Patents

Literature

66results about How to "Close safe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

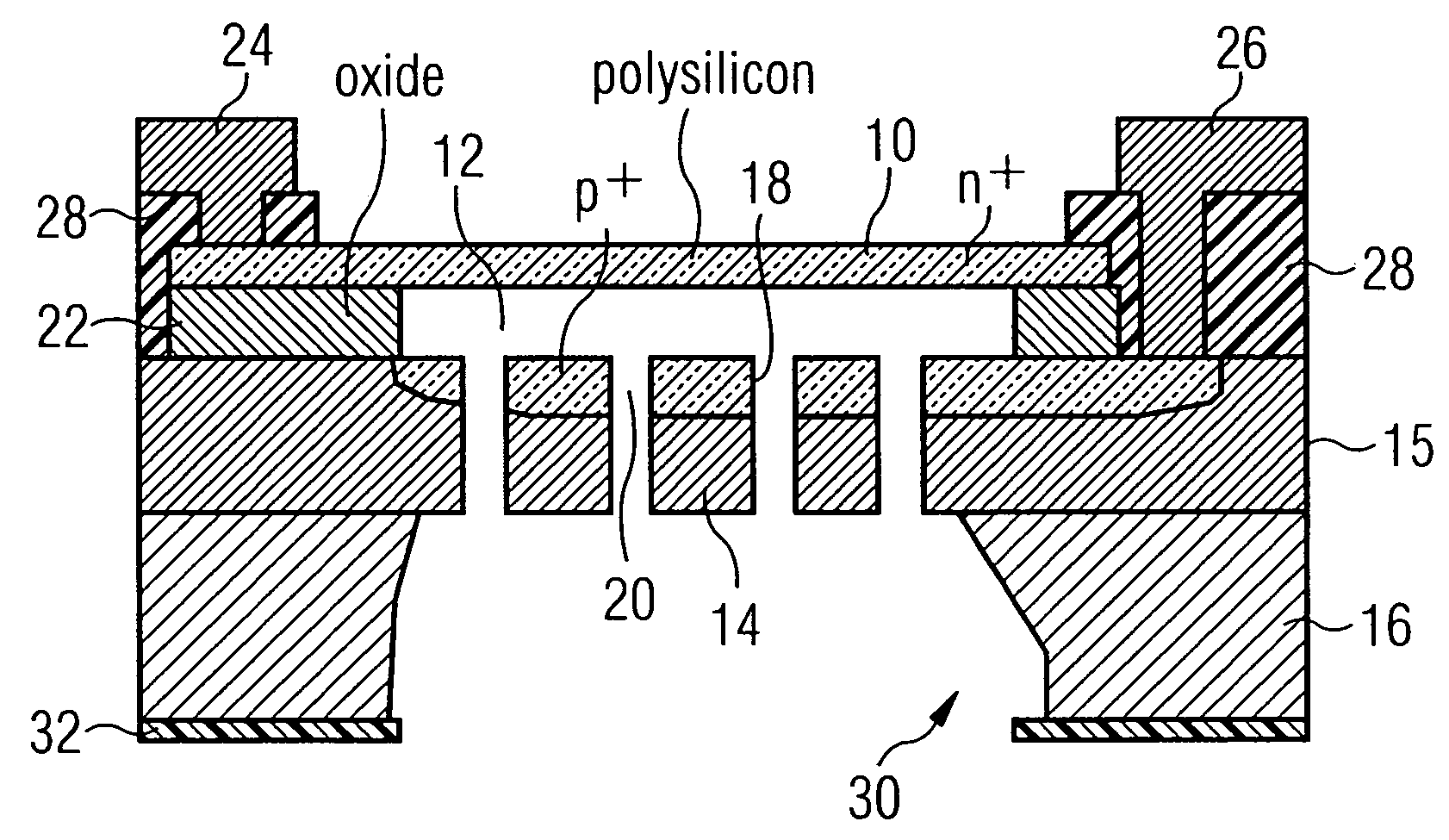

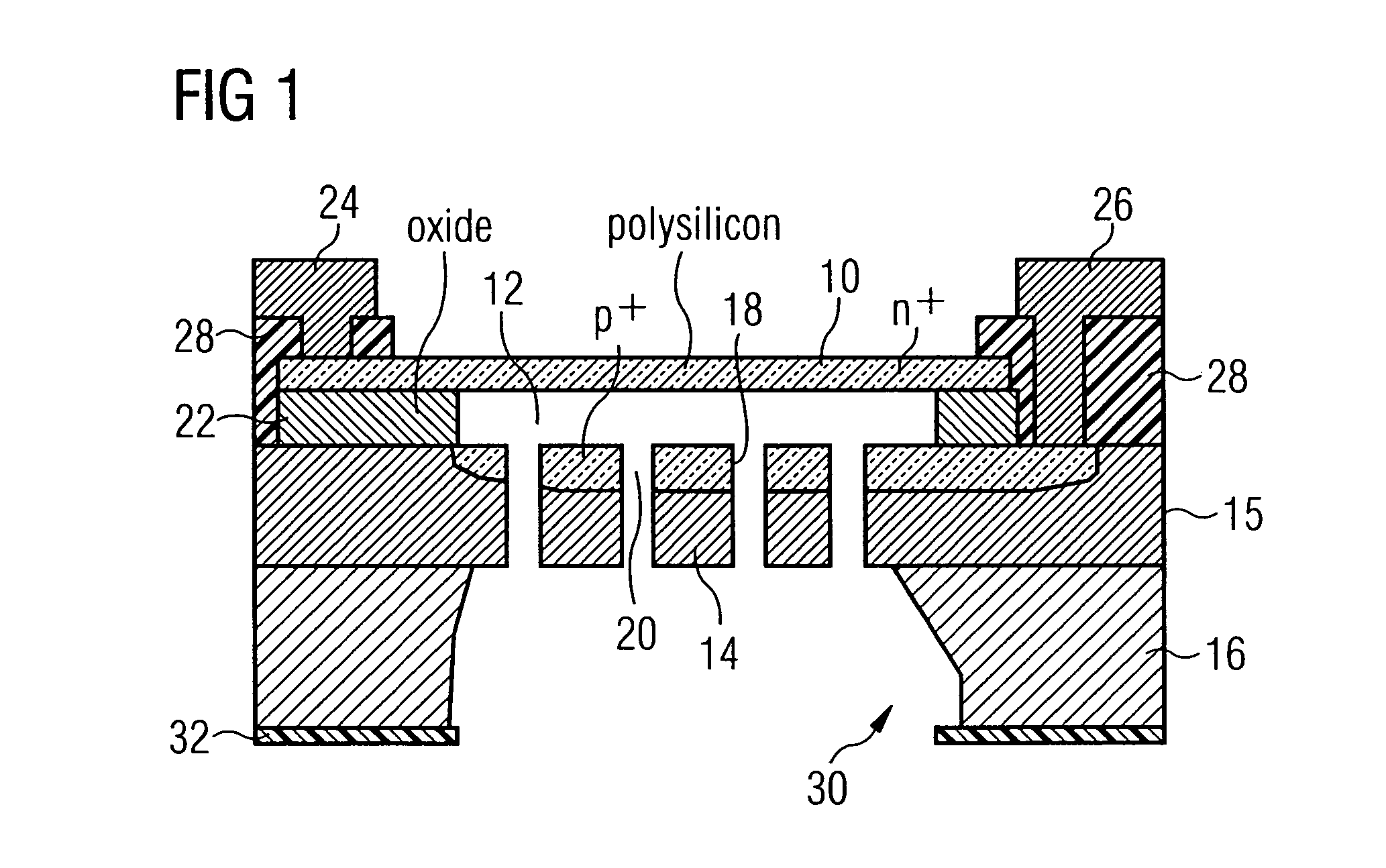

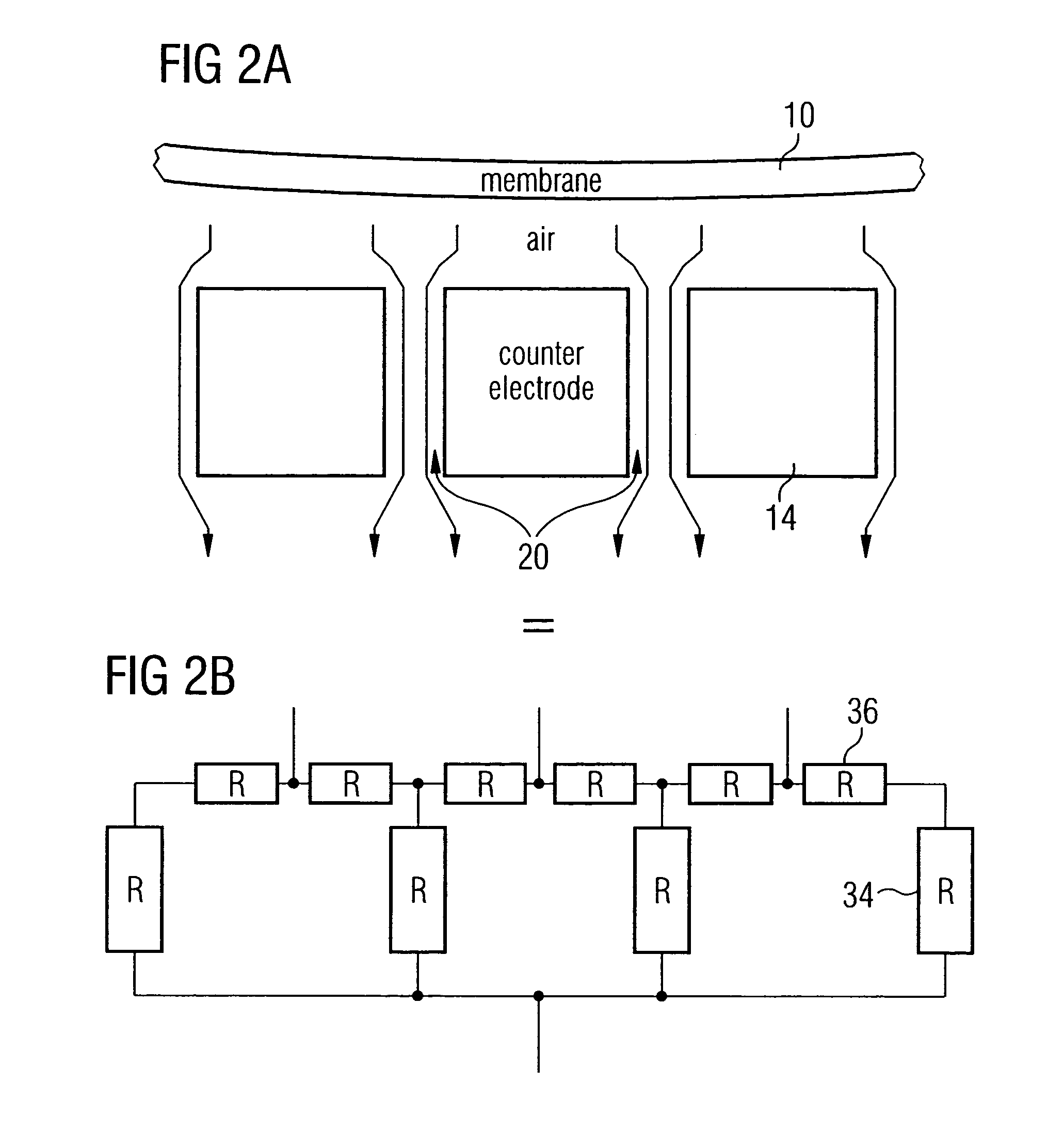

Micromechanical sensors and methods of manufacturing same

InactiveUS7190038B2Easy to closeProcess integrationSemiconductor electrostatic transducersFluid pressure measurement by electric/magnetic elementsEngineeringMaterial Perforation

A micromechanical sensor and, in particular, a silicon microphone, includes a movable membrane and a counter element in which perforation openings are formed, opposite to the movable membrane via a cavity. The perforation openings are formed by slots, the width of which maximally corresponds to double the spacing defined by the cavity between the membrane and the counter element.

Owner:INFINEON TECH AG

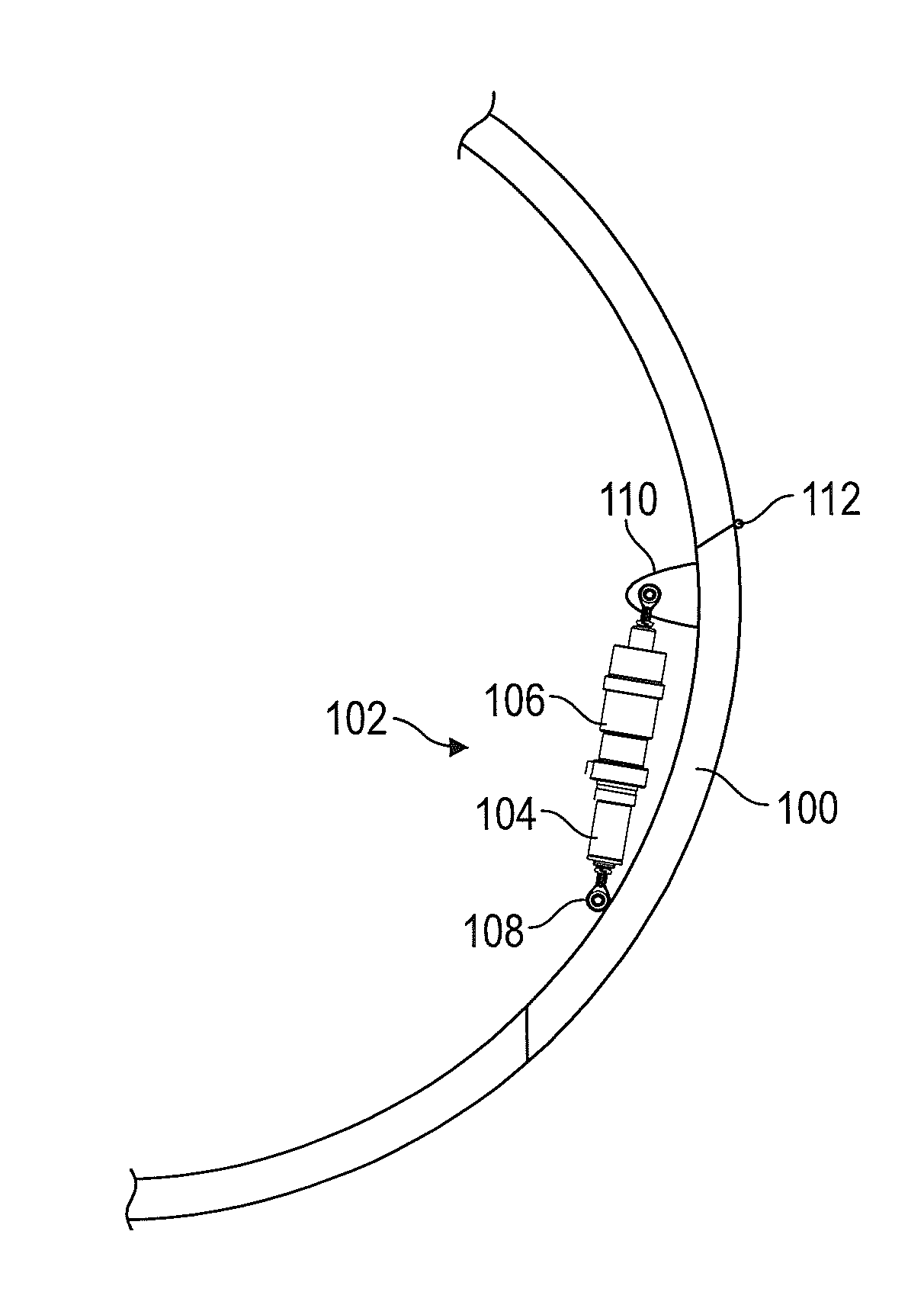

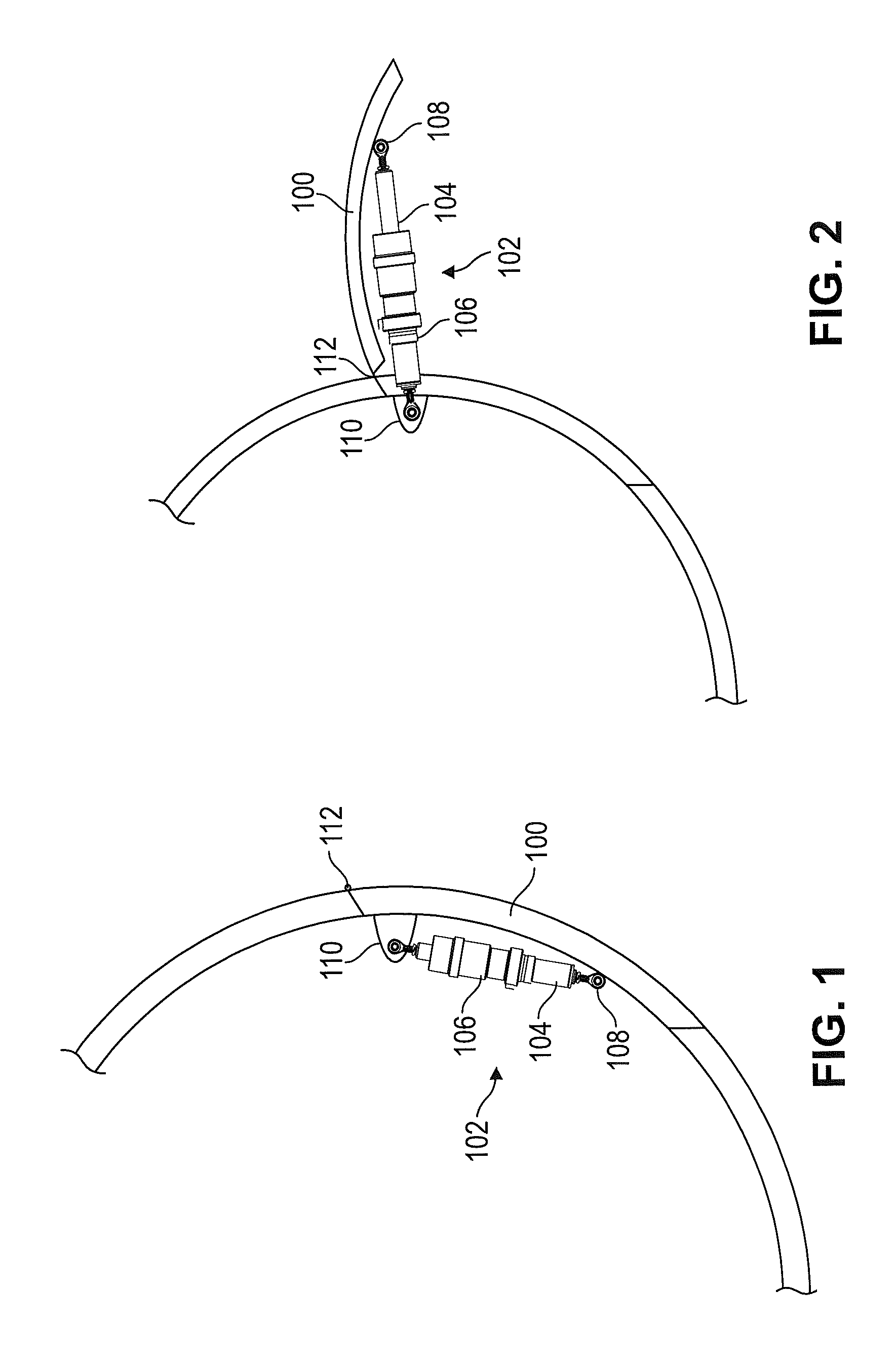

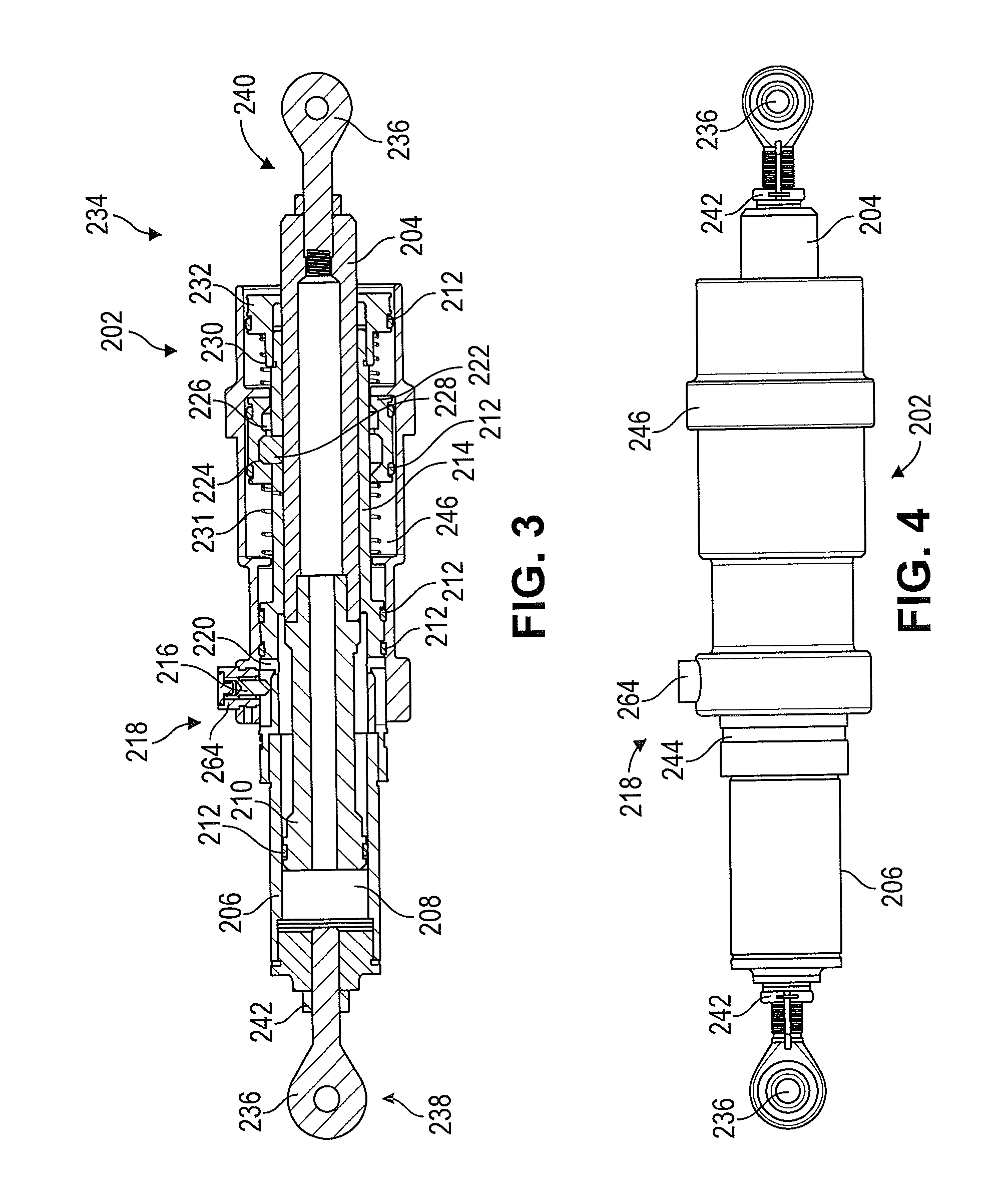

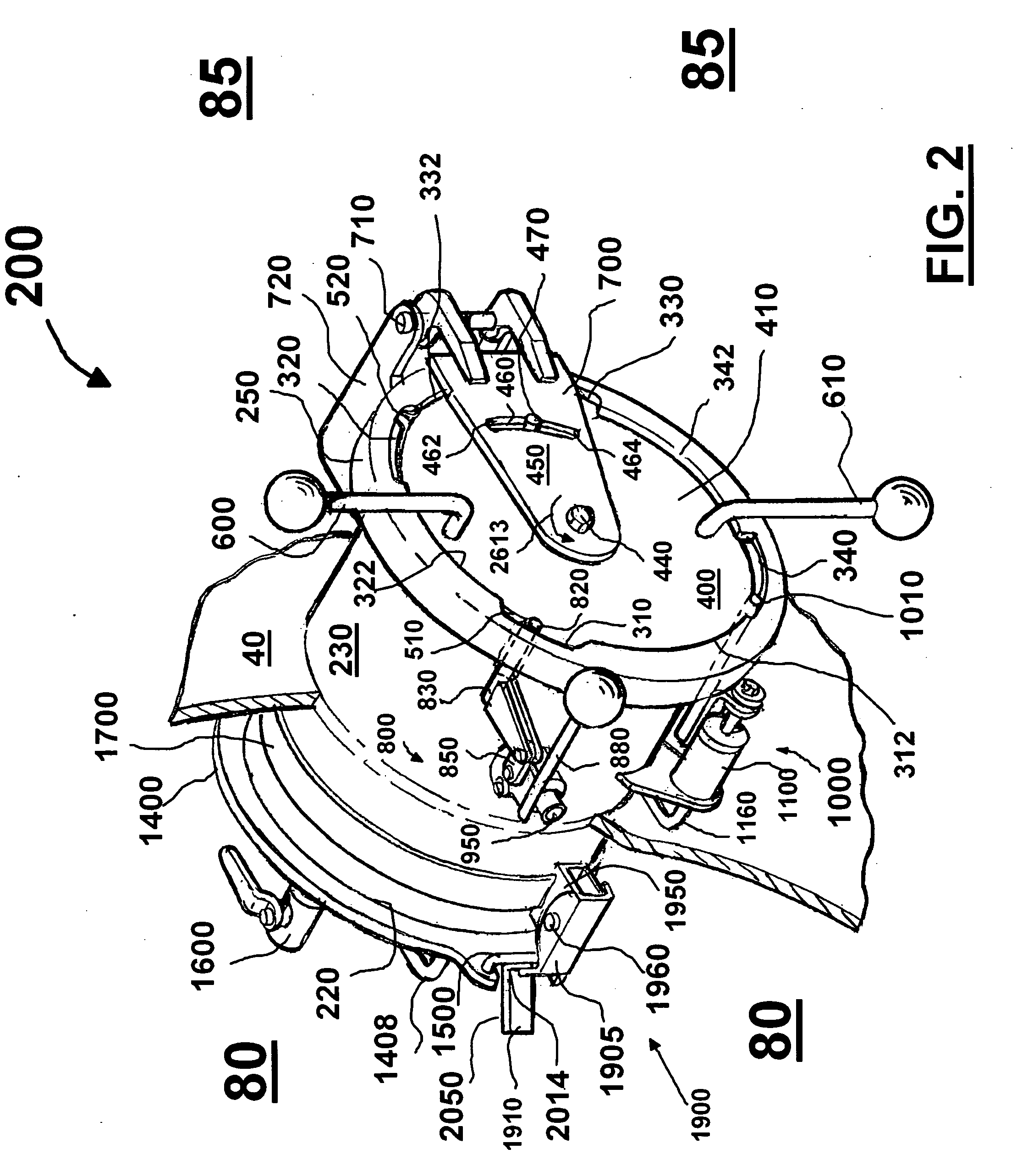

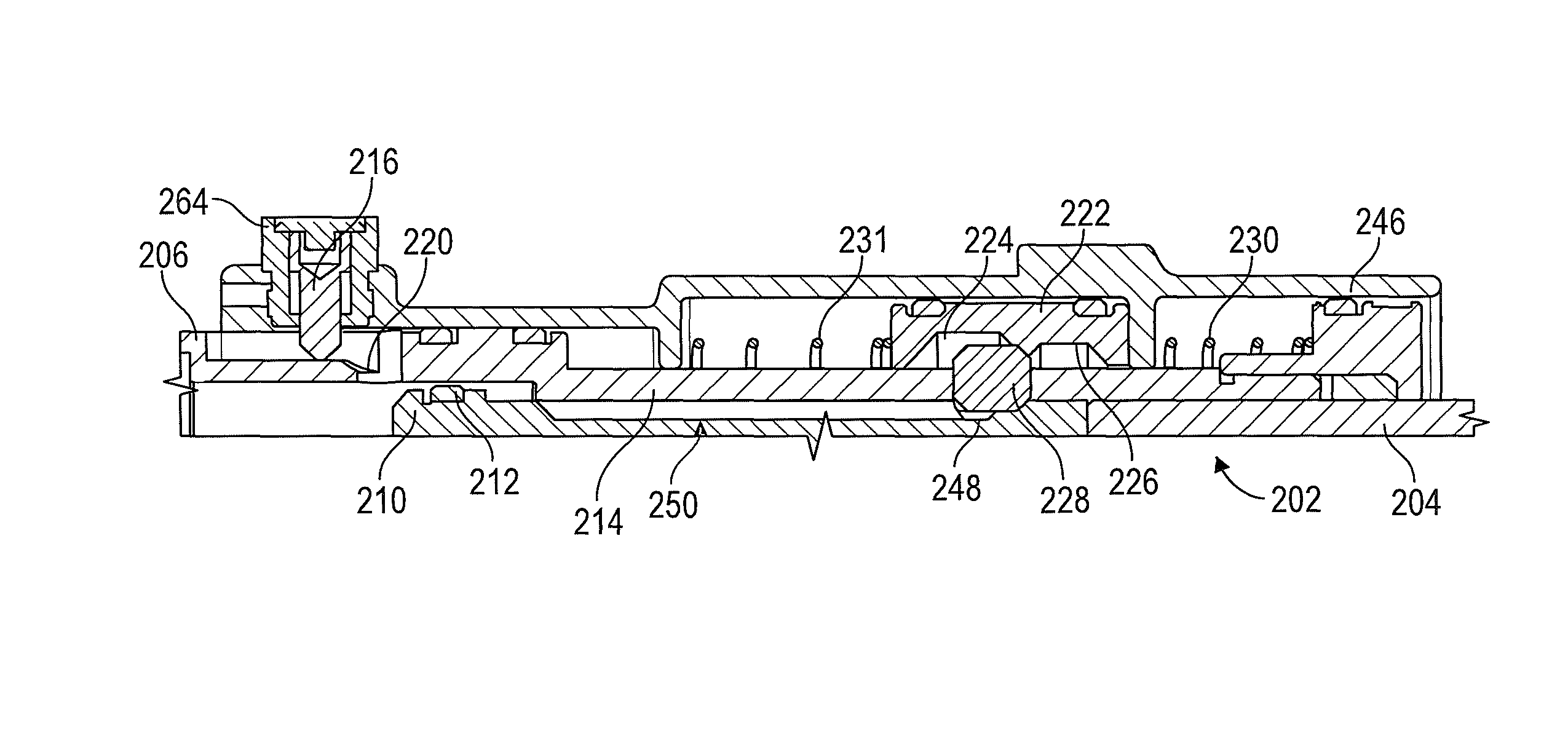

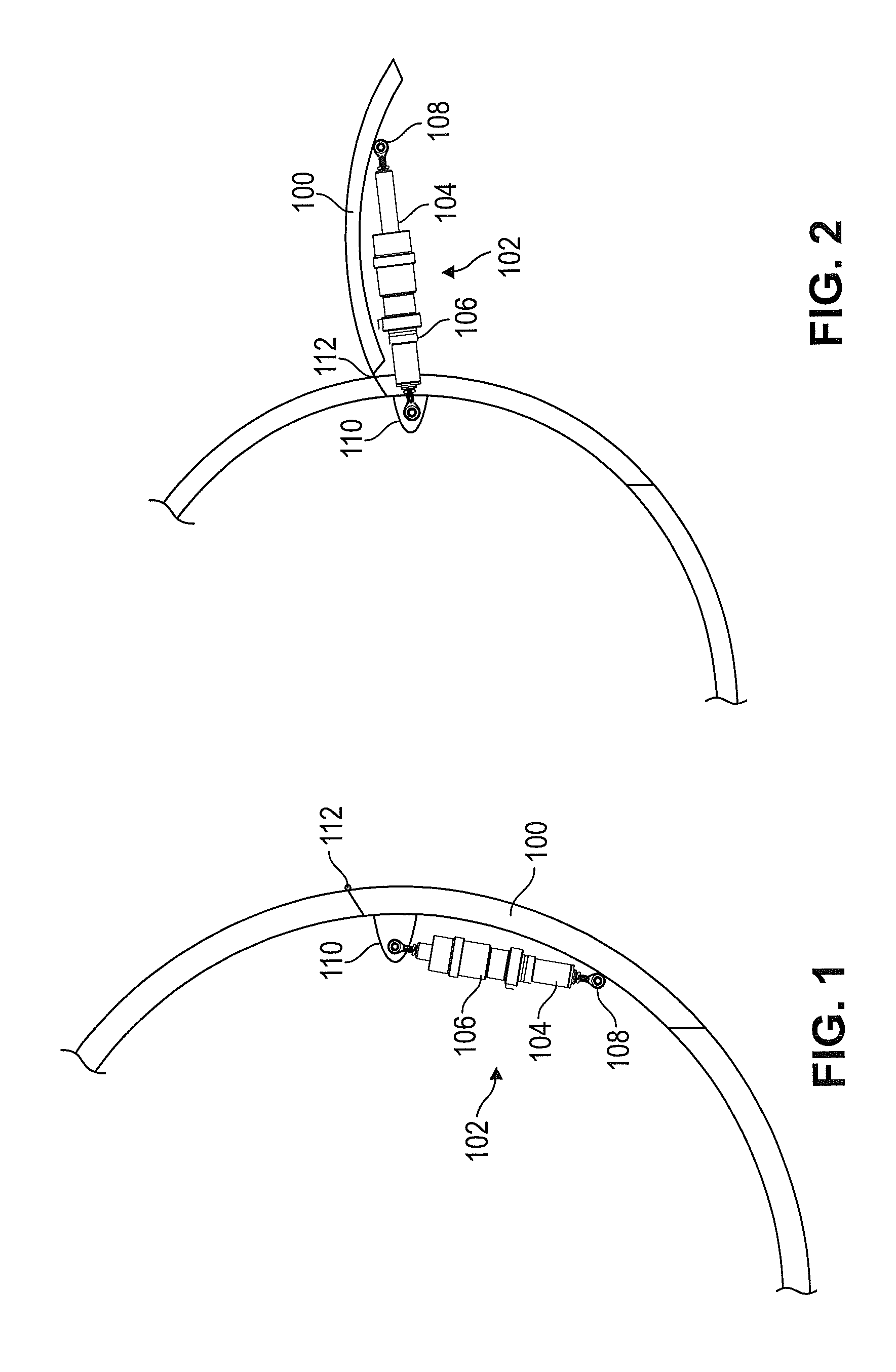

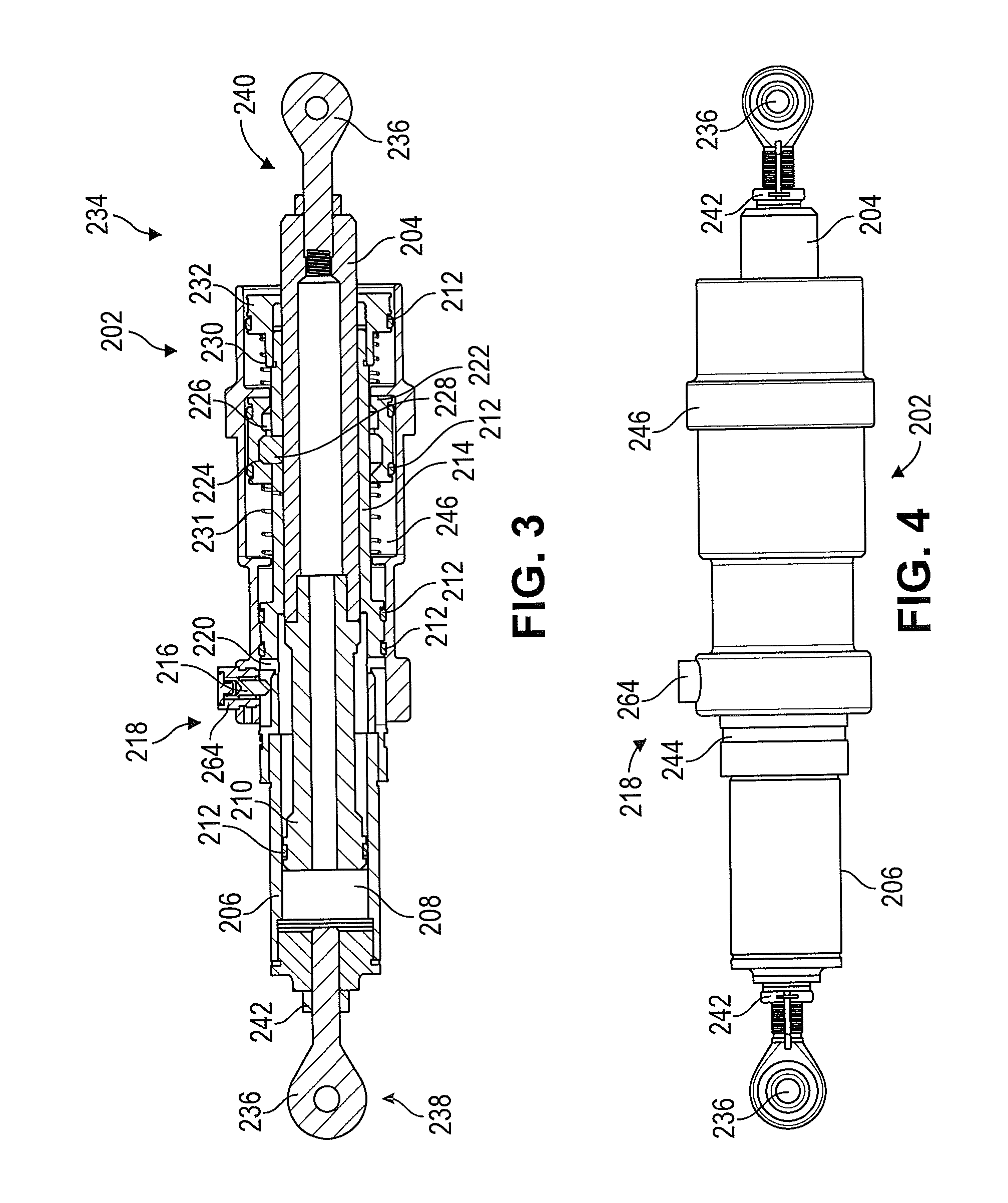

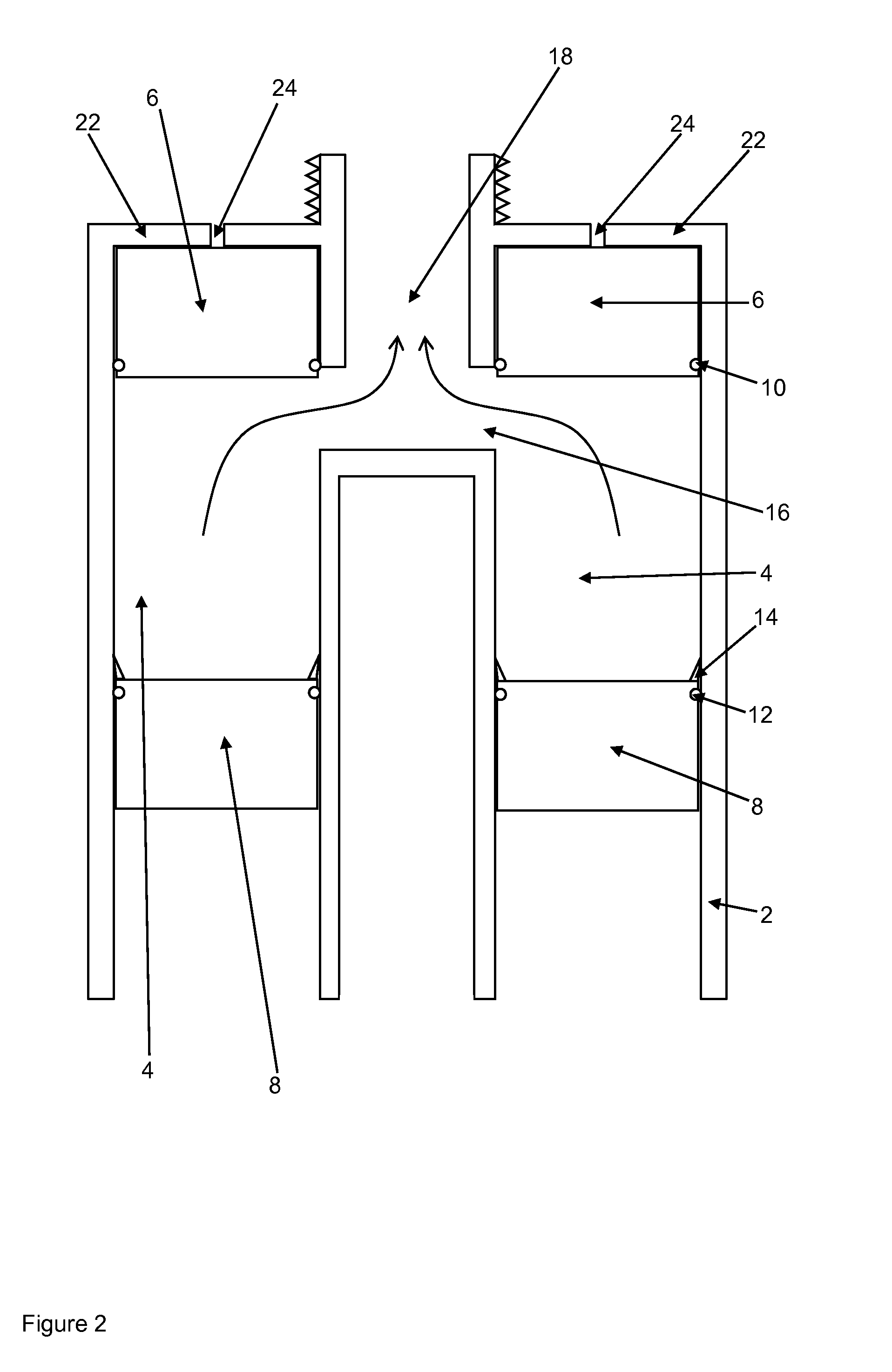

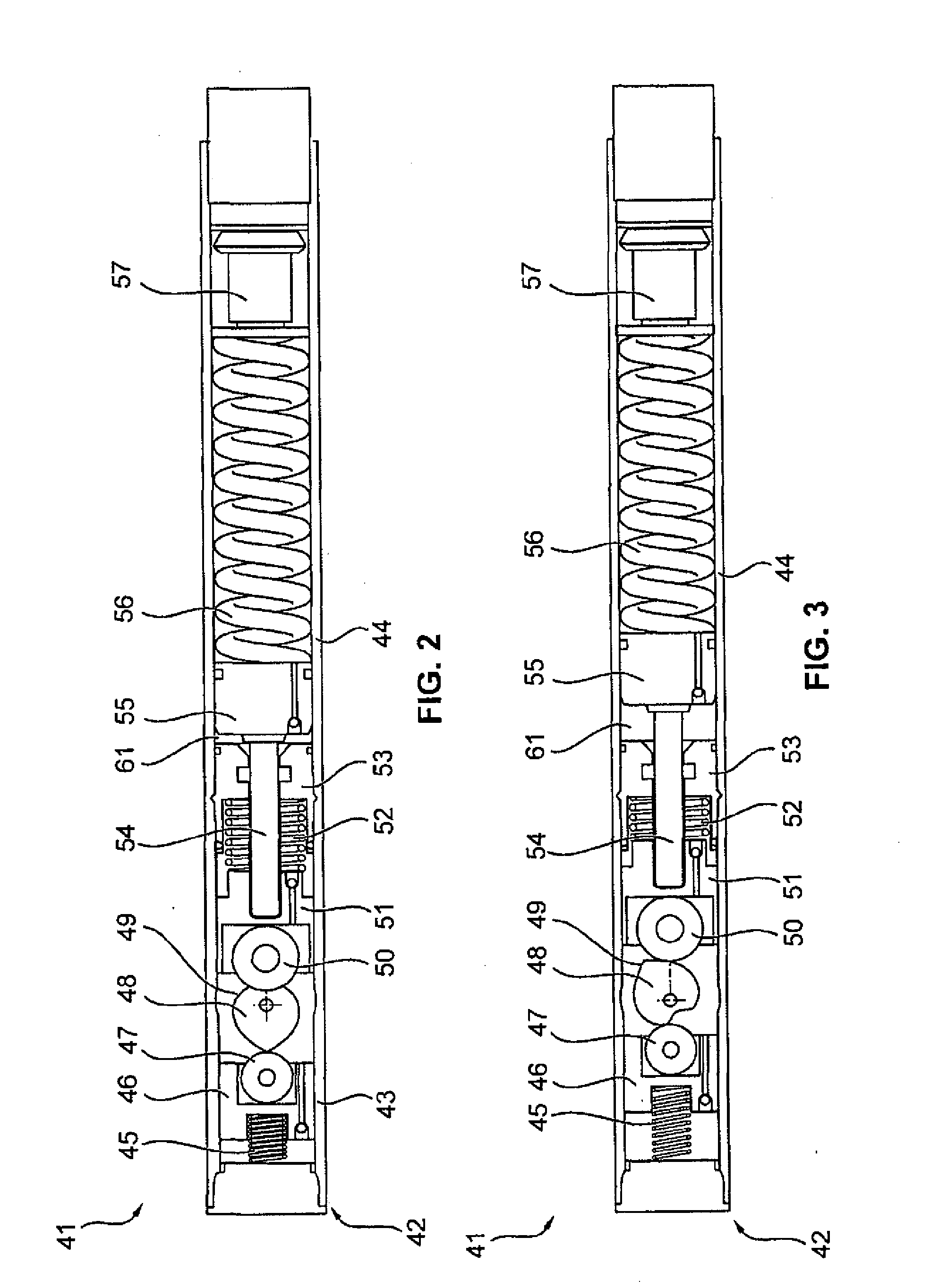

Pull Then Lift Hold Open Rod Lock Mechanism

ActiveUS20150267724A1Low costMaximizing numberSpringsAircraft accessoriesLocking mechanismEngineering

A hold open rod includes an inner tube assembly coupled to an outer tube assembly, the inner tube assembly movable within the outer tube assembly, a lock body coupled to the outer tube assembly, and an inner collar coupled to the lock body, the inner collar having a lock groove and unlock groove. The hold open rod further includes a locking dog configured to engage the unlock groove when the hold open rod is in an unlocked configuration and the locking dog further configured to engage the lock groove when the hold open rod is in a locked configuration, an unlocked indicator on a first region of the lock body, the unlocked indicator exposed when the hold open rod is in the unlocked configuration, and a first rod end coupled to the outer tube assembly and a second rod end coupled to the inner rod assembly.

