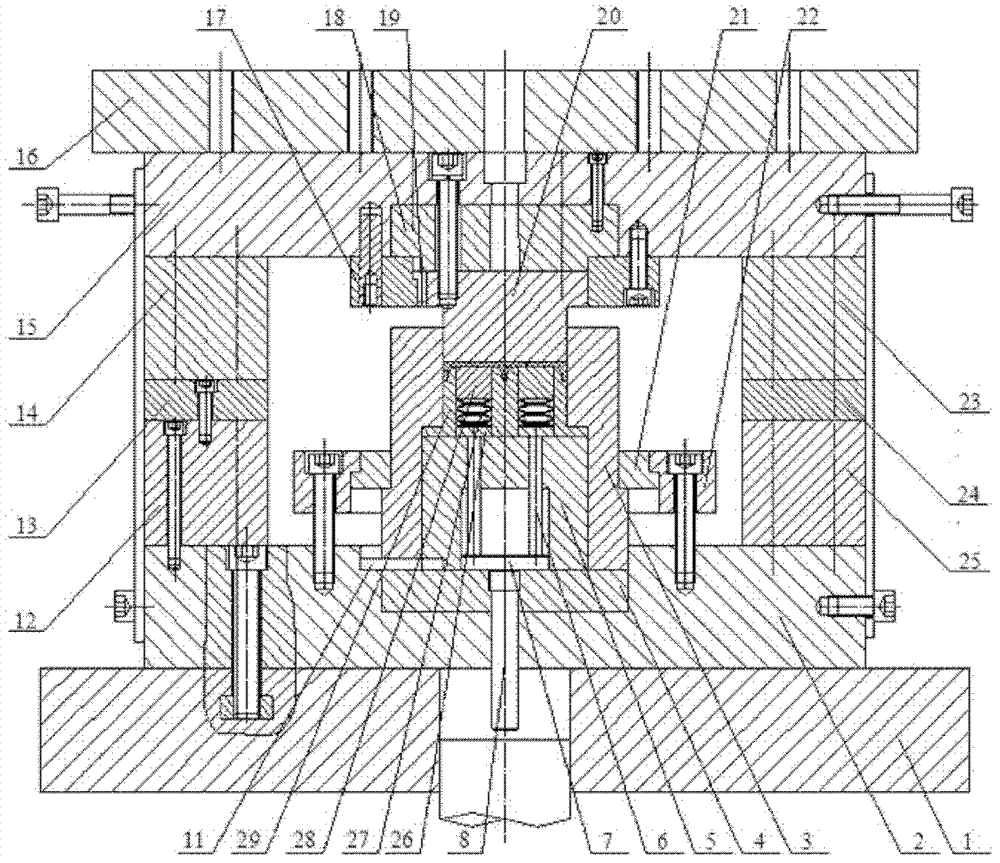

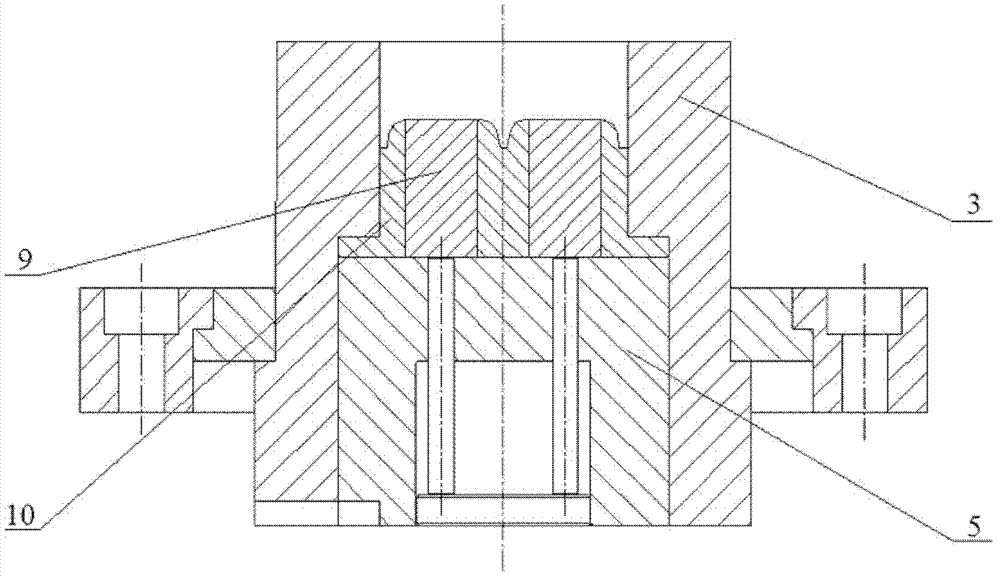

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0036] A damped flow control forming method for forgings of aluminum alloy ribs, comprising the steps of forming a pre-forging and forming a final forging,

[0037] 1. Pre-forging forming:

[0038] (1) Design the size of the pre-forging

[0039] The web thickness and the cross-sectional area along the length direction of the pre-forging are equal to the web thickness and the corresponding cross-sectional area along the length direction of the final forging, and the height of the ribs is moderately reduced, the width of the ribs is increased, and the ribs and the web are enlarged The transition fillet radius between. Generally, the rib height of the pre-forging is reduced by 20% to 30% compared with the height of the final forging, and the width of the rib and the radius of the transition fillet are calculated and determined according to the principle of equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com