Patents

Literature

76results about How to "Prevent runaway" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

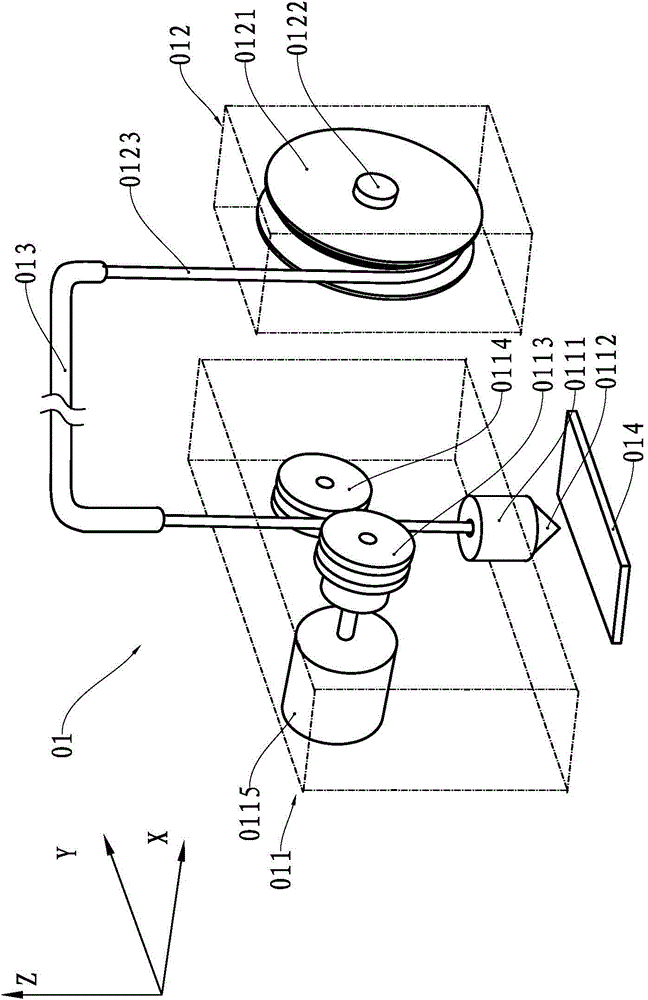

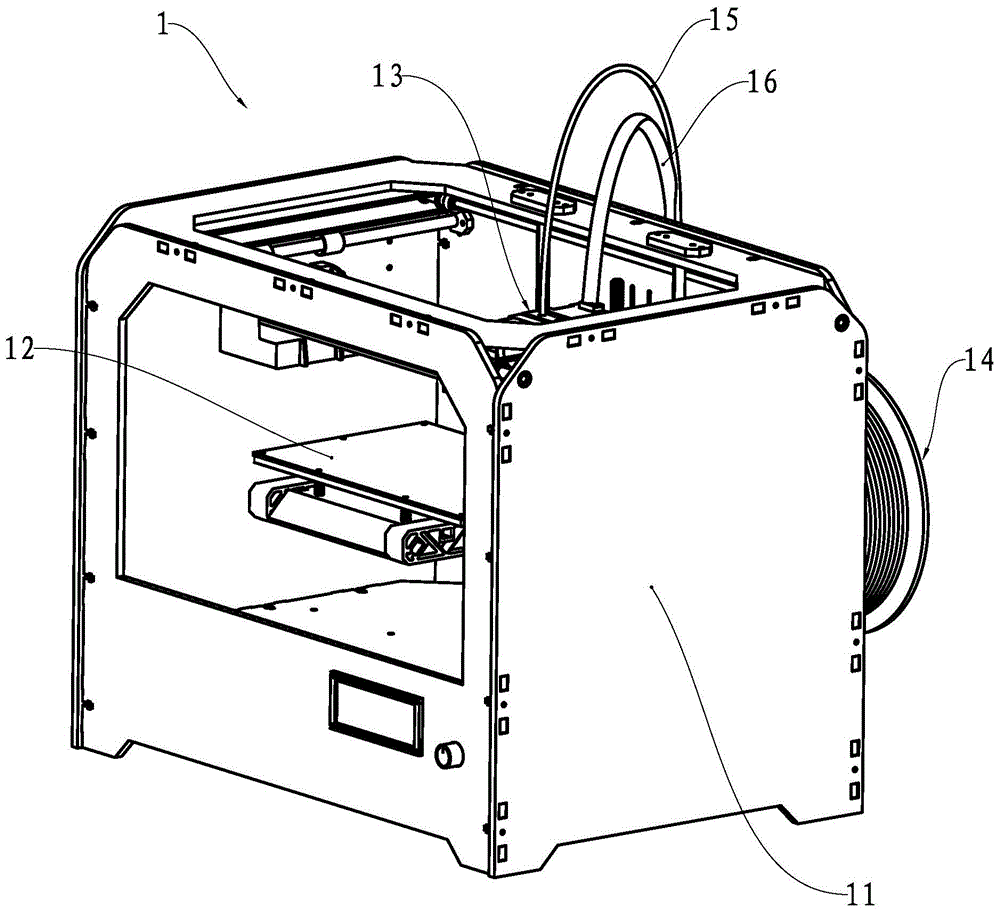

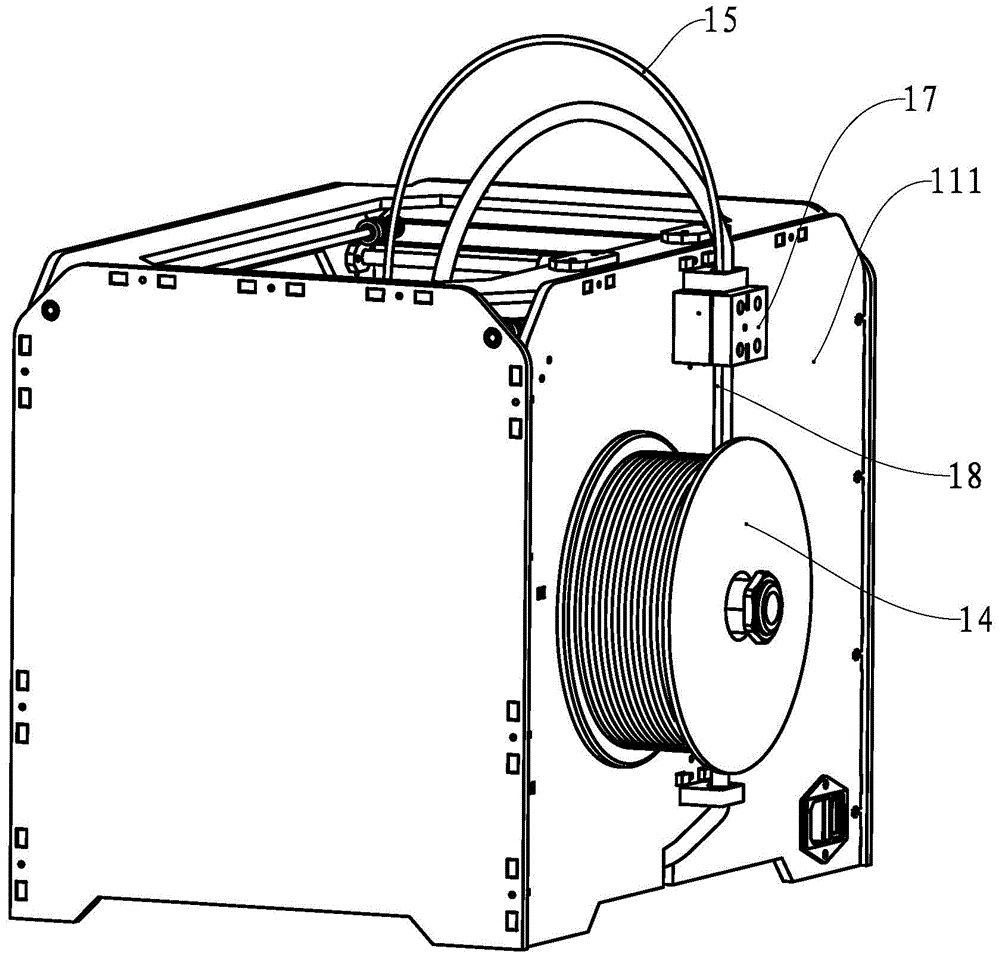

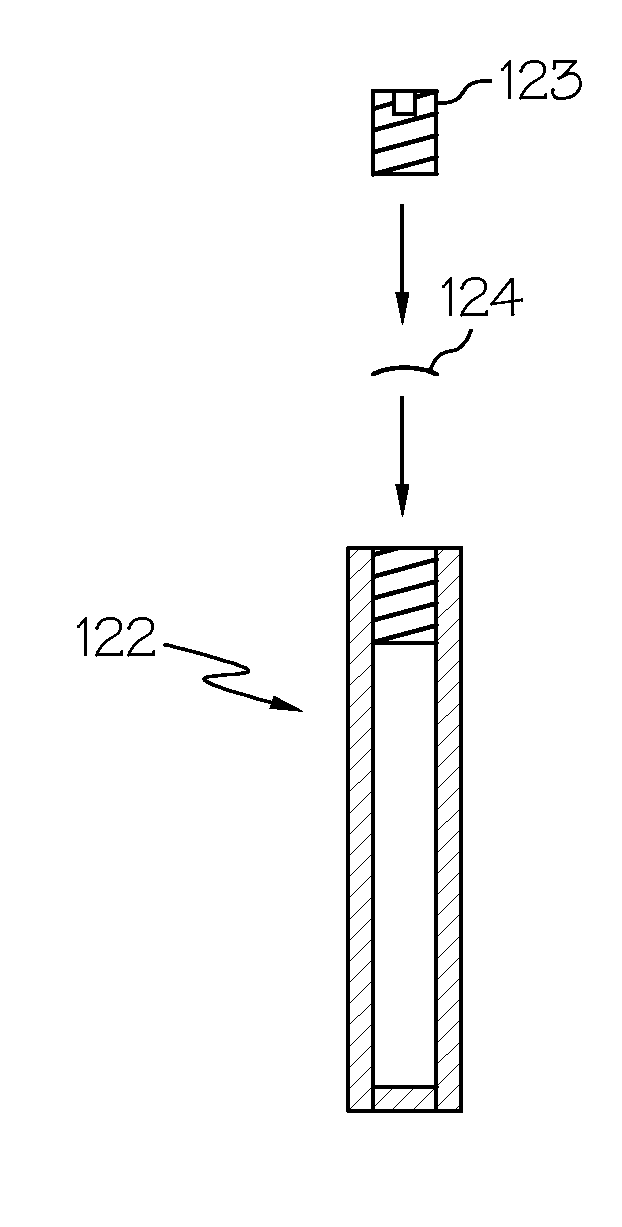

