Low-pressure pilot control high-flow superhigh-pressure hydraulic cartridge valve system

A pilot-controlled, high-flow technology, used in fluid pressure actuation devices, servo motor assemblies, mechanical equipment, etc., can solve problems such as increased design costs, deformation of cartridge valves and pilot solenoid valves, and system failures, achieving a degree of control. And the effect of high reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

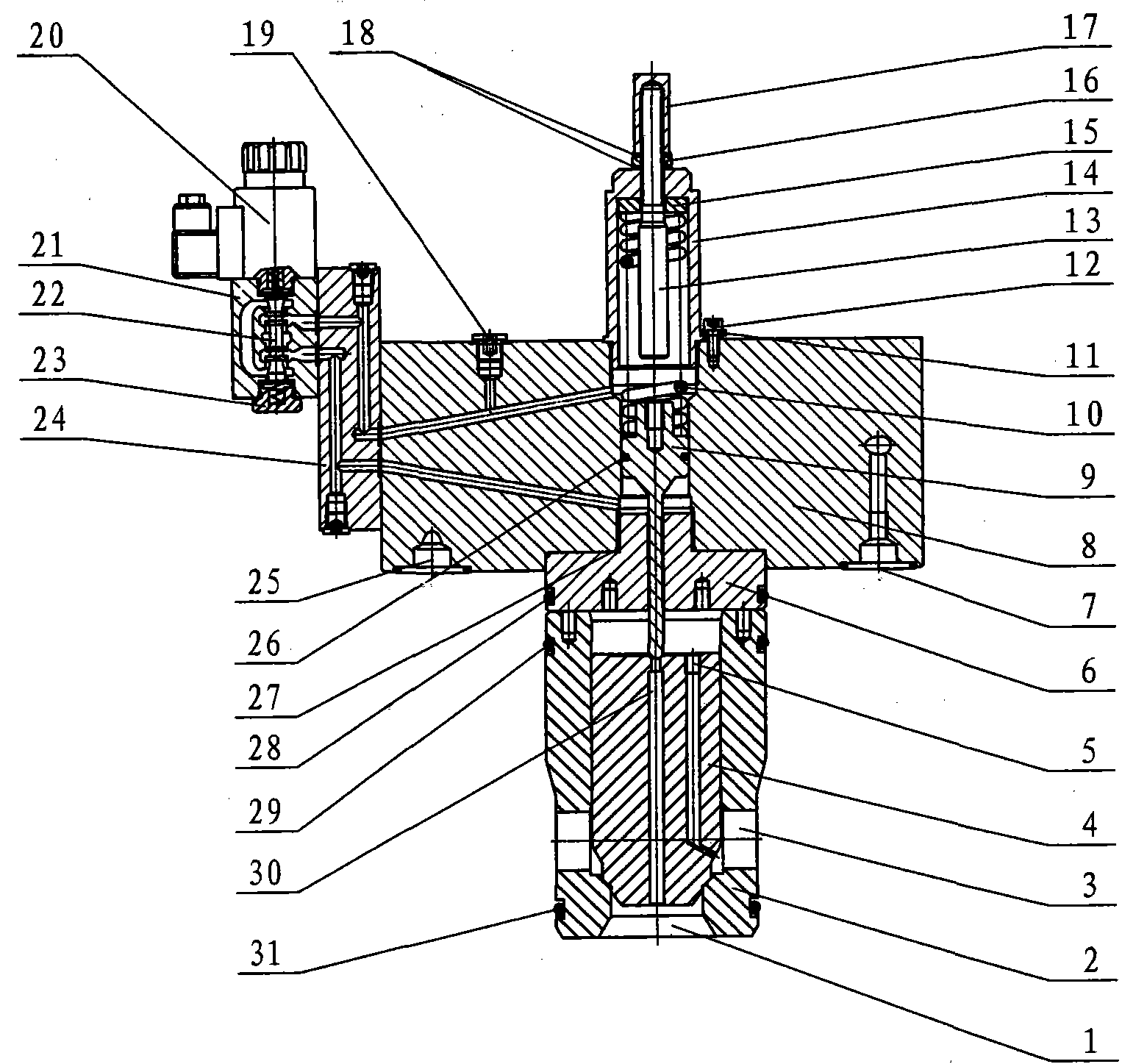

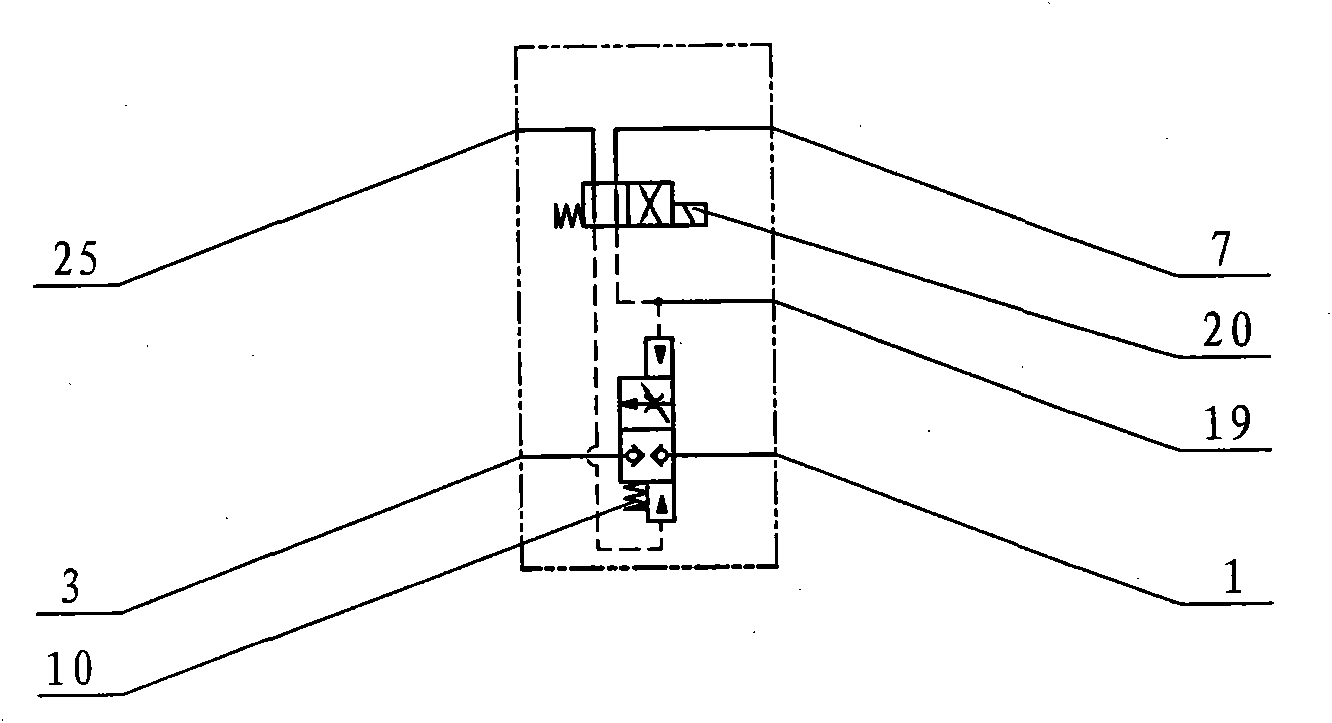