Owner:MARATHONNORCO AEROSPACE

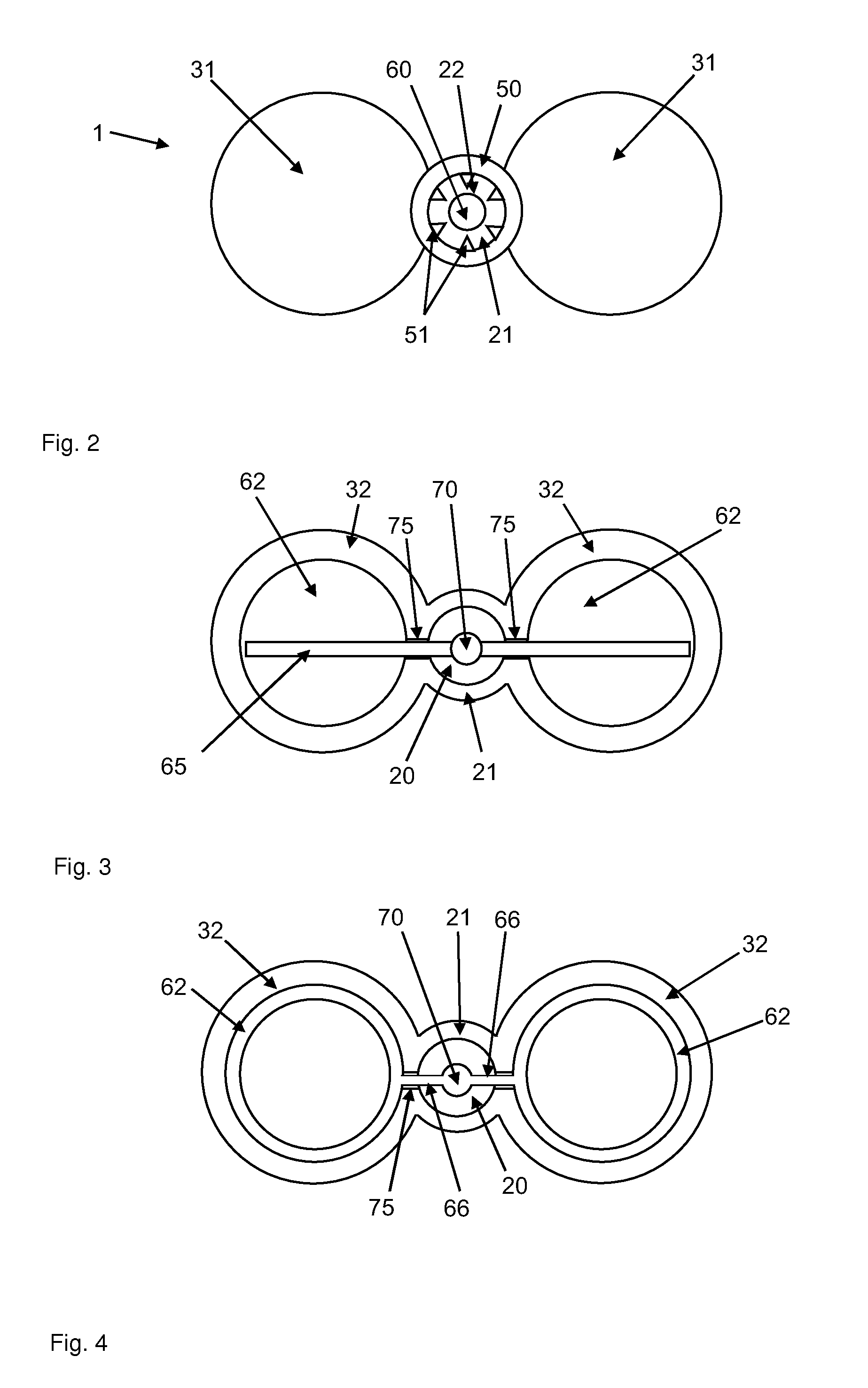

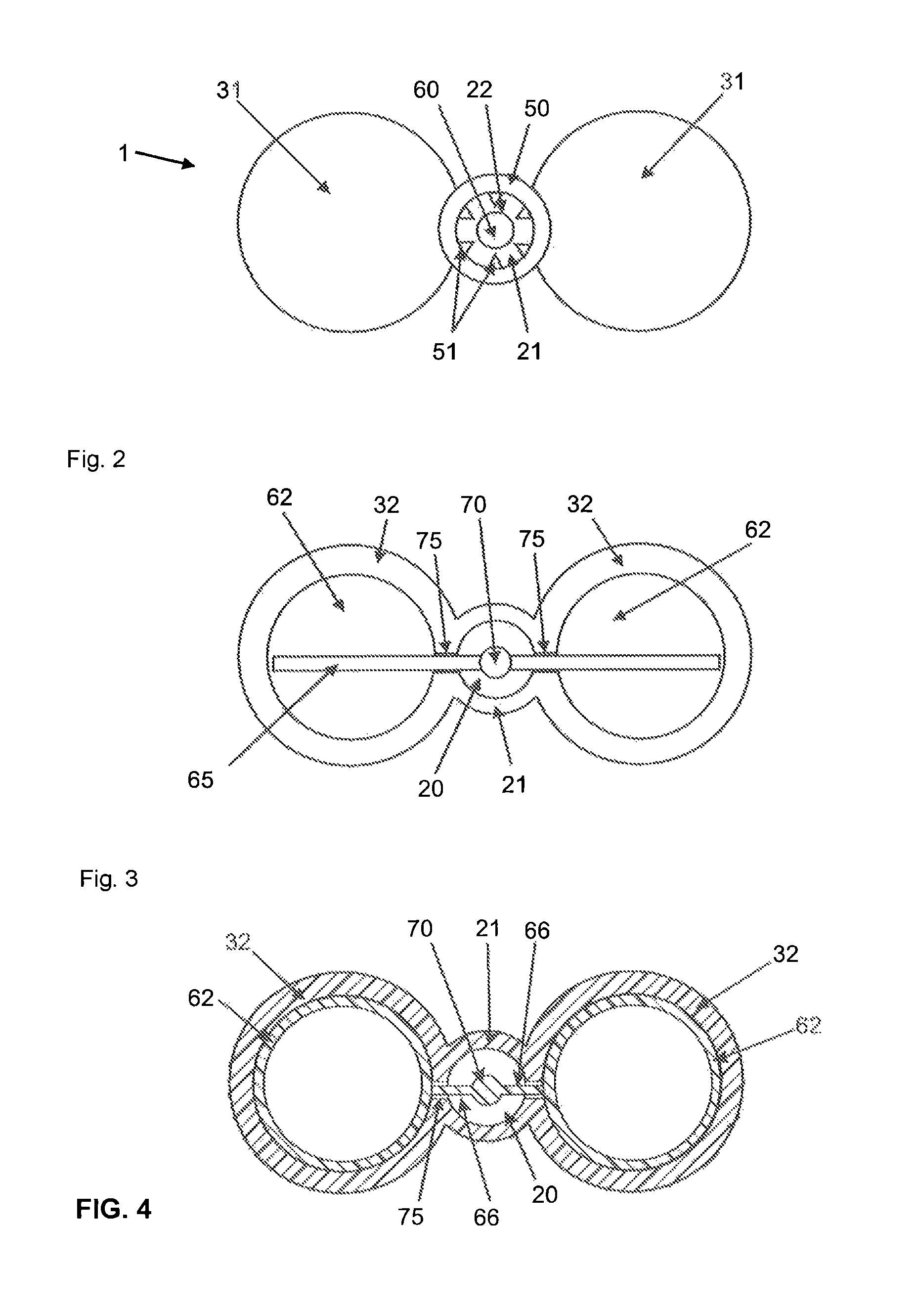

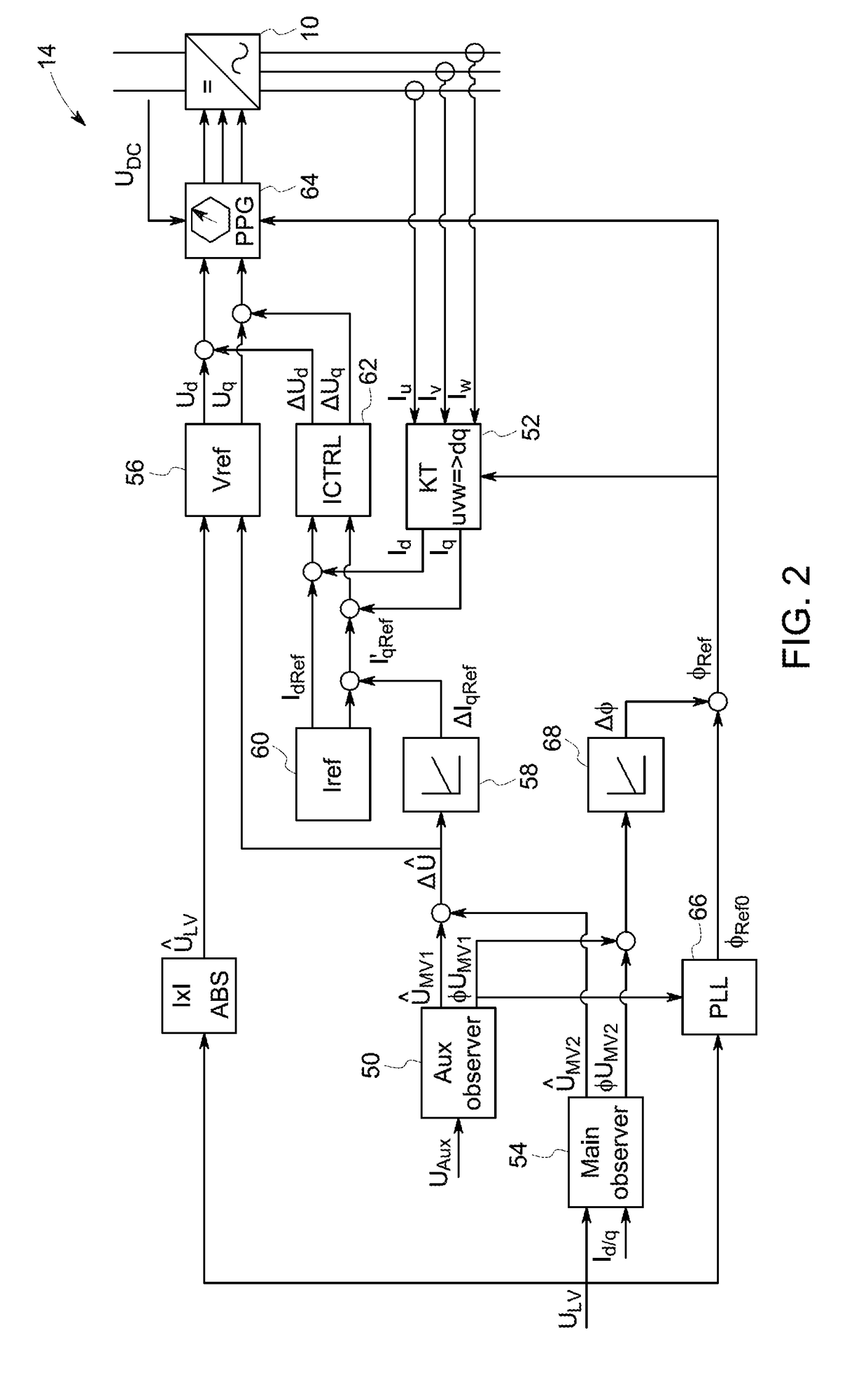

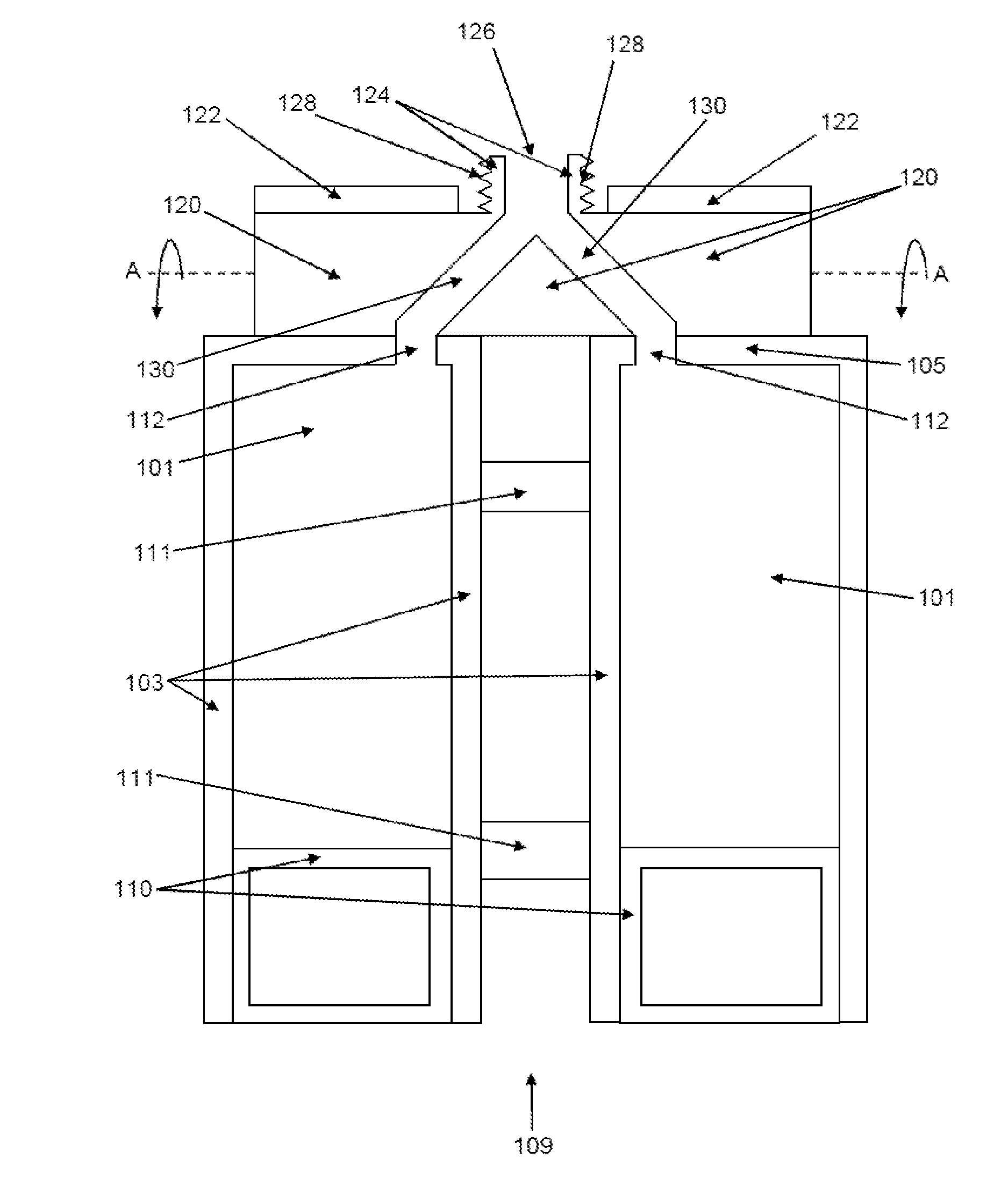

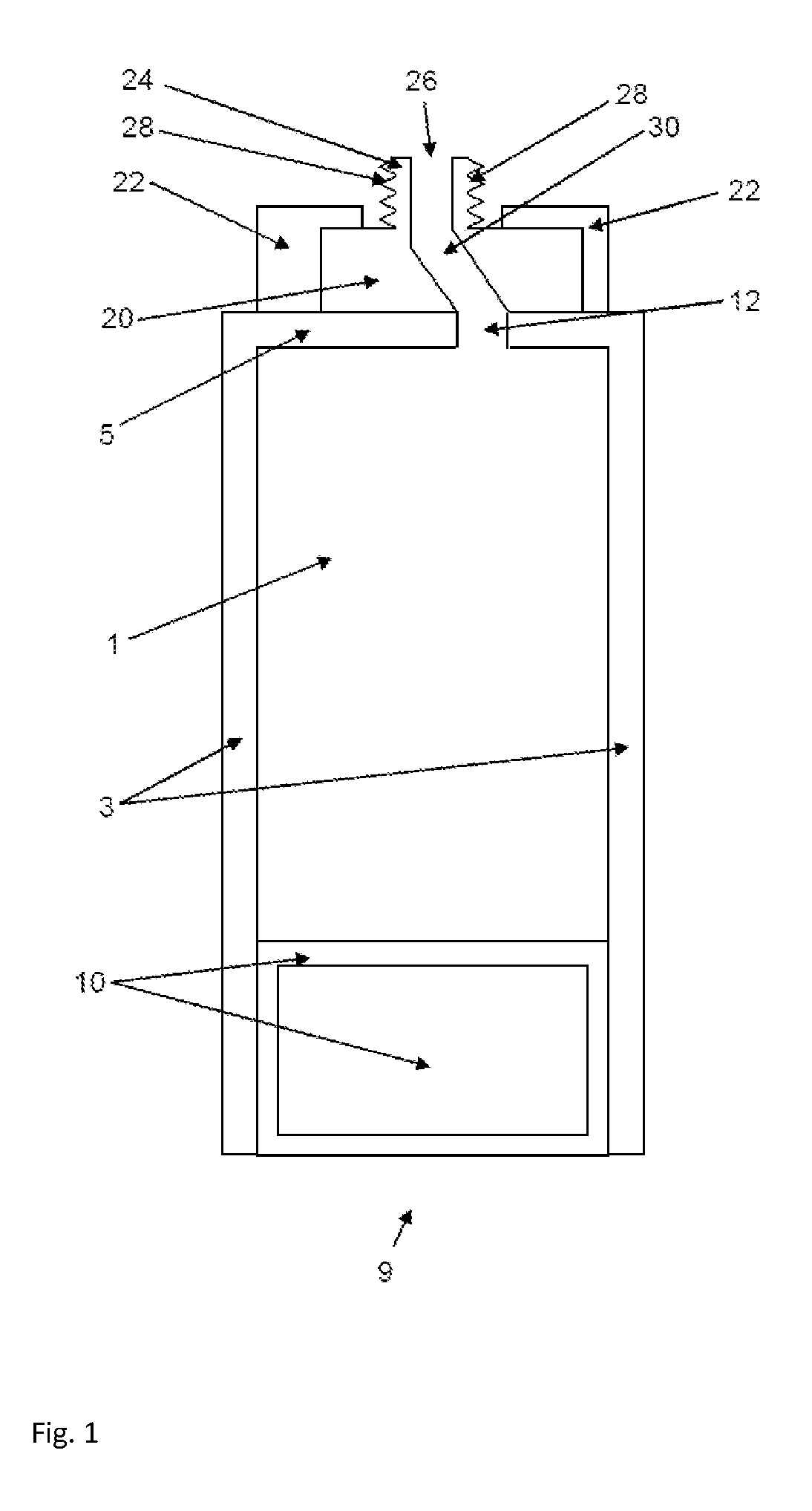

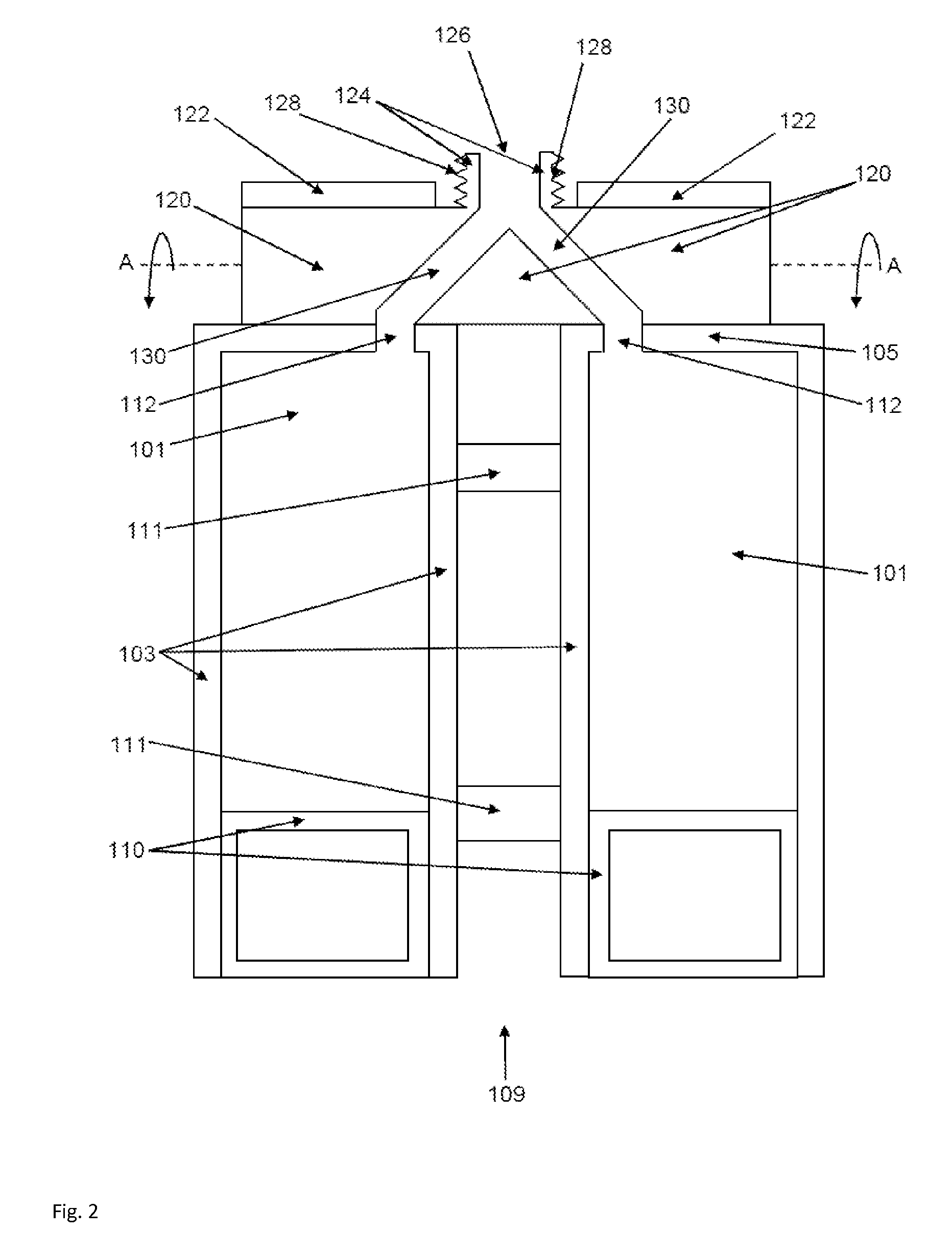

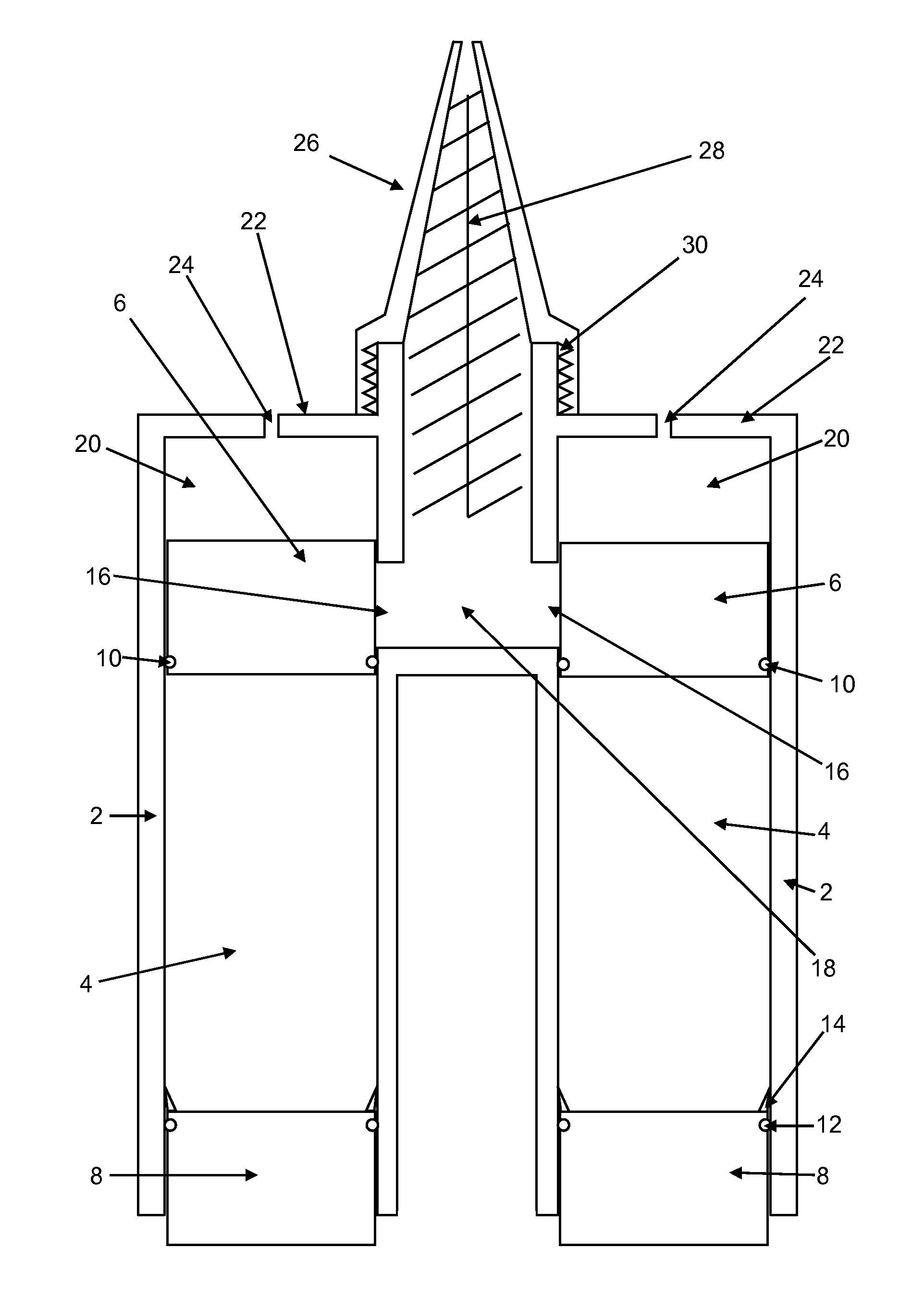

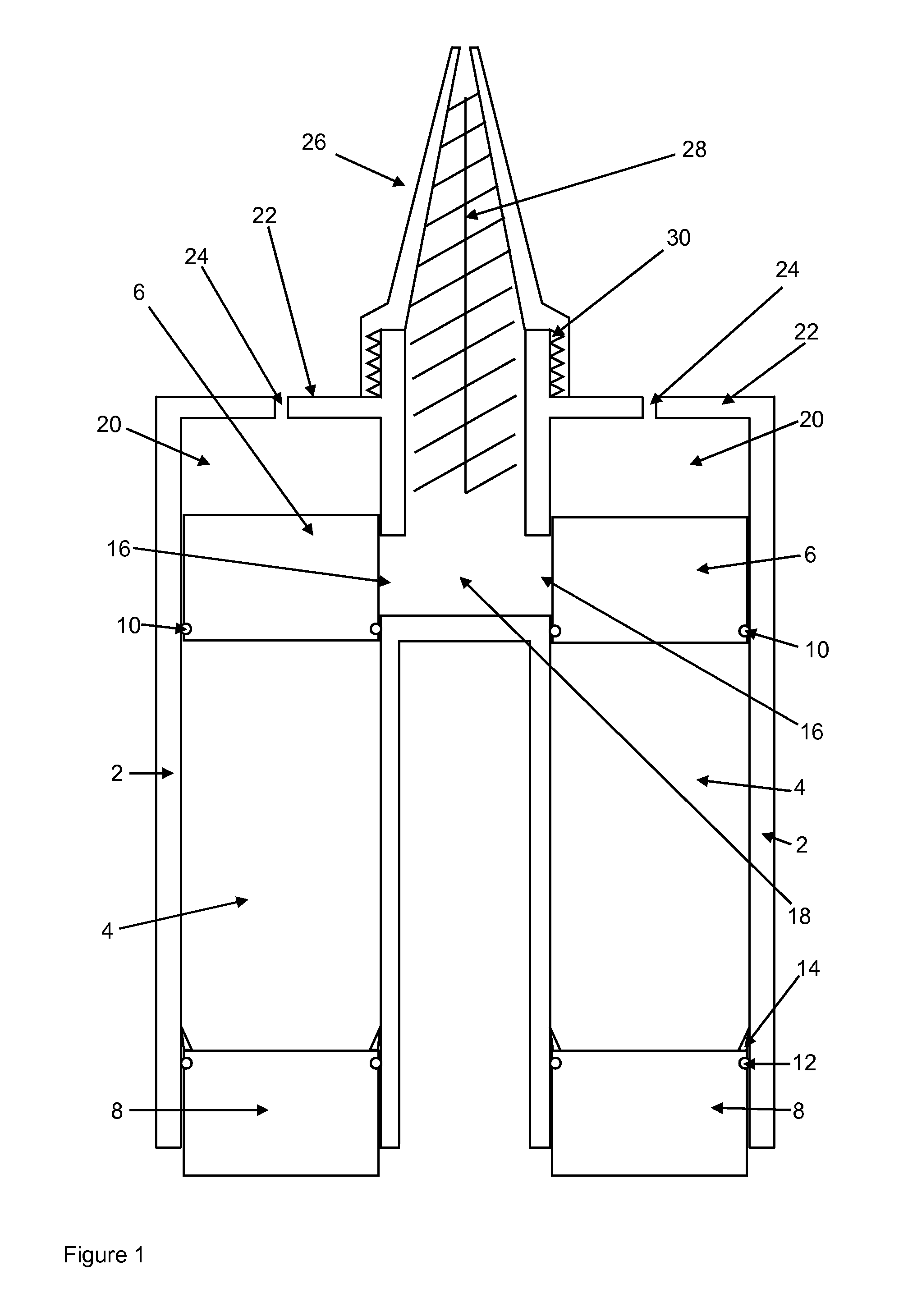

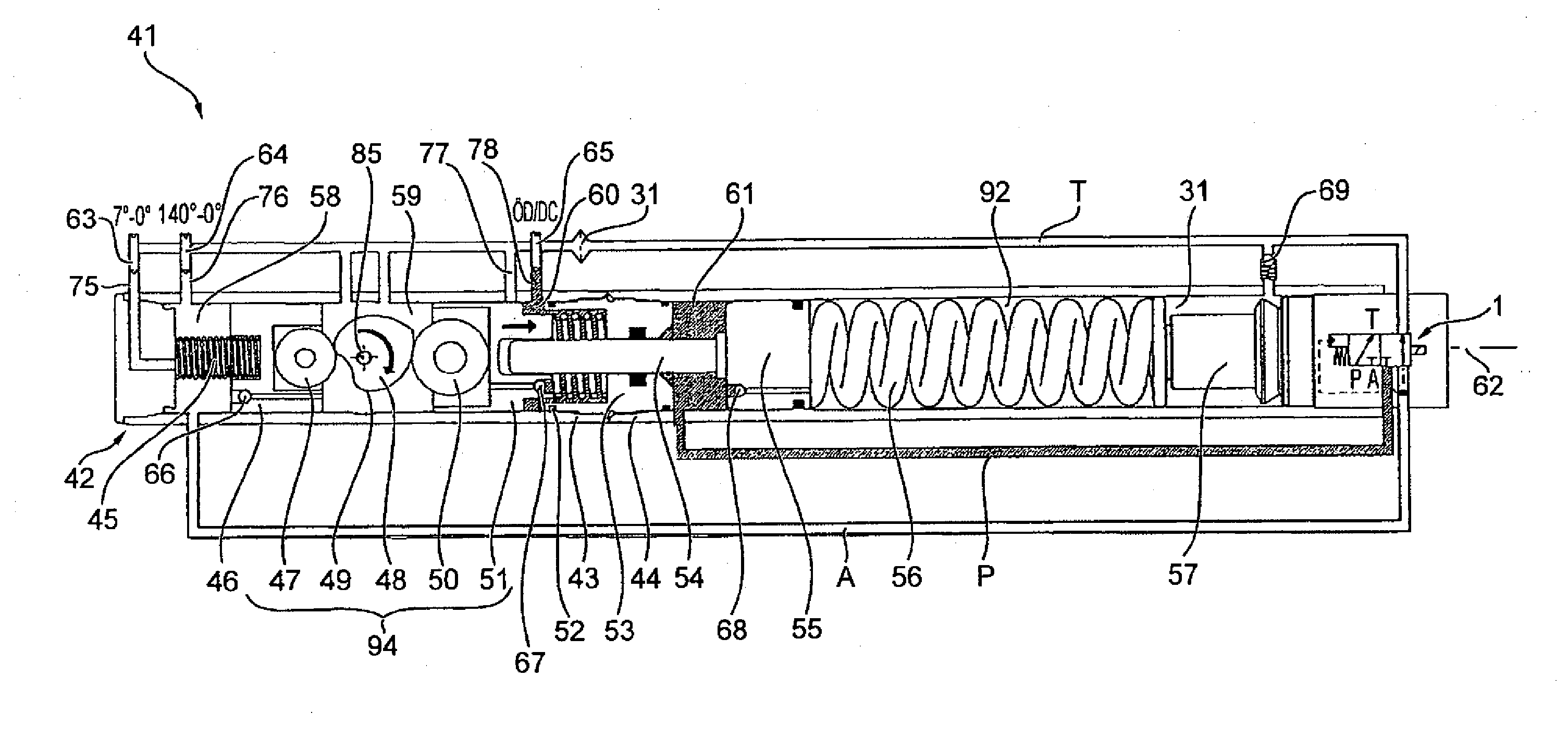

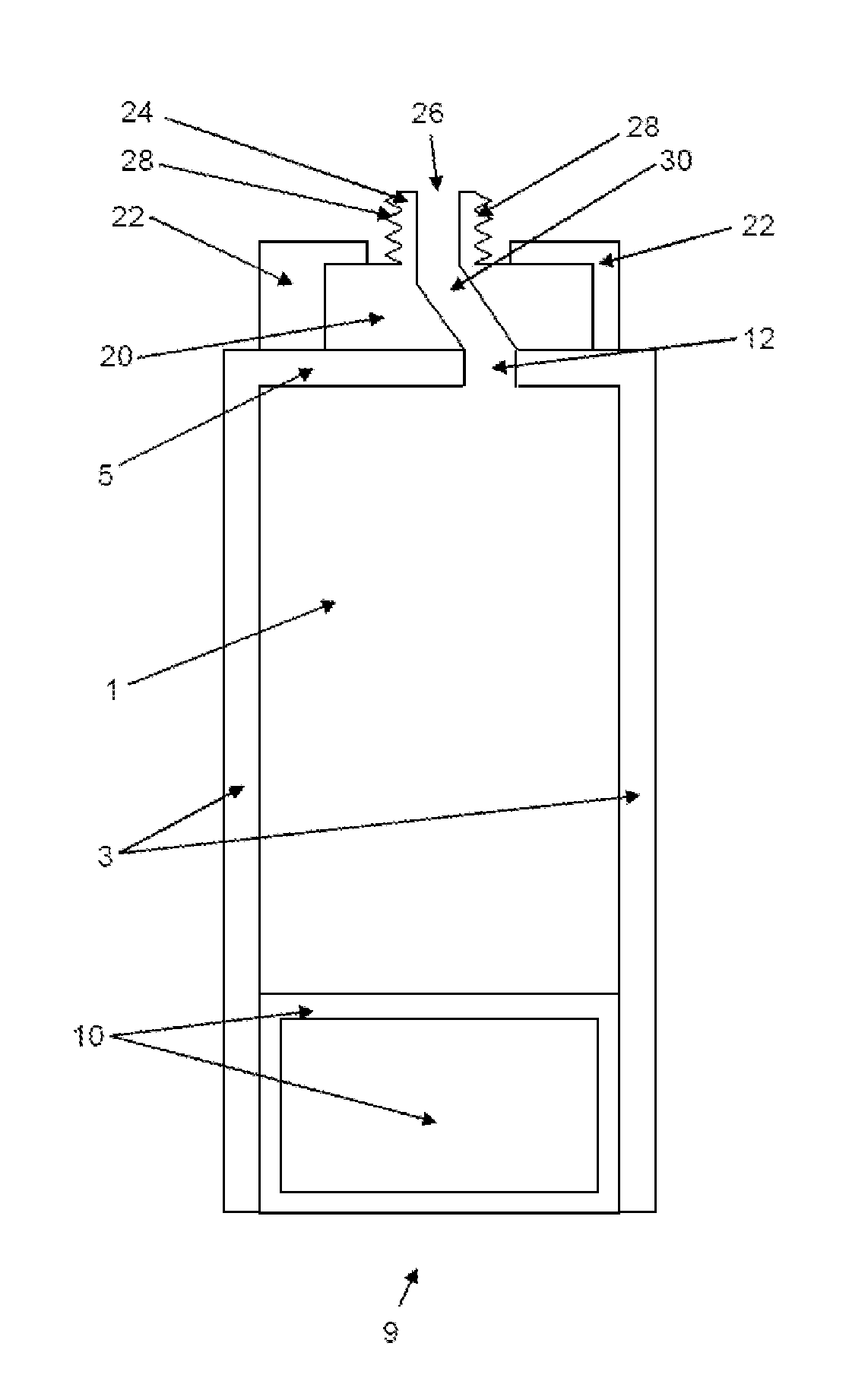

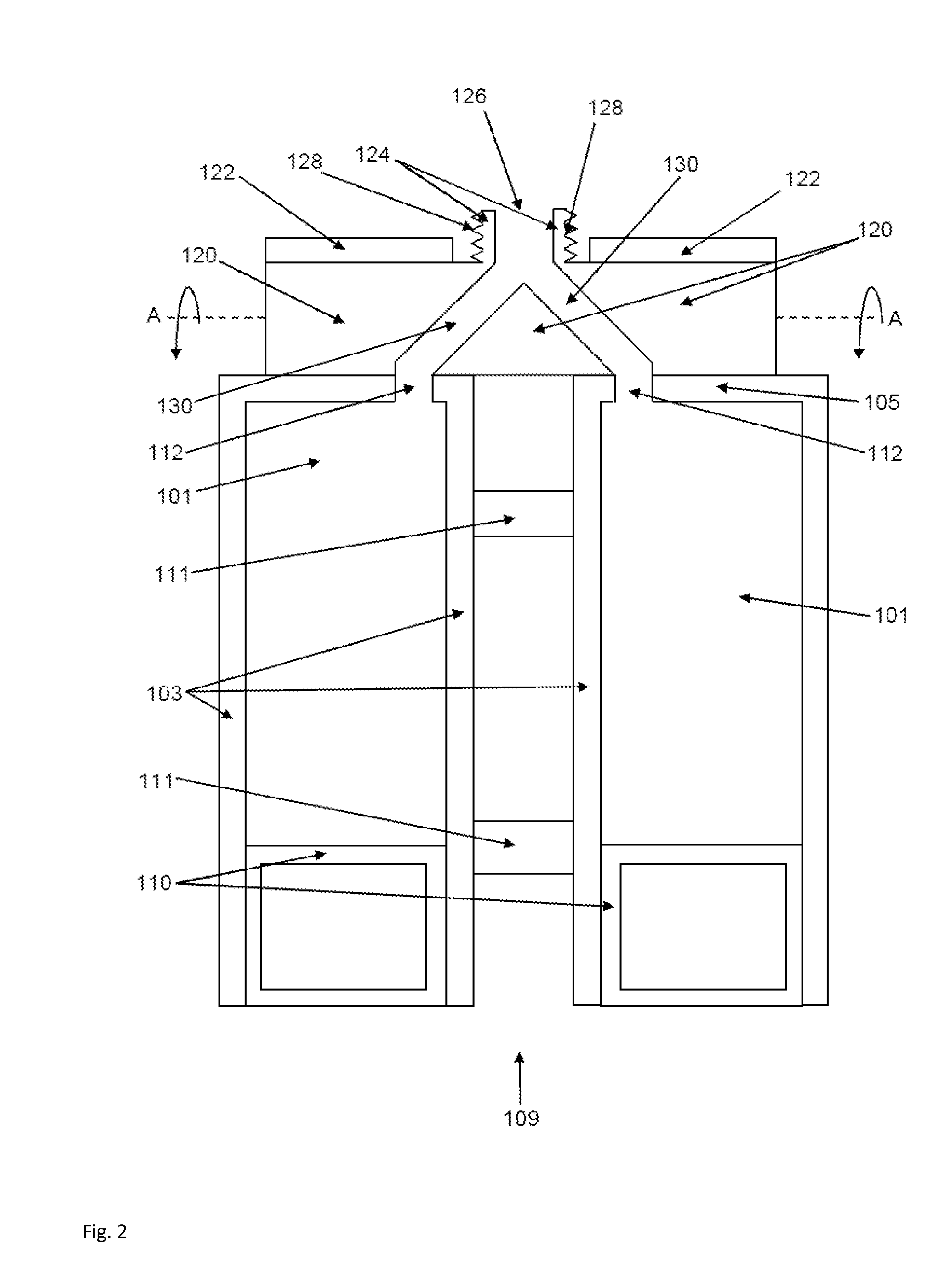

Cartridge System and Dispensing Tube For Said Cartridge System

InactiveUS20110272436A1Easy and inexpensive to manufactureSafe and rapid to openLiquid surface applicatorsFlow mixersEngineeringMechanical engineering

A cartridge system mixes and applies a mixing ware, such as, for example, a medical cement. The cartridge system has two cartridges that are arranged parallel to each other, and a mixing space having an outlet opening, wherein the cartridges each comprise at least one opening in the cartridge walls that connects the cartridges to the mixing space. The cartridges each comprise a feed plunger for expelling starting components of the mixing ware out of the cartridges through the openings, wherein a closure that can be shifted in the mixing space is arranged in the mixing space in a manner such that it closes the openings of the cartridges in a starting position and in that the openings to the mixing space are opened, at least in part, in a final position of the shiftable closure, wherein the shiftable closure can be shifted from a starting position to a final position. A dispensing tube for the cartridge system has, opposite from a dispensing tube tip of the dispensing tube, an extension with a diameter is smaller than an internal diameter of the mixing space, and which is designed to shift the shiftable closure during the insertion of the dispensing tube into the cartridge system head of the cartridge system such that the openings of the cartridges are open, at least in part.

Owner:HERAEUS MEDICAL

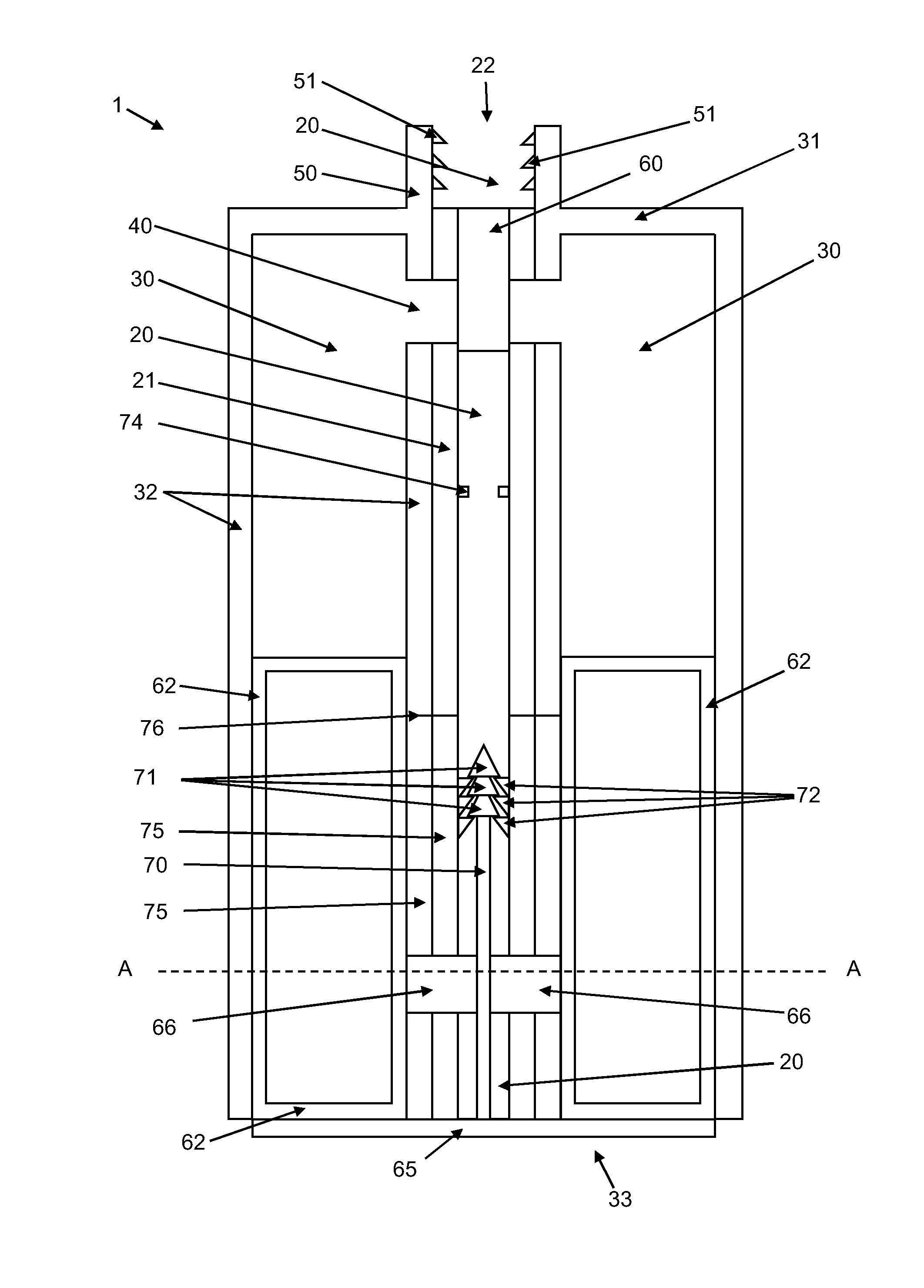

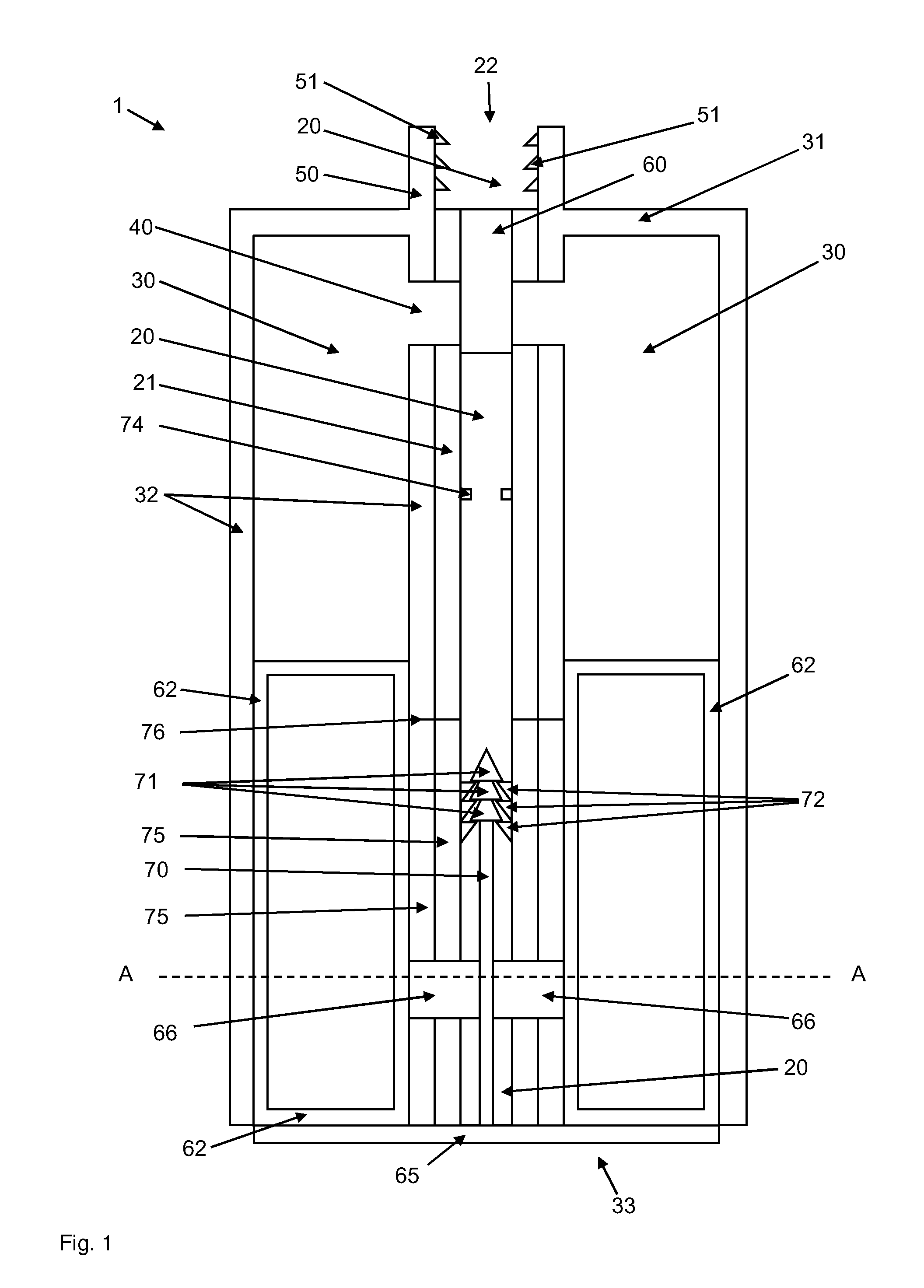

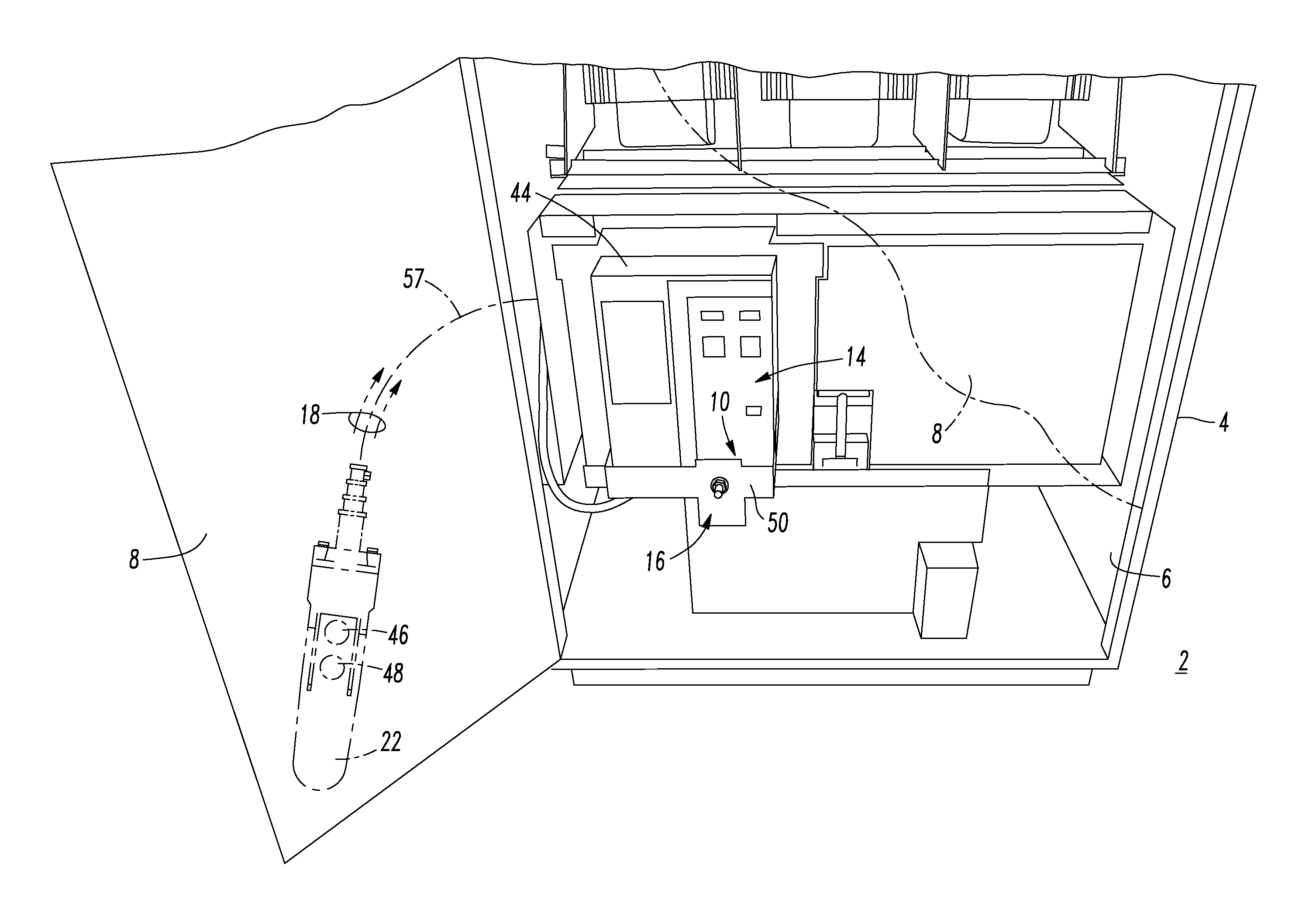

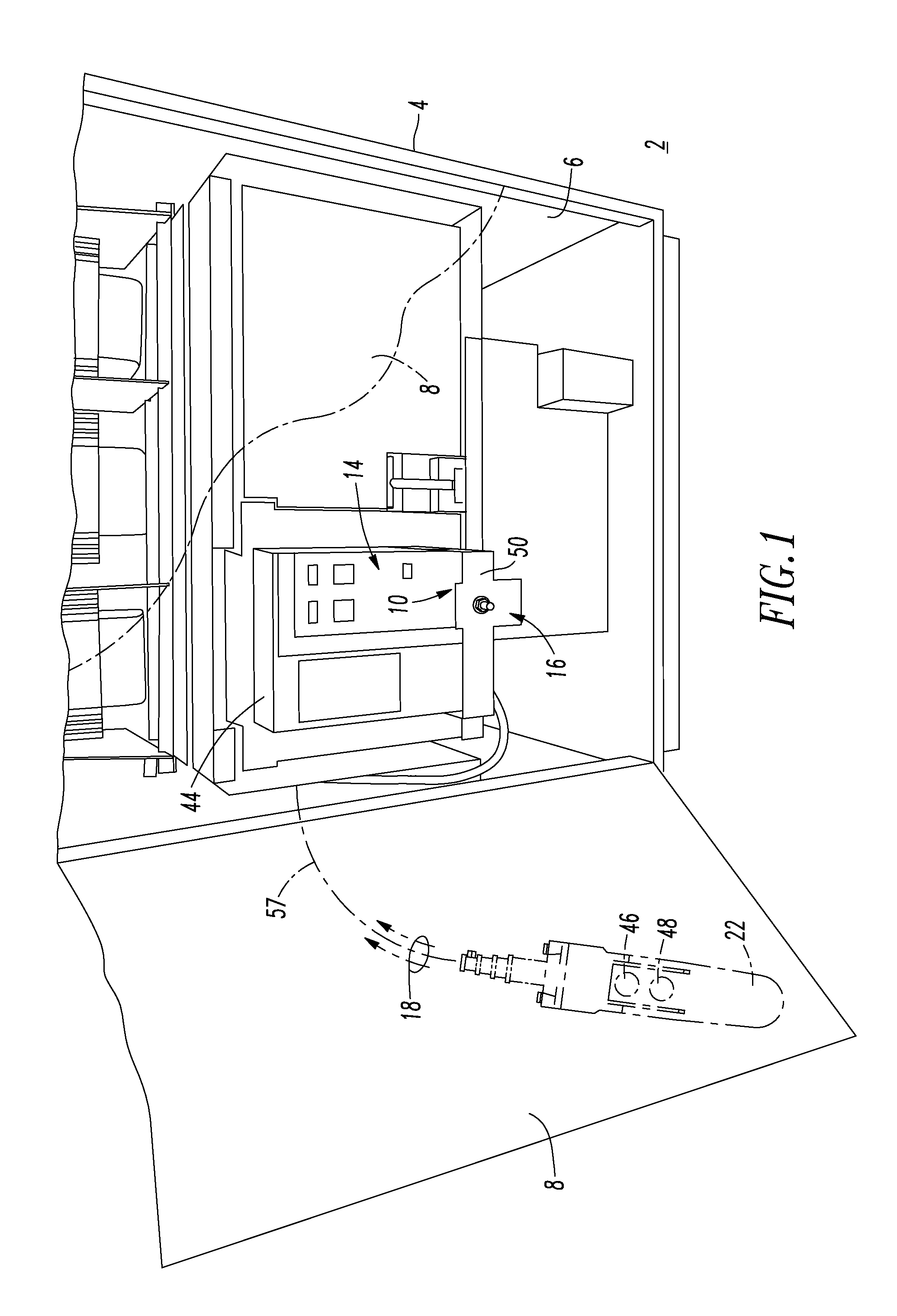

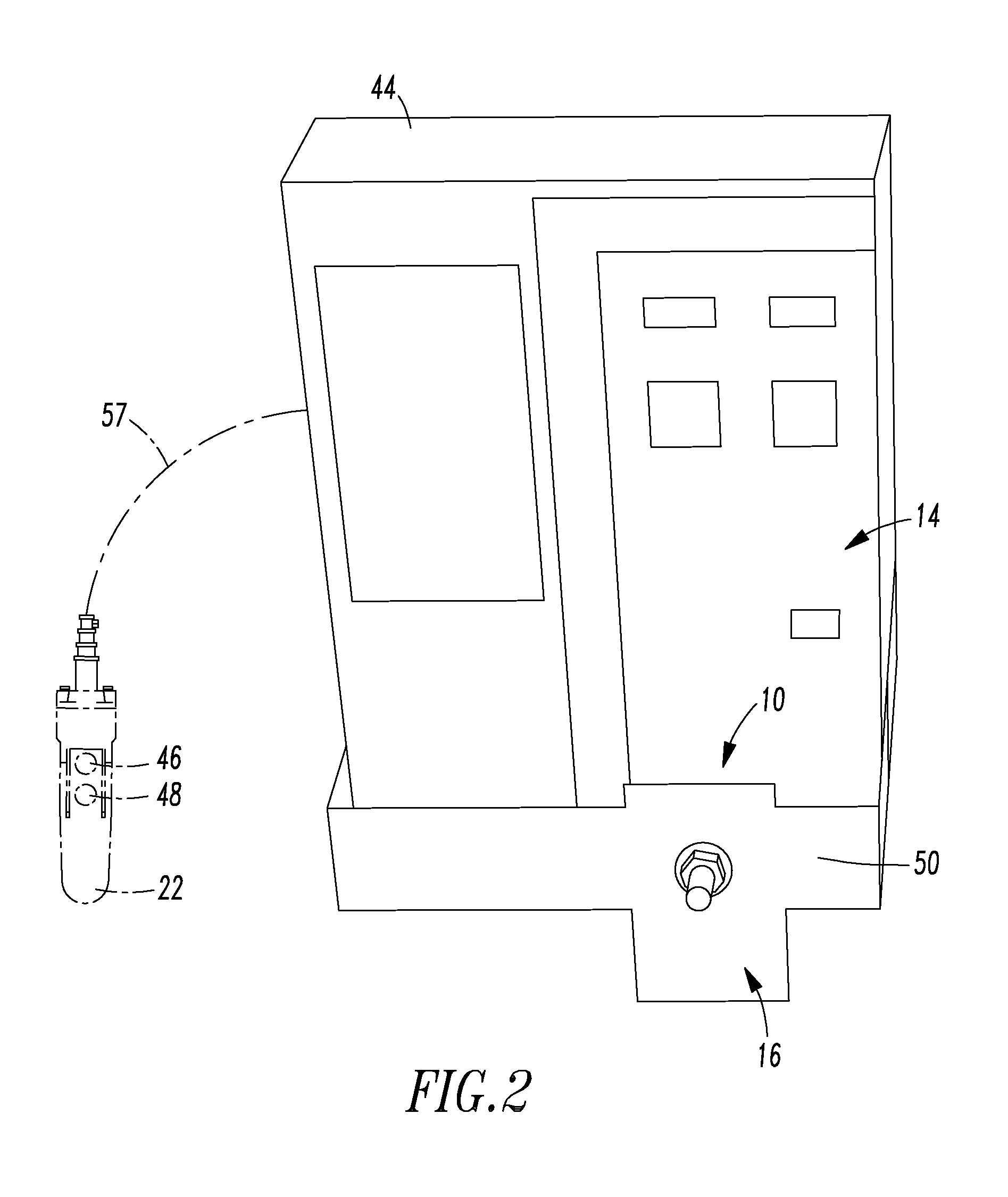

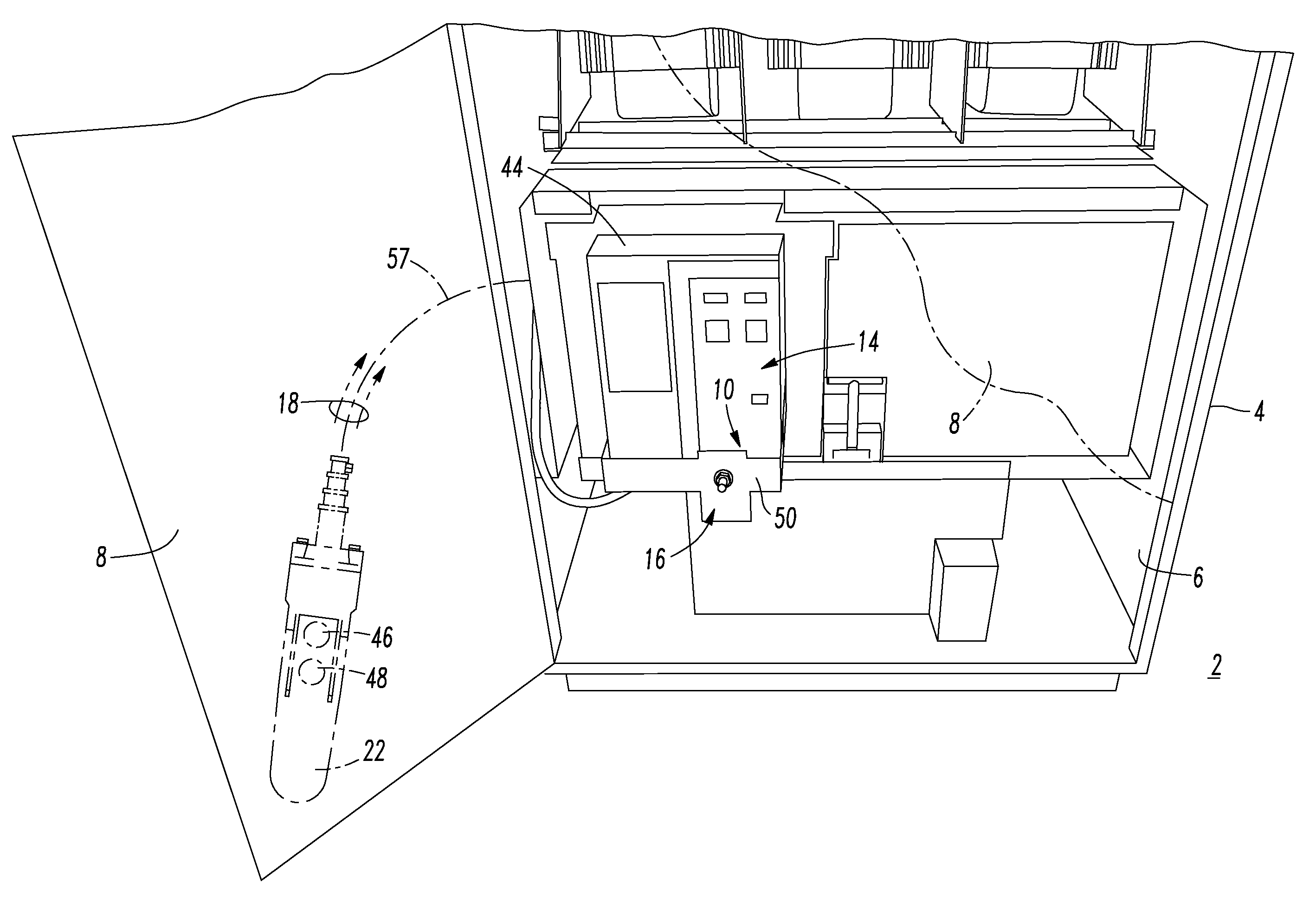

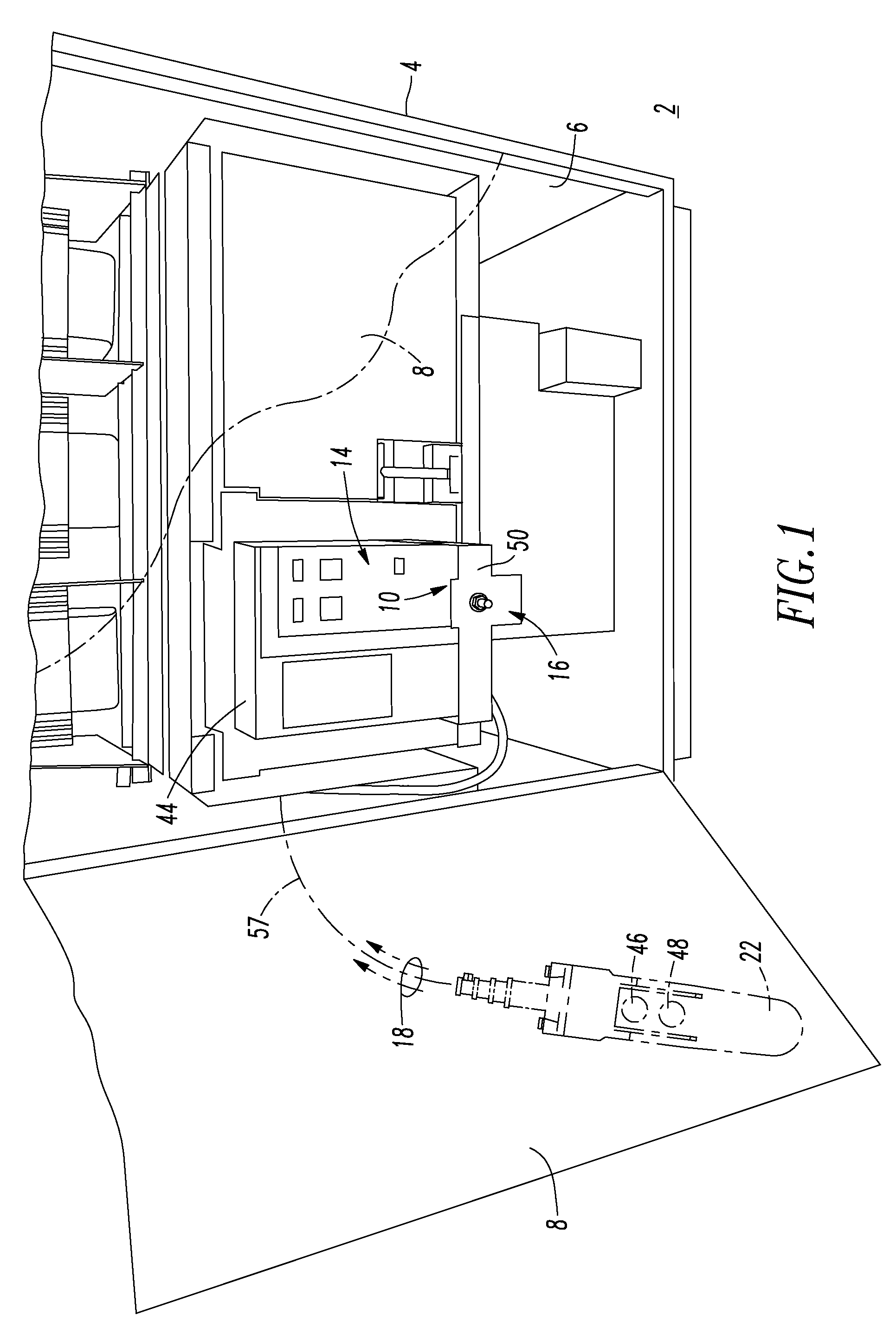

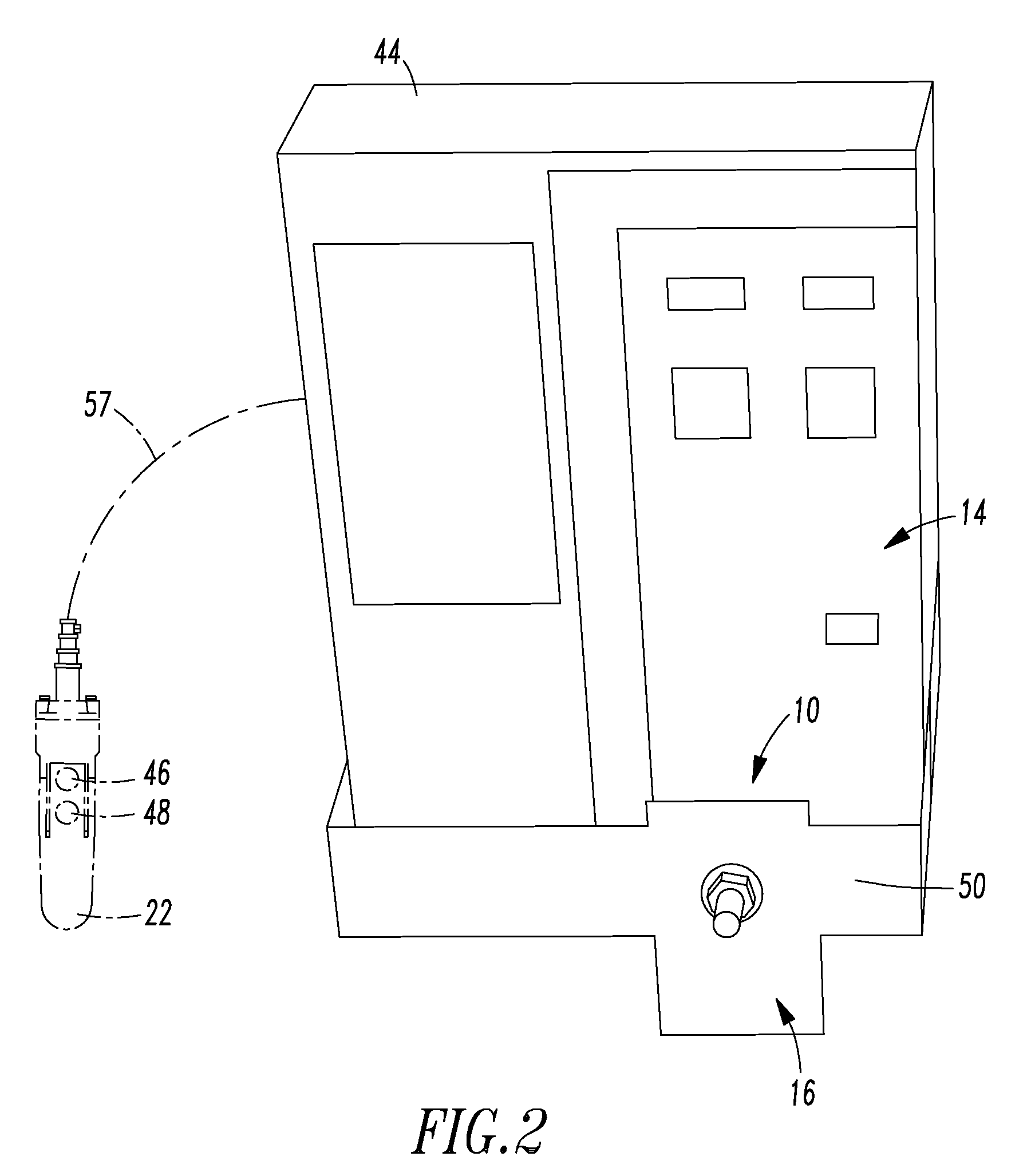

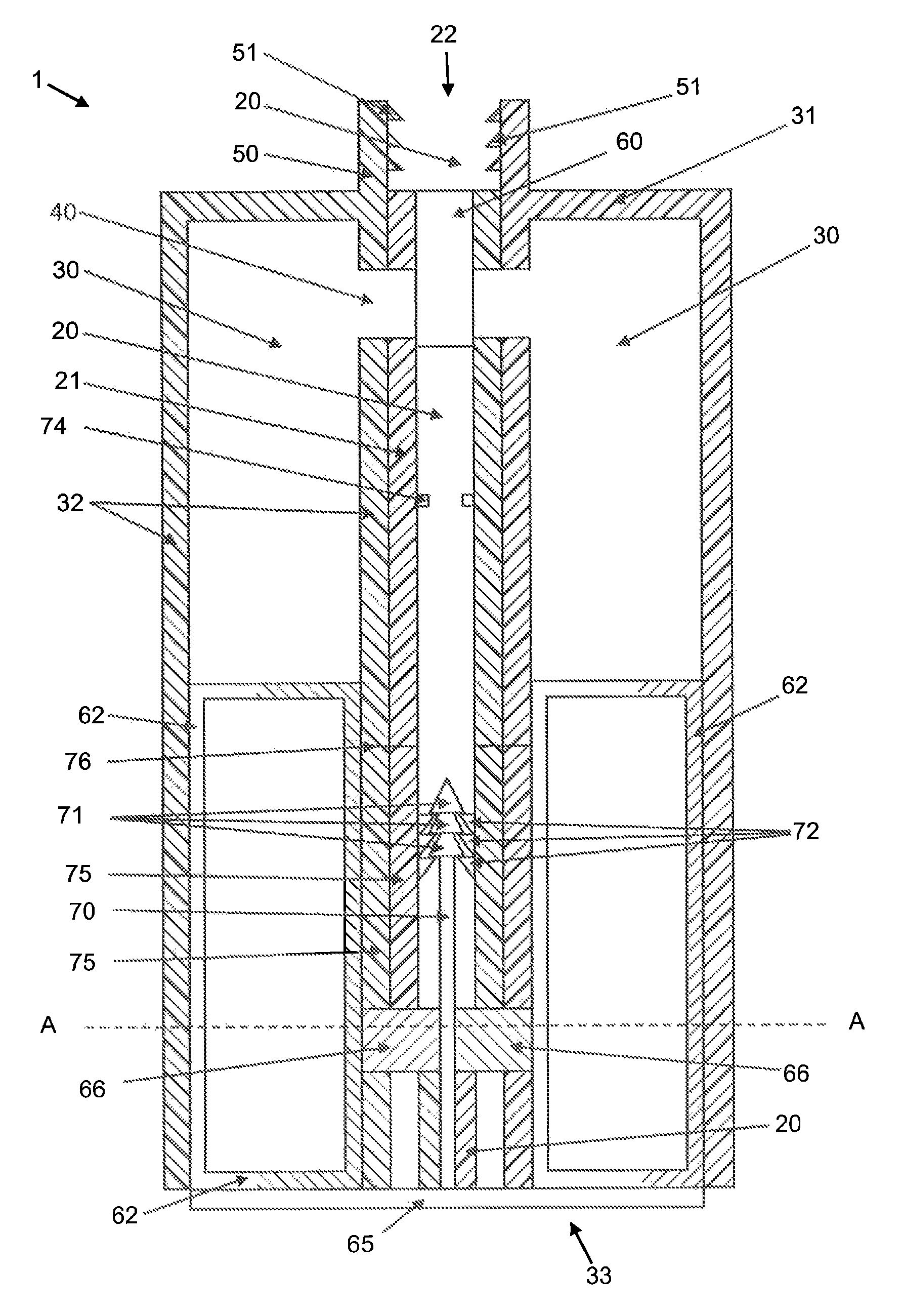

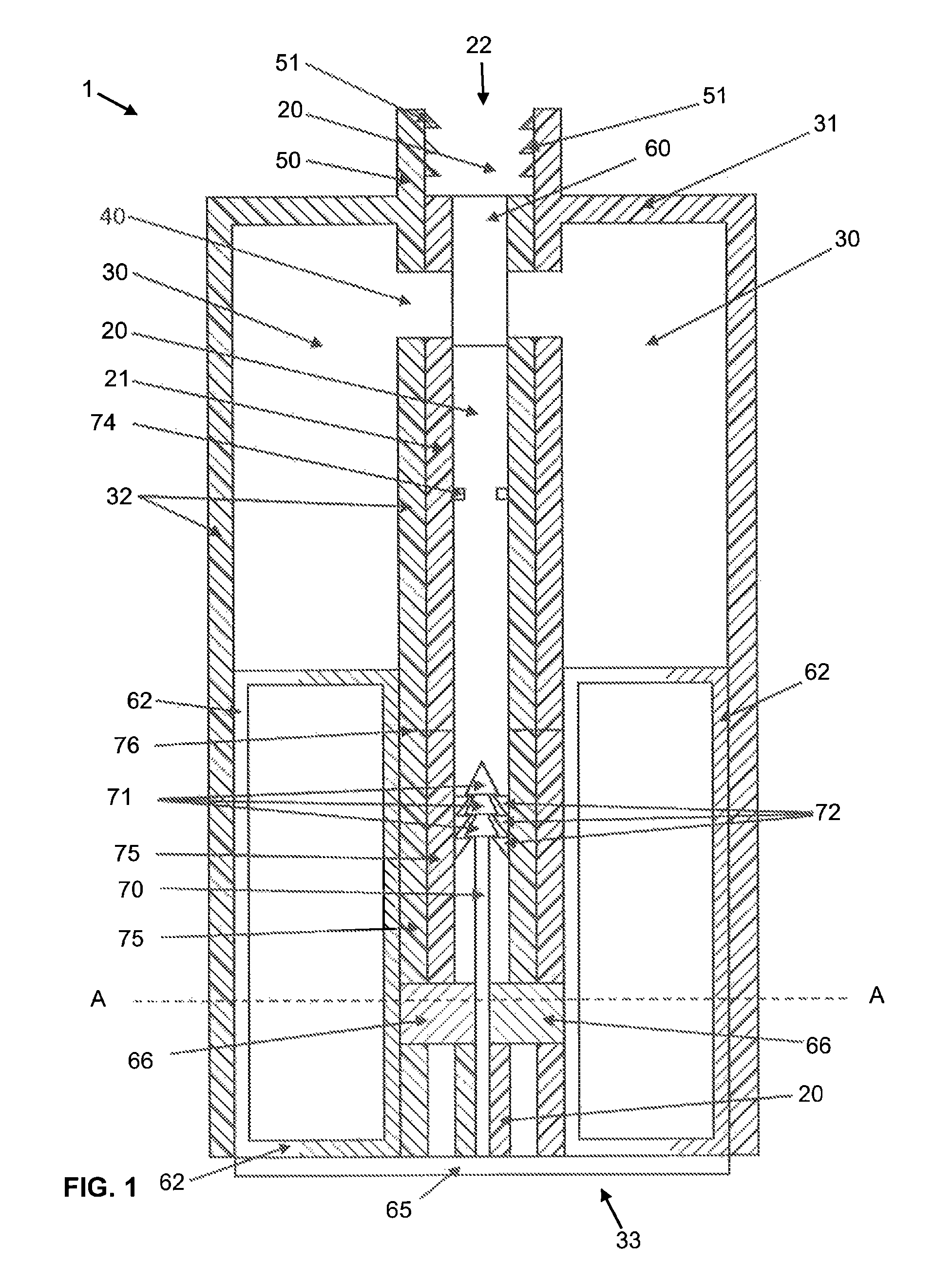

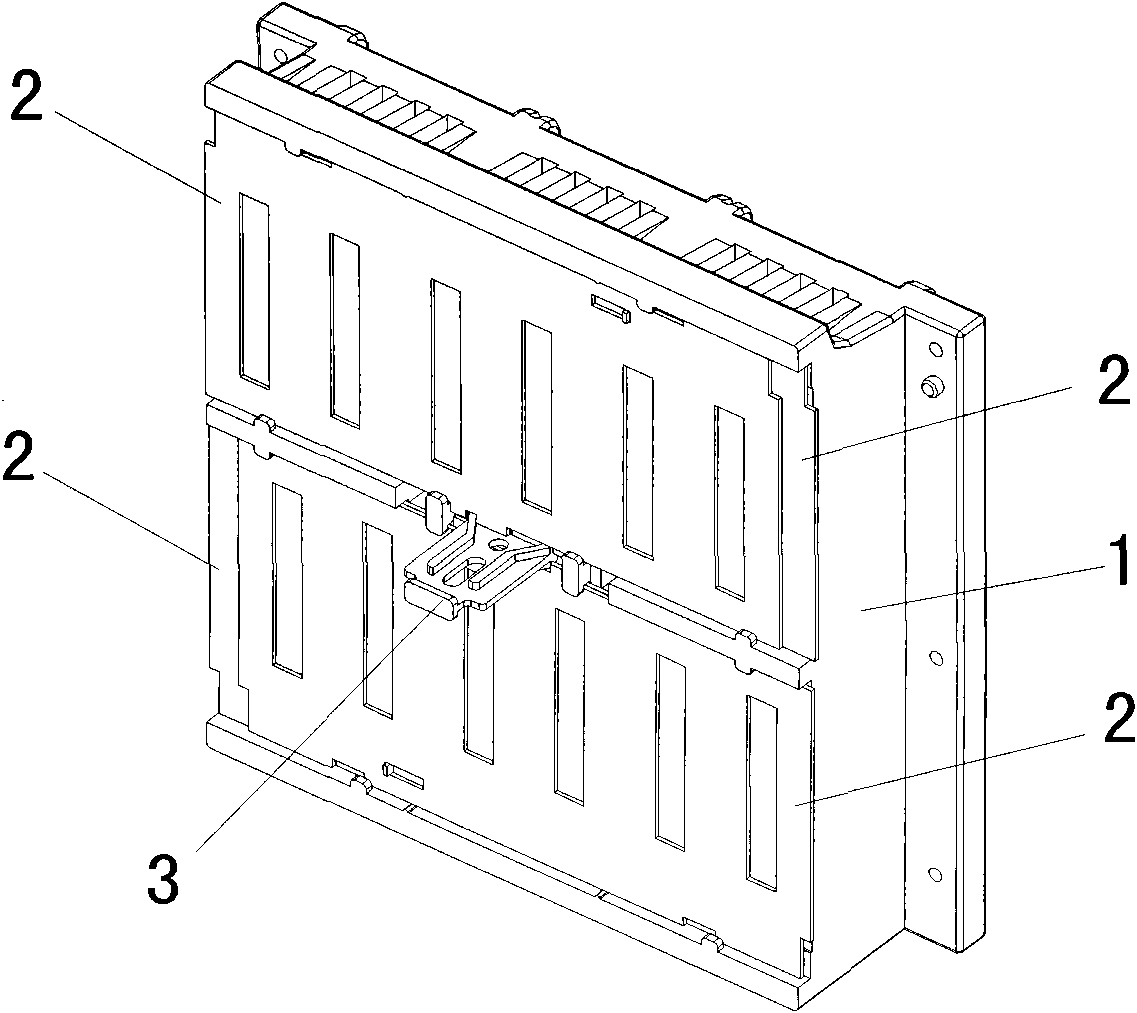

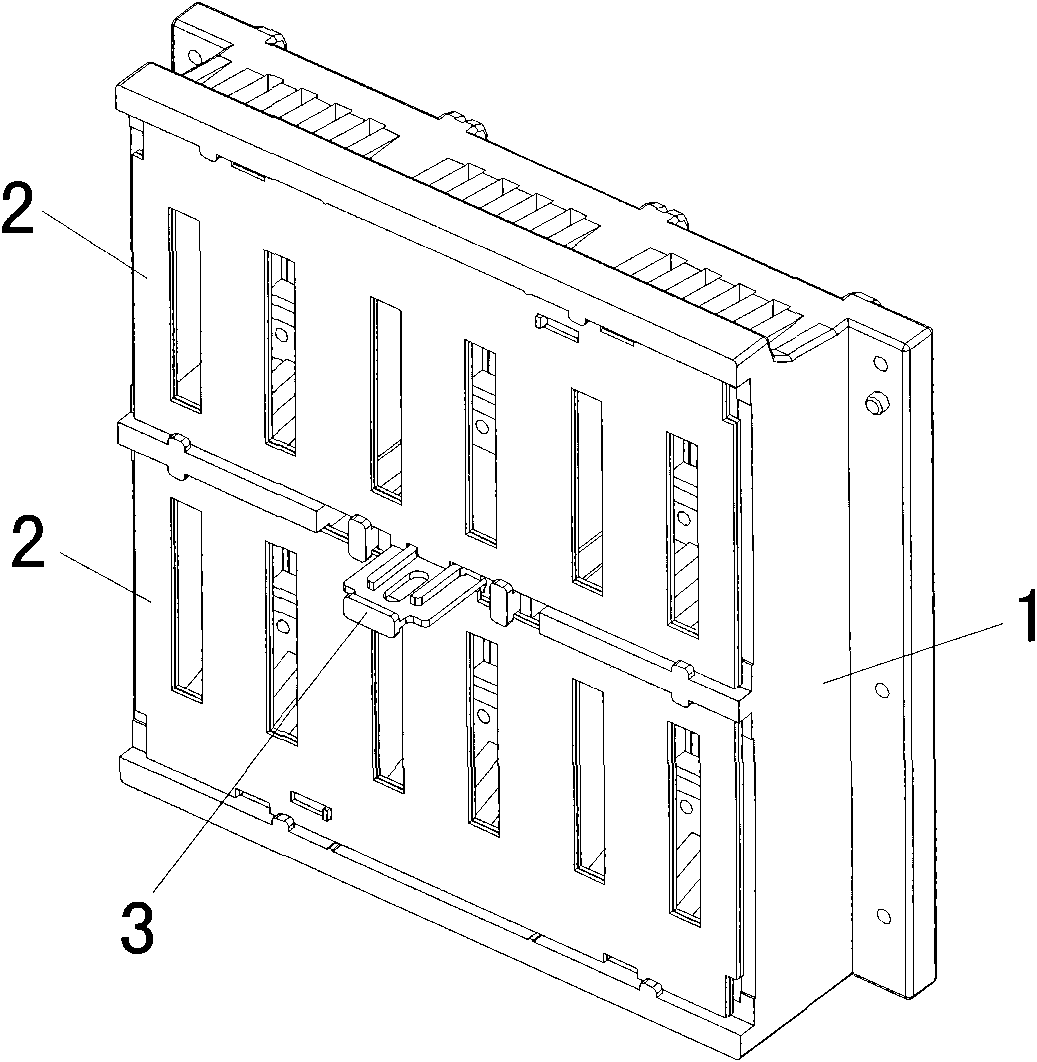

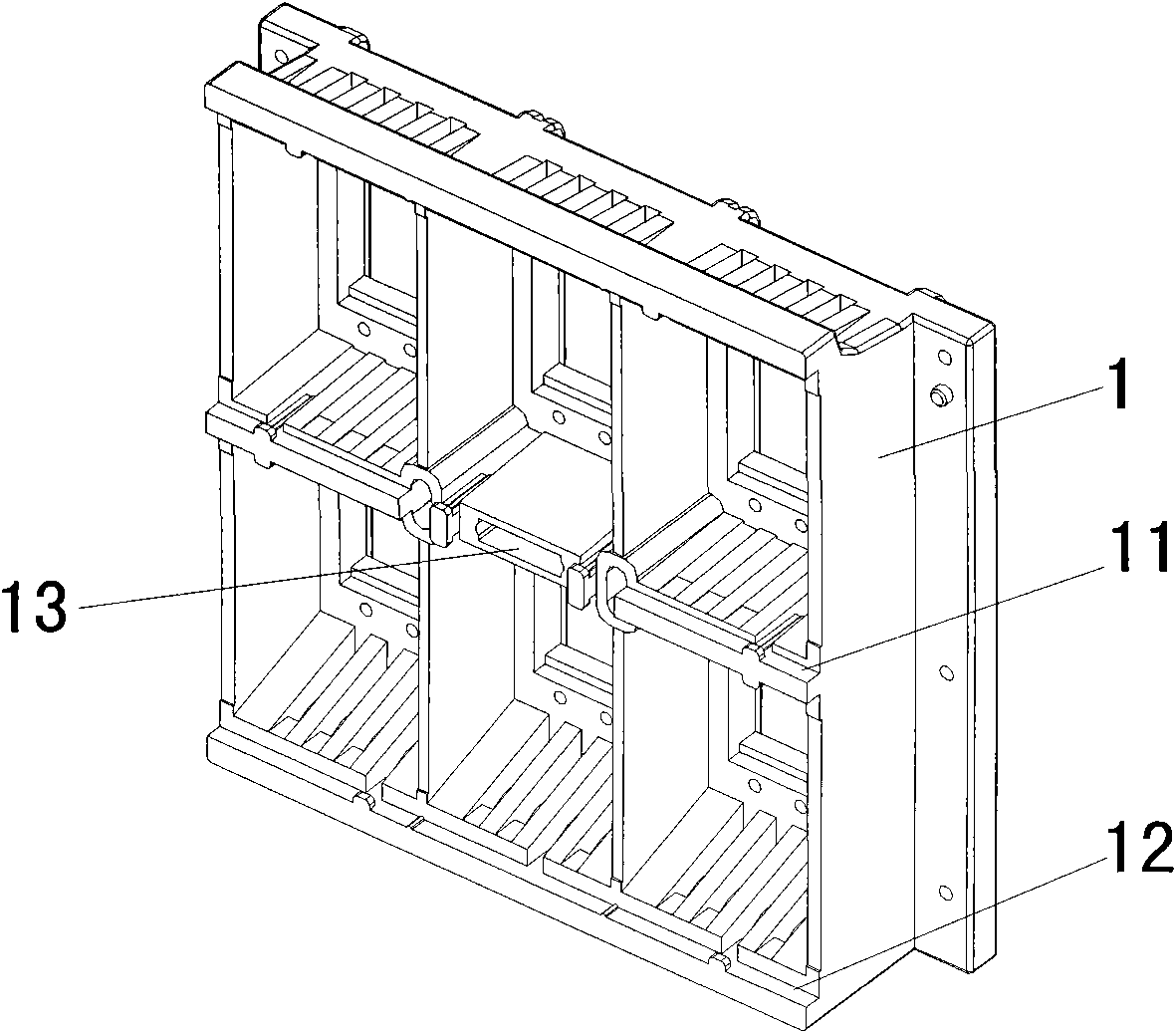

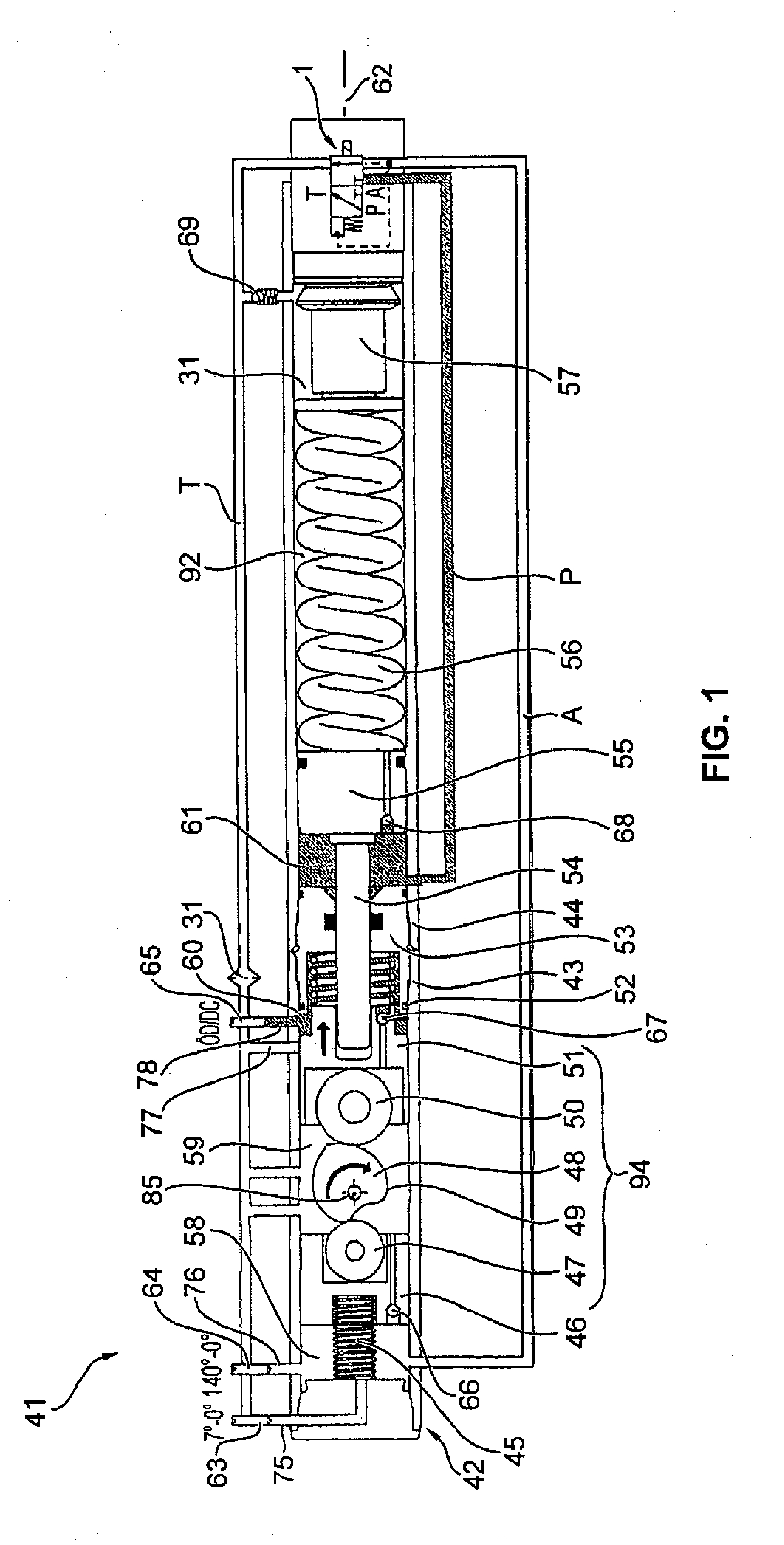

System, network protector enclosure, and automatic racking system

ActiveUS20110216508A1Improve worker safetyClose safeSwitchgear with withdrawable carriageHigh-tension/heavy-dress switchesNetwork protectorEmbedded system

A system includes an electrical enclosure having an inner volume and a door structured to open to expose the inner volume and structured to close to enclose the inner volume. A racking mechanism is disposed in the inner volume and includes a member movable in a first direction to a first position and an opposite second direction to a different second position. A network protector is carried by the racking mechanism and is movable thereby between a connect position in the inner volume corresponding to the first position of the member of the racking mechanism, and a test position in the inner volume corresponding to the different second position of the member of the racking mechanism. A control mechanism is structured to move the member of the racking mechanism between the first position and the different second position of the member responsive to a number of remote commands.

Owner:EATON INTELLIGENT POWER LTD

System, network protector enclosure, and automatic racking system

ActiveUS8319123B2Improve worker safetyClose safeSwitchgear with withdrawable carriageHigh-tension/heavy-dress switchesInterior spaceNetwork protector

A system includes an electrical enclosure having an inner volume and a door structured to open to expose the inner volume and structured to close to enclose the inner volume. A racking mechanism is disposed in the inner volume and includes a member movable in a first direction to a first position and an opposite second direction to a different second position. A network protector is carried by the racking mechanism and is movable thereby between a connect position in the inner volume corresponding to the first position of the member of the racking mechanism, and a test position in the inner volume corresponding to the different second position of the member of the racking mechanism. A control mechanism is structured to move the member of the racking mechanism between the first position and the different second position of the member responsive to a number of remote commands.

Owner:EATON INTELLIGENT POWER LTD

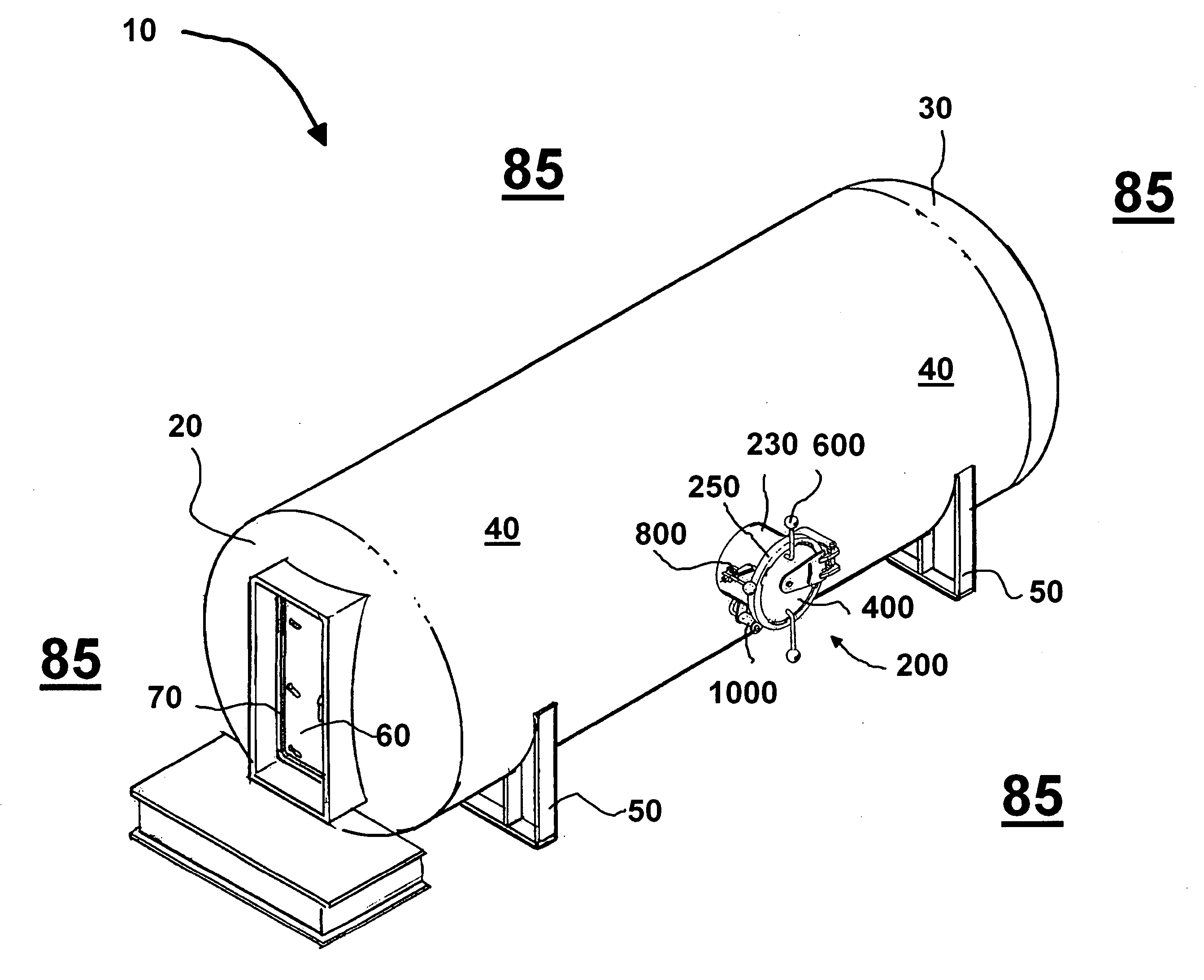

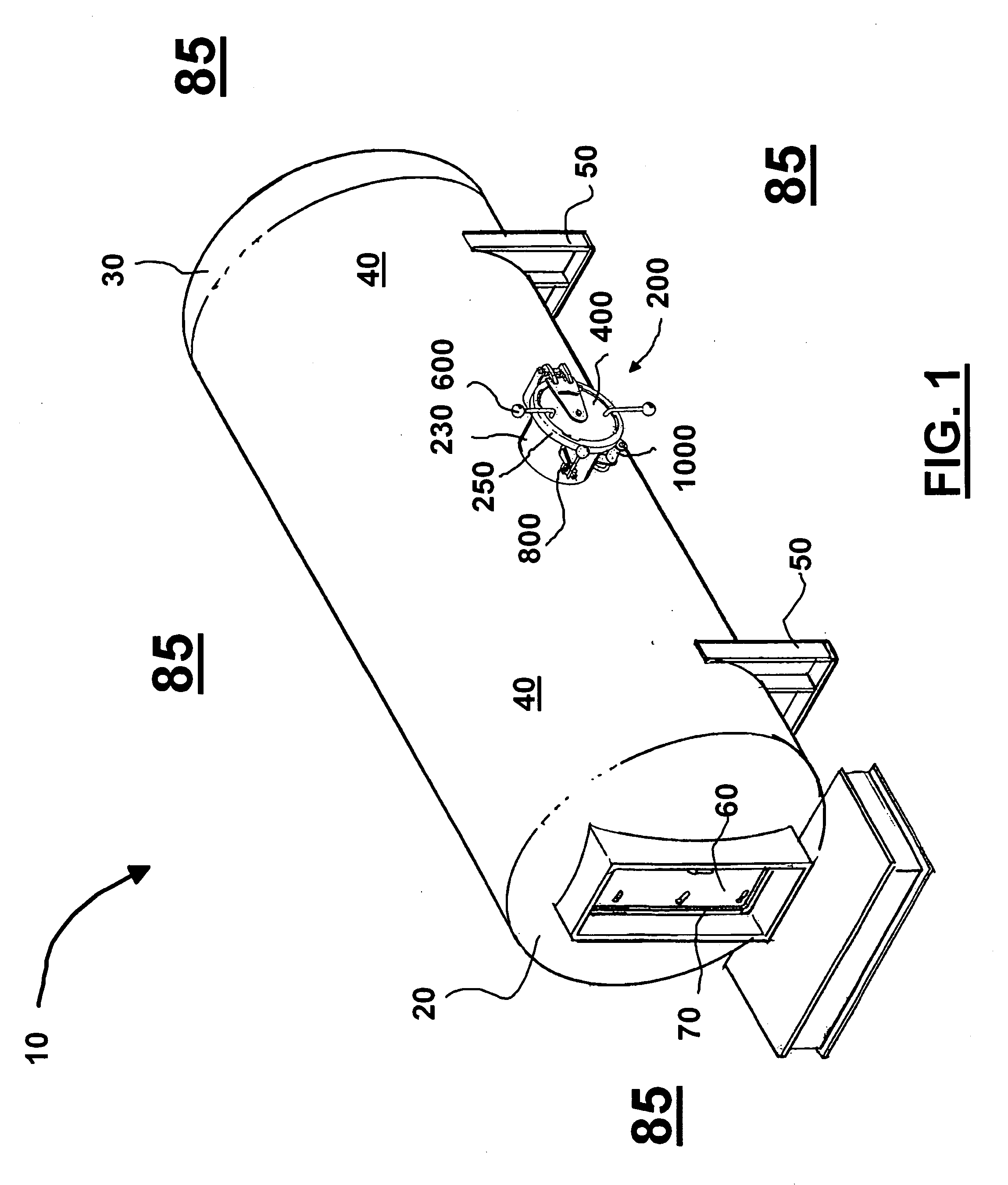

Interlock vessel for hyperbaric transfer system

InactiveUS20100037892A1Close safeTighter engagementBreathing protectionTreatment roomsInterlockDecompression chamber

An interlock vessel having an air-tight body with opposing ends. A portion of the body is designed to fit into a decompression (hyperbaric) chamber, wherein a diver or a patient undergoing a decompression treatment is positioned. The opposing ends are closed by pivotally moveable doors and locking assemblies that retain the doors in a closed position until the pressure inside the decompression chamber and the exterior of the chamber can be equalized. The outer door has two locking systems: (a) an interlock system and (b) a safety / delay locking system. Both locking assemblies are manually operated.

Owner:BARTLETT ROBERT D

Cartridge system and dispensing tube for said cartridge system

InactiveUS9095871B2Easy and inexpensive to manufactureSafe and rapid to openLiquid surface applicatorsFlow mixersEngineeringCartridge

A cartridge system mixes and applies a mixing ware, such as, for example, a medical cement. The cartridge system has two cartridges that are arranged parallel to each other, and a mixing space having an outlet opening, wherein the cartridges each comprise at least one opening in the cartridge walls that connects the cartridges to the mixing space. The cartridges each comprise a feed plunger for expelling starting components of the mixing ware out of the cartridges through the openings, wherein a closure that can be shifted in the mixing space is arranged in the mixing space in a manner such that it closes the openings of the cartridges in a starting position and in that the openings to the mixing space are opened, at least in part, in a final position of the shiftable closure, wherein the shiftable closure can be shifted from a starting position to a final position. A dispensing tube for the cartridge system has, opposite from a dispensing tube tip of the dispensing tube, an extension with a diameter is smaller than an internal diameter of the mixing space, and which is designed to shift the shiftable closure during the insertion of the dispensing tube into the cartridge system head of the cartridge system such that the openings of the cartridges are open, at least in part.

Owner:HERAEUS MEDICAL

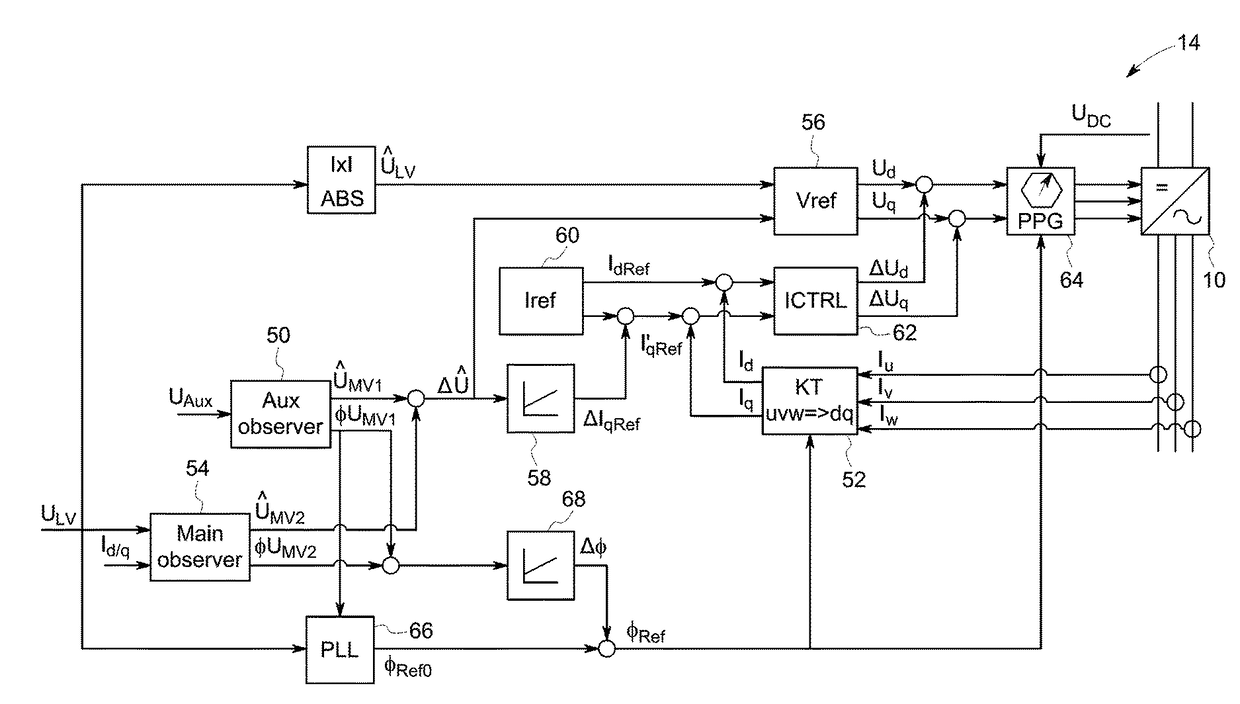

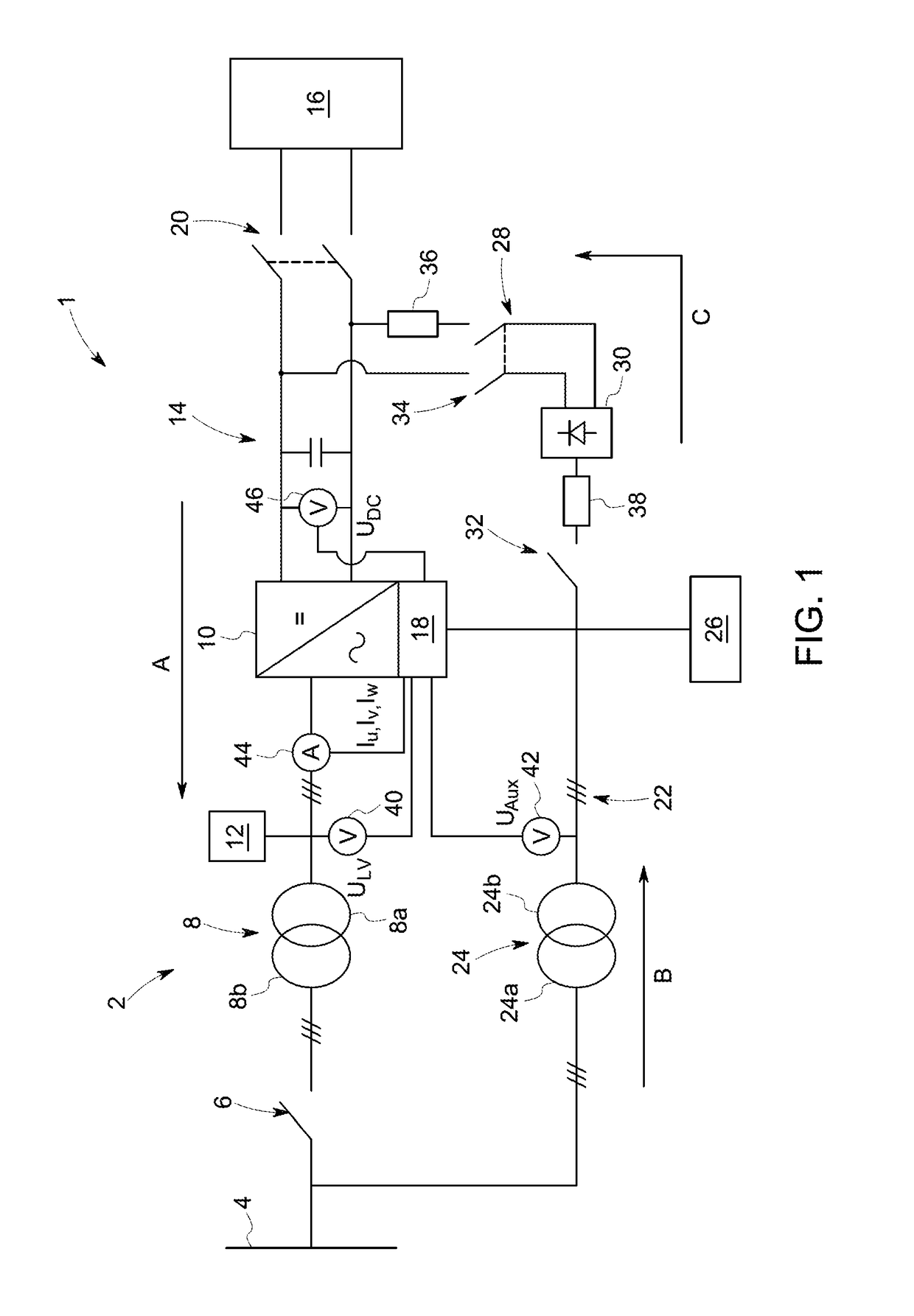

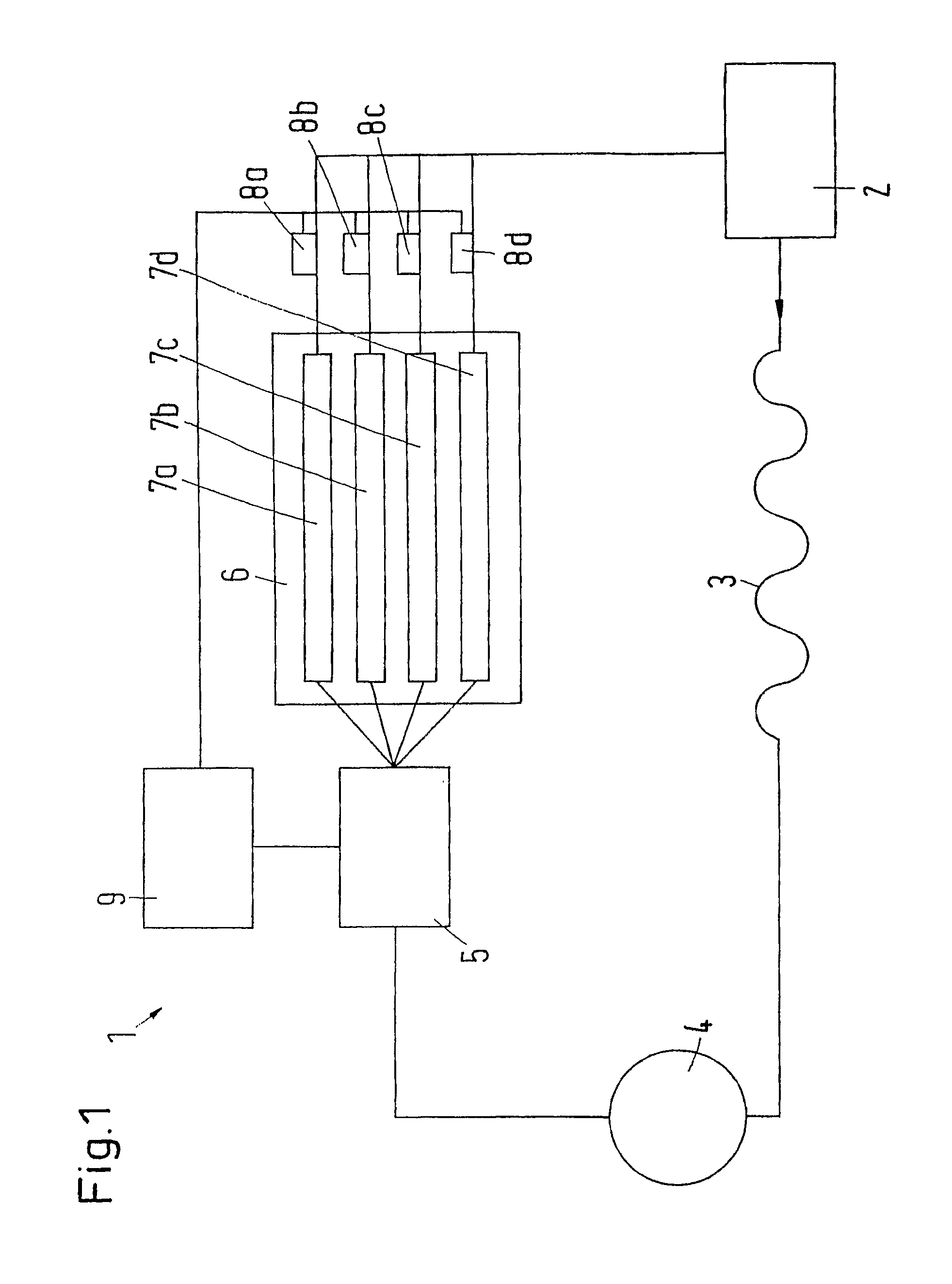

Electric circuits and power systems incorporating the same

ActiveUS20180254628A1Reduce probabilityAvoid problemsAc-dc conversionSingle network parallel feeding arrangementsElectric power systemPower grid

The invention relates to a power system with an electric circuit connected between a power grid and a power source. The electric circuit includes a main power converter having main input terminals connected to the power source 16 by a DC link and output terminals. The main power converter is controlled by a controller. The electric circuit includes a main transformer having a primary winding 8a and a secondary winding, the primary winding being connected to the output terminals of the main power converter. Main switchgear is connected between the secondary winding of the main transformer and the power grid. An auxiliary transformer has a primary winding connected to the power grid in parallel with the main switchgear and a secondary winding connected to the controller. A pre-charge circuit is connected between the auxiliary transformer and the DC link.

Owner:GE ENERGY POWER CONVERSION TECH

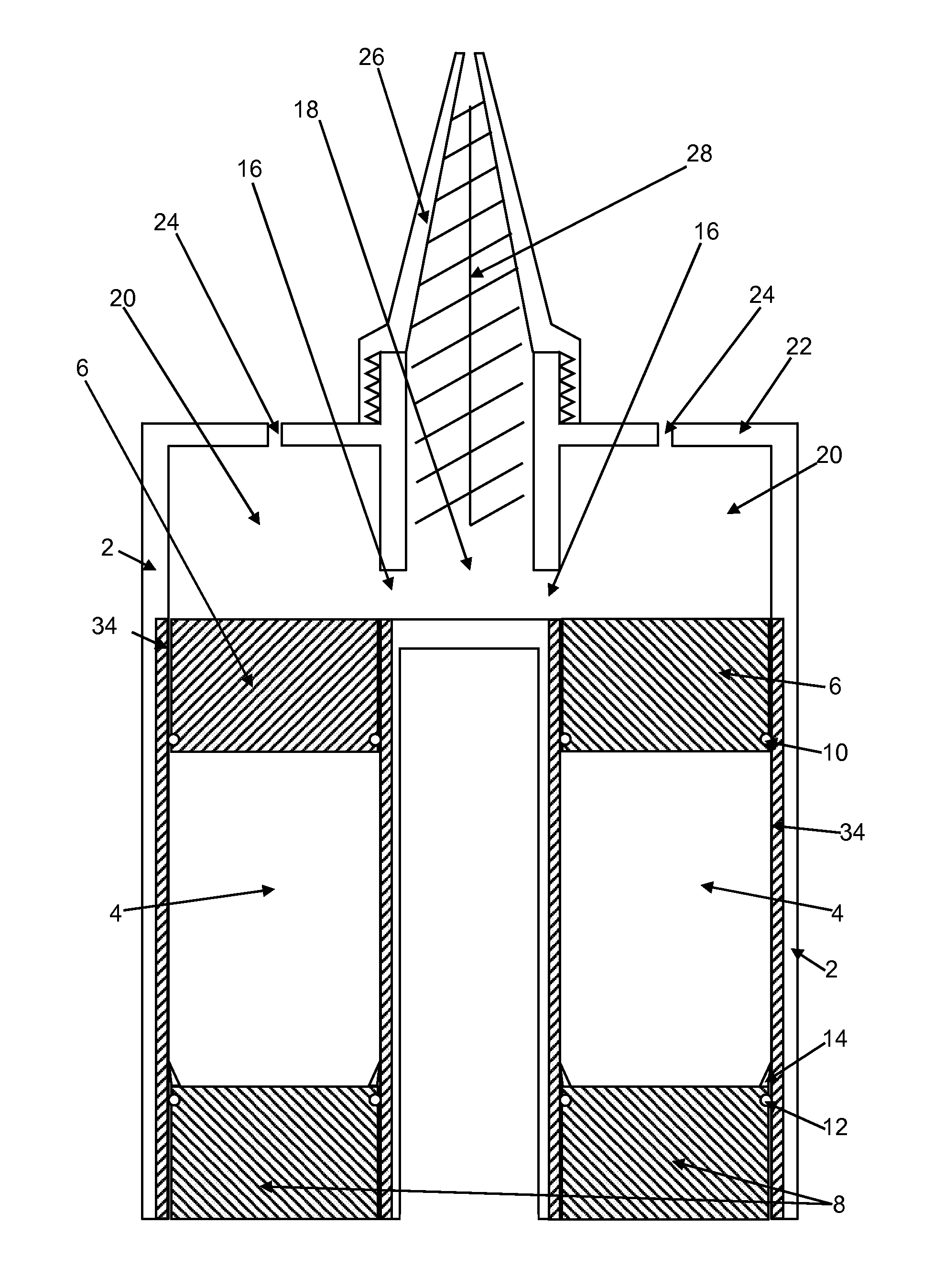

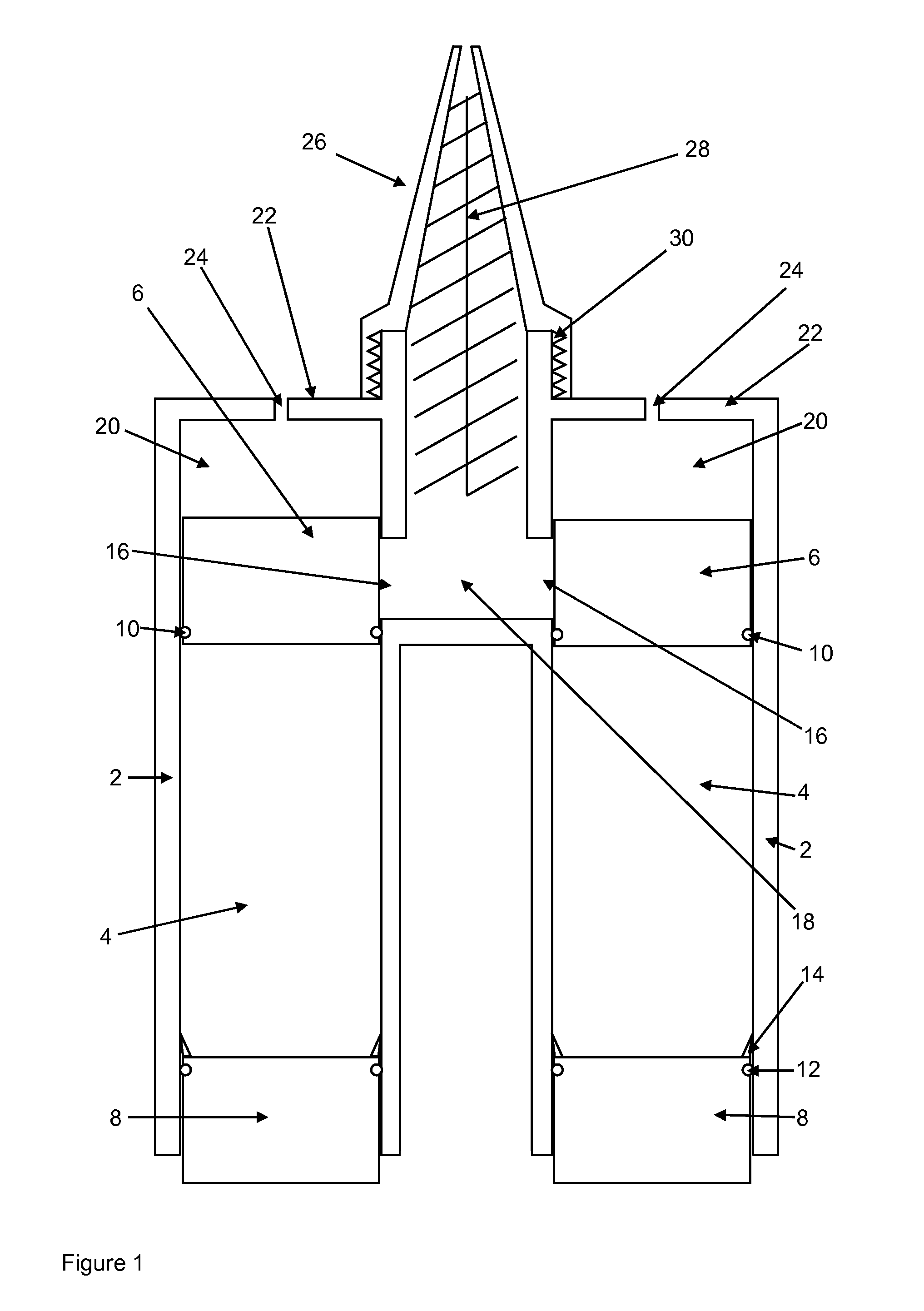

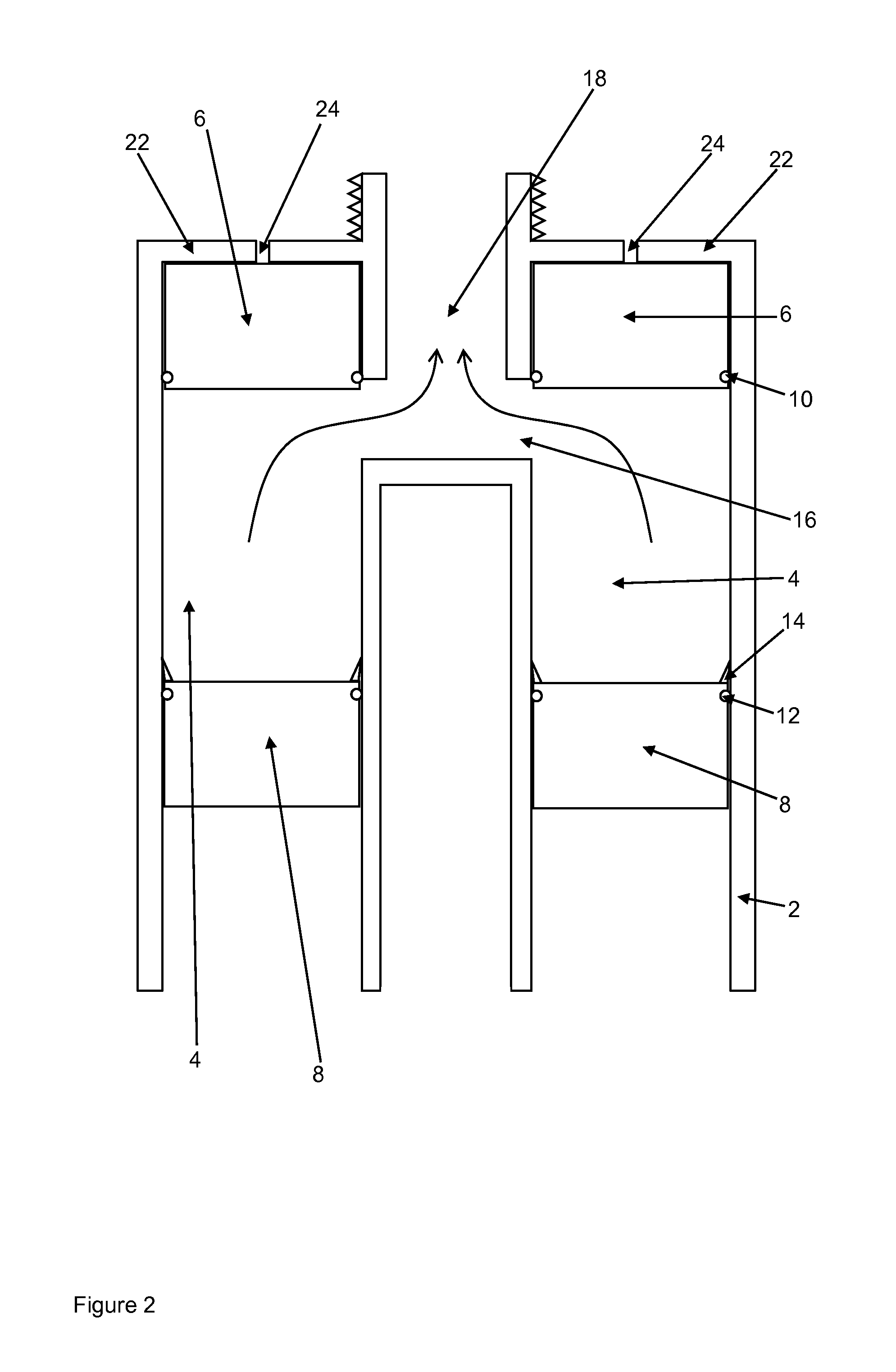

Cartridge system with rotatable closure and dispensing tube

ActiveUS8596499B2Reduces and overcomes shortcomingClose safeLiquid surface applicatorsTeeth fillingAxis of symmetryEngineering

Cartridge systems for application of a material have at least one cartridge having cartridge walls, a cartridge head having at least one opening in the cartridge head, and a bracket arranged on the cartridge head. A valve is mounted in rotatable manner in the bracket and has at least one passage through the valve that is connected to an outlet opening of the valve. In a closed position, the valve closes the at least one opening of at least one cartridge in a sealed manner. The at least one passage of the valve is connected to the at least one opening when the valve is located in an open position such that the cartridge content is squeezable out of the at least one cartridge through the outlet opening, and further wherein the valve is configured to be transitioned from a closed position to an open position through a rotation of the valve about an axis of symmetry of the valve.

Owner:HERAEUS MEDICAL

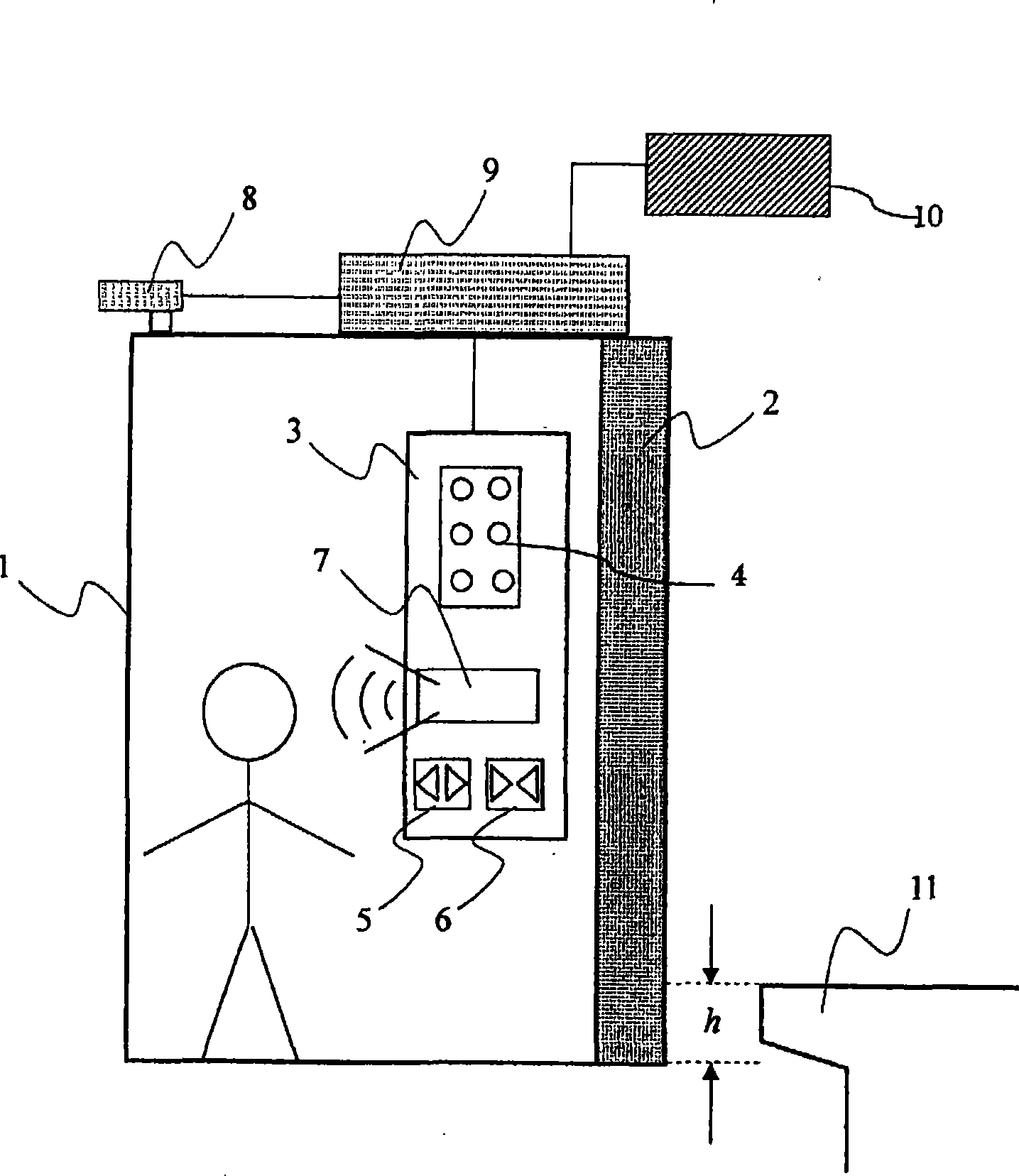

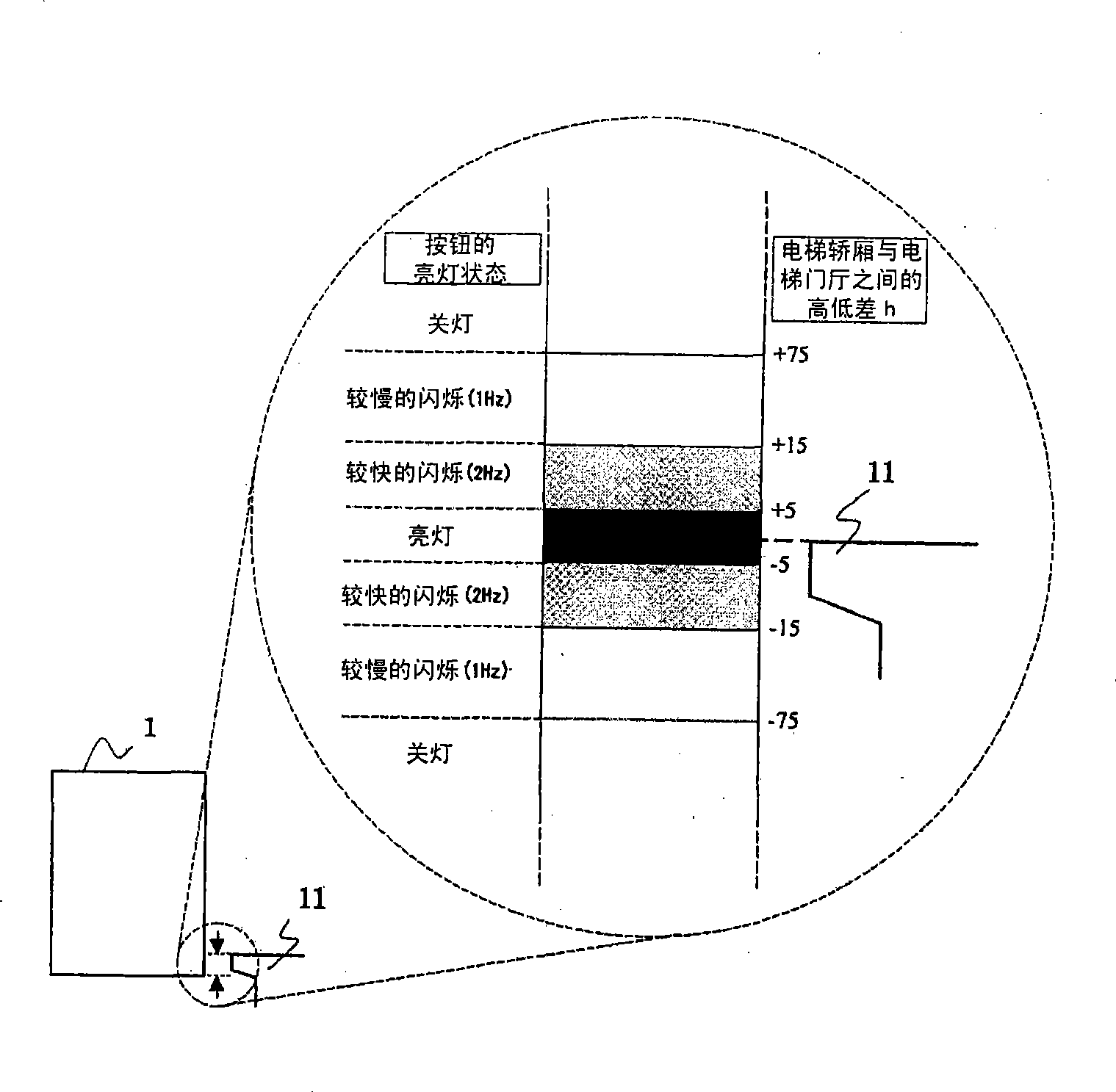

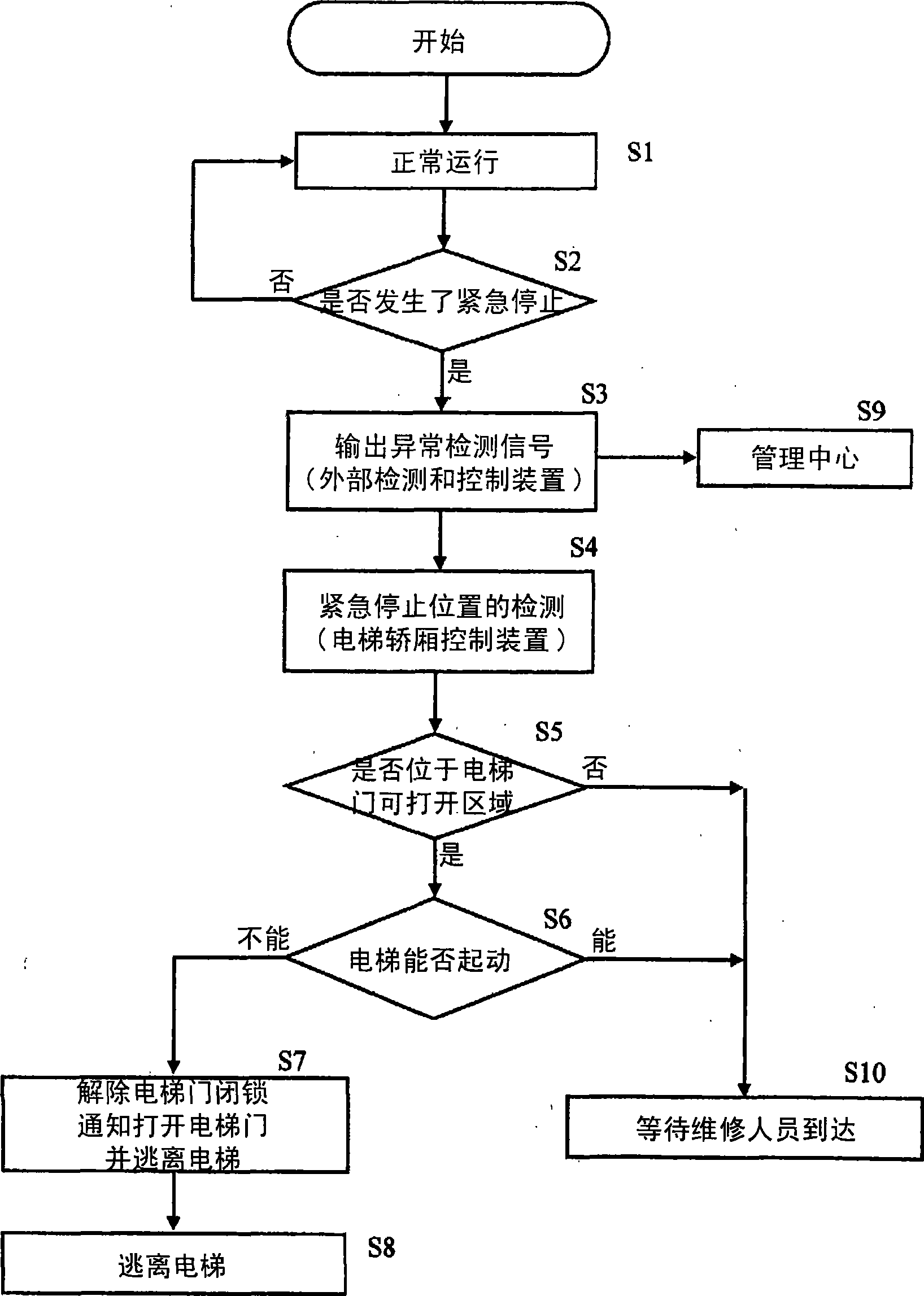

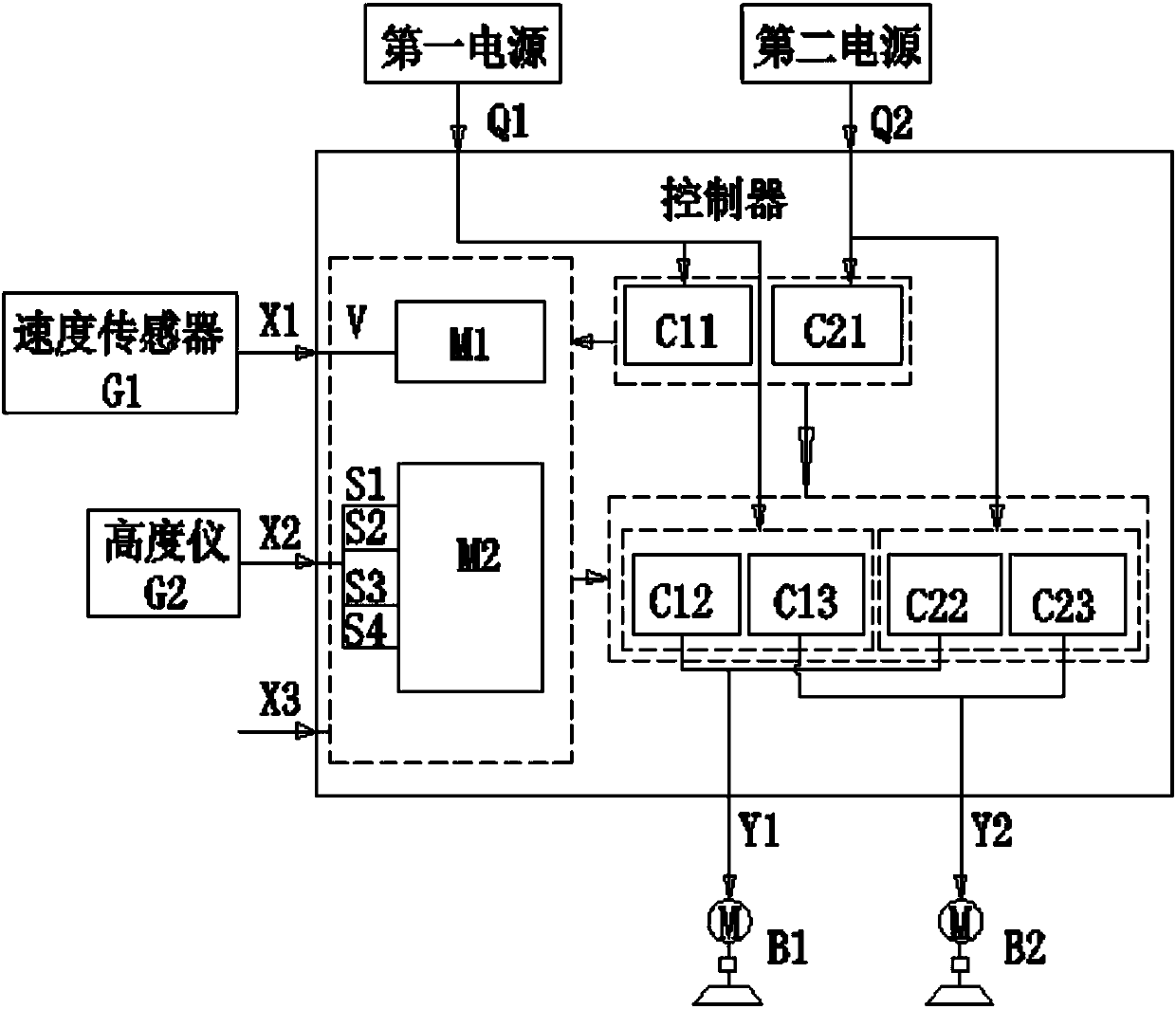

Elevator abnormality or fault control system

The present invention provides a control system for abnormity or fault of elevators, if the elevator cage emergently stops and passengers are in the case, and if the distance between the emergent stop place and the elevator door of the floor is in prescribed range, the system may open the door of elevator cage from inside without waiting for maintenance technician. The system detects emergent stop place; estimates whether the elevator is in state of capable of starting if the distance between the emergent stop place and the elevator door of the floor is in prescribed range; reliving the shut of the elevator door if the estimation result is that the elevator may not start; and informing passenger in the cage to open the elevator door and escape from the elevator.

Owner:HITACHI LTD +1

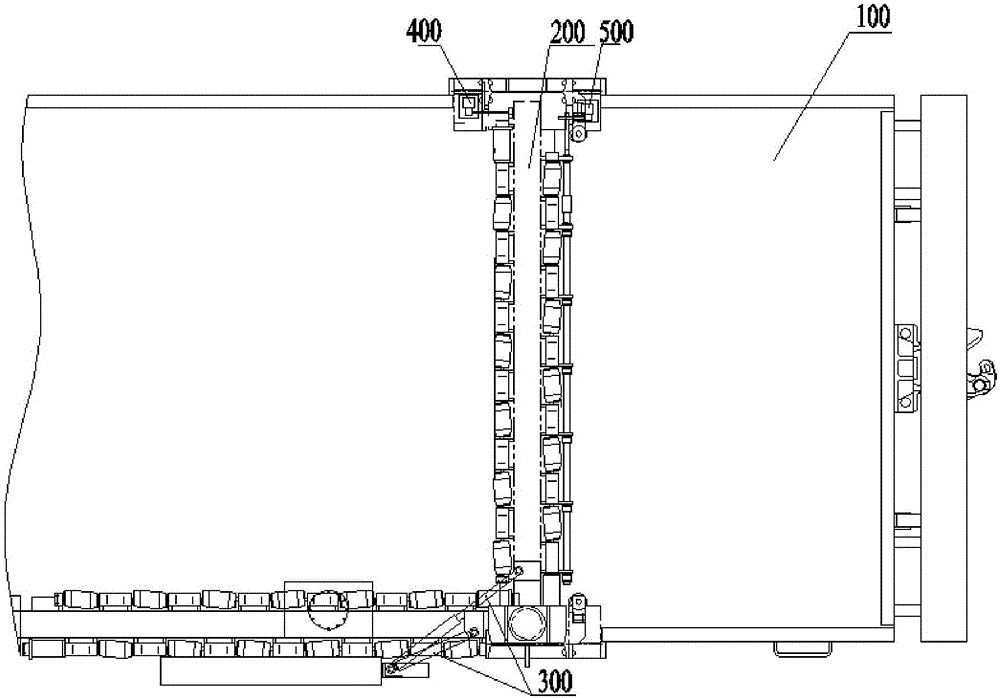

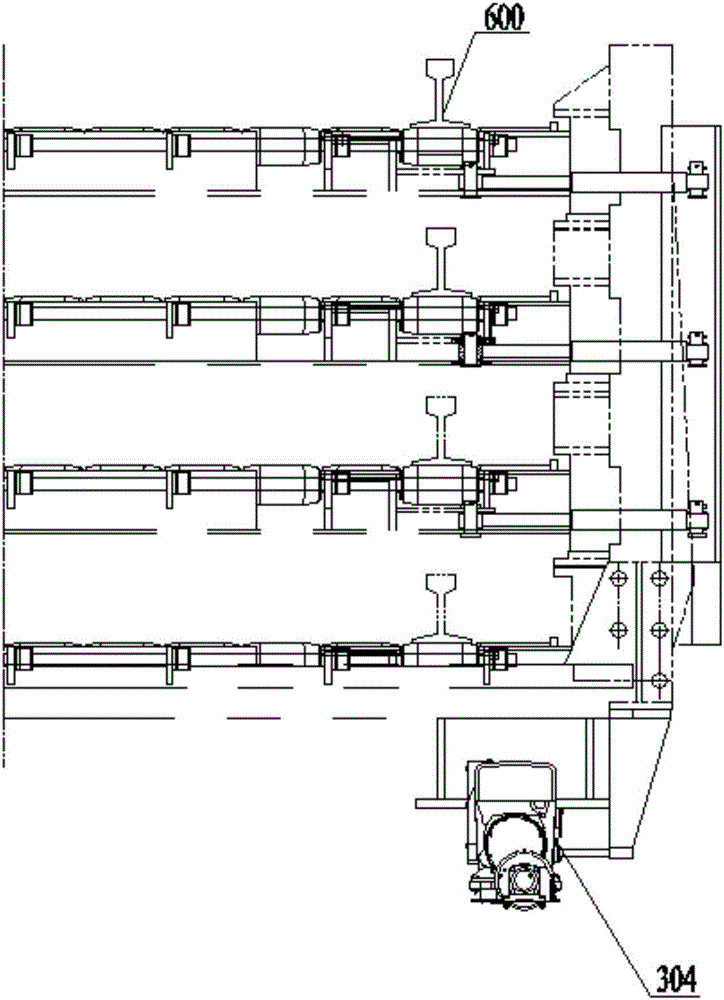

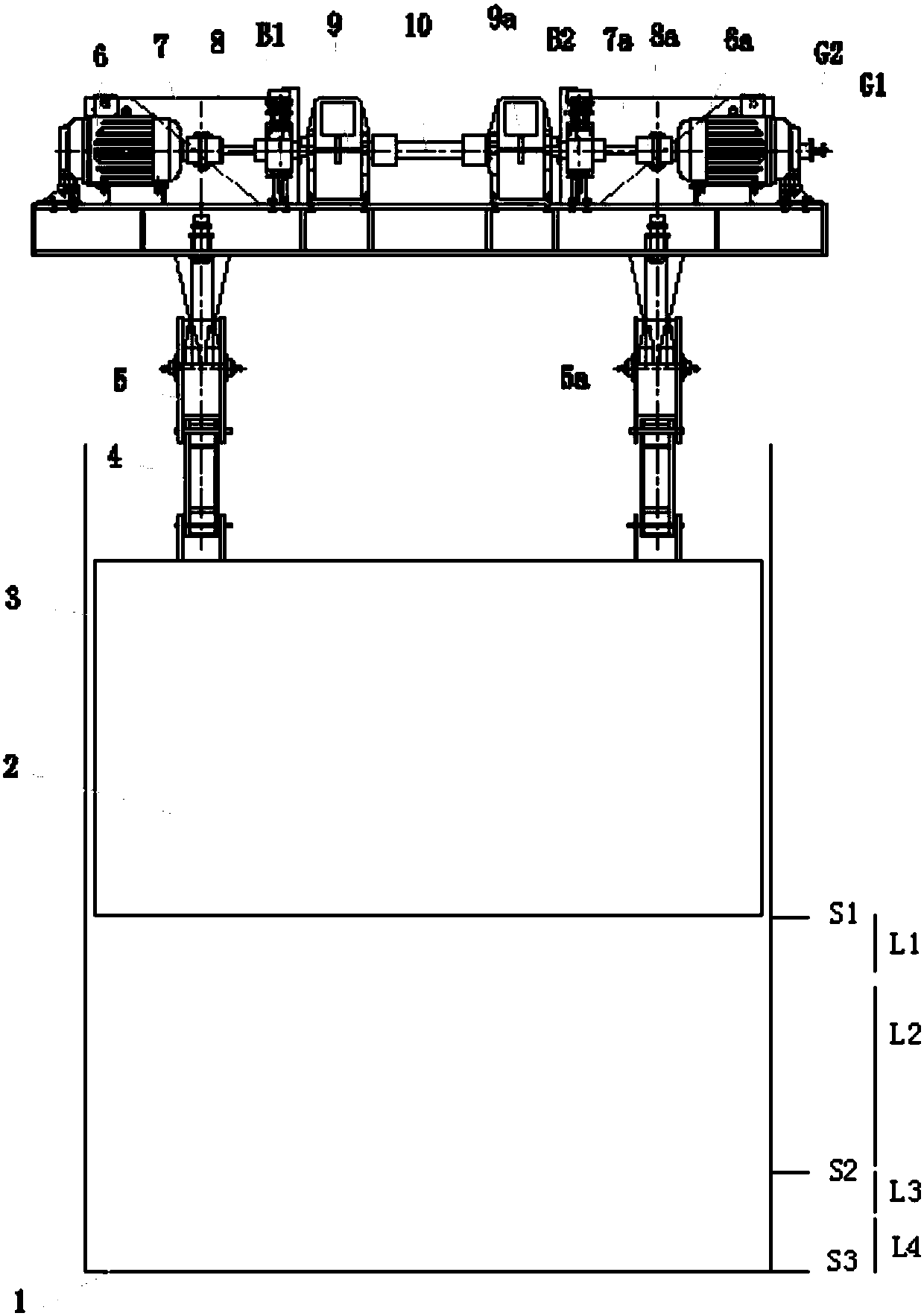

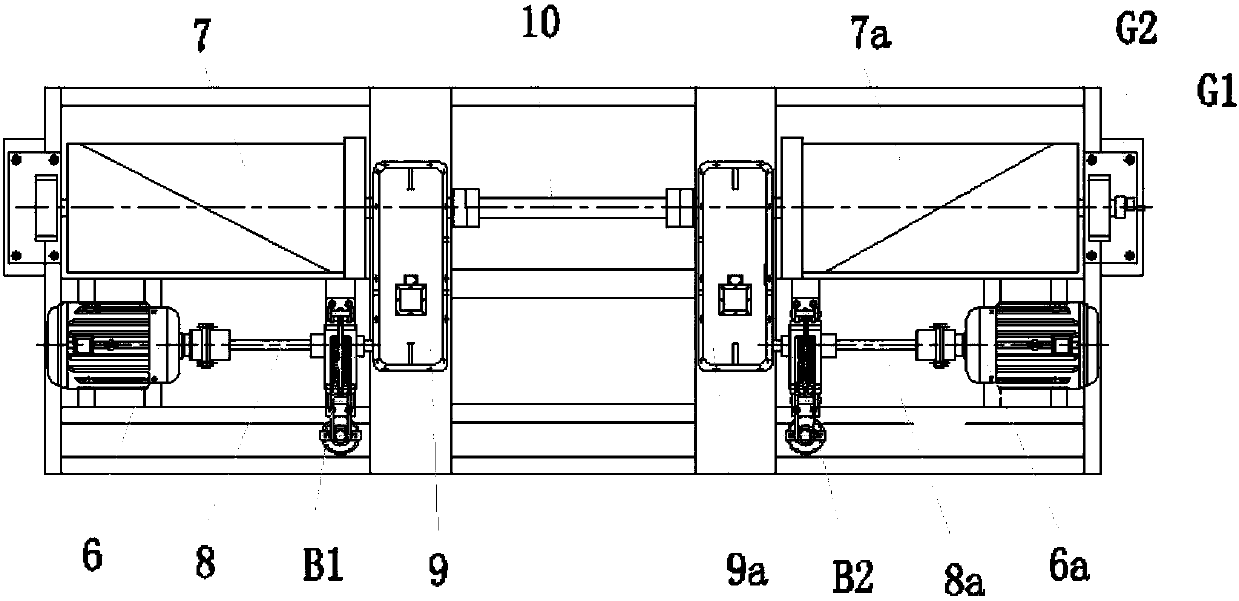

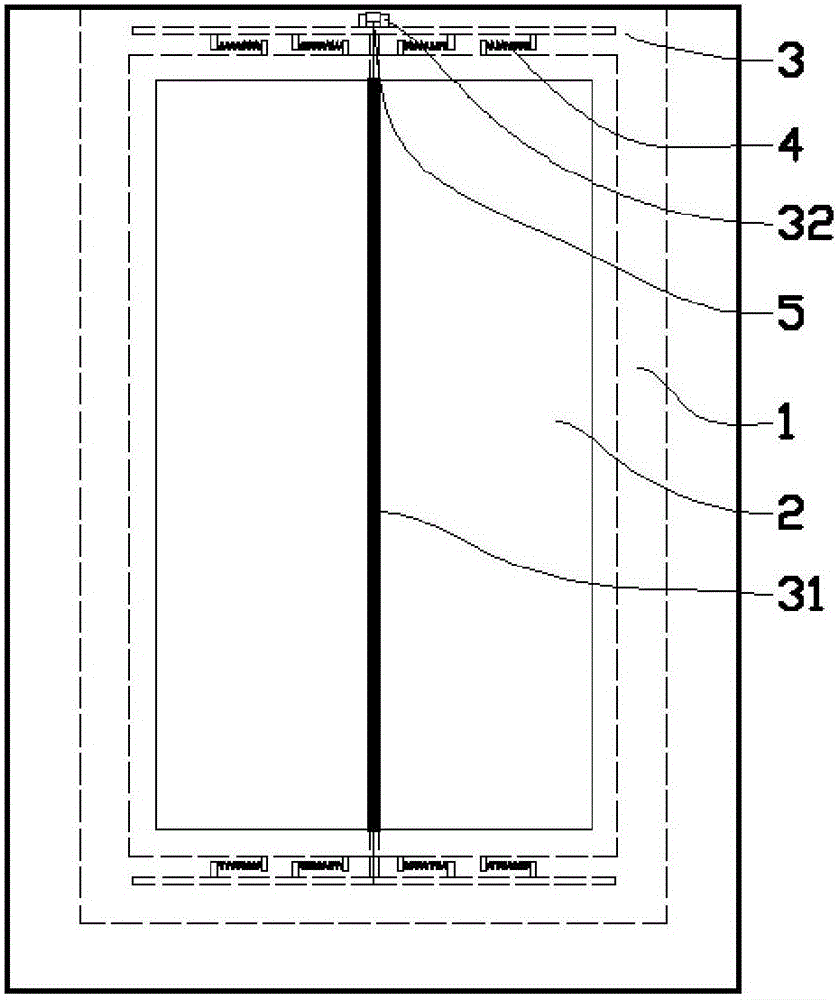

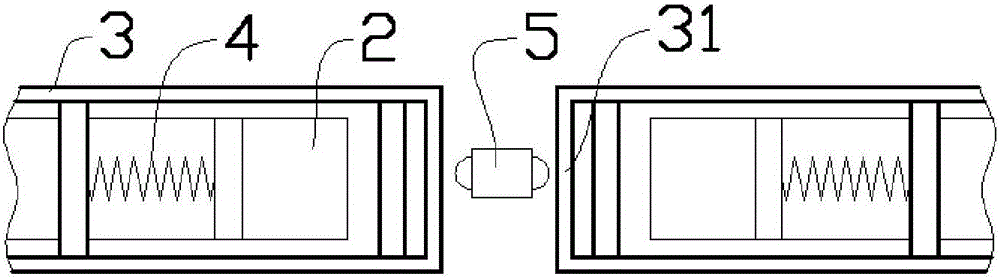

Rolling path beam opening and closing device and long steel rail transport train set

ActiveCN106515759ASafe and secure openingClose safeWagons/vansCargo supporting/securing componentsControl systemAutomation

The invention provides a rolling path beam opening and closing device and a long steel rail transport train set, and relates to manufacturing technologies of rail transport vehicles. The rolling path beam opening and closing device comprises a control system and an opening and closing mechanism. The control system is used for controlling the opening and closing device to open or close a rolling path beam. The long steel rail transport train set comprises a train body and the rolling path beam arranged on the train body, wherein the rolling path beam is provided with the opening and closing device, namely the mentioned rolling path beam opening and closing device. Due to the fact that the control system controls the opening and closing device to open or close the rolling path beam, automation of steel rail assembling and disassembling of the long steel rail transport train set can be achieved easily, opening and closing of the rolling path beam are safer and more reliable, the working intensity of operation personnel can be greatly relieved, and operation efficiency is improved.

Owner:CRRC SHENYANG CO LTD

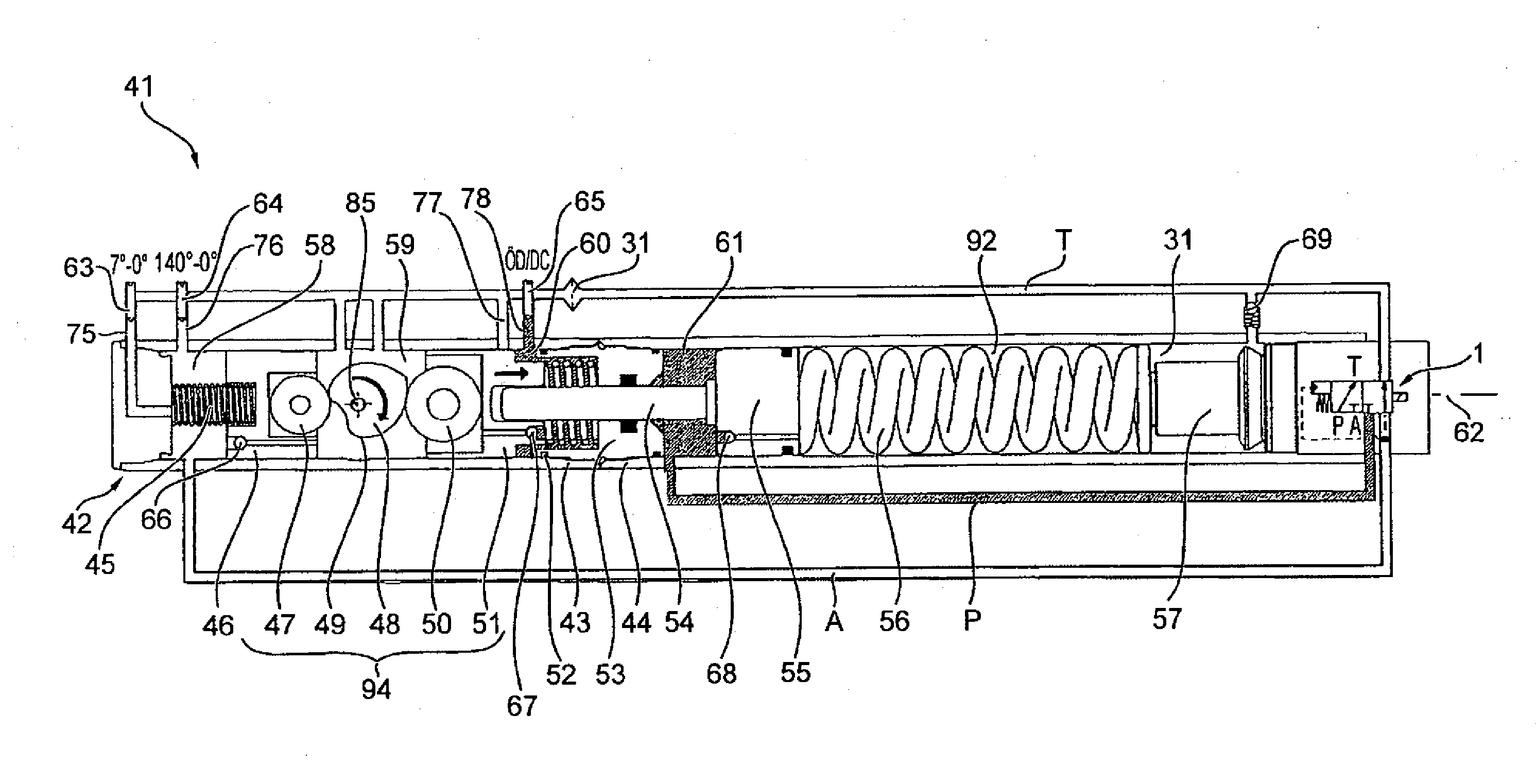

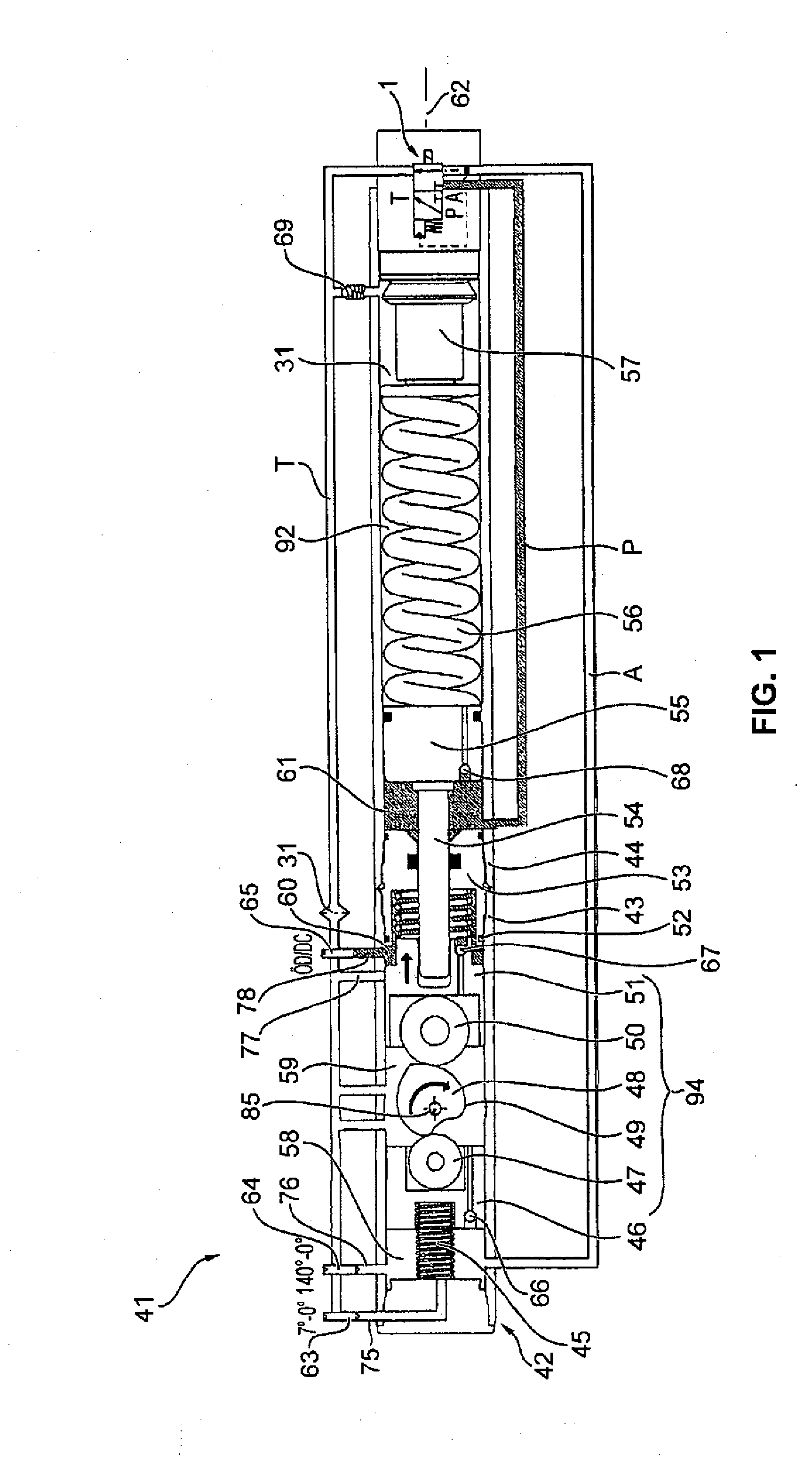

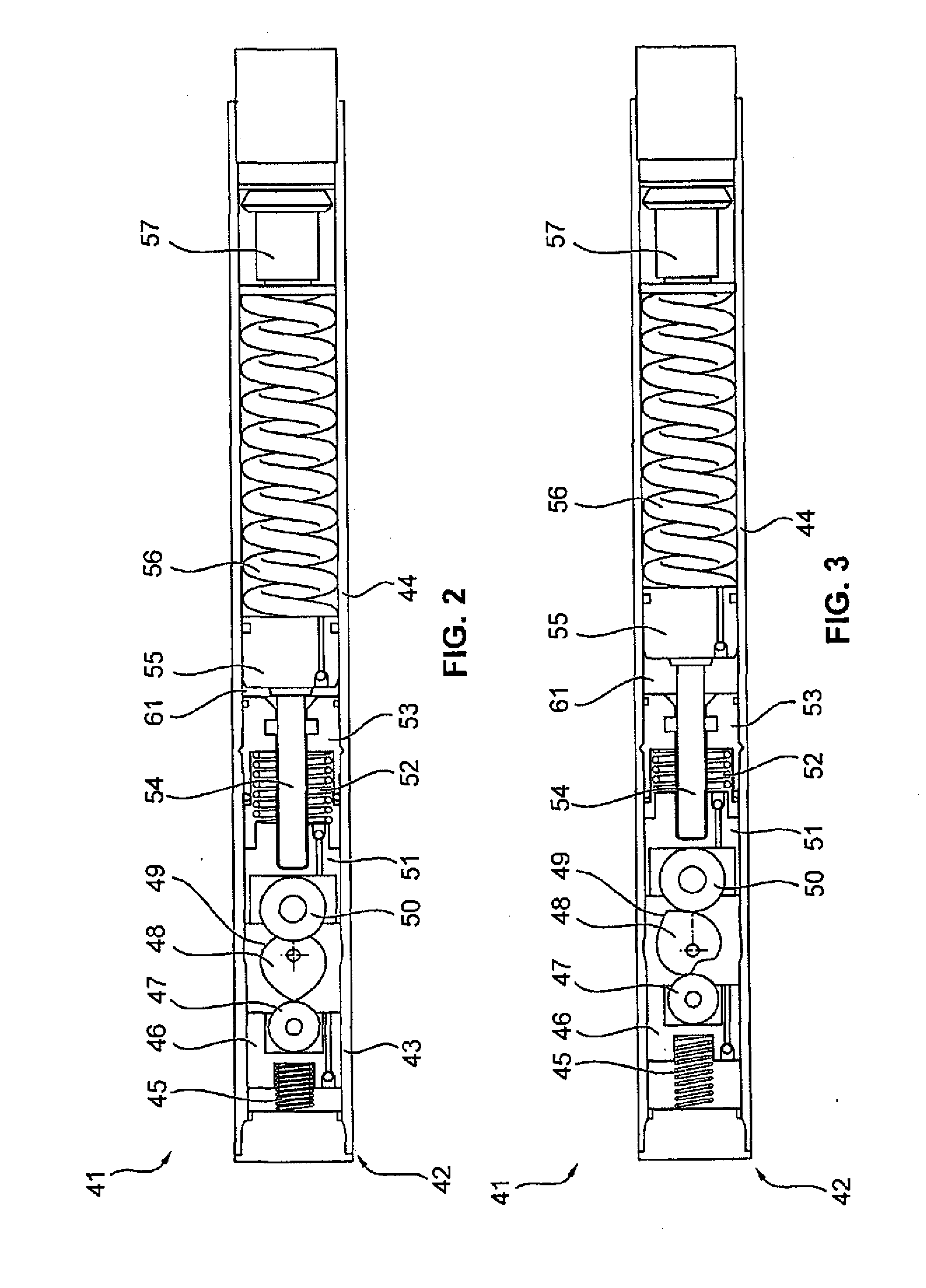

Door closer comprising device for preventing a spring-back

ActiveUS20120240351A1Slender structureReduce manufacturing costOperating means/releasing devices for valvesBuilding braking devicesEngineeringCheck valve

A door closer, in particular a hinge door closer, including a locking function or free-swing function, having a door closer housing, an output shaft to be connected to a door, a piston assembly connected to the output shaft and guided in the door closer housing, a closer spring, a piston rod adapted to connect the piston assembly to the closer spring, a hydraulic lock compartment adapted to lock the closer spring, and a spring-loaded check valve arranged between the lock compartment and a space becoming smaller during the opening process of the door, in particular an accommodating space for the closer spring. The spring-loaded check valve locks toward the space becoming smaller.

Owner:DORMAKABA DEUT GMBH

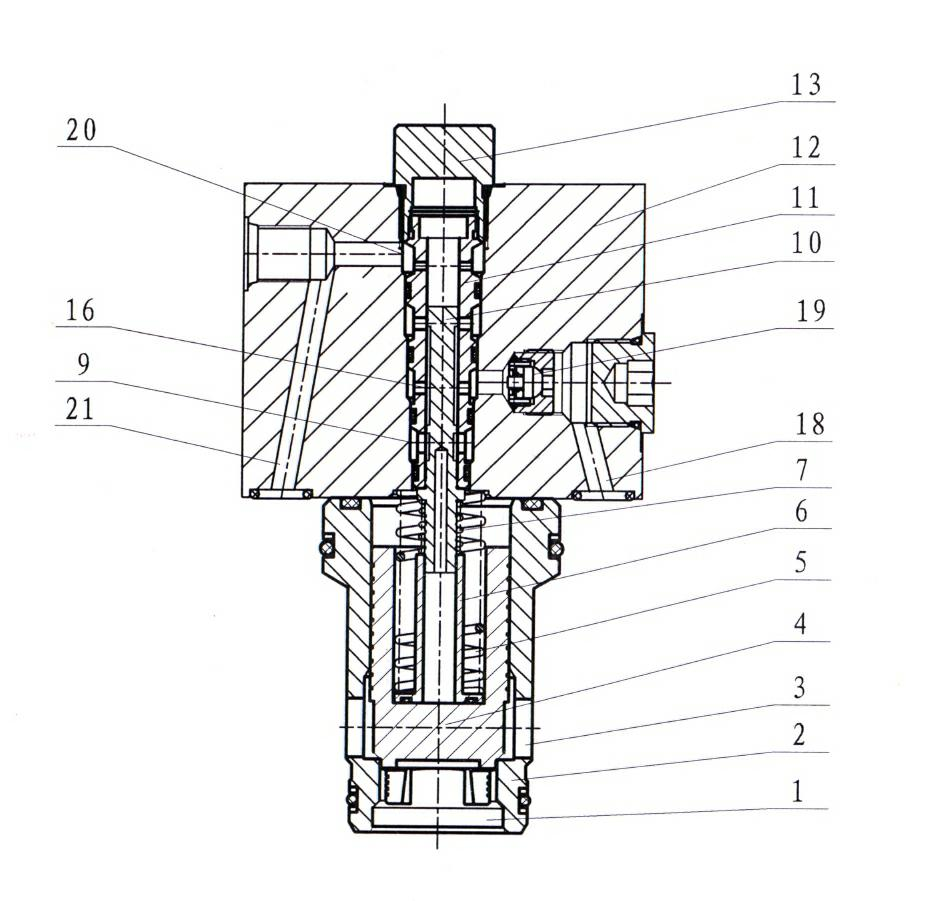

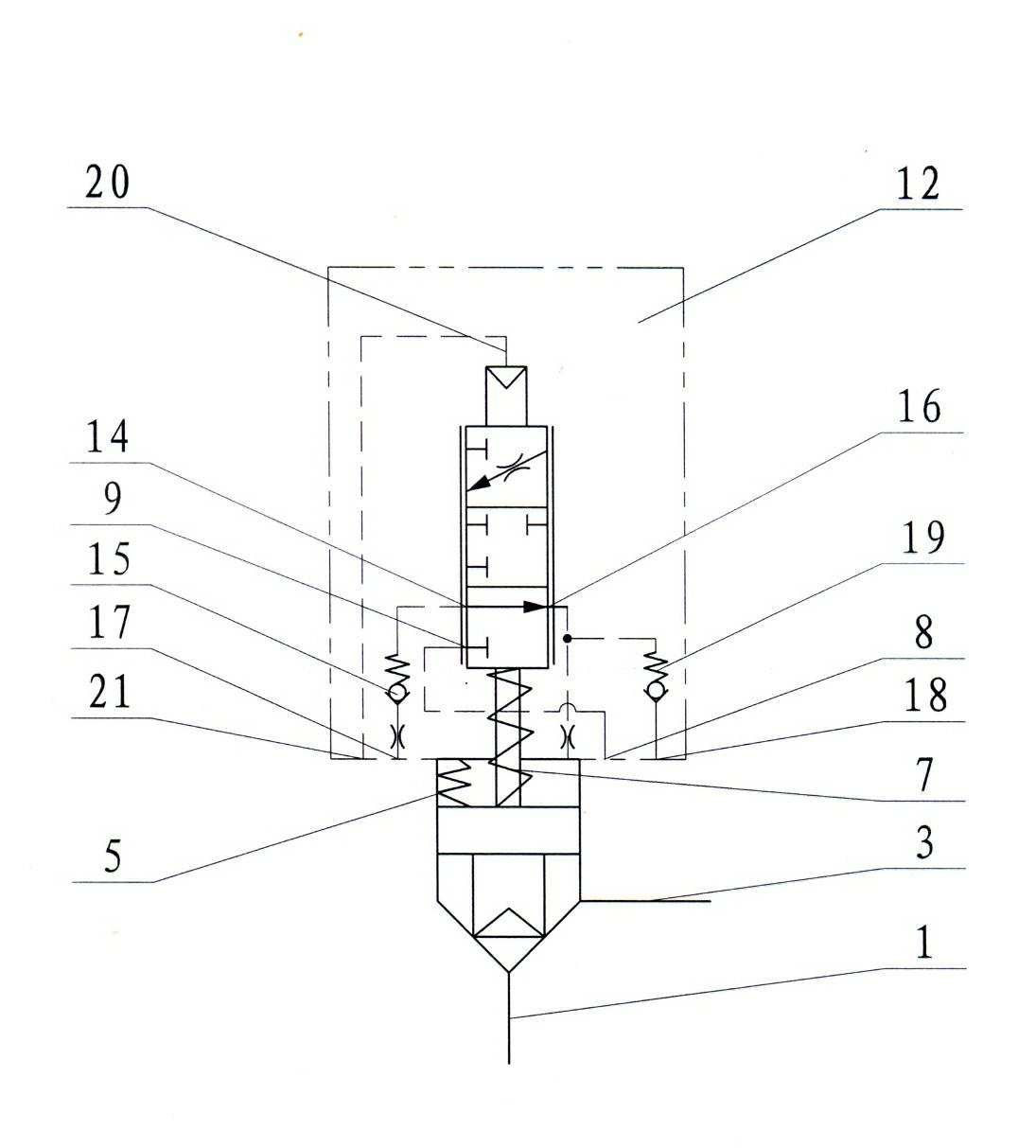

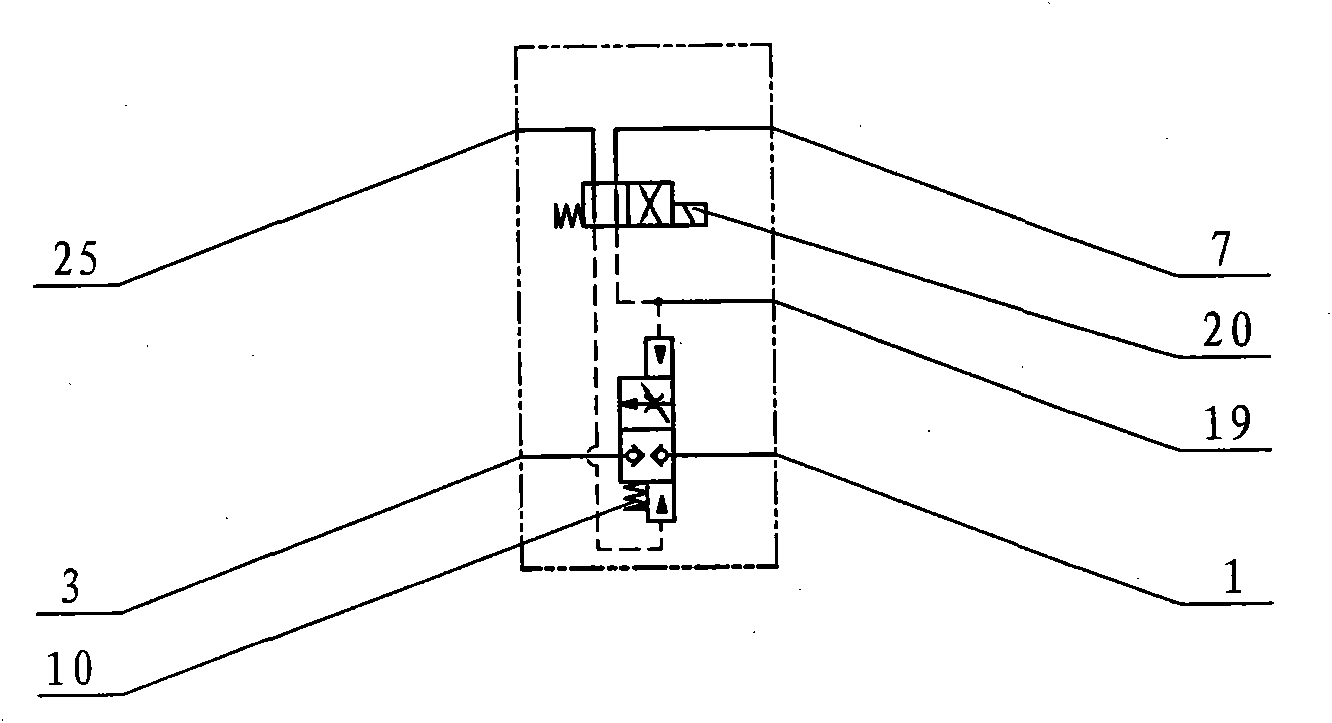

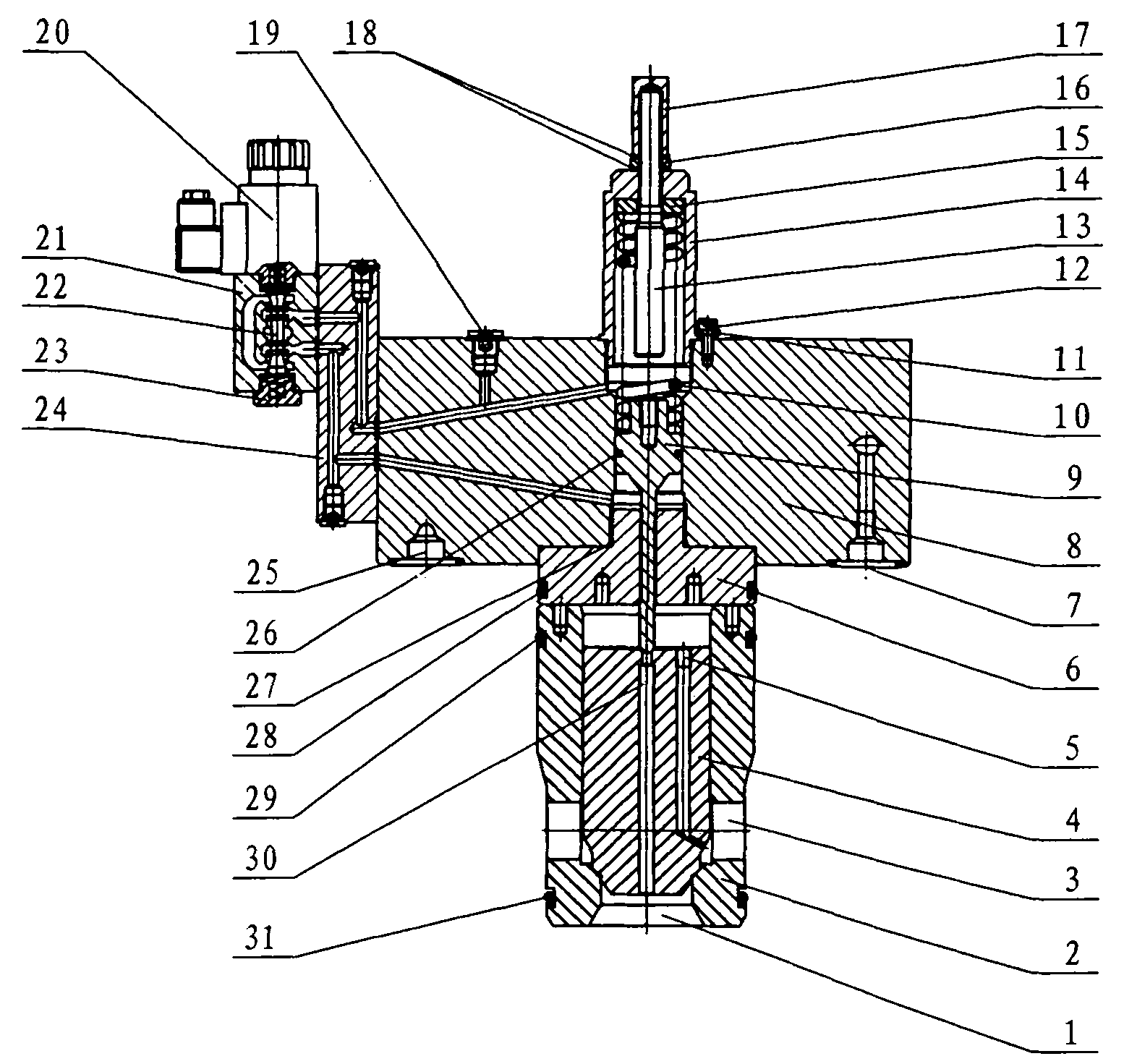

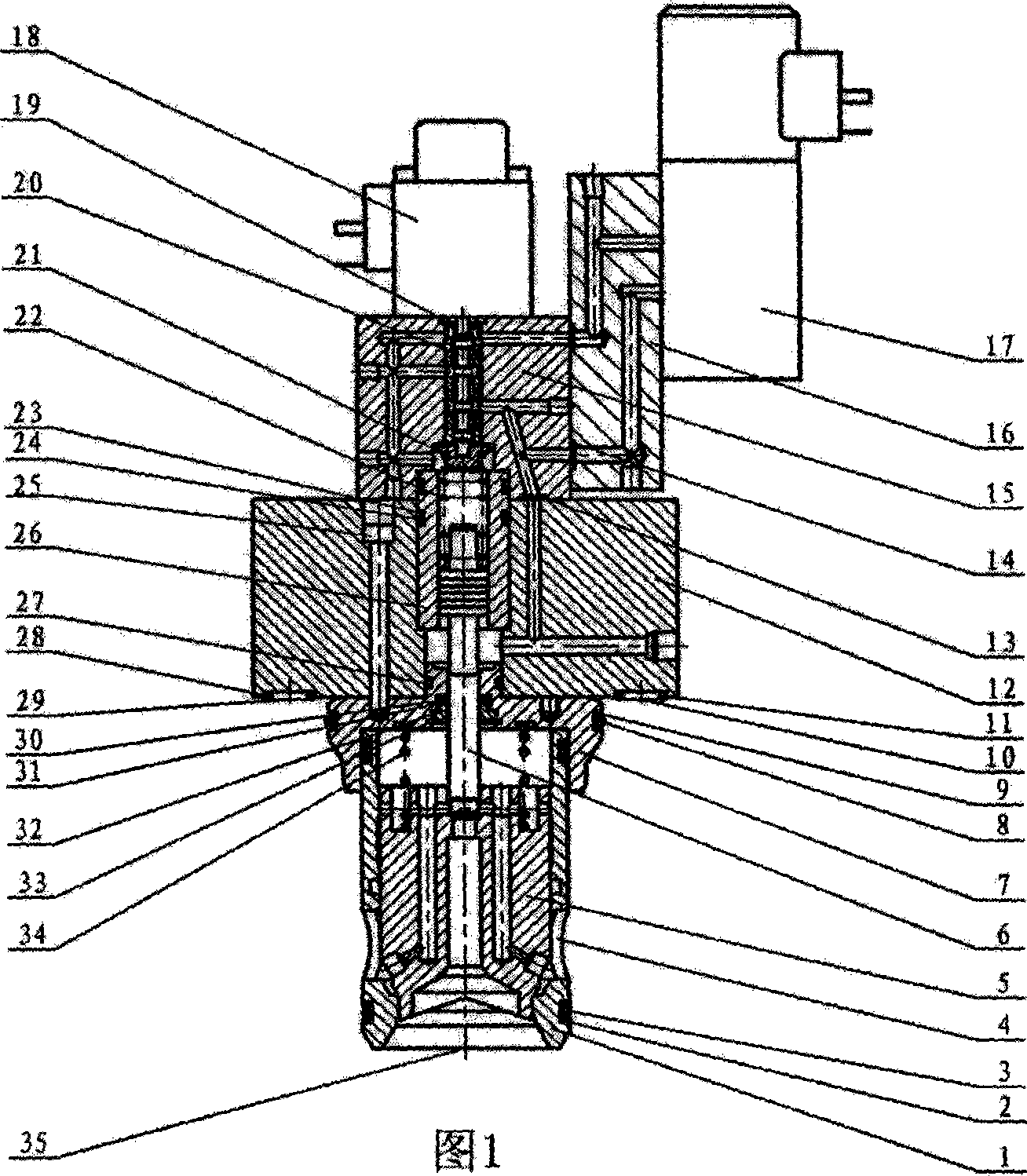

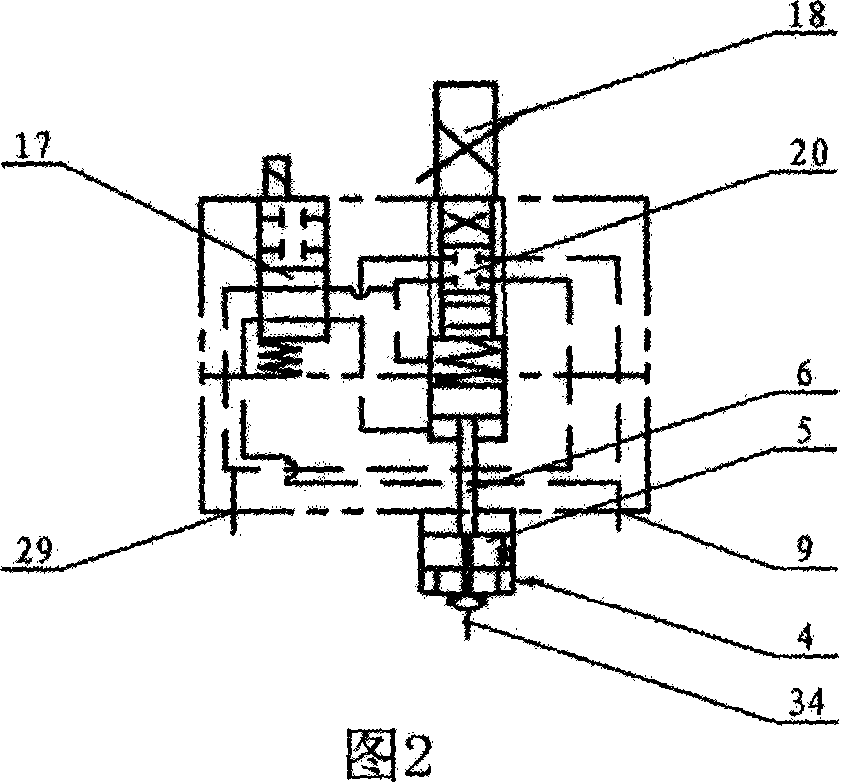

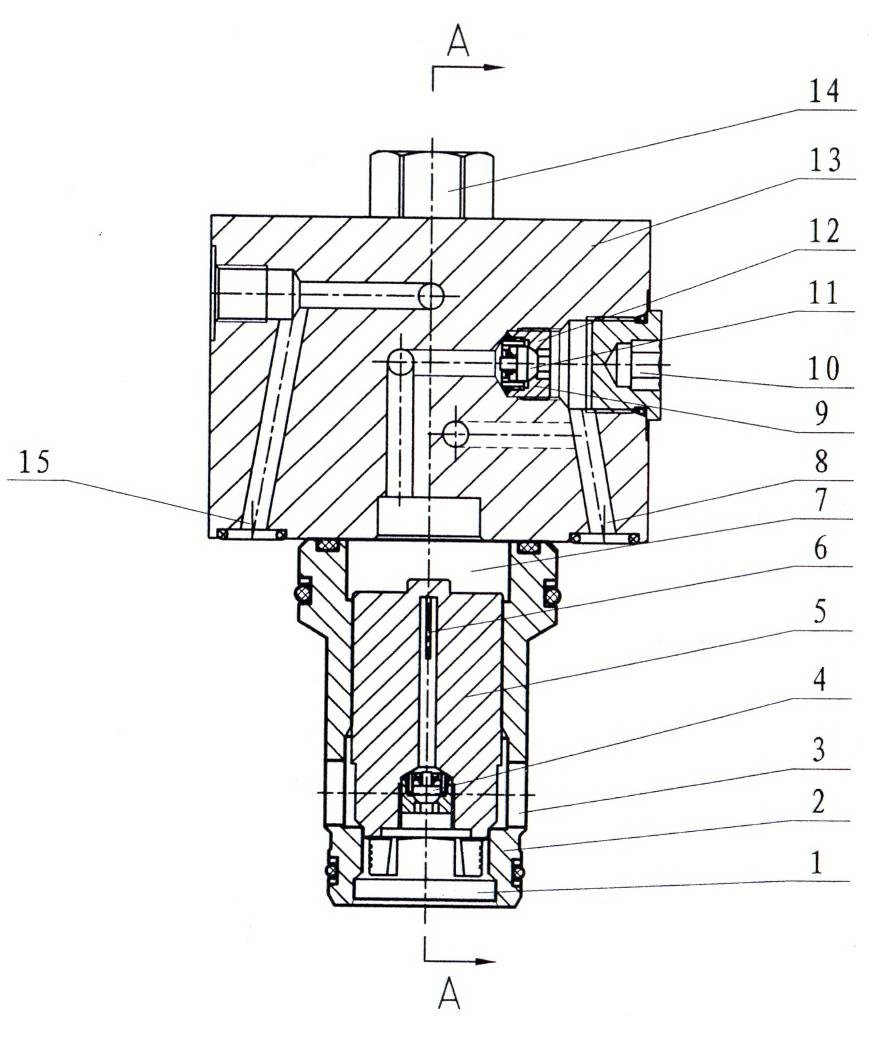

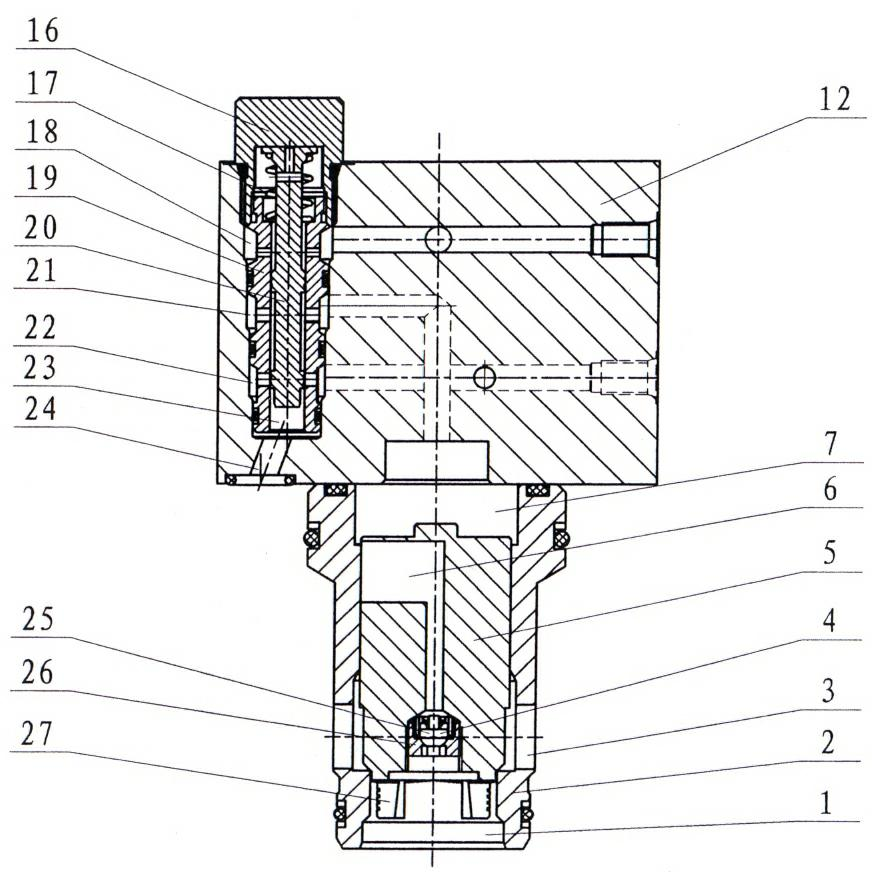

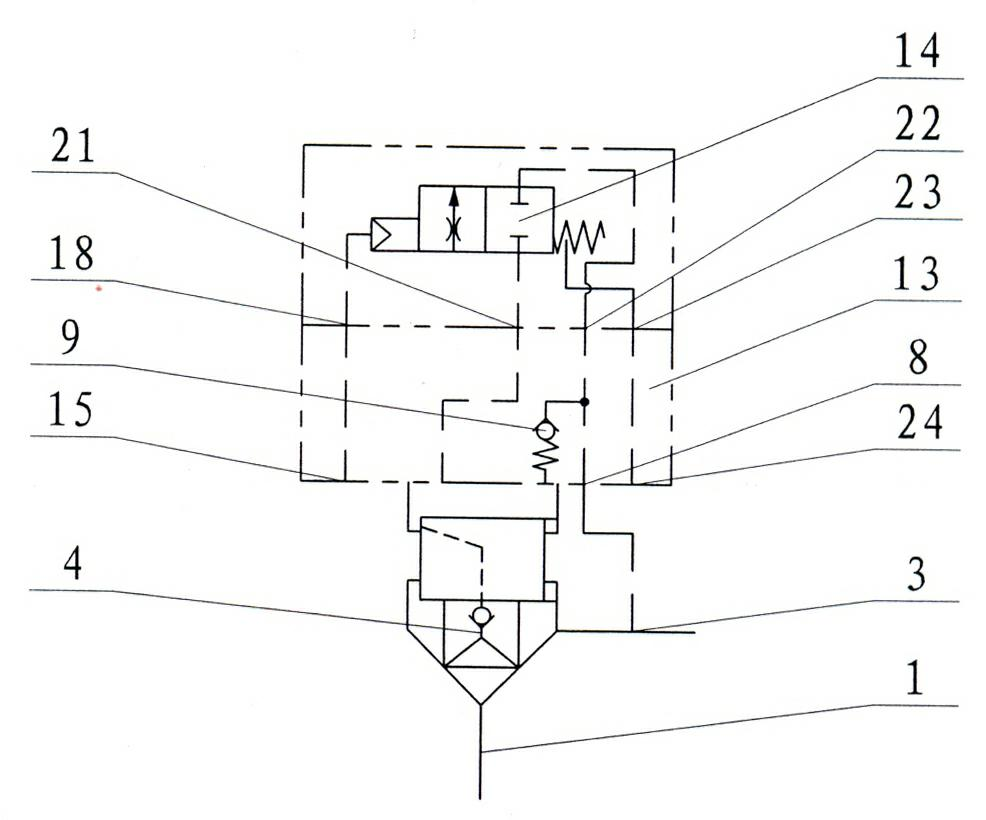

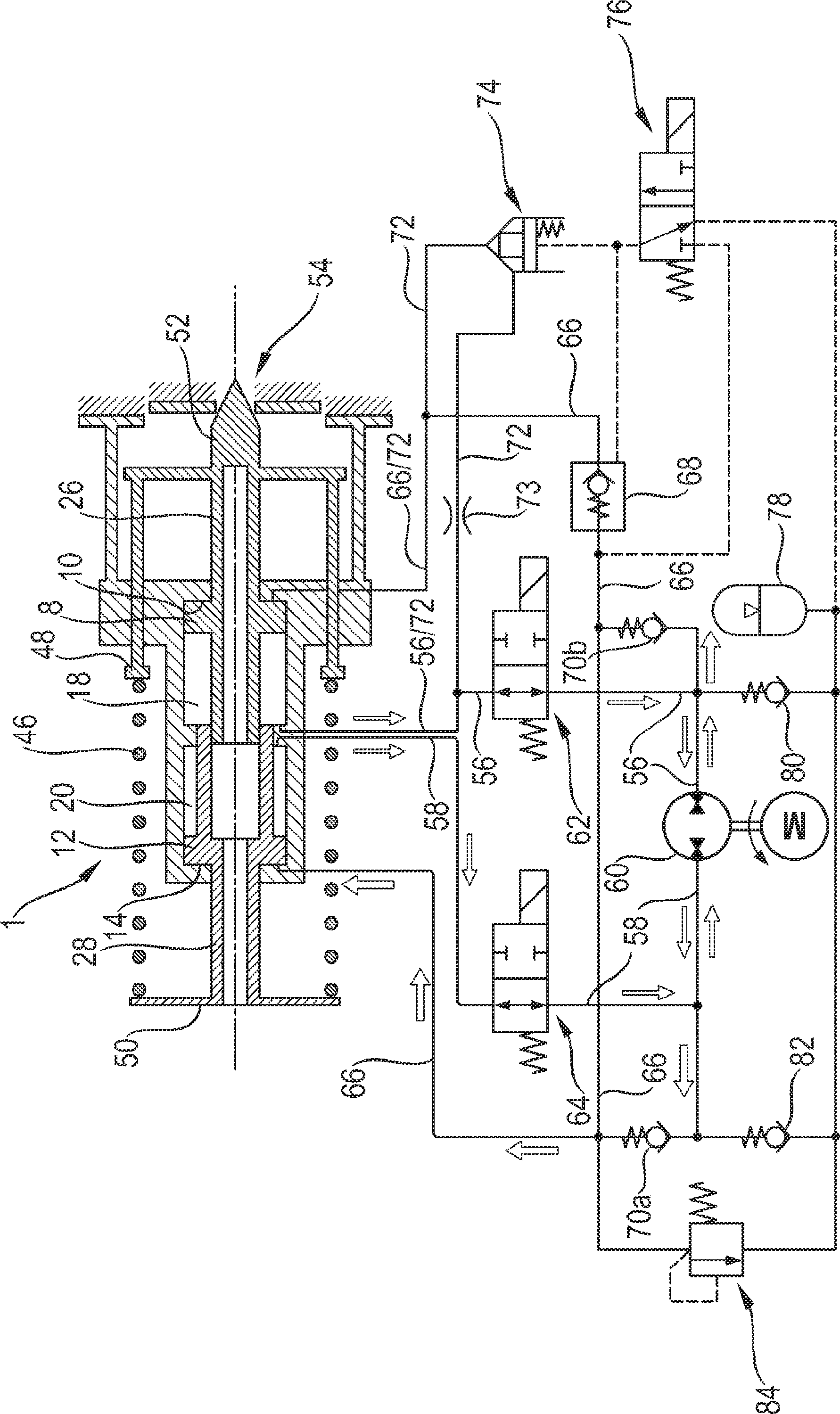

Large-flow mechanical feedback pilot control plug-in type proportional throttling valve system

InactiveCN102221024AClose safeSafe and reliable openingServomotor componentsHysteresisClosed loop feedback

The invention relates to a large flow mechanical feedback pilot control plug-in type proportional throttling valve system and in particular relates to forward and reverse flowing throttling valve system engineering machinery equipment. The system is characterized in that the side of a main valve sleeve is provided with a main valve oil inlet and a main valve oil outlet, a back-moving spring is arranged between a main valve core and a guide sleeve, one end of a pilot valve sleeve is provided with a screw cover, a device feedback spring is arranged between the guide valve core and the guide sleeve, a first control port is communicated with one end of a first check valve, the other end of the first check valve is communicated with a pilot valve oil inlet, a second control port is communicated with one end of a second check valve, the other end of the second check valve is communicated with a pilot valve work port, the pilot valve oil inlet is communicated with the pilot valve work port, a third control port is communicated with a guide valve control port, the guide valve return opening is communicated with the guide sleeve and a cover plate return opening. The throttling valve system provided by the invention has the advantages of simple structure, instantaneous open, high linearity and small hysteresis based on the adopted mechanical closed loop feedback, thus the throttling valve system can be widely applied to a hydraulic control system of engineering machinery, machine tool casting-forging, diecast metallurgy, shipping and mine industry.

Owner:SHANDONG TAIFENG INTELLIGENT CONTROL CO LTD

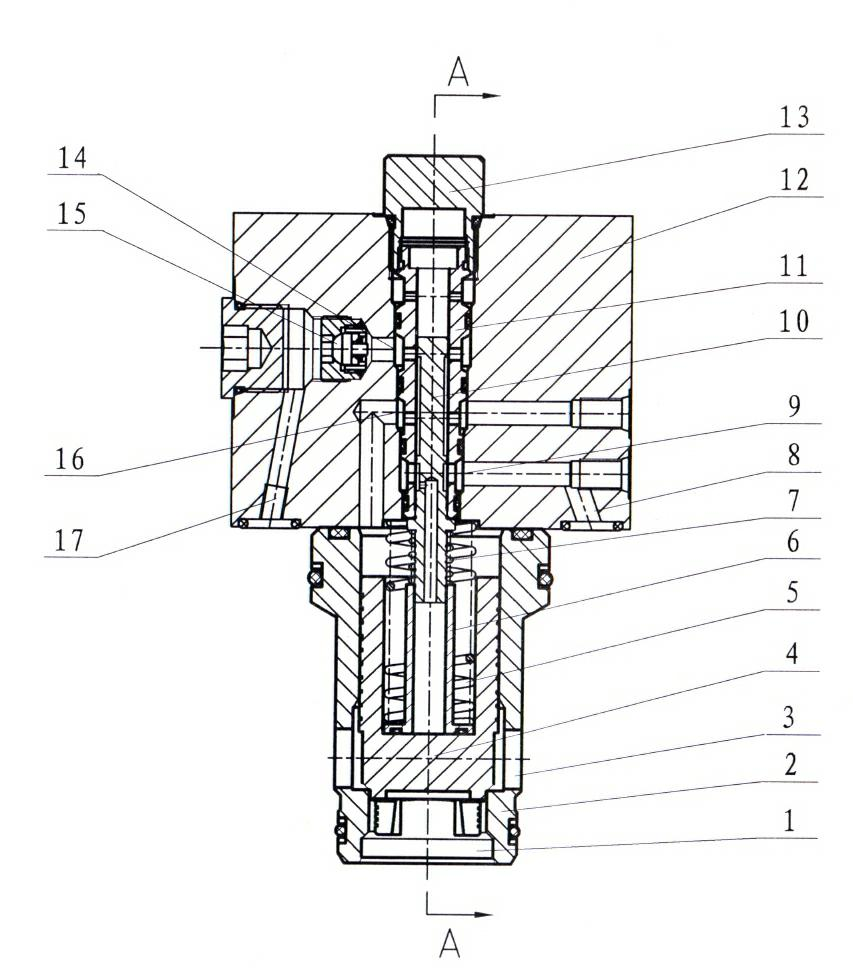

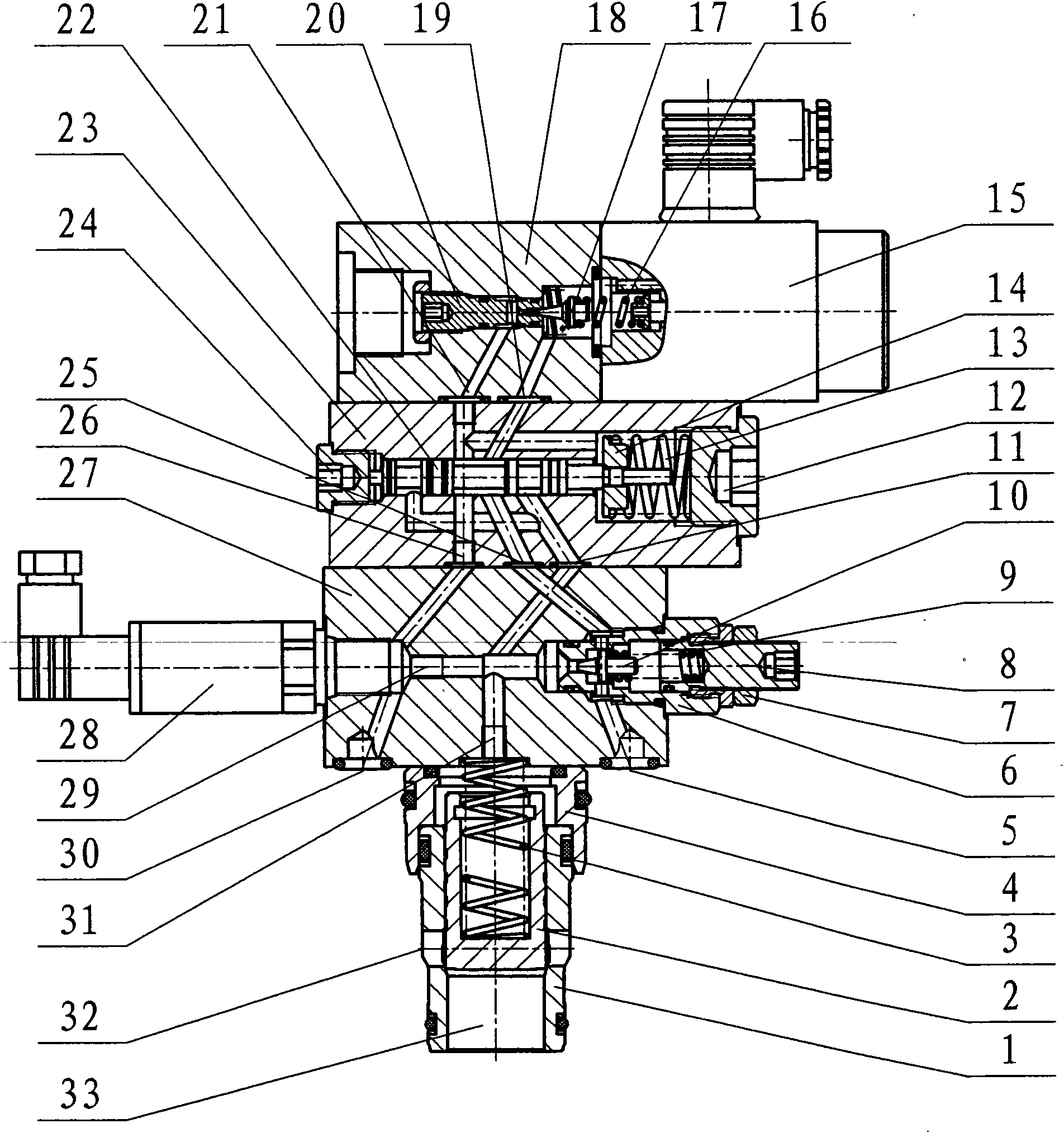

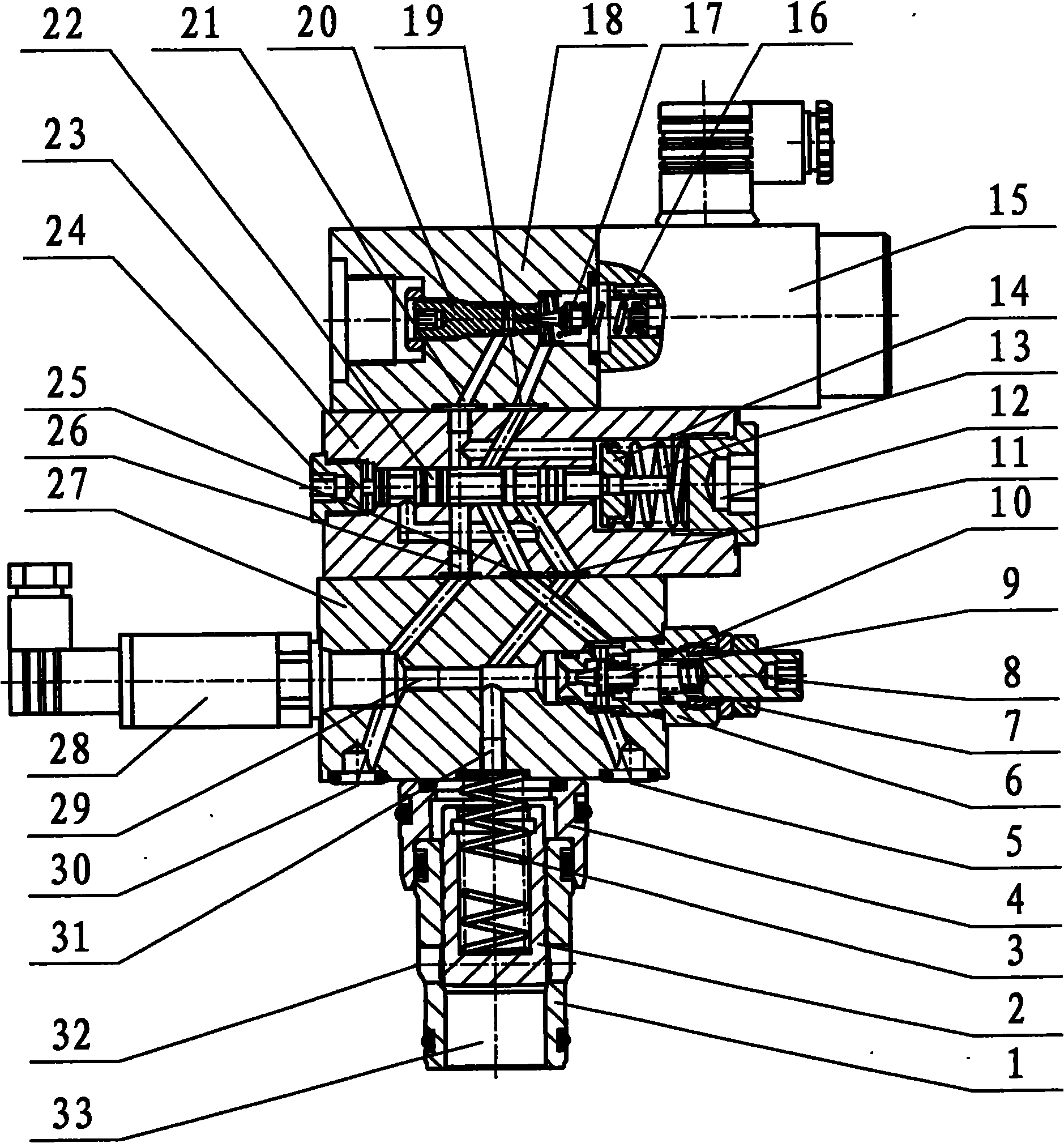

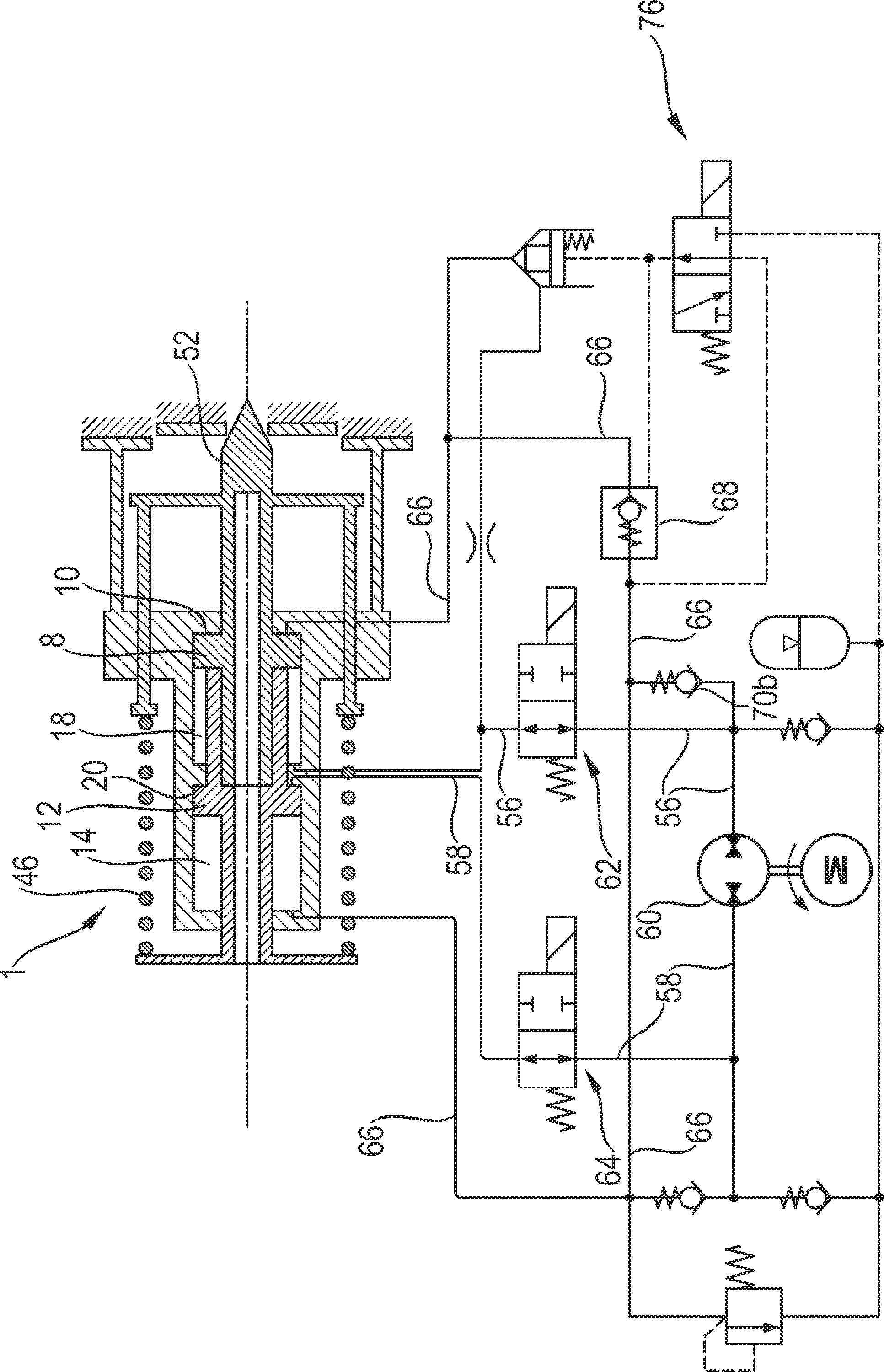

Low-pressure pilot control high-flow superhigh-pressure hydraulic cartridge valve system

The invention relates to a low-pressure pilot control high-flow superhigh-pressure hydraulic cartridge valve system, in particular to a low-pressure pilot control high-flow superhigh-pressure hydraulic cartridge valve system device. The system is characterized in that a master valve core is arranged in the axial hole of a valve bush; the middle of the master valve core is provided with a through hole which is communicated with the oil outlet of a master valve; a piston rod is arranged in the axial hole of a control cover plate; a top cover is arranged between the piston rod and the valve bush; the other end of the piston rod is provided with a return spring; the other end of the return spring is provided with a spring seat; the other end of the spring seat is provided with a threaded sleeve; one end of the threaded sleeve is provided with a bonded washer and a locking nut; the side face of the control cover plate is provided with a pressure tap, a control orifice and an oil return orifice; holes in a transition plate and the control cover plate are communicated with one end of the piston rod; and the other side of a pilot valve body is provided with a threaded plug. The system provided by the invention is simple in structure, can be opened instantaneously, and can be closed in a safe and reliable way; the pilot stage is controlled by low pressure to realize the superhigh-pressure control; and the system provided by the invention can be widely used in hydraulic control systems in machine tool die-casting and forging metallurgy, ships and mining.

Owner:SHANDONG TAIFENG INTELLIGENT CONTROL CO LTD

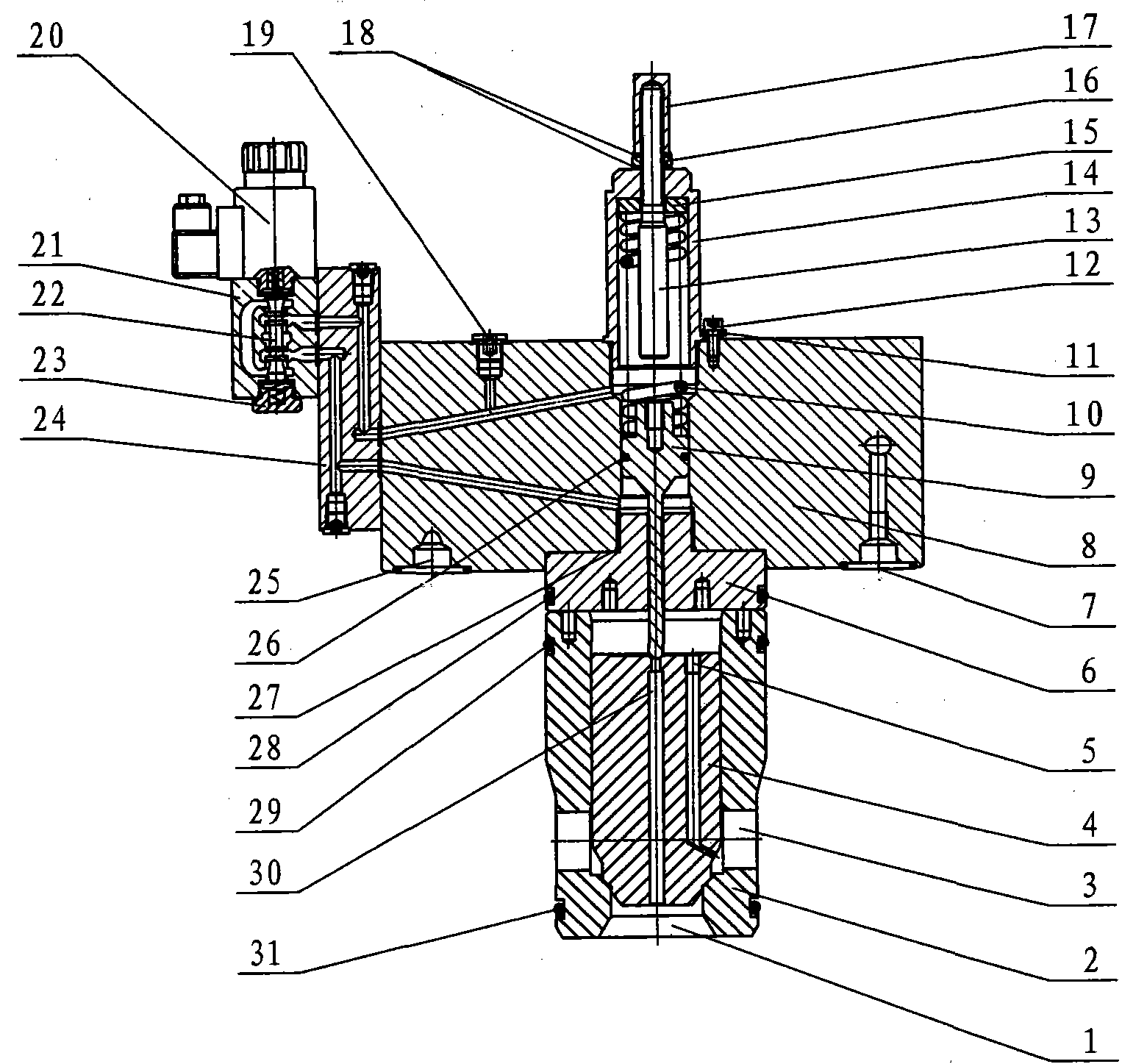

Pressure feedback secondary pilot control plugged-in type proportion relief valve system

ActiveCN102072213AClose safeSafe and reliable openingServomotor componentsProportional controlClosed loop feedback

The invention relates to a pressure feedback secondary pilot control plugged-in type proportion relief valve system, in particular to a pressure feedback secondary pilot control plugged-in type proportion relief valve system device capable of realizing pressure proportion regulation in the open or closed process by a hydraulic system valve. The side face of a main valve sleeve is provided with a main valve oil inlet and a main valve oil outlet; a main valve core is arranged in an axial hole of the main valve sleeve; a first return spring is arranged between a cover gasket and the main valve core; the side face of a control cover plate is provided with a pressure sensor; a cone valve core and an adjusting screw rod are arranged in an axial hole of a threaded sleeve; a pressure adjusting spring is arranged between the cone valve core and the adjusting screw rod; a locking nut is arranged at one end of the adjusting screw rod; and the middle part of the jointing of the control cover plate and the cover gasket is provided with a first damping hole, and a third damping hole is arranged between a control oil port of the control cover plate and the first damping hole. The pressure feedback secondary pilot control plugged-in type proportion relief valve system has the effects that the structure is simple, and the pressure feedback secondary pilot control plugged-in type proportion relief valve system is opened instantly, is controlled proportionally, adopts the pressure closed loop feedback, and is widely used in the hydraulic control systems of machine tools, casting and forging,compression casting, metallurgy, ships and mine industry.

Owner:SHANDONG TAIFENG INTELLIGENT CONTROL CO LTD

Mechanical feedback plug-in mounting type proportional throttle valve system

The invention relates to a mechanical feedback plug-in mounting type proportional throttle valve system, particularly to a system for realizing flow throttling during hydraulic rapid opening and safe and reliable closing processes. A hollow valve spool is arranged inside an axial hole of a valve bush, a top cover is sleeved at the large diameter end of the valve bush, a return spring is arranged between the top cover and the hollow valve spool, a control cover plate is sleeved at the upper end of a projection part in the middle of the top cover, a ratio electromagnet is connected with the upper end of a pilot operated servo valve, a servo-piston rod is arranged in the middle of the control cover plate, an internal valve bush is sleeved on the servo-piston rod and matched with the control cover plate, a feedback spring is connected with a spring base, the spring base is connected with the valve spool, a servo slide valve bush is sleeved on the valve spool and is provided with six radial oil ports, a transition plate is arranged on the side face of the valve, a reversal valve is arranged at the upper end of the transition plate, and a seal ring is arranged at the lower end of the transition plate. The proportional throttle valve system has simple structure, can be rapidly opened, and widely used in a hydraulic control system in machine tool industry, casting industry, compression casting industry, metallurgical industry, shipping industry, mining industry, etc.