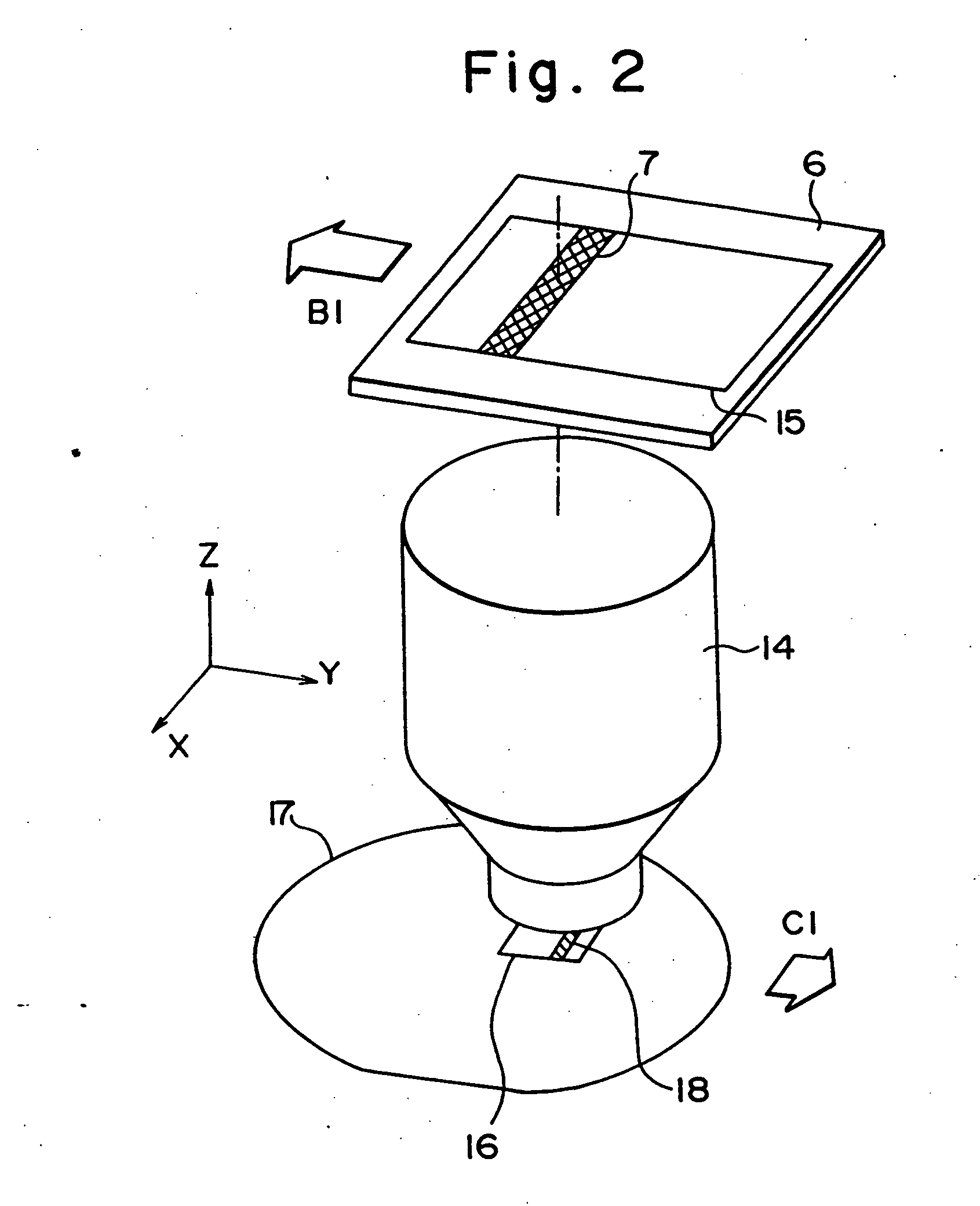

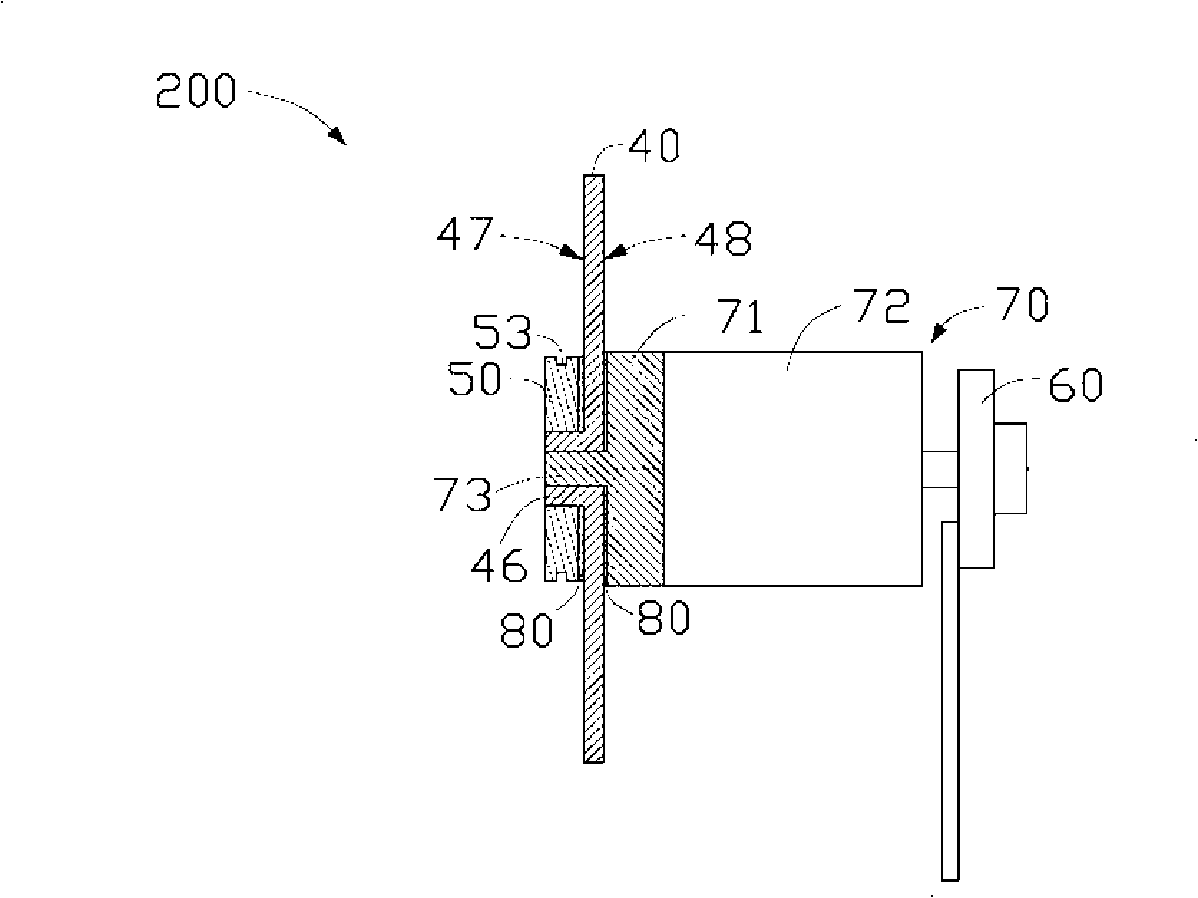

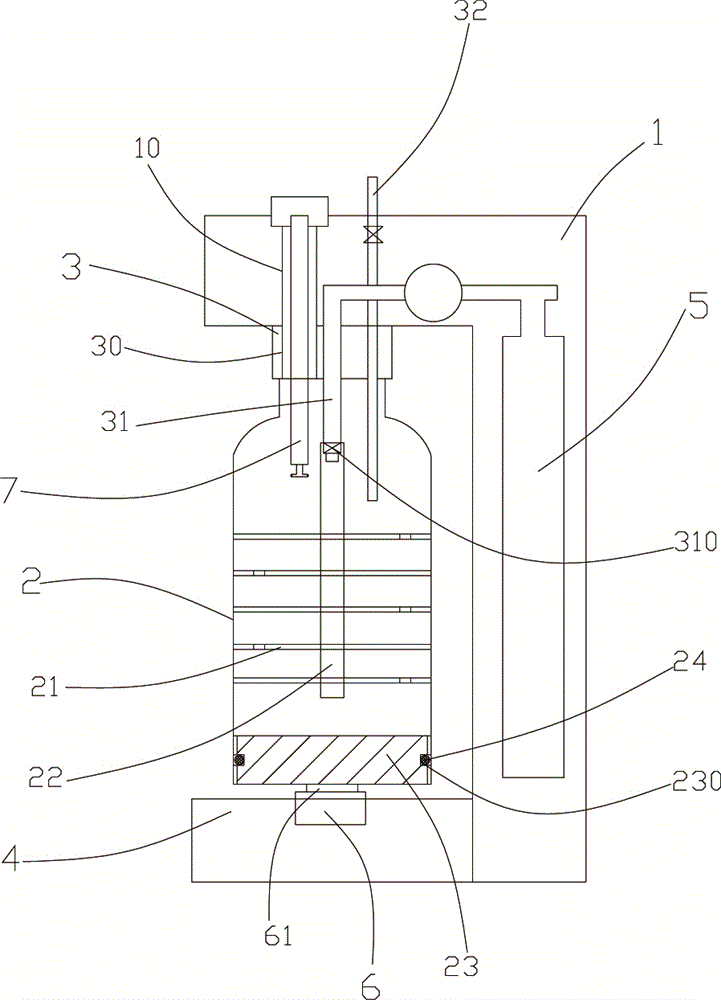

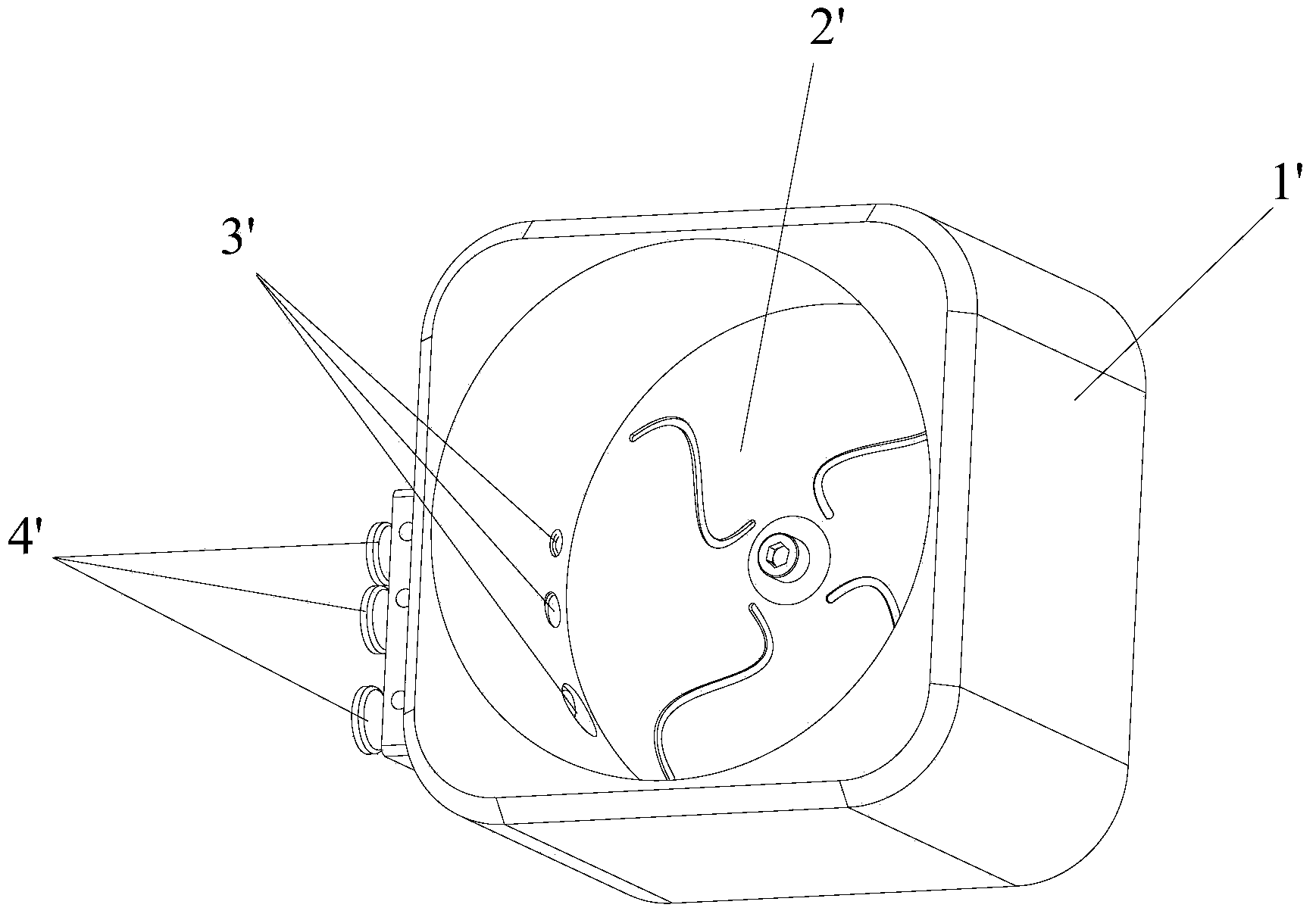

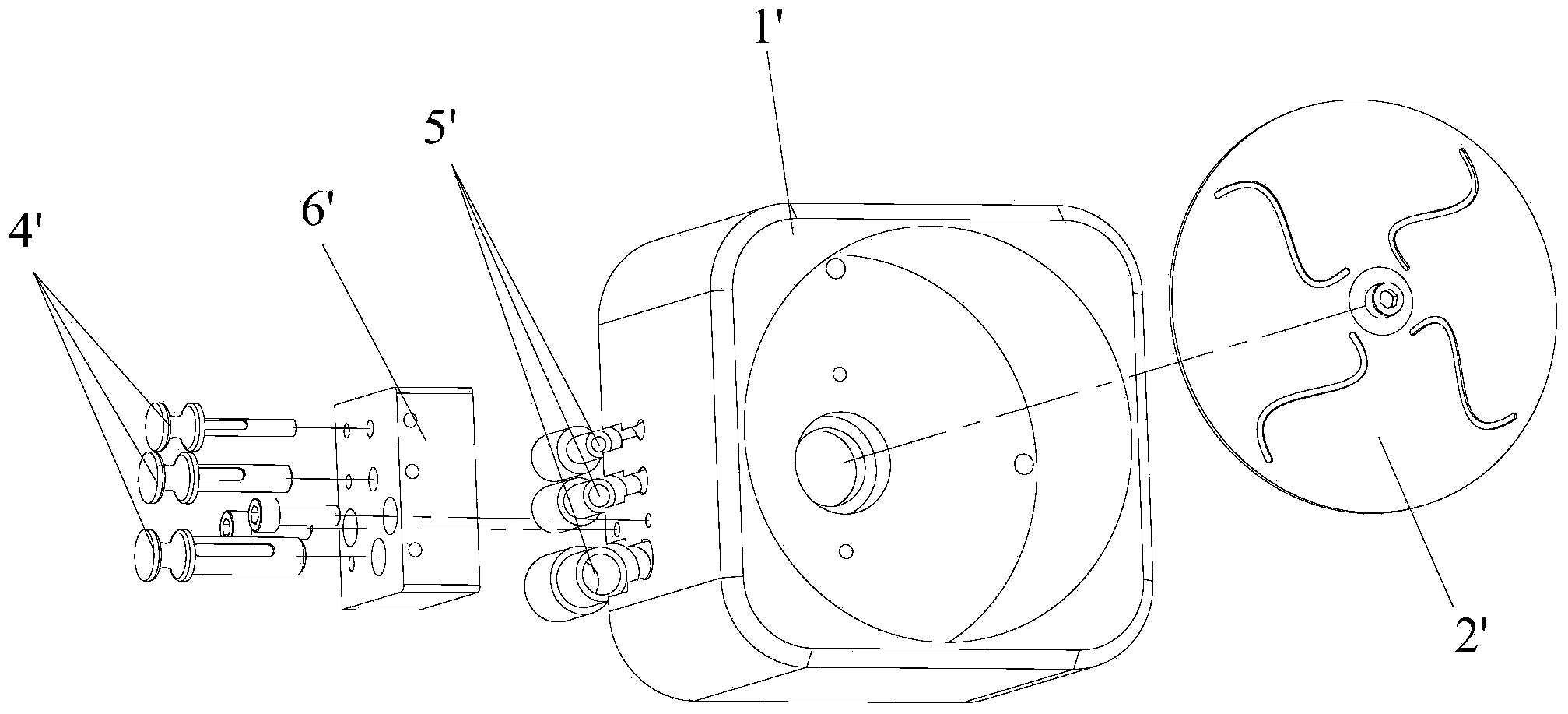

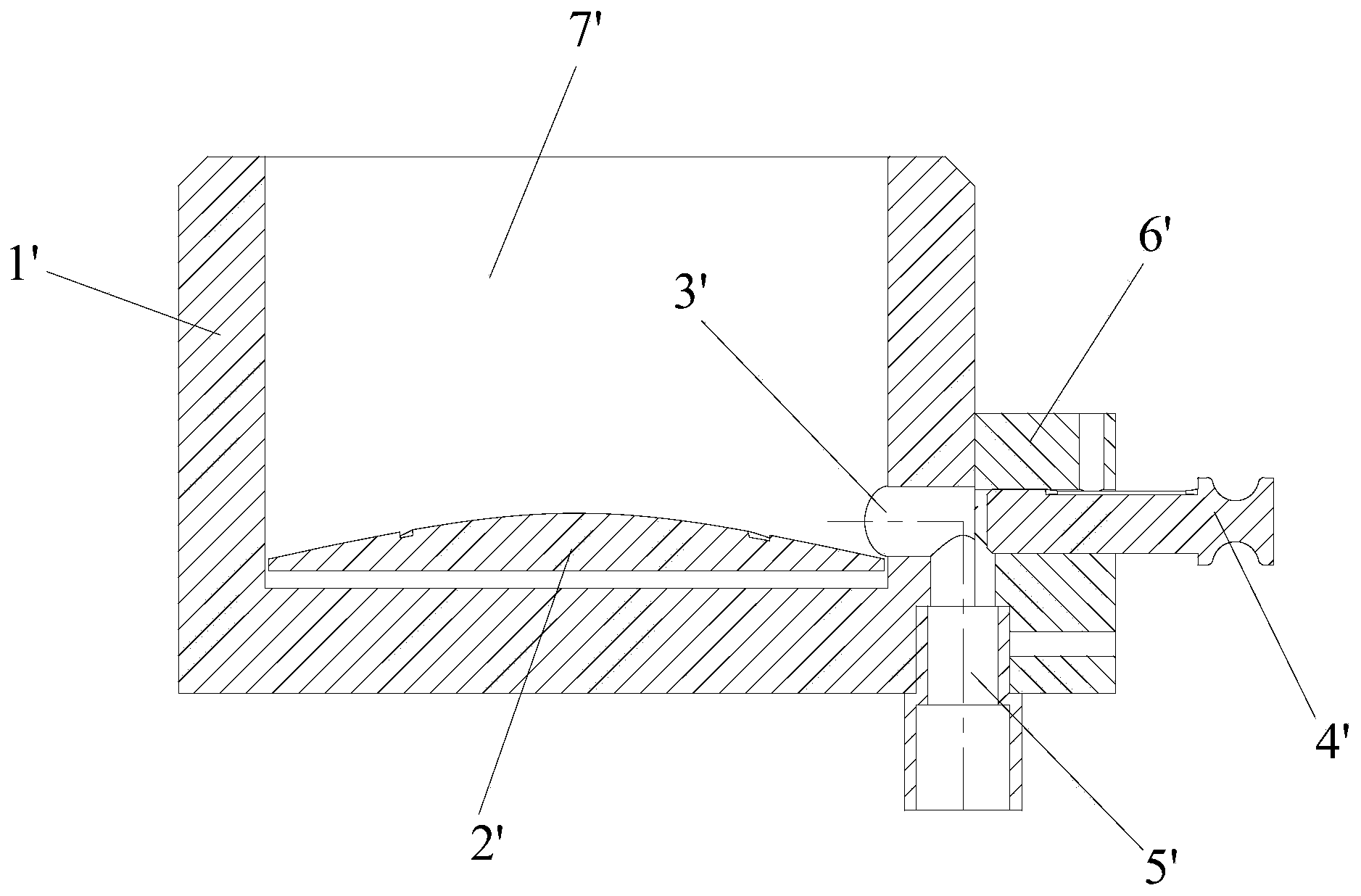

