High-flow hydraulic feedback pilot control plug-type proportion throttle valve system

A proportional throttle valve and pilot control technology, which is applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problems of high cost, unstable movement, large space occupation, etc., and achieve safe and reliable closing and opening , high degree of control and reliability, and high linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

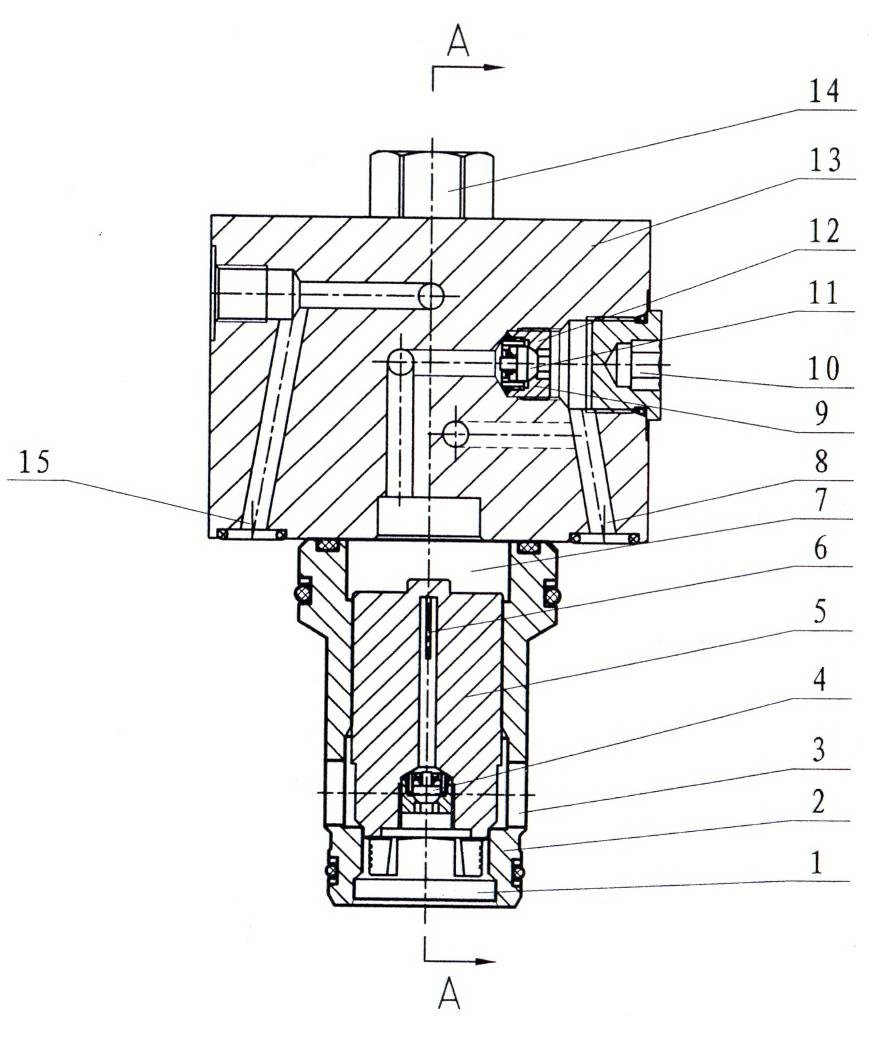

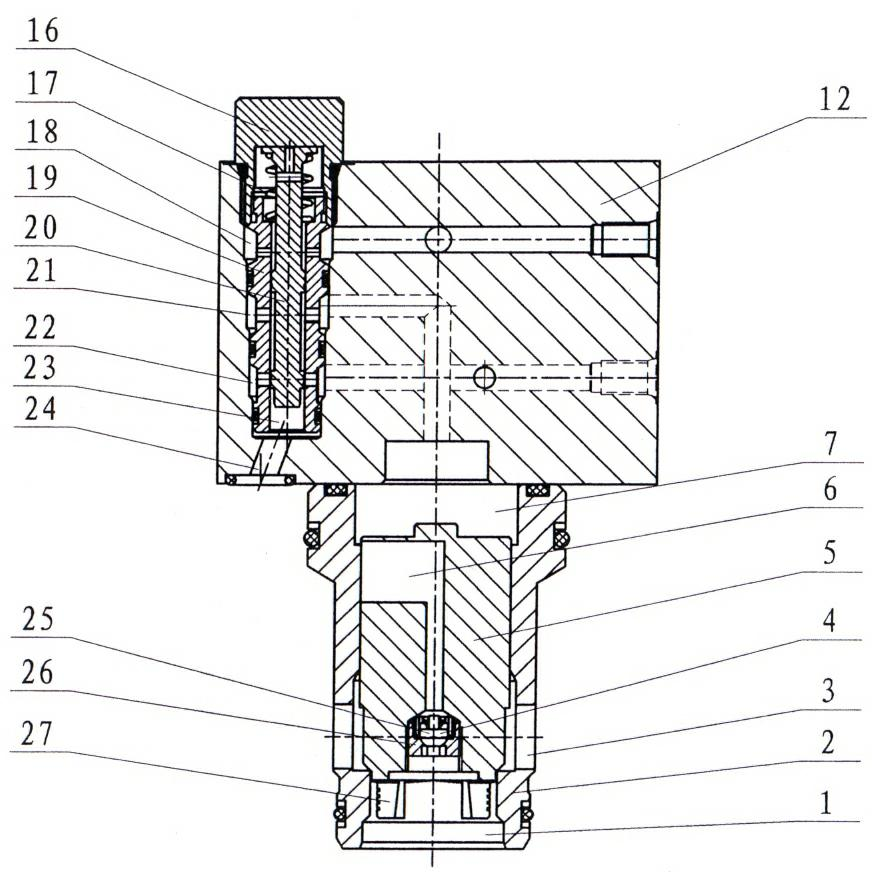

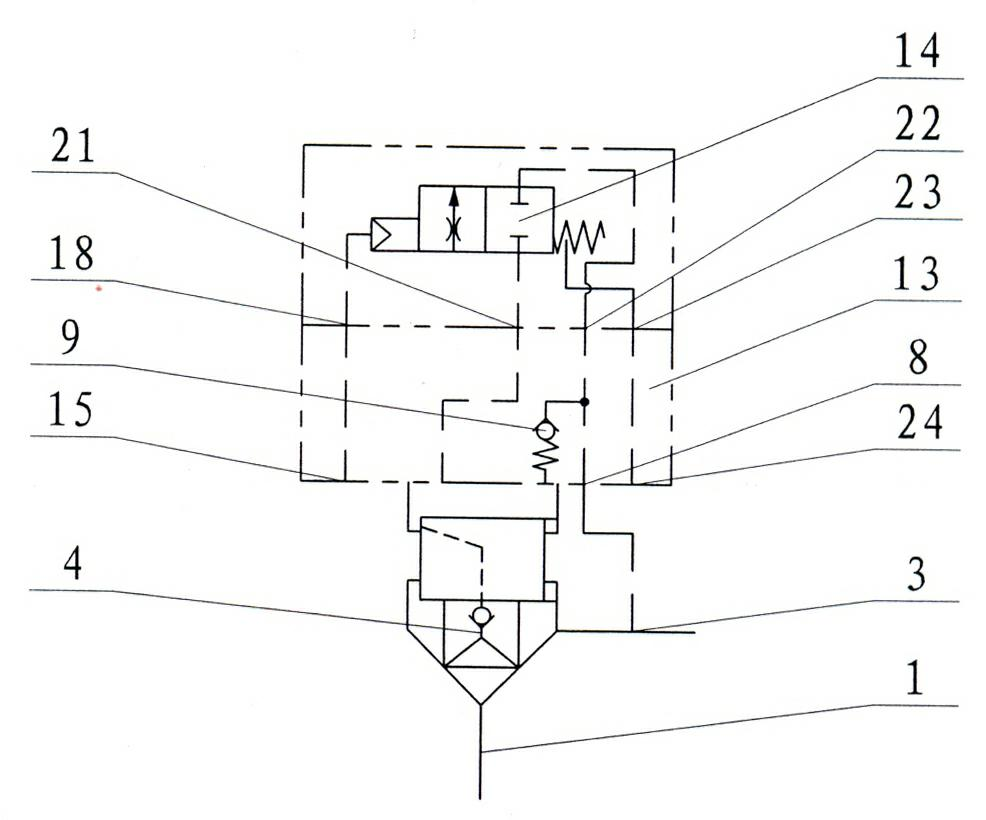

[0012] refer to figure 1 , figure 2 and image 3 , the large-flow hydraulic feedback pilot control plug-in proportional throttle valve system of the present invention: it is composed of the main valve sleeve 2, the main valve core 5, the pilot valve sleeve 19, the pilot valve core 20 and the control cover plate 13, the main valve sleeve The main valve oil inlet 1 and the main valve oil outlet 3 are arranged on the side of 2, the main valve core 5 is installed in the axial hole of the main valve sleeve 2, and the first check valve 4 is arranged in the axial hole of the main valve core 5. The first one-way valve 4 is composed of the first valve seat 26 and the first semi-round valve core 25. One end of the main valve core 5 is provided with a cross-shaped throttle groove 27, and the other end of the main valve core 5 is provided with a slender orifice. 6. One end of the slender orifice 6 is connected to the No. 1 one-way valve 4, one end of the slender orifice 6 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com