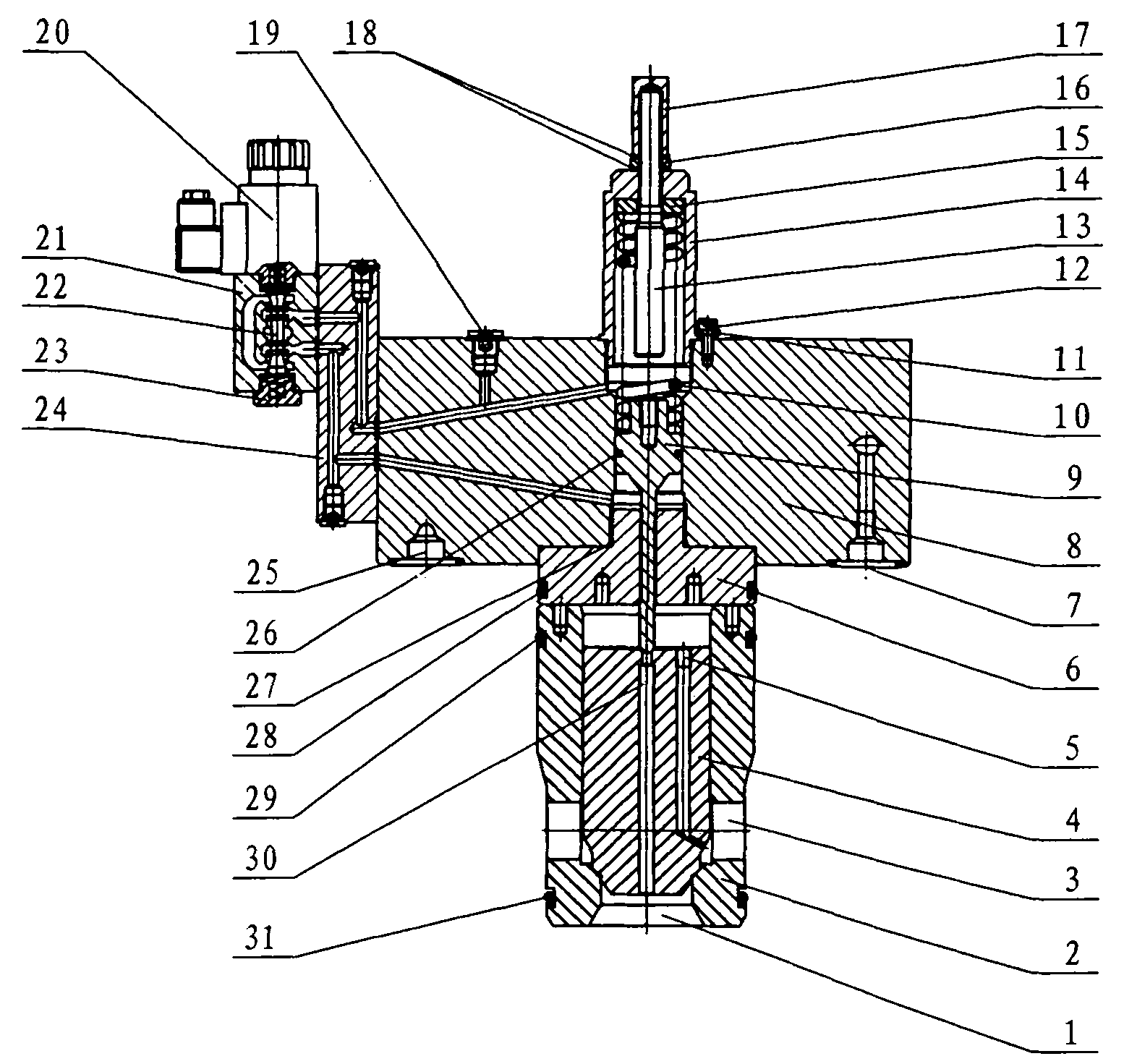

[0010] refer to figure 1 , 2 , the low-pressure pilot control large-flow ultra-high pressure hydraulic cartridge valve system of the present invention is realized by adopting the following technical scheme: it is composed of a valve sleeve 2, a main valve core 4, a pressure amplification mechanism and a pilot valve. There are main valve oil inlet 3 and main valve oil outlet 1, the main valve core 4 is installed in the axial hole of the valve sleeve 2, and the through hole 30 is set in the middle of the main valve core 4 to communicate with the main valve oil outlet 1, and the main valve One end of the core 4 is provided with a damping hole 5 to communicate with the oil inlet 3 of the main valve, a piston rod 9 is provided in the axial hole of the control cover plate 8, and a top cover 6 is provided between the piston rod 9 and the valve sleeve 2, and the raised part of the top cover 6 is rotated. Into the control cover plate 8, the piston rod 9 passes through one end of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com