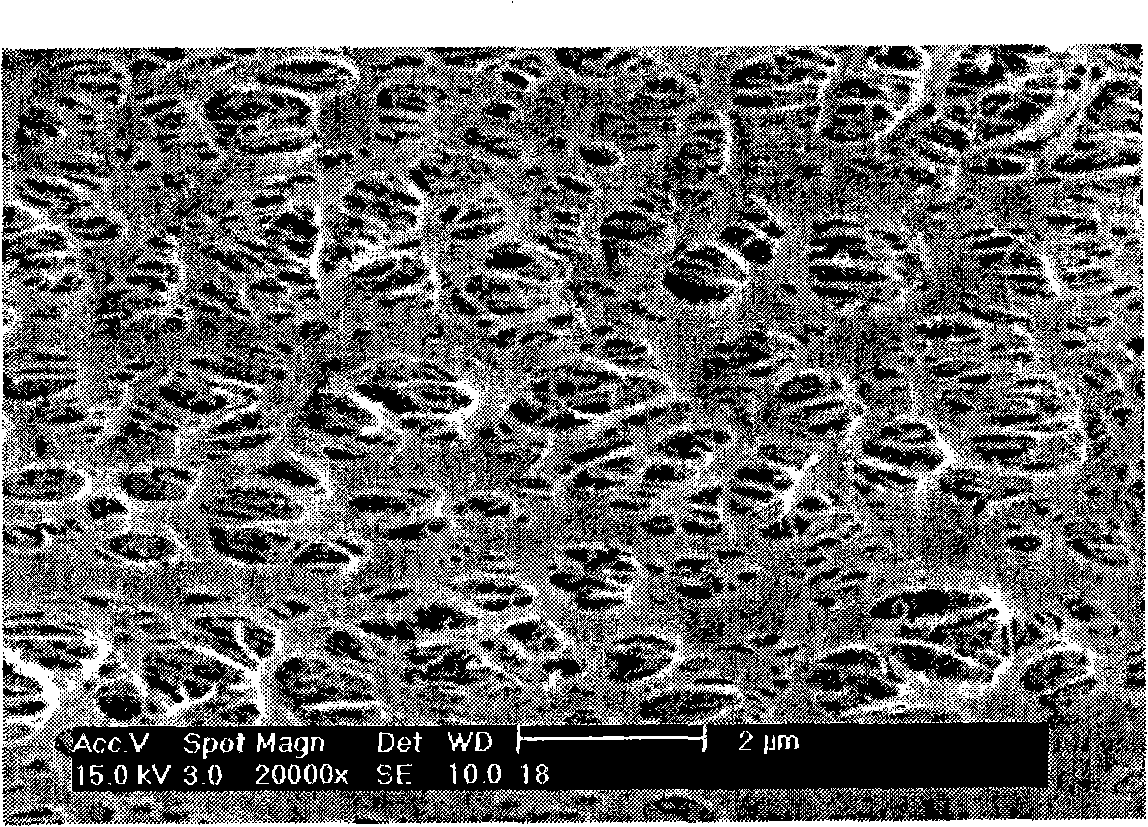

Detection device, three-dimensional printer and three-dimensional printing method

ActiveCN104552946APrevent runawayAvoid quality problemsAdditive manufacturing apparatusOptical detectionEngineeringRestoring force

The invention relates to a detection device used in a fused deposition type three-dimensional printer. The detection device comprises a mounting seat and a first detection unit, wherein the first detection unit comprises a first detection wheel, a spring, a first photoelectric sensor as well as a positioning roller and an extrusion roller rotatably mounted on the mounting seat; an axis of the extrusion roller is parallel to that of the positioning roller, and the distance between the axes is adjustable; restoring force of the spring enables the distance between the axis of the extrusion roller and the axis of the positioning roller to be reduced; a channel for wire forming is formed between a working surface of the extrusion roller and a working surface of the positioning roller wheel; the first detection wheel is coaxially connected with the extrusion roller or the positioning roller in an equal-angular-speed manner; the first detection wheel comprises a base part and a covering part circumferentially arranged along the base part; a light path of the first photoelectric sensor penetrates through a plane formed by rotating the covering part around an axis of the first detection wheel. The detection device can be used for detecting whether the three-dimensional printer has the problems of empty printing and the like or not. In addition, the invention further provides the three-dimensional printer employing the detection device and a printing method of the printer.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

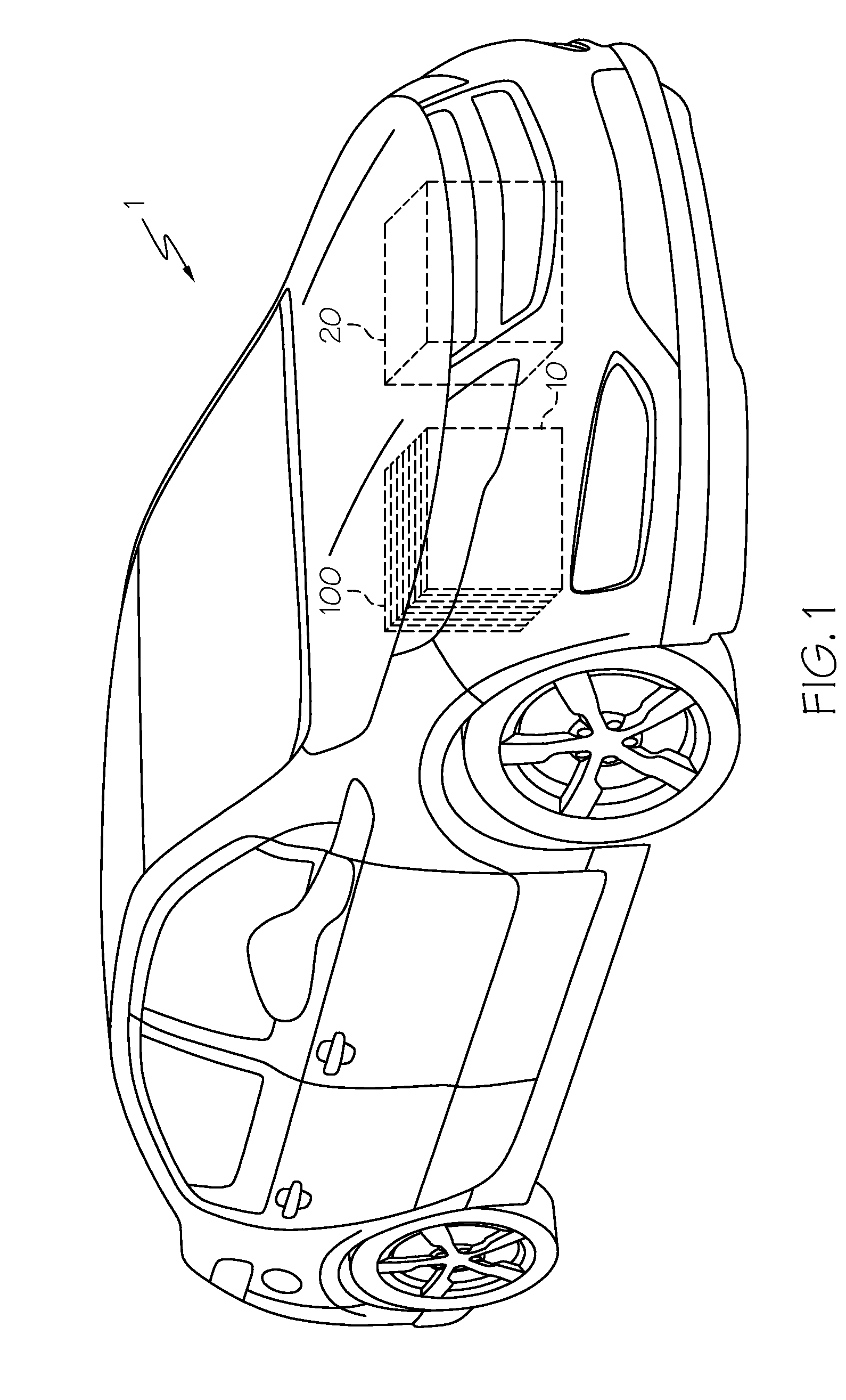

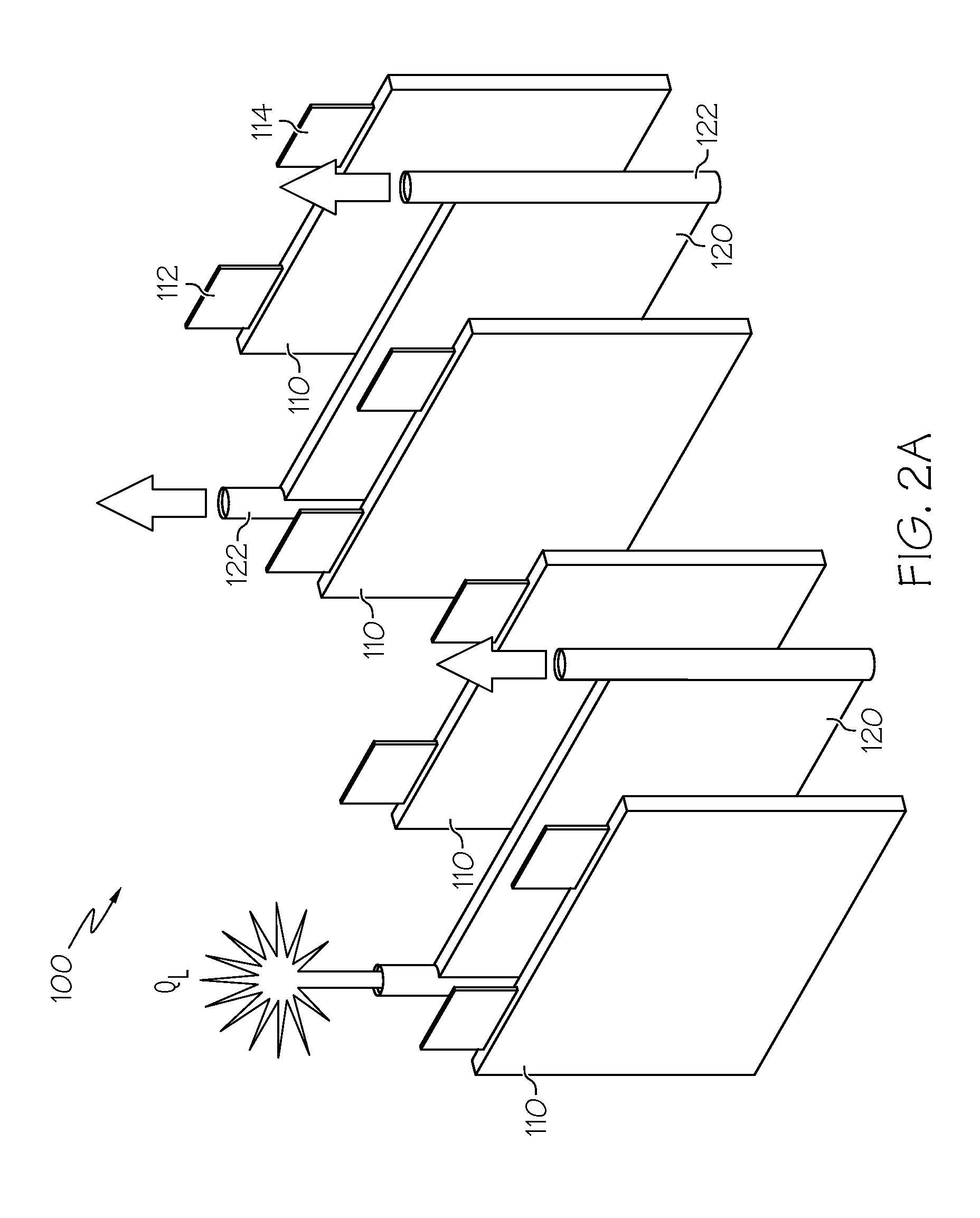

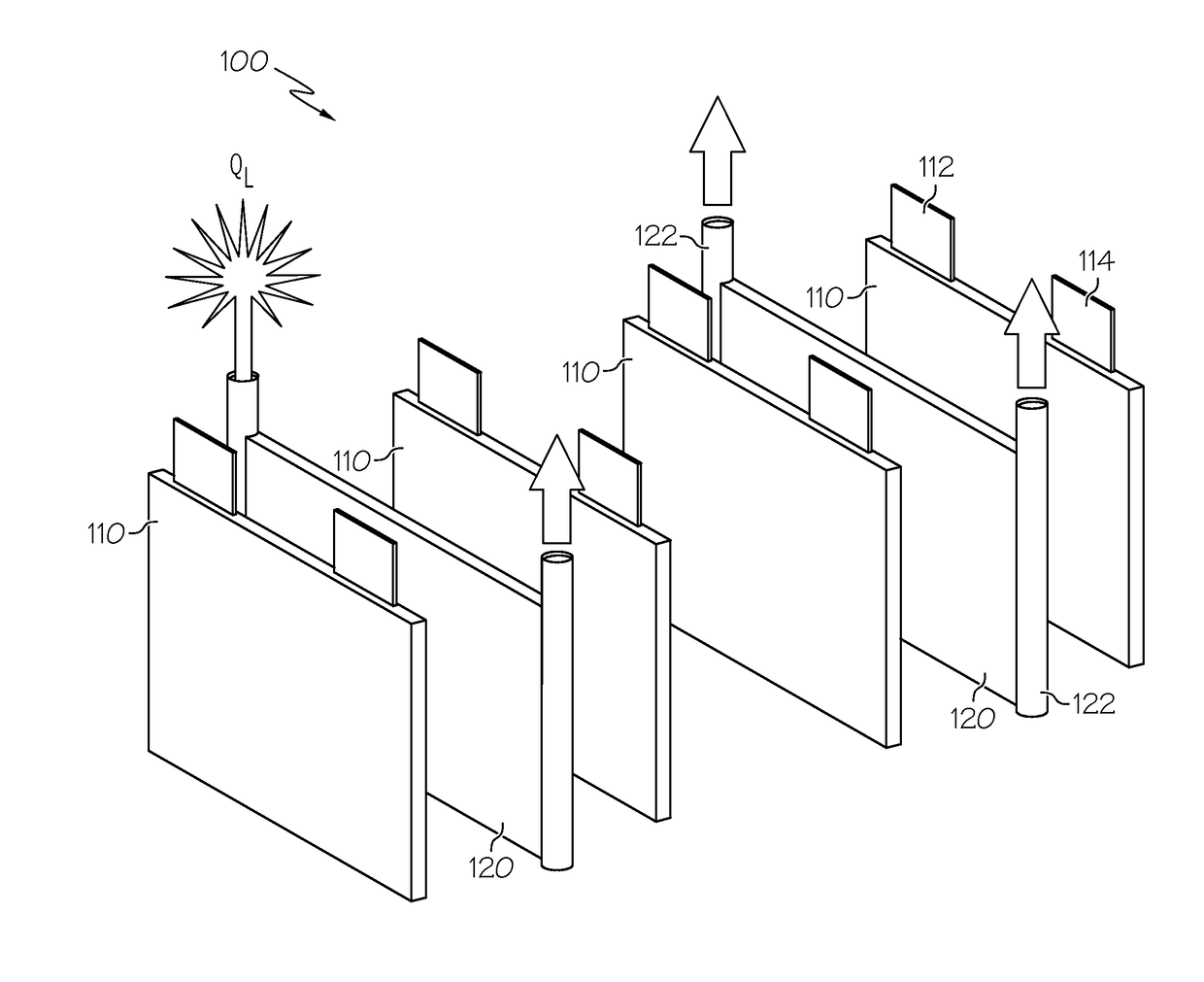

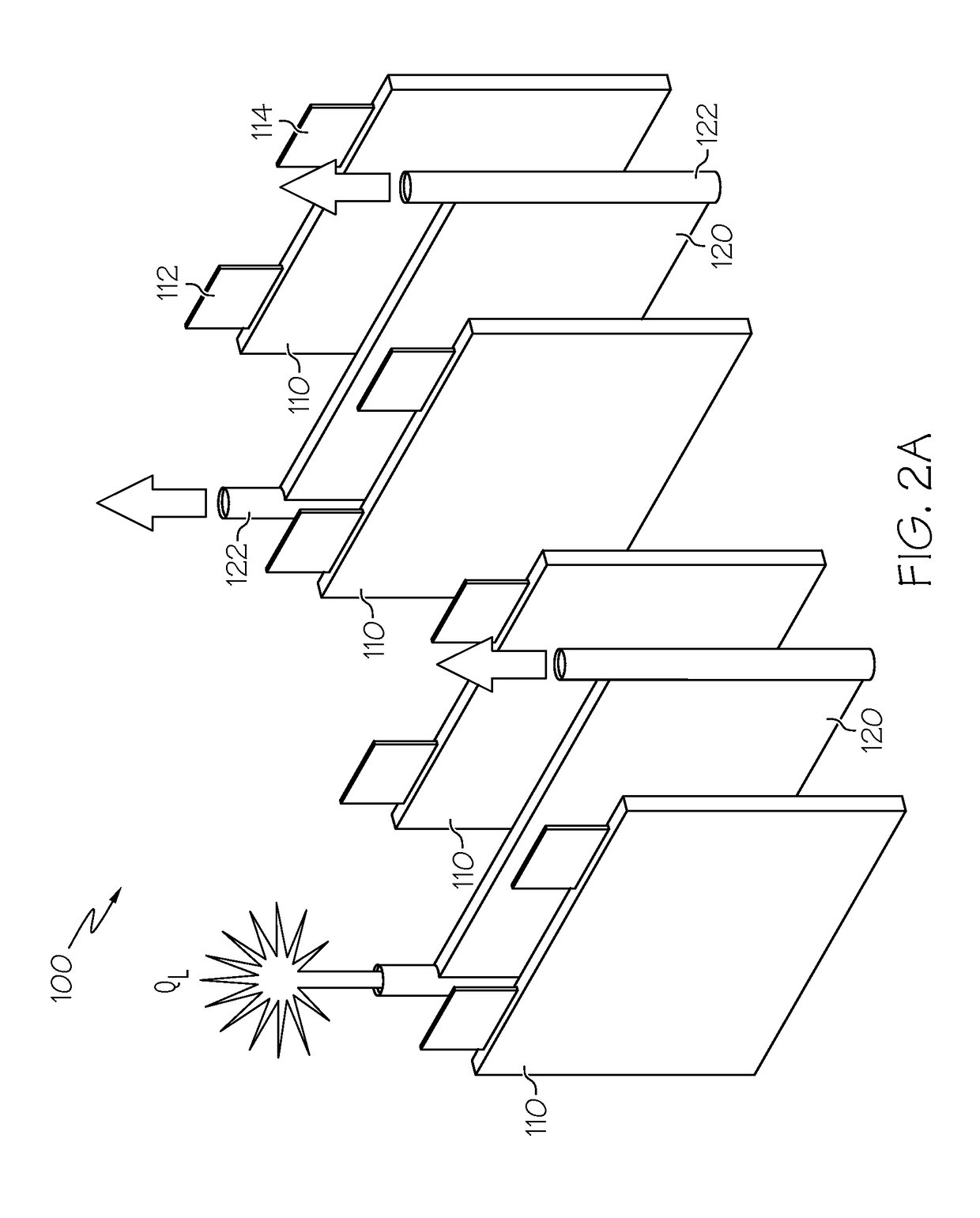

Method for mitigating thermal propagation of batteries using heat pipes

ActiveUS20130130074A1Control damageProlong lifeElectric devicesSafety devices for heat exchange apparatusEngineeringPhase change

A battery module with one or more battery cells and a heat exchange member placed in thermal communication with the battery cell, and a method of making a heat pipe system from the heat exchange member. The heat exchange member includes a container with a heat transfer fluid disposed therein. In one form, the heat transfer fluid is capable of going through a phase change as a way to absorb at least a portion of heat present in or generated by battery cell. A pressure control device cooperates with the container and heat transfer fluid such that upon attainment of a predetermined thermal event within the battery cell, the pressure control device permits liberation of at least a portion of the heat transfer fluid to an ambient environment, thereby relieving pressure on the container and removing some of the excess heat caused by the thermal event.

Owner:GM GLOBAL TECH OPERATIONS LLC

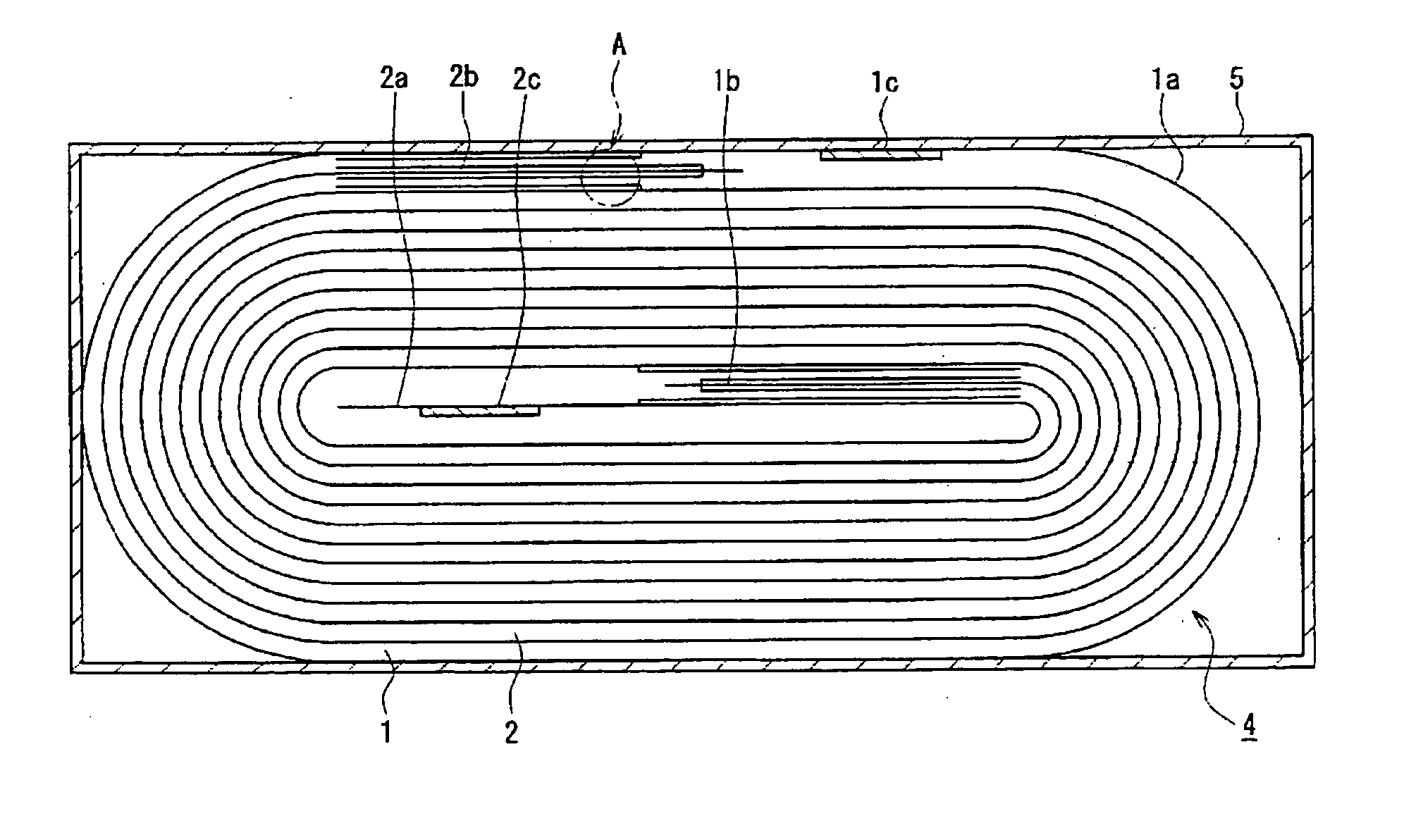

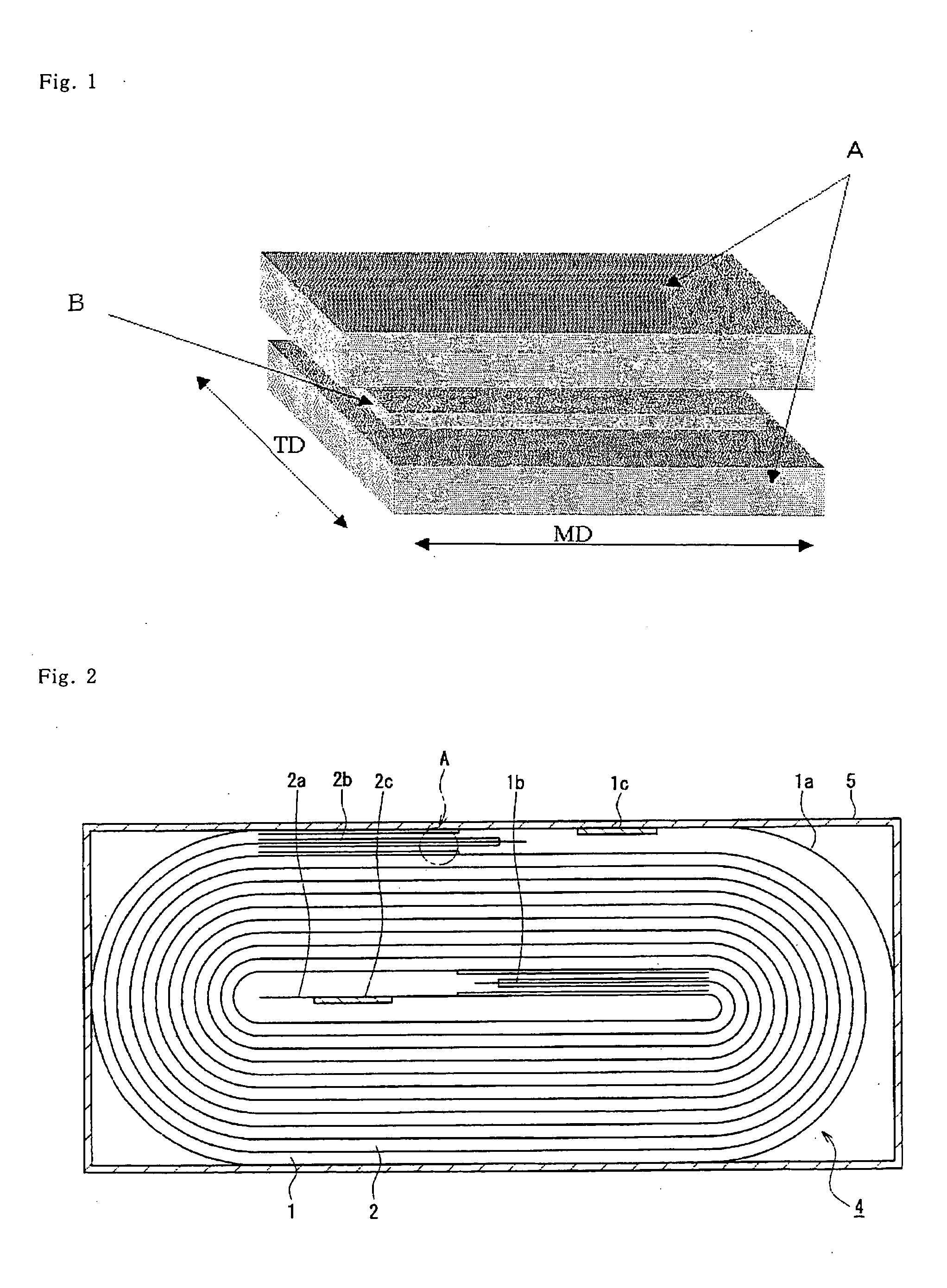

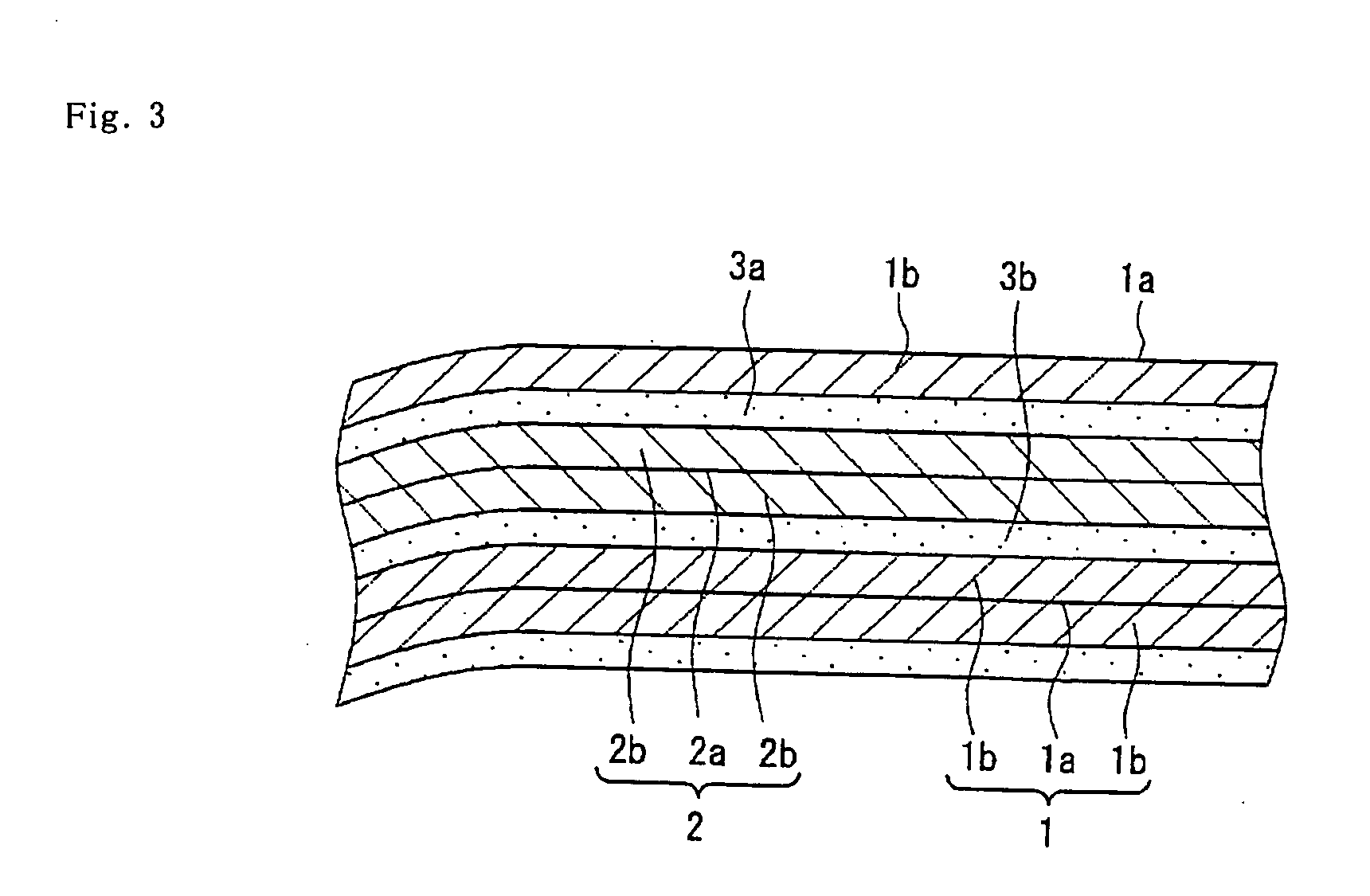

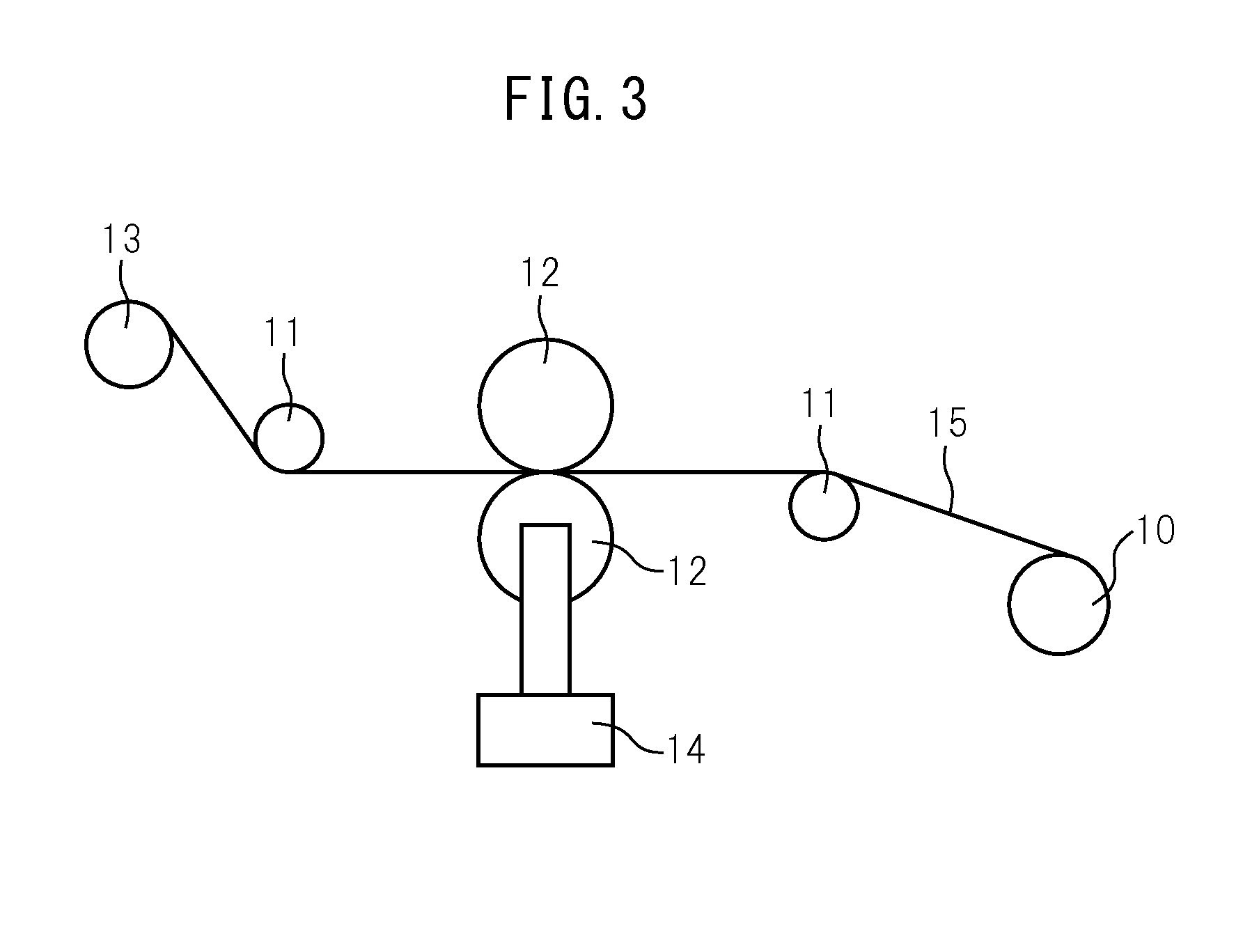

Non-aqueous electrolyte secondary battery

InactiveUS20050058896A1Improve securityLarge capacityCell seperators/membranes/diaphragms/spacersFinal product manufactureMaterials scienceNon aqueous electrolytes

A non-aqueous electrolyte secondary battery comprises a positive electrode, a negative electrode, two kinds of separators and an non-aqueous electrolytic solution, wherein the positive electrode, the negative electrode and the separators are laminated and wound to form a wound electrode body. The secondary battery is characterized in that the first separator having a gas permeability of 400 sec / 100 cm3 or less is provided on the outer surface of the negative electrode, and the second separator having a coefficient of thermal shrinkage of 30% or less in a transverse direction is provided on the inner surface of the negative electrode.

Owner:HITACHT MAXELL LTD

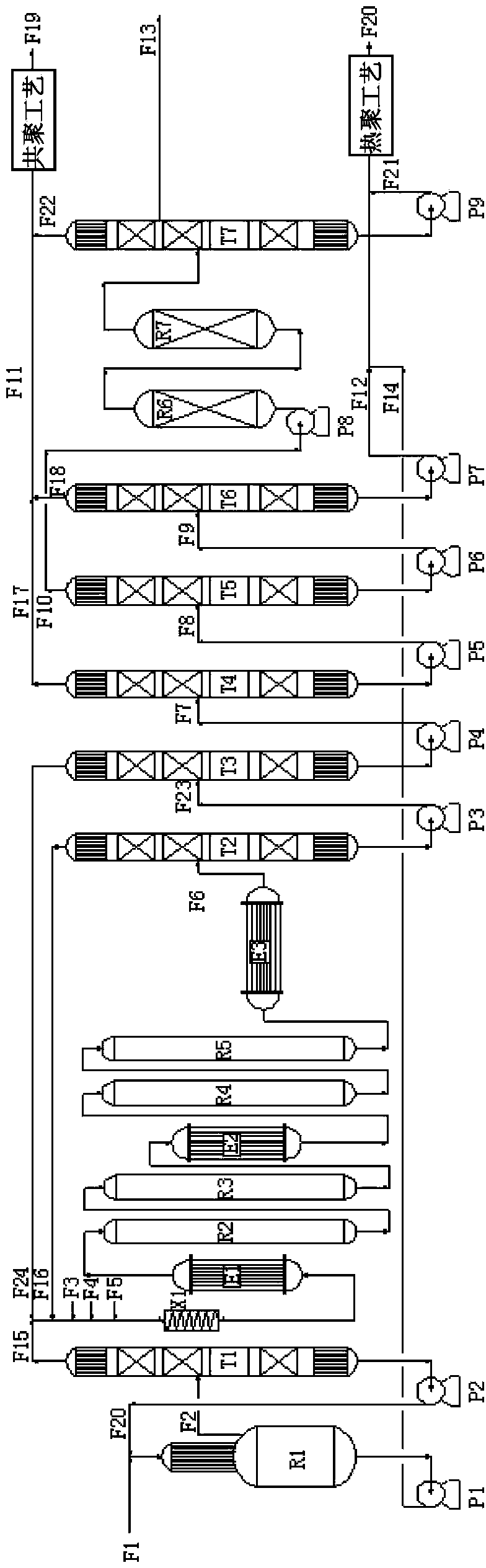

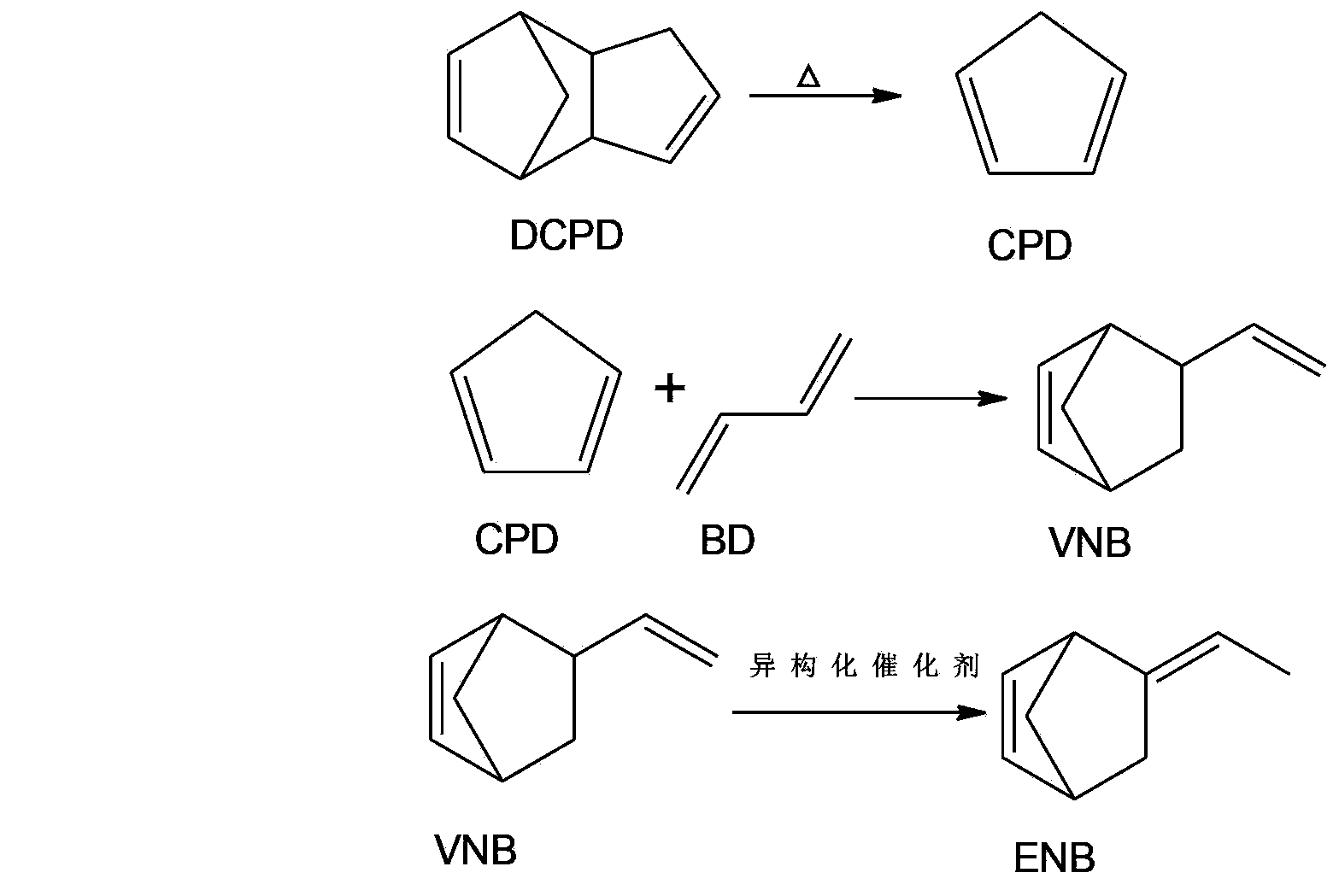

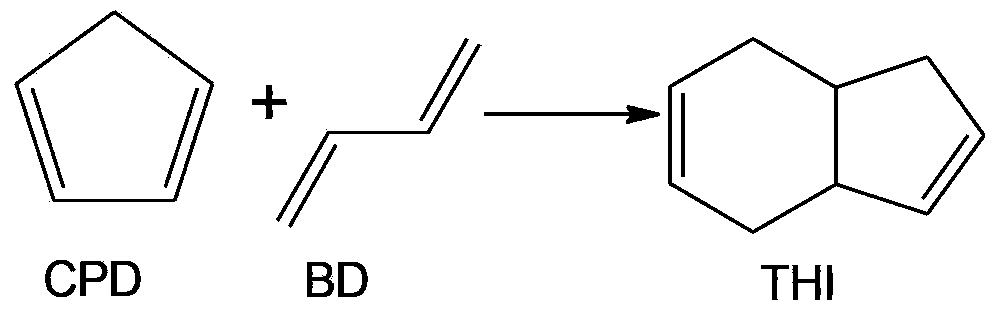

Preparation method of high-purity ethylidene norbornene (ENB)

ActiveCN103483135AHigh yieldAvoid lostHydrocarbon by isomerisationHydrocarbon by depolymerisationIsomerizationDead volume

The invention relates to a preparation method of high-purity ethylidene norbornene (ENB), which comprises the following steps: 1) preparing cyclopentadiene (CPD) from cracked C9 bicyclic section distillate; 2) reacting the CPD and 1,3-butadiene (BD) in a non-dead-volume cascade tubular reactor to generate 5-vinyl-2-norbornene (VNB); 3) separating the crude VNB to obtain refined VNB, collecting the unreacted BD, CPD and circulating solvent, and returning to the front of the tubular reactor, thereby forming a circulating loop; and 4) dehydrating the refined VNB obtained in the step 3), carrying out isomerization reaction to obtain crude ENB, and removing light and heavy components from the crude ENB by a refining tower to obtain the high-purity ENB. The method has the advantages of simple and reliable process route and low facility request, and is suitable for large-scale production.

Owner:HENGHE MATERIALS & SCI TECH CO LTD

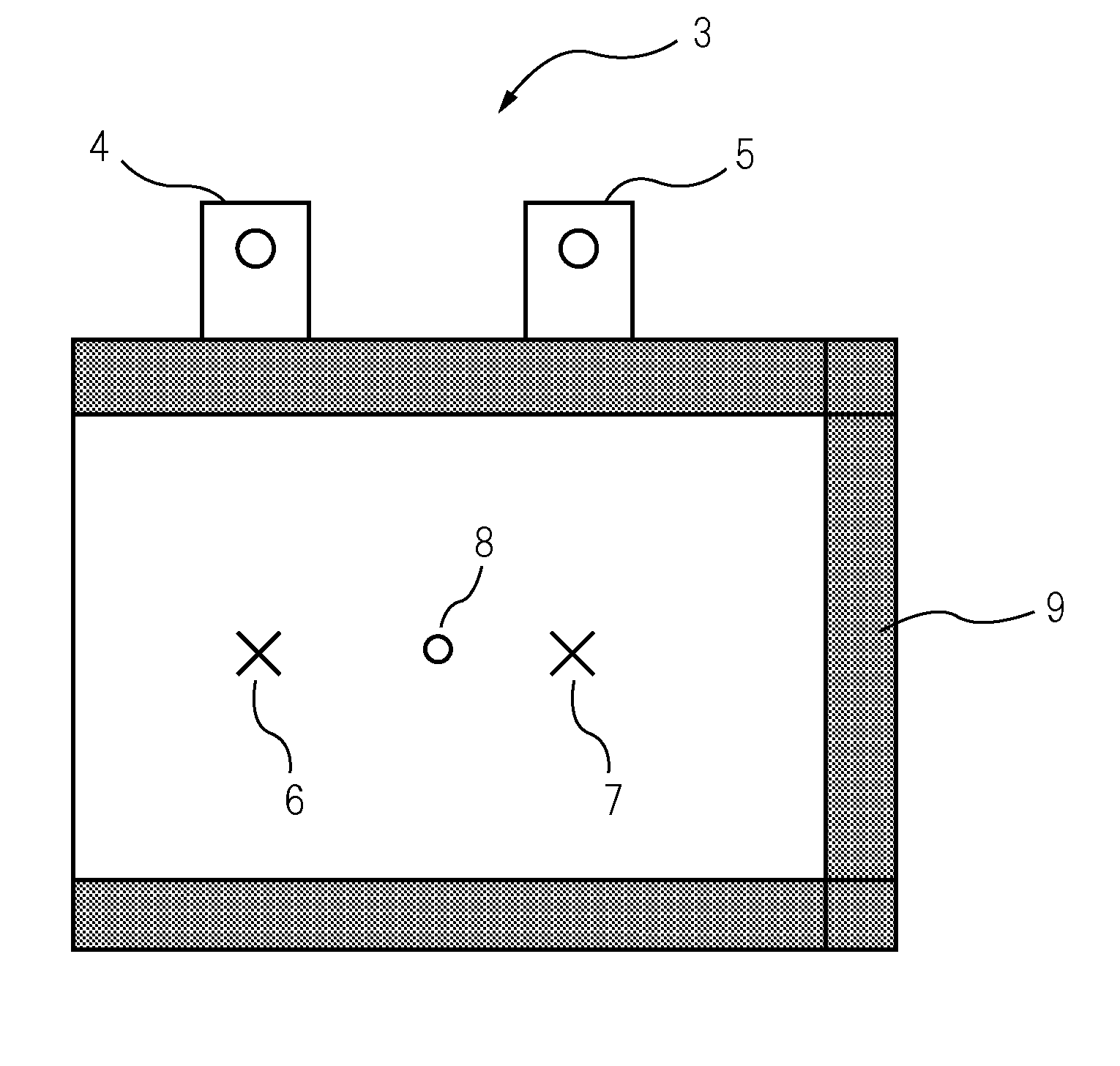

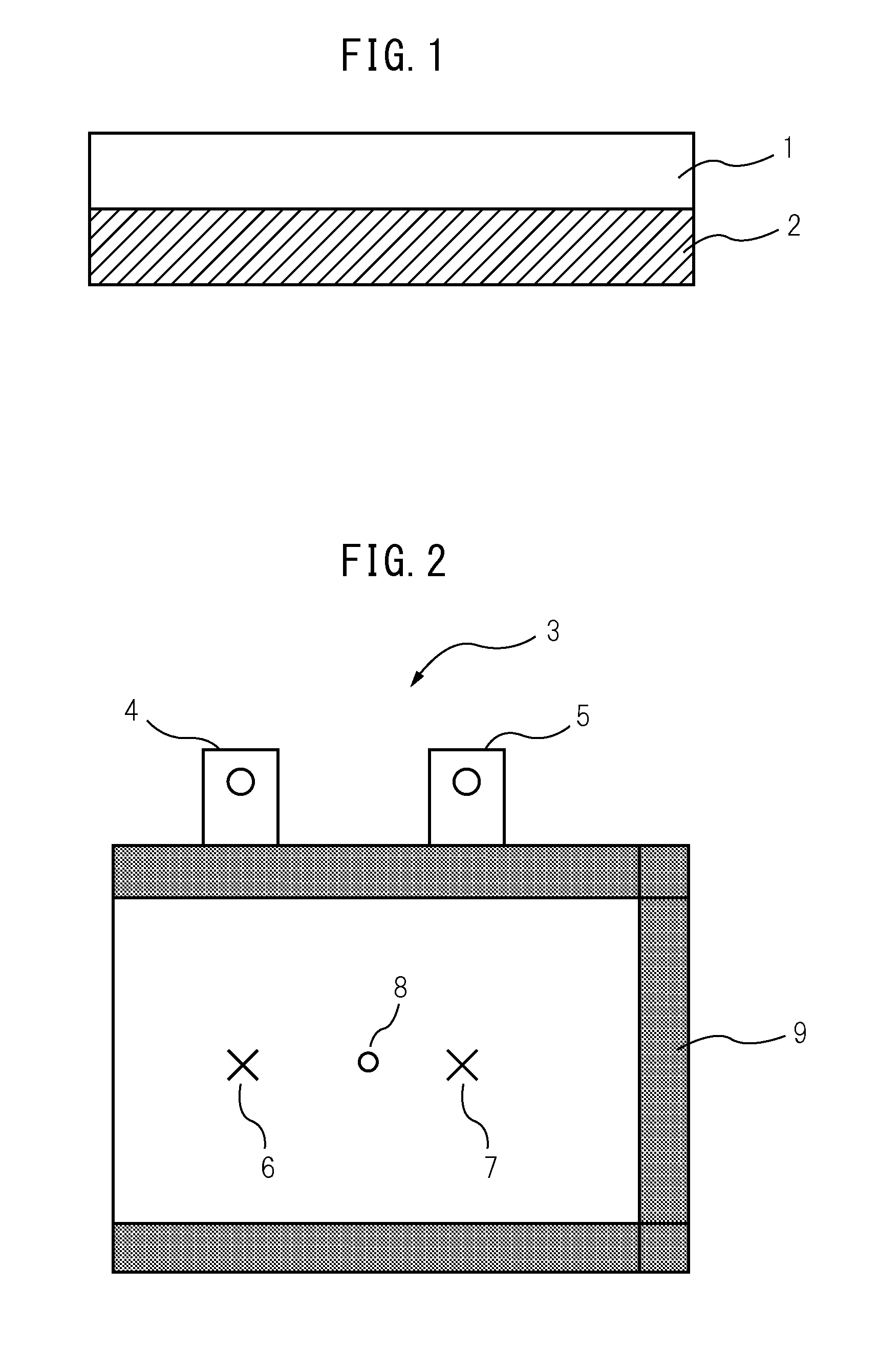

Lithium Ion Capacitor

ActiveUS20150371788A1High output densityImprove featuresHybrid capacitor separatorsHybrid capacitor electrodesPolyolefinPorous membrane

Provided is a lithium ion capacitor that is capable, during internal short circuiting, of suppressing an increase in capacitor temperature and controlling the onset of gasification, smoking and ignition, and of having preferably both low resistance (i.e., high output density) and high cycle characteristics. The lithium ion capacitor comprises an electrode laminated body stored in a casing together with a non-aqueous electrolytic solution containing a lithium ion-containing electrolyte; wherein the electrode laminated body is laminated so that a negative electrode collector having a negative electrode active material comprised of a carbon material, and a positive electrode body having a positive electrode active material face each other through a laminated separator where a polyolefin porous membrane and an insulating porous membrane are laminated; and characterized in that the insulating porous membrane is in contact with the negative electrode body.

Owner:ASAHI KASEI KK

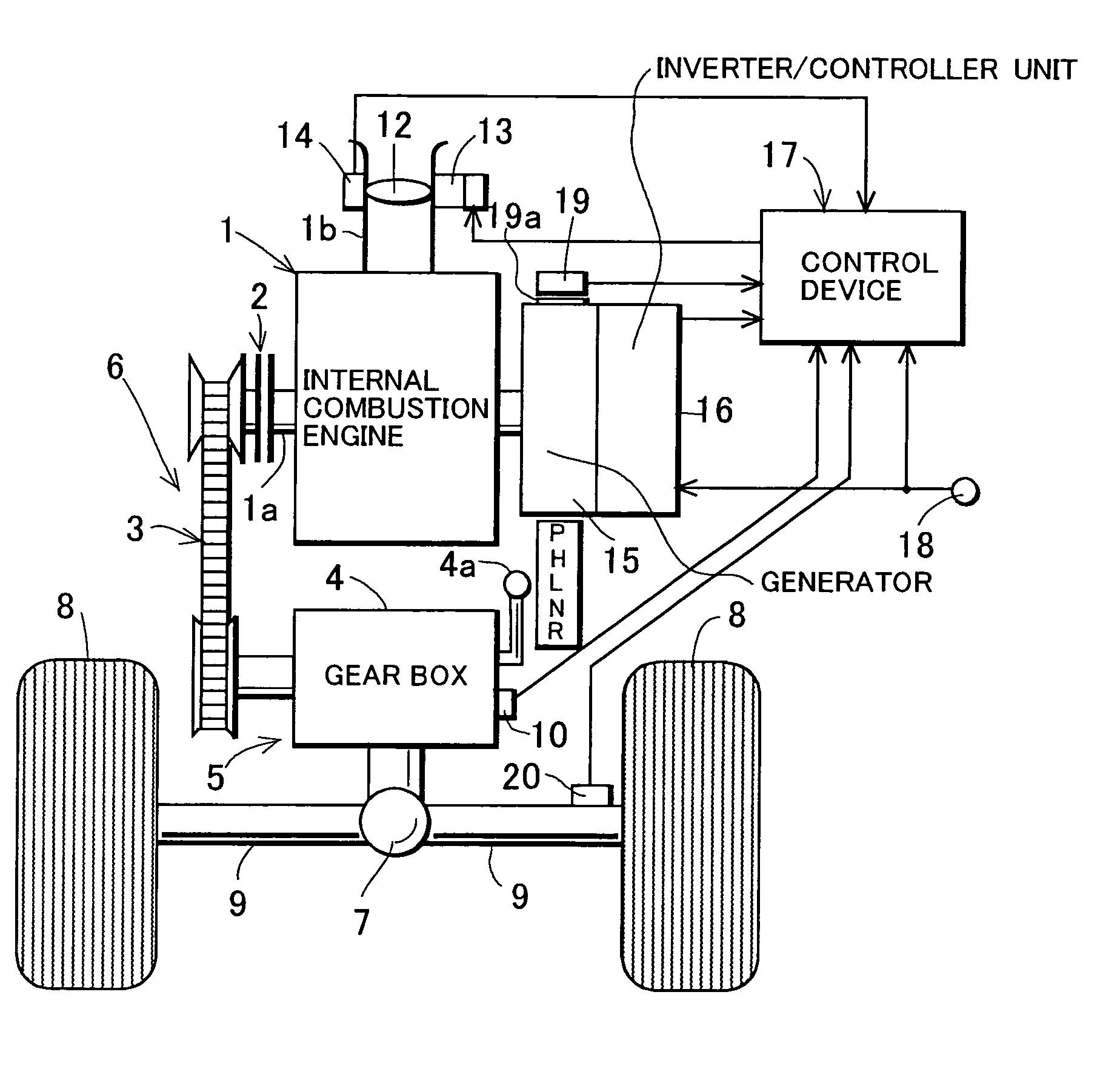

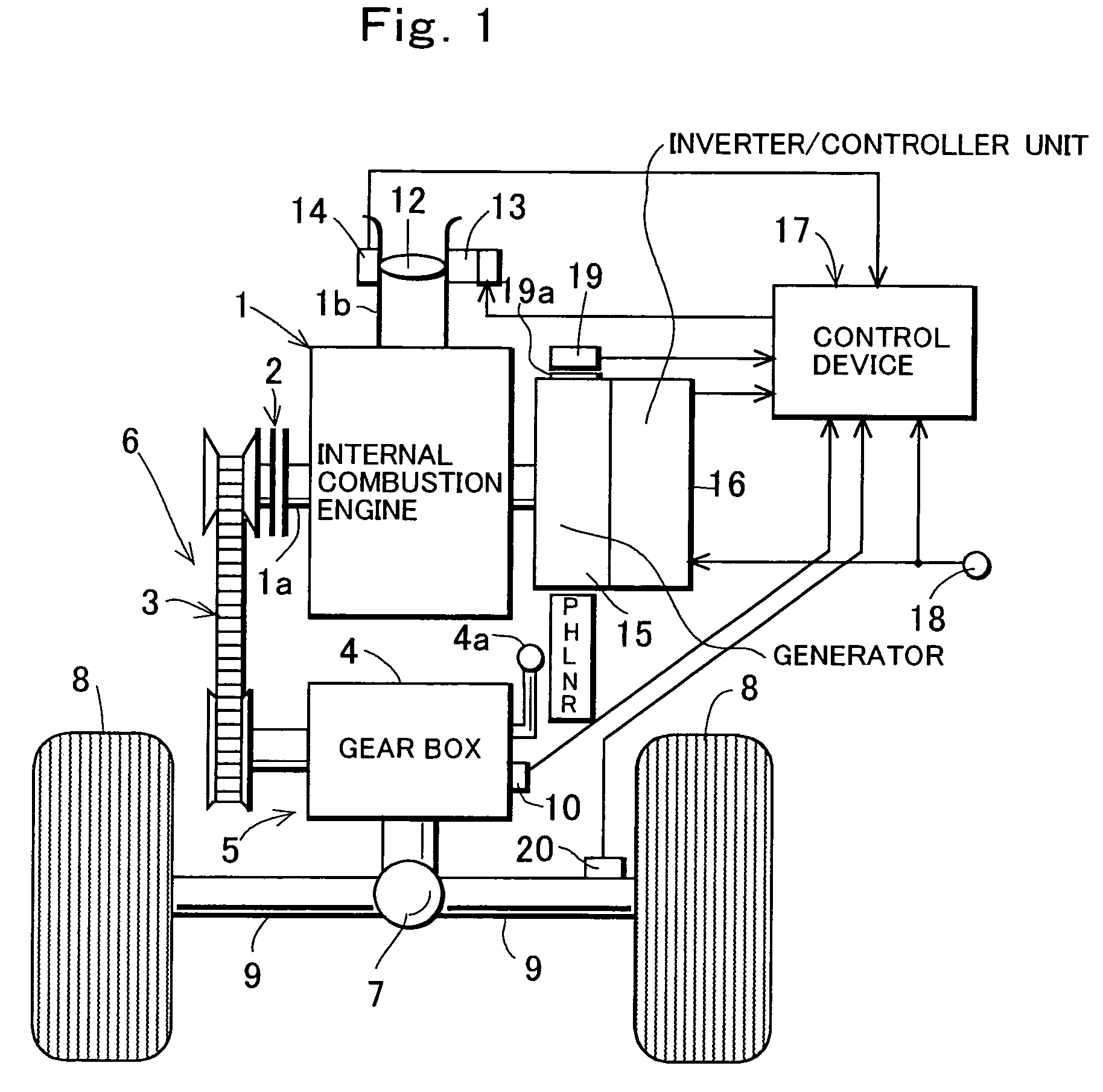