Owner:SHANDONG TAIFENG INTELLIGENT CONTROL CO LTD

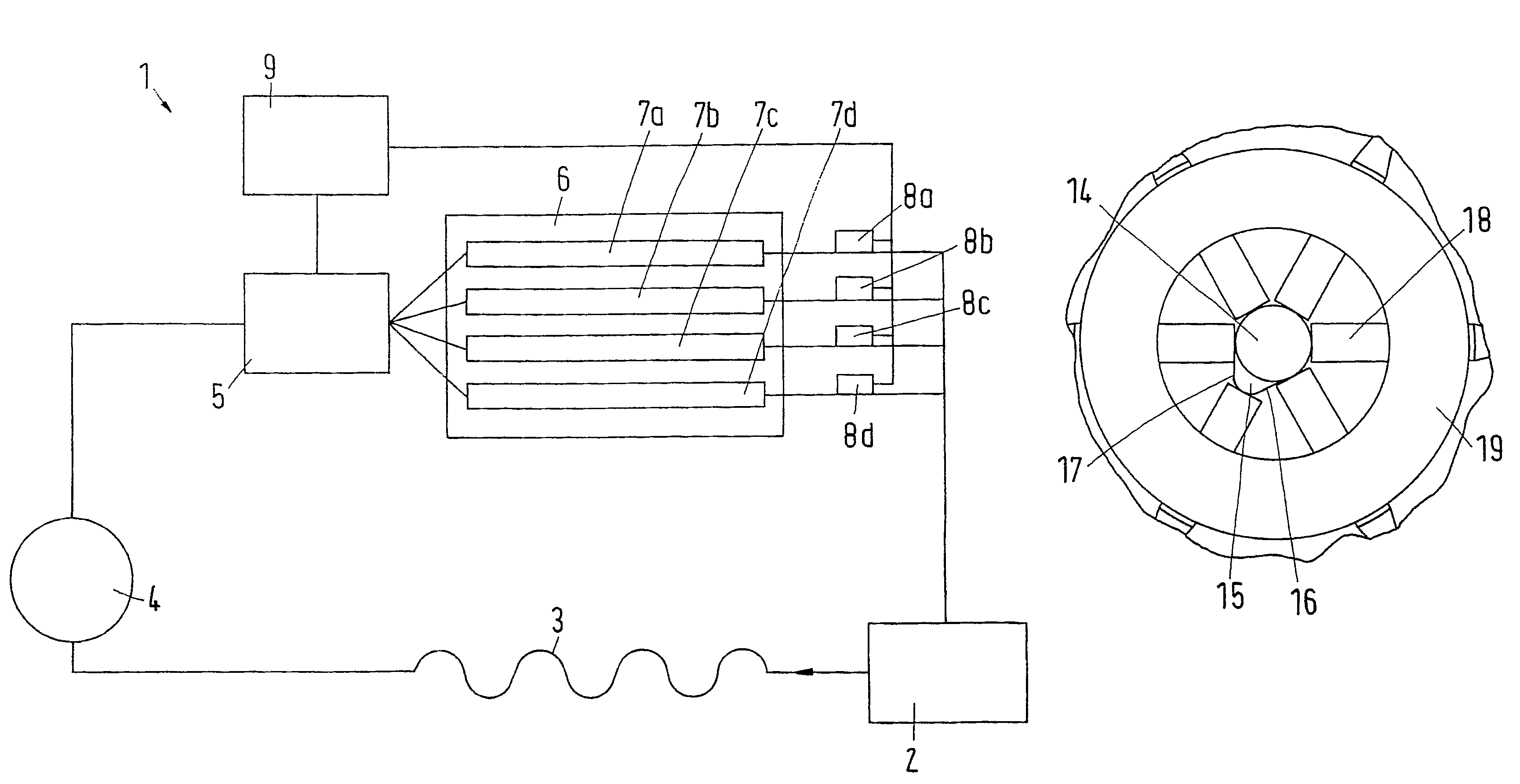

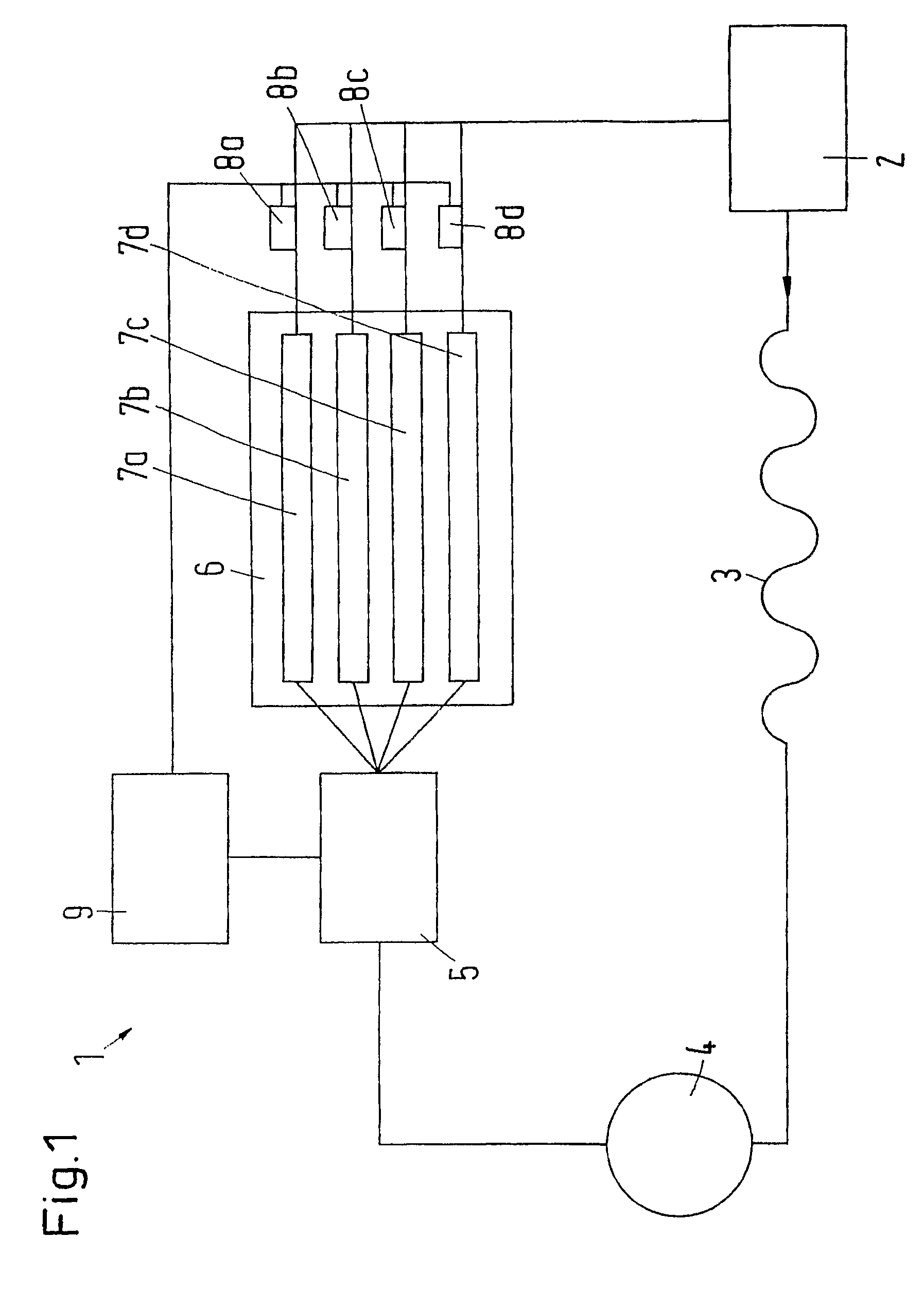

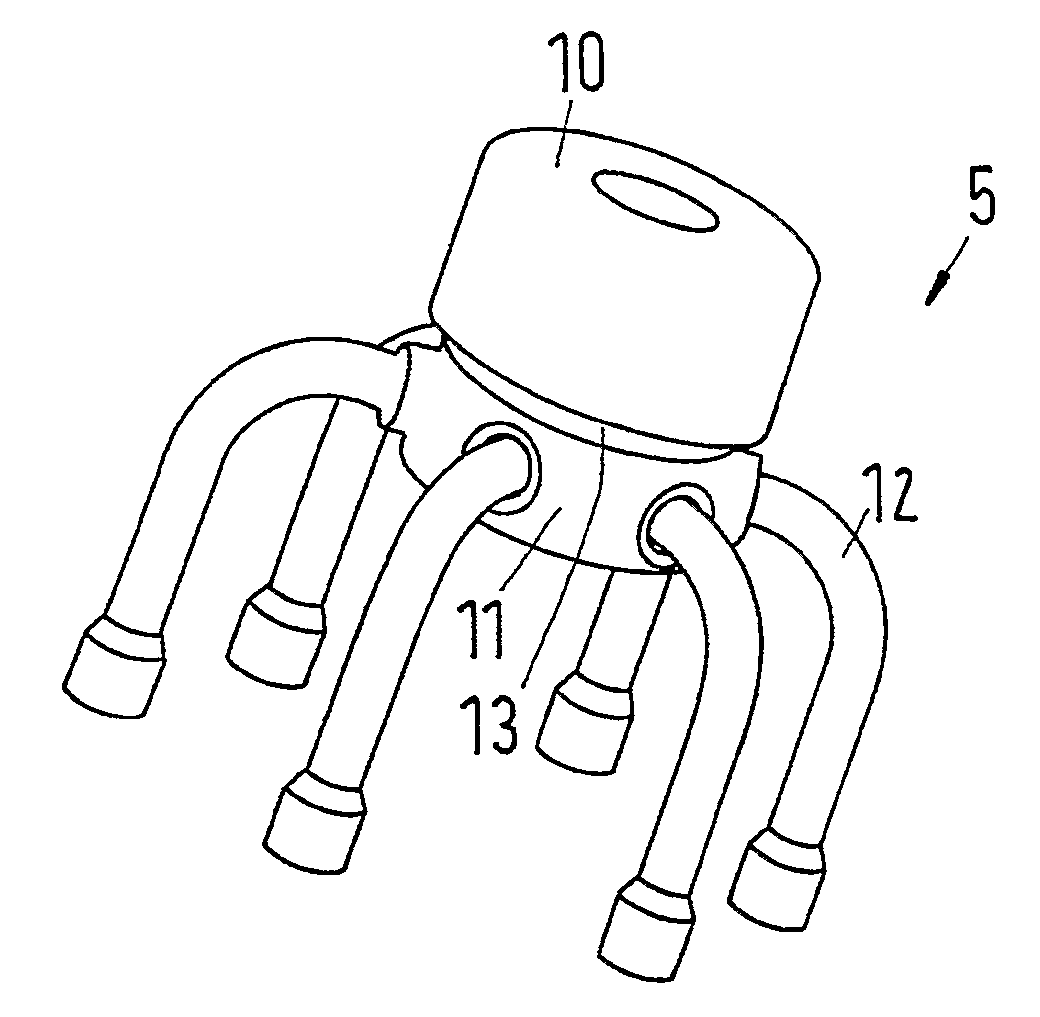

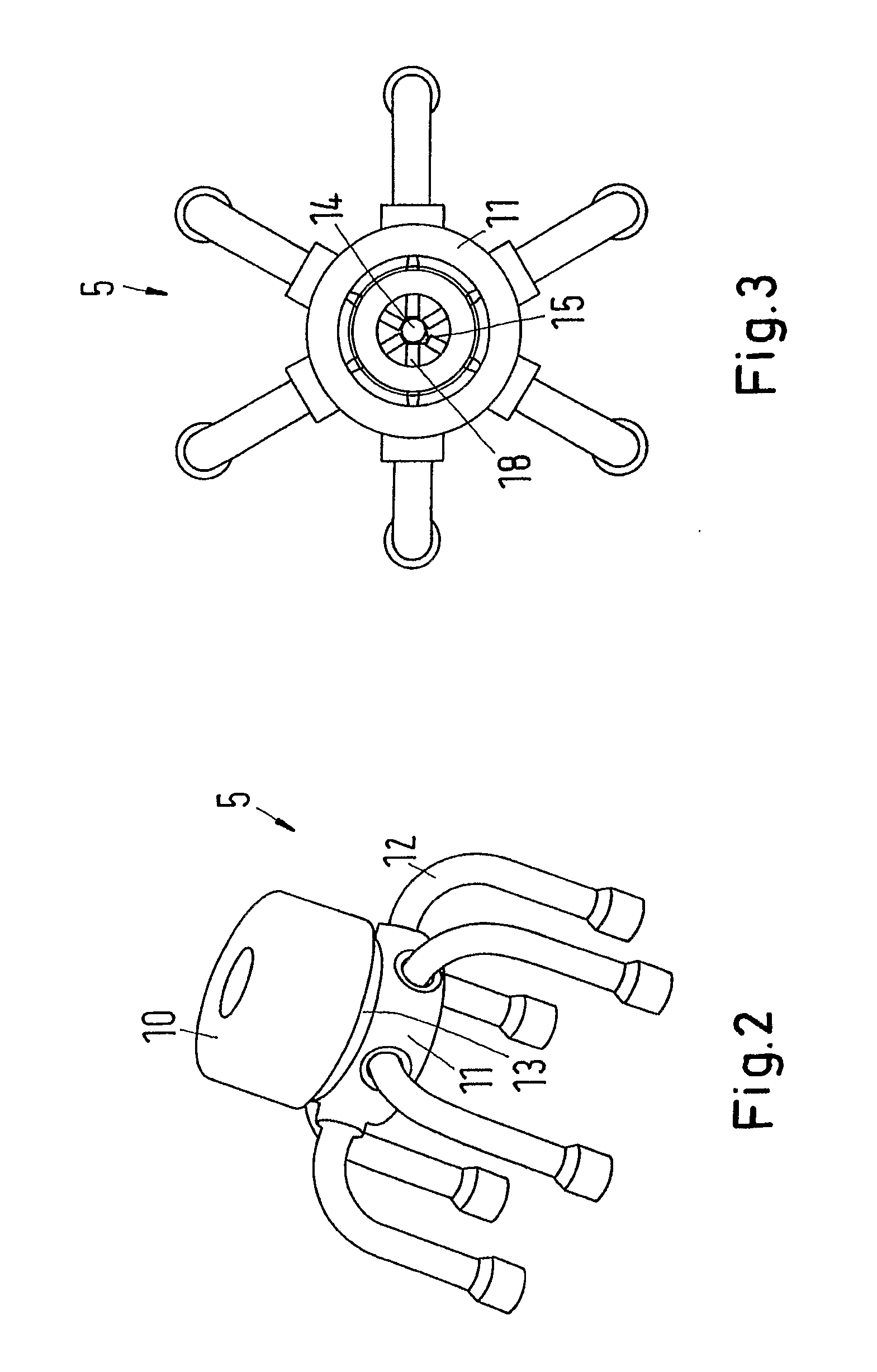

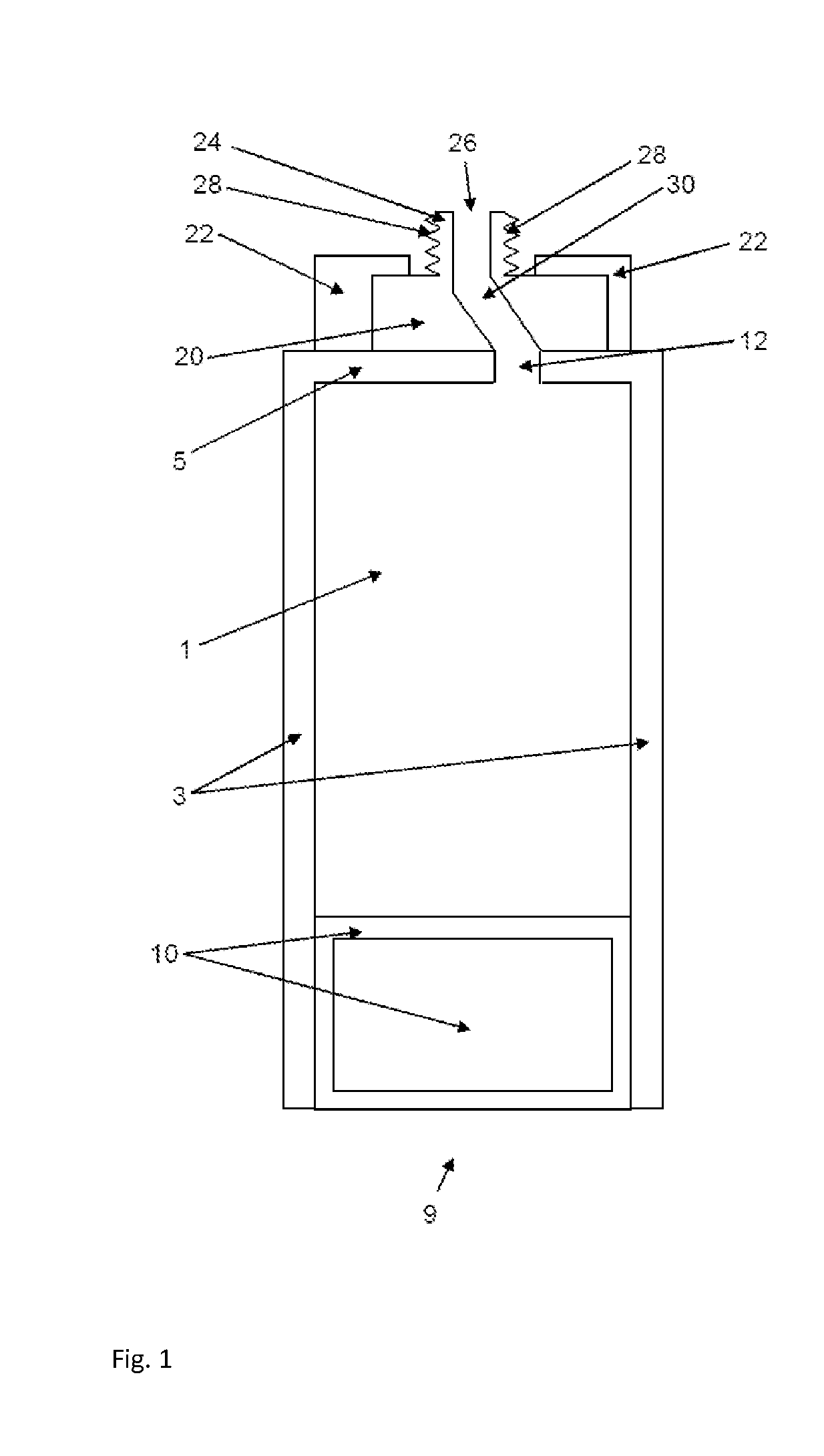

Refrigeration system

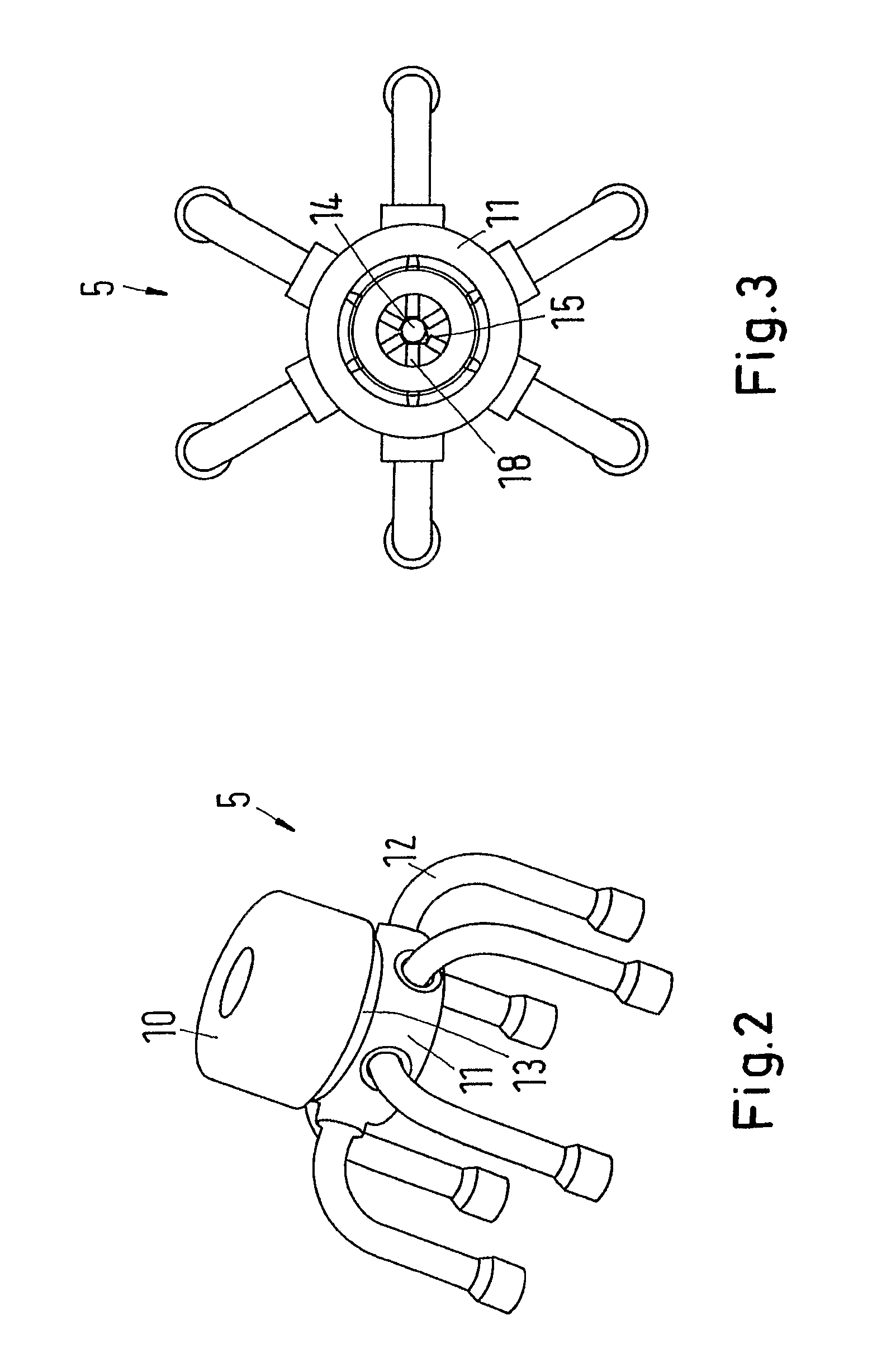

InactiveUS8794028B2Simple designEasy to manufactureEvaporators/condensersFluid circulation arrangementRefrigerant distributionEngineering

A refrigeration system including a refrigerant circuit with a plurality of evaporator paths and a distributor (5) for distributing refrigerants to the evaporator paths. The distributor including a controllable valve (14) for each evaporator path. The refrigeration system can be operated by using a distributor (5), which includes a housing (11) and a rotor rotatably mounted in the housing (11) and at least one radially oriented projection (15) on the circumference of the rotor, which interacts respectively with a valve element of a valve.

Owner:DANFOSS AS

High-flow hydraulic feedback pilot control plug-type proportion throttle valve system

ActiveCN102162476AClose safeSafe and reliable openingServomotor componentsHysteresisProportional control

The invention relates to a high-flow hydraulic feedback pilot control plug-type proportion throttle valve system, and in particular a high-flow hydraulic feedback pilot control plug-type proportion throttle valve system engineering mechanical device which flows forward and reverse. The side face of a main valve sleeve is provided with a main valve oil inlet and a main valve oil outlet; an axial hole of the main valve sleeve is provided with a main valve plug internally; the axial hole of the main valve plug is provided with a number one check valve internally; one end of the main valve plug is provided with a cross throttling groove, and the other end of the main valve plug is provided with a thin and long throttle valve; the axial hole of a pilot valve sleeve is internally provided with a pilot valve plug; a restoration spring is arranged between the pilot valve plug and a thread insert; one end of a number two check valve is communicated with a main valve plug control chamber; one end of the number two check valve is communicated with a number three pilot valve control port; and one end of the number two check valve is communicated with a number one control port. The proportion throttle valve system provided by the invention has the advantages of simple structure, temporary starting, proportion control, high linearity and small hysteresis loop, and is widely used for a hydraulic control system of the industries of machine tool forging and metallurgy of engineering machinery, ship and mine.

Owner:SHANDONG TAIFENG INTELLIGENT CONTROL CO LTD

Refrigeration system

InactiveUS20100307190A1Simple designEasy to manufactureCompression machines with non-reversible cycleEvaporators/condensersRefrigerant distributionEngineering

The invention relates to a refrigeration system comprising a refrigerant circuit provided with a plurality of evaporator paths and a distributor (5) for distributing refrigerants to the evaporator paths, said distributor comprising a controllable valve (14) for each evaporator path. The aim of the invention is to enable the refrigeration system to be operated as desired using simple means. To this end, the distributor (5) comprises a housing (11) and a rotor which is rotatably mounted in the housing (11) and comprises at least one radially oriented projection (15) on the circumference thereof, which interacts respectively with a valve element of a valve.

Owner:DANFOSS AS

Pull then lift hold open rod lock mechanism

Owner:MARATHONNORCO AEROSPACE

Multi-component cartridge system with shiftable closures in the cartridges

InactiveUS8986313B2Easy and inexpensive to manufactureReduce and overcome shortcomingLiquid surface applicatorsClosure using stoppersMechanical engineeringPlunger

A cartridge system for mixing and applying a mixing ware. The cartridges are arranged parallel and they are connected to a mixing space and an outlet opening. The cartridges each comprise a feed plunger for expelling starting components of the mixing ware from the cartridges through the openings, and each cartridge has at least one closure allocated to it that is shiftable in longitudinal direction of the cartridges, whereby the closures close the openings of the cartridges in a starting position, and the openings are open, at least in part, in an end position of the shiftable closures. In open position, the closure is shifted into a hollow space. The closures are cylindrical in shape and in their end position are capable of being lowered into cylindrical hollow spaces of the cartridges in order to uncover the openings.

Owner:HERAEUS MEDICAL

Accident quick gate falling speed regulation device for wind hoist and control method

ActiveCN107558446ASolve problems with complex dynamics that are difficult to controlPrevent runawayBarrages/weirsHydro energy generationEngineeringDamping torque

The invention discloses an accident quick gate falling speed regulation device for a wind hoist and a control method. The accident quick gate falling speed regulation device comprises a brake, a height gauge, a speed sensor and a controller. The balancing magnitude relation of damping torque and holding force of the brake is controlled by acquiring the comparison value of the gate falling speed and the predetermined speed, and the purpose that a gate falls down at the predetermined speed is achieved; by acquiring the gate falling speed and the position signal, control is conducted according toa sequence closing method, quick falling of the gate and timely water flowing speed reduction are achieved, a hydraulic turbine set is prevented from operating in a runaway manner, the gate slowly falls into a bottom sill, the impact is reduced, and the gate and the bottom sill are protected from being damaged due to impact. According to the accident quick gate falling speed regulation device forthe wind hoist and the control method, the full-closed-loop automatic redundancy design is adopted, it is guaranteed that the gate is quickly, stably and safely closed in time under the accident state.

Owner:湖南联诚能源发展有限公司

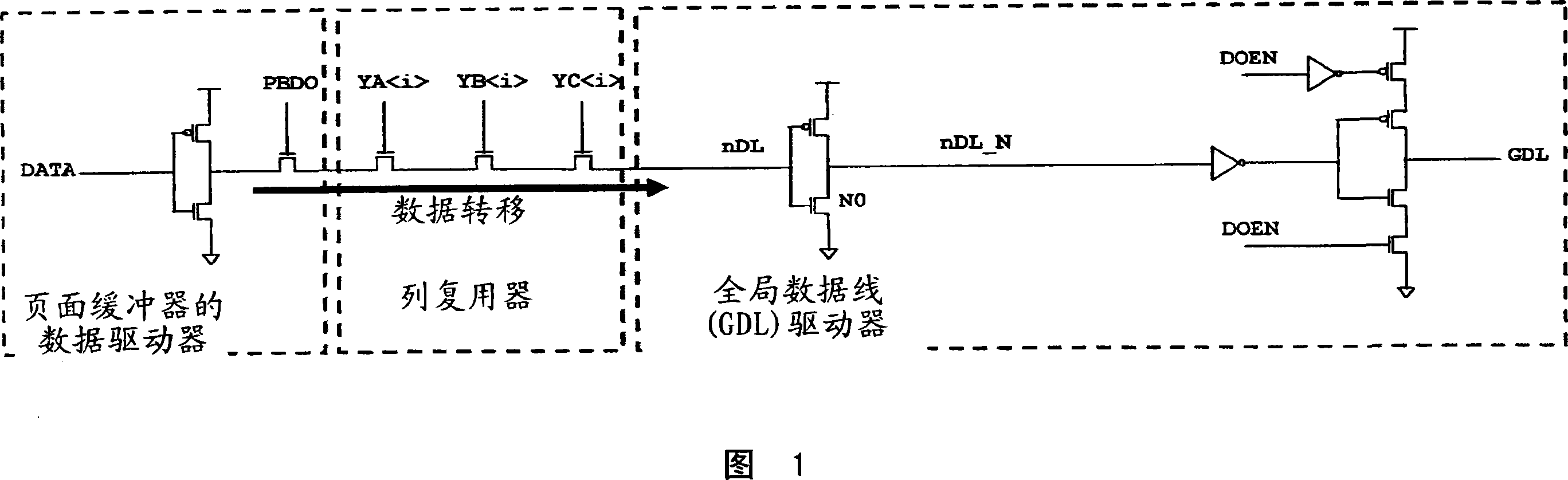

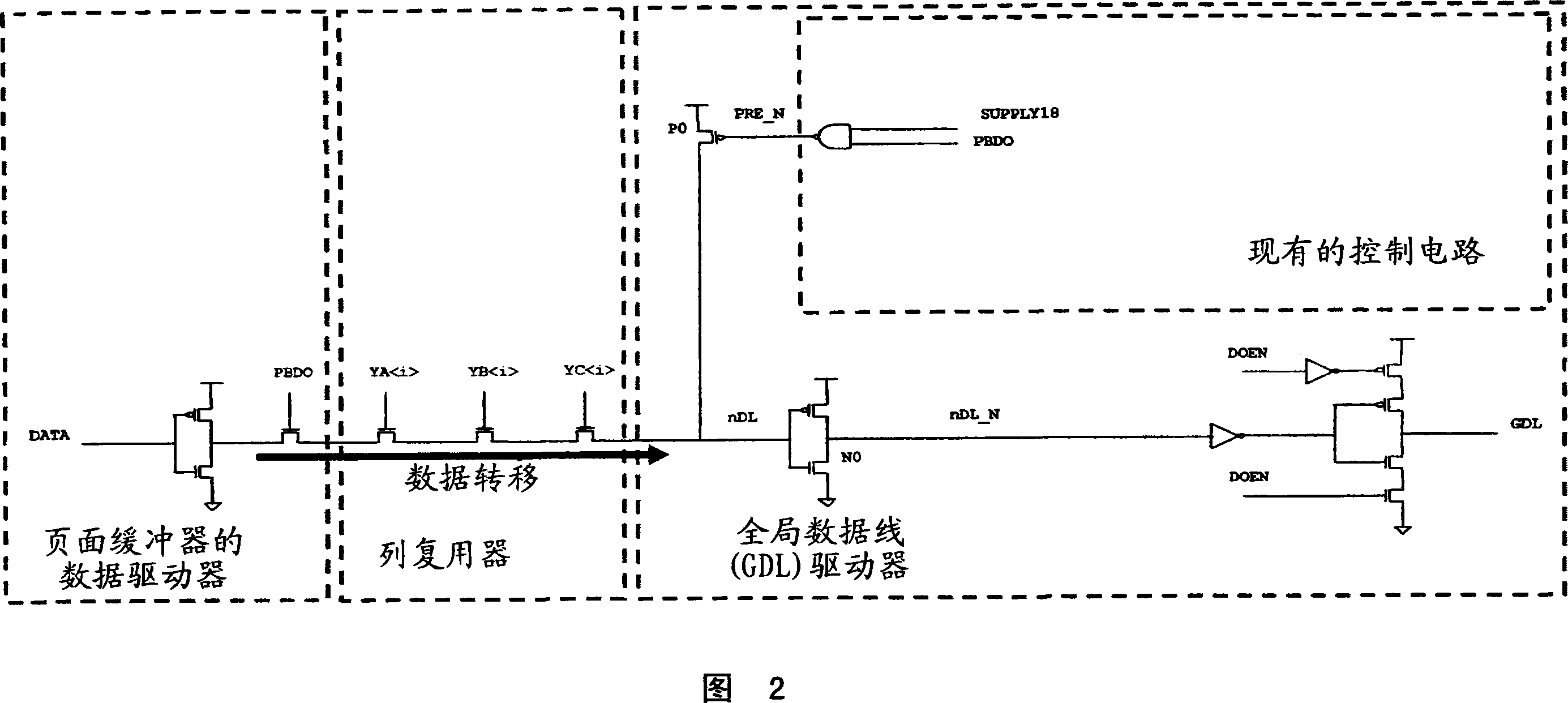

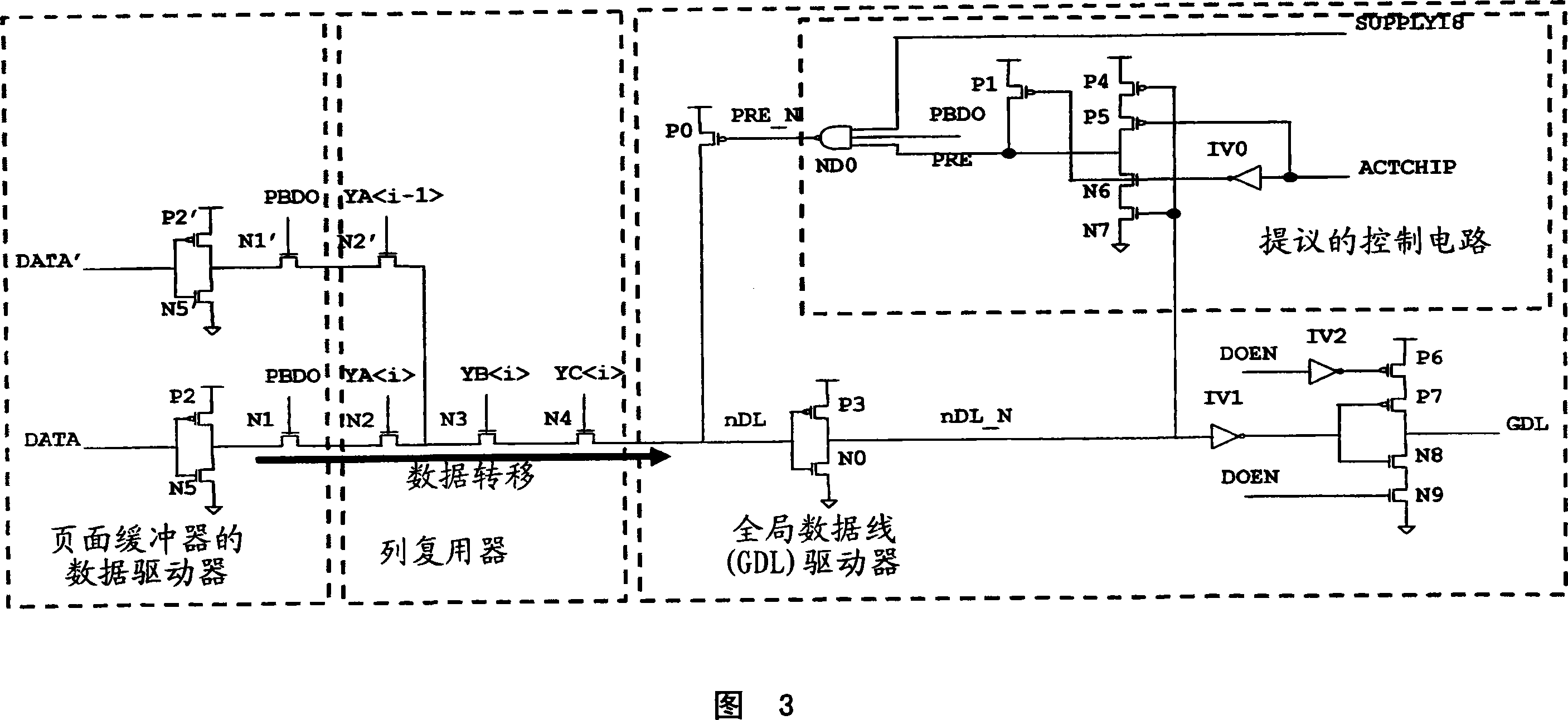

Non-volatile memory device and method of handling a datum read from a memory cell

Memory devices that include a pre-charge transistor for connecting / disconnecting the input line of the global data line driver to a supply voltage line are more power consuming than the memory devices that do not include it because of a small though significant flow of current through the pre-charge transistor even in stand-by state. This problem is solved with a method implemented in a novel memory device, by turning on the pre-charge transistor only when, at the same time, the enabling signal of the page buffer is asserted, a low voltage functioning mode is selected and the memory device is not in a stand-by state, or the memory device is in a stand-by state but the datum read from the memory is high. The pre-charge transistor is securely turned off in all other cases.

Owner:MICRON TECH INC

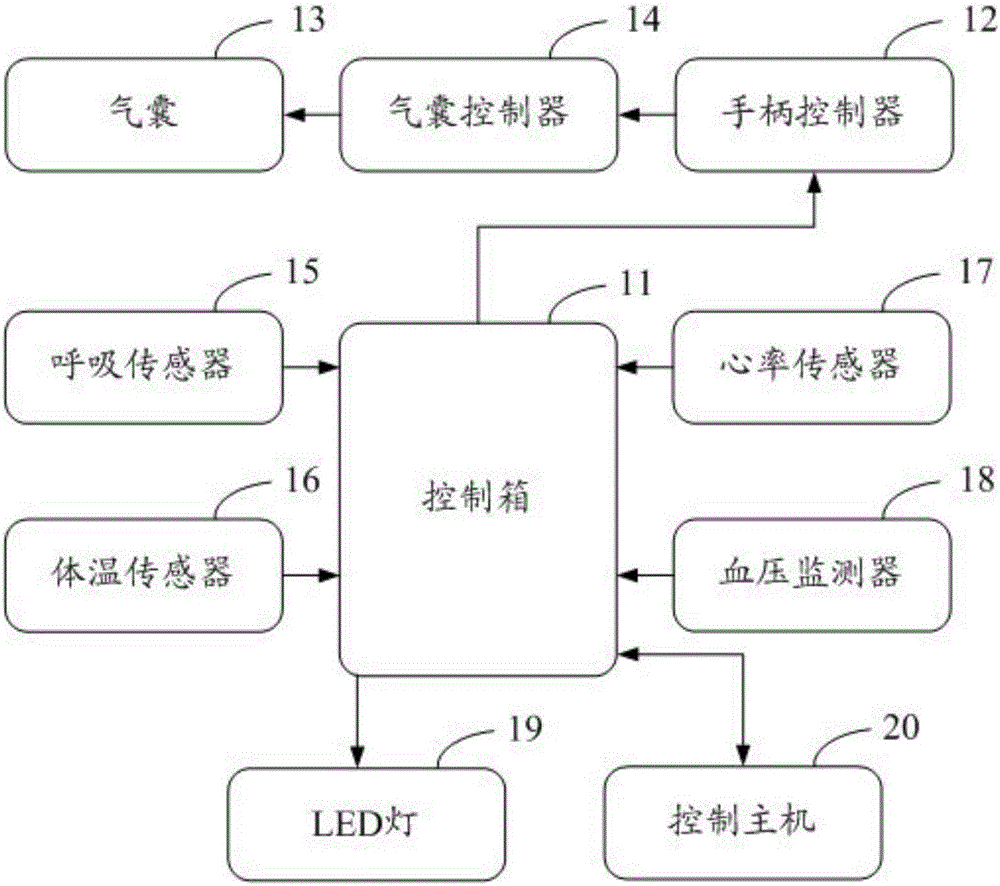

Active breathing control system

InactiveCN106237548ABreath-hold safetyClose safeEvaluation of blood vesselsRespiratory organ evaluationControl systemEngineering

The invention discloses an active breathing control system which comprises a control box, a handle controller, an airbag, an airbag controller, a respiration sensor, a body temperature sensor, a heart rate sensor, a blood pressure monitor, an LED lamp and a control host machine. The airbag controller is connected to the airbag. The control box is connected to the airbag controller and is used for controlling the airbag controller to allow the airbag to be inflated or deflated. The handle controller is arranged between the control box and the air controller and is used for manually controlling the inflation and deflation of the airbag. The respiration sensor, the body temperature sensor, the heart rate sensor, and the blood pressure monitor are connected to the control box. The LED lamp is connected to the control box and is started when the airbag is inflated. The control box is connected to the control host machine which is used for emitting a beam closing command to a linear accelerator according to the signals monitored by the body temperature sensor, the heart rate sensor, and the blood pressure monitor. According to the system, the closing of a ray beam can be timely controlled, and the effect of precise radiotherapy is improved.

Owner:广州市岱尼欣贸易有限公司

Safety device for opening and closing isolating baffles of withdrawable circuit breaker

InactiveCN102386579AResilience is stableSafe and reliable opening and closingSwitchgear shutters/guardsEngineeringCircuit breaker

A safety device for opening and closing isolating baffles of a withdrawable circuit breaker is arranged in a base support of a drawer seat of the circuit breaker and comprises four isolating baffles, a guide plate and two springs. Two of the four isolating baffles are arranged on a horizontal slide pre-arranged on the upper portion of the base support, and the other two baffles are arranged on a horizontal slide pre-arranged on a lower portion of the base support. The guide plate is inserted on a slot hole pre-arranged on the base support. The upper surface and the lower surface of the guide plate are respectively provided with two guide rails, and the inner end of the guide plate is provided with two guide rods. The two guide rails arranged on the upper surface of the guide plate are respectively in embedded connection with the two isolating baffles arranged on the upper portion of the base support, and the two guide rails arranged on the lower surface of the guide plate are respectively in embedded connection with the two isolating baffles arranged on the lower portion of the base support. The two springs are respectively sleeved on the two guide rods arranged on the guide plate. The safety device has the advantages of being compact in structure, reliable in opening and closing of the isolating baffles of the drawer seat of the circuit breaker, synchronous and stable, convenient in assembly and utilization and the like.

Owner:SHANGHAI JINGYI ELECTRICAL APPARATUS FACTORY CO LTD +1

Door Closer With Free-Swing Function

ActiveUS20120233812A1Slender structureReduce manufacturing costOperating means/releasing devices for valvesBuilding braking devicesEngineeringTranslational motion

Owner:DORMAKABA DEUT GMBH

Cartridge Closure and Cartridge Having Said Closure

ActiveUS20110272434A1Reduces and overcomes shortcomingClose safeLiquid surface applicatorsTeeth fillingEngineeringMechanical engineering

A cartridge system for application of a material has at least one cartridge having at least one cartridge has cartridge walls and one cartridge head each having at least one opening in each cartridge head, and a bracket that is arranged on the cartridge head or cartridge heads. A valve is mounted in rotatable manner in the bracket, wherein the valve has at least one passage through the valve that is connected to an outlet opening, wherein the valve, in a closed position, closes at least one opening of at least one cartridge, in particular all openings of all cartridges, in a sealed manner. The at least one passage is connected to the opening or openings in an open position of the valve such that the cartridge content can be squeezed out of the at least one cartridge through the outlet opening, and further wherein the valve can be transitioned from a closed position to an open position through a rotation of the valve.

Owner:HERAEUS MEDICAL

Multi-component cartridge system with shiftable closures in the cartridges

InactiveUS20130138113A1Easy and inexpensive to manufactureSafe and rapid to openLiquid surface applicatorsClosure using stoppersEngineeringMechanical engineering

A cartridge system for mixing and applying a mixing ware. The cartridges are arranged parallel and they are connected to a mixing space and an outlet opening. The cartridges each comprise a feed plunger for expelling starting components of the mixing ware from the cartridges through the openings, and each cartridge has at least one closure allocated to it that is shiftable in longitudinal direction of the cartridges, whereby the closures close the openings of the cartridges in a starting position, and the openings are open, at least in part, in an end position of the shiftable closures. In open position, the closure is shifted into a hollow space. The closures are cylindrical in shape and in their end position are capable of being lowered into cylindrical hollow spaces of the cartridges in order to uncover the openings.

Owner:HERAEUS MEDICAL

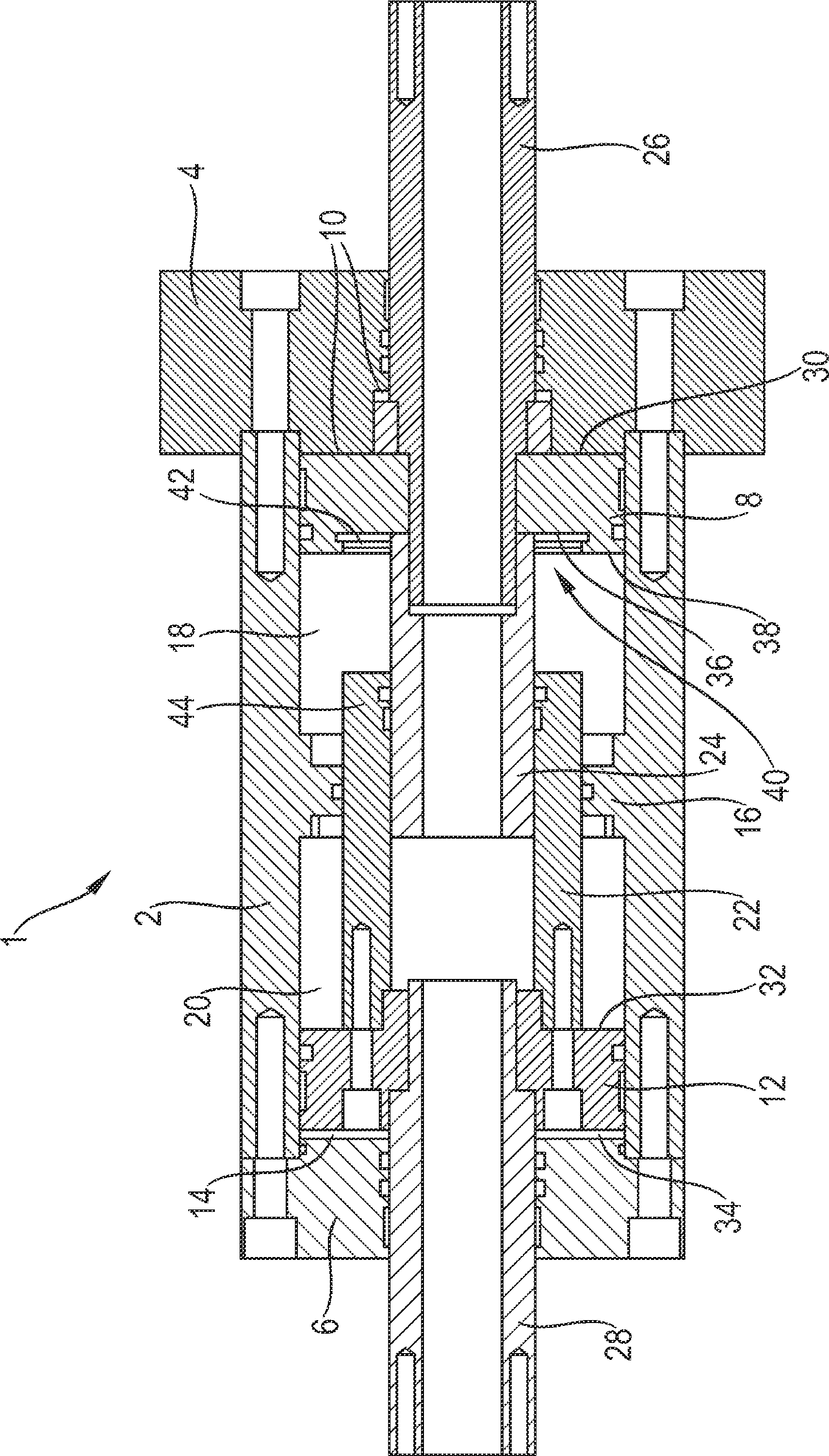

Four-chamber cylinder for a hydraulic actuating device with emergency function and hydraulic actuating device employing same

ActiveCN104251240AClose safeFluid-pressure actuator safetyOperating means/releasing devices for valvesEngineeringTurbine

The invention provides a four-chamber cylinder for a hydraulic actuating device with emergency function and a hydraulic actuating device employing same. The four-chamber cylinder according to the disclosure has two piston devices which in each case have a piston and a piston rod. Each piston limits two counteractive chambers. When one chamber is adjusted and operated to press the piston device to another piston, and accordingly the other chamber extends one of abutting piston rods into the guiding gap of another piston rods in a telescopic way. The emergency spring retains under prestress during adjusting of the four-chamber cylinder, and two pistons extrude towards each other. In this way, a compact four-chamber cylinder is realized. The four-chamber cylinder serves for adjusting a valve, a turbine or a process device with increased safety demands. An actuating movement is possible via the emergency spring even in the case of a supply failure, wherein the four-chamber cylinder can be installed and operated bi-directionally.

Owner:ROBERT BOSCH GMBH

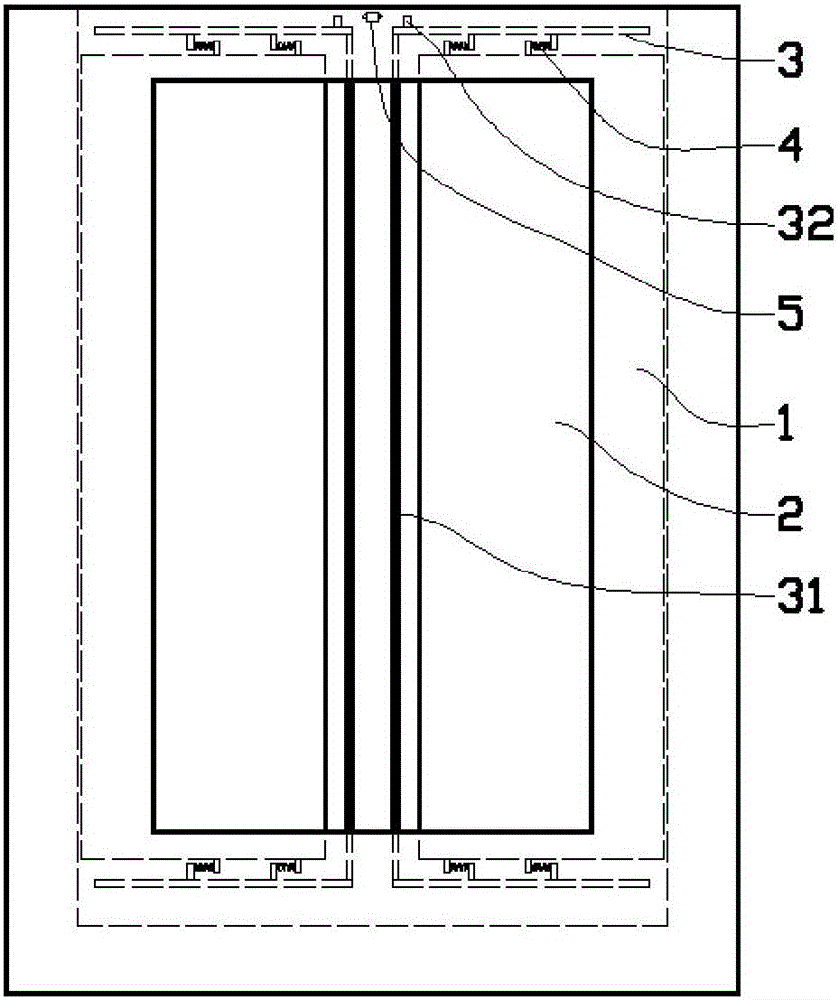

Safe gauze screen elevator

The invention provides a safe gauze screen elevator. The safe gauze screen elevator comprises a lift car. Elevator doors which are used in pairs and capable of opening and closing by sliding left and right are designed in front of the lift car. Screen window frames which are used in pairs and capable of sliding left and right are assembled in the parts, which are above the elevator doors and below the elevator doors, of the lift car. The front of the screen window frames and the rear of the screen window frames are both covered with gauze screens. Vertical pressing rods are designed at the front ends of the screen window frames and the screen window frames are connected with the upper ends of the elevator doors and the lower ends of the elevator doors by springs separately. When the springs are in a natural condition, the pressing rods at the front ends of the screen window frames are above 5cm more forward than the front ends of the elevator doors; when the elevator doors is closed, the pressing rod at the front ends of the screen window frames on the left and the pressing rod at the front ends of the screen window frames on the right push each other tightly. According to the safe gauze screen elevator, the elevator can be safer when closed and at the same time the elevator doors can be faster when opened by the outward drawing force of the screen window frames when the elevator doors are closed.

Owner:SUZHOU MAYFORD ELEVATOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com