Mechanical feedback plug-in mounting type proportional throttle valve system

A proportional throttle valve, mechanical feedback technology, applied in mechanical equipment, fluid pressure actuating devices, servo motor components, etc., can solve the problems of unreliable closing, slow response speed, high investment cost, and achieve rapid opening and control. and high reliability, safe and reliable closing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

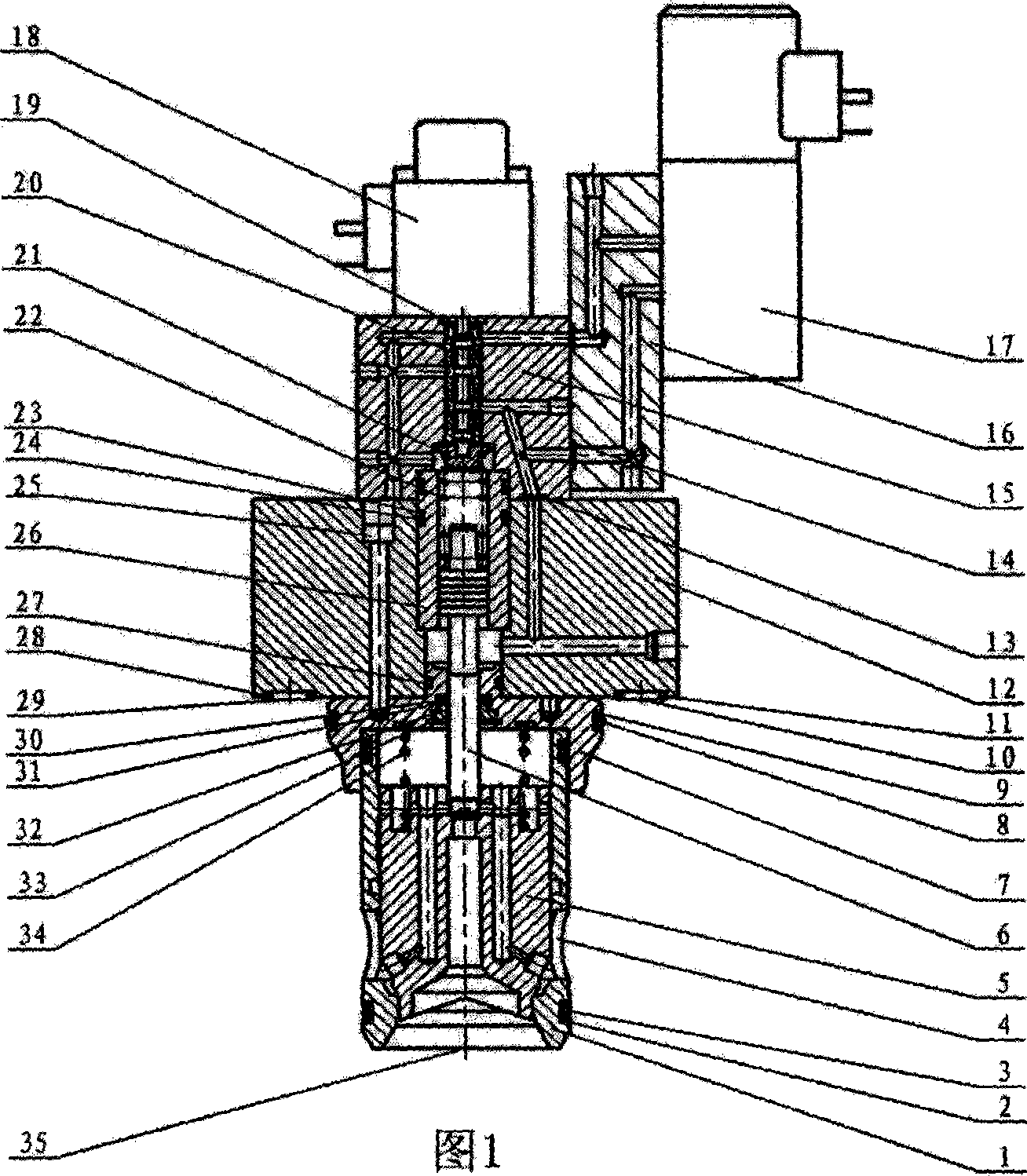

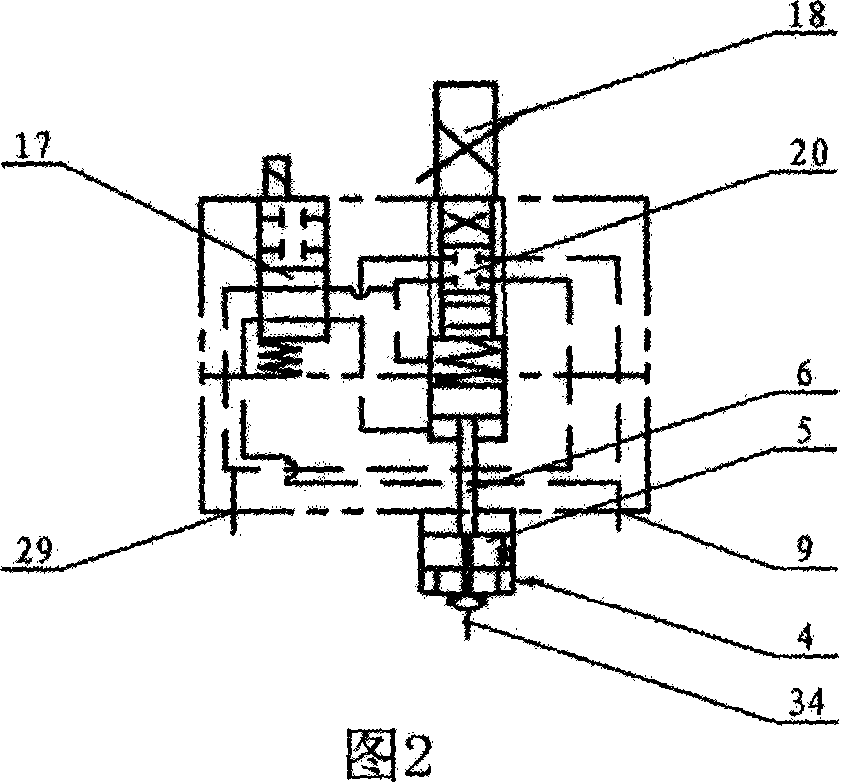

[0010] Referring to Figures 1 and 2, the mechanical feedback plug-in proportional throttle valve system of the present invention is composed of a valve sleeve 1, a main valve core 5, a pilot servo mechanism and a reversing valve 17, and a main valve is provided on the side of the valve sleeve 1 Valve oil inlet 4 and main valve oil outlet 35, the main valve core 5 is installed in the axial hole of the valve sleeve 1, the top cover 7 is set on the large diameter end of the valve sleeve 1, the gap between the top cover 7 and the main valve core 5 A return spring 34 is arranged between them, and the control cover 12 is nested on the upper end of the raised part in the middle of the top cover 7, connected by a screw 25, the upper end of the control cover 12 is connected with the pilot servo valve body 15, and the upper end of the control cover 12 is connected with the pilot servo valve body A sealing ring 13 is installed between the lower ends of 15, and the lower end of the control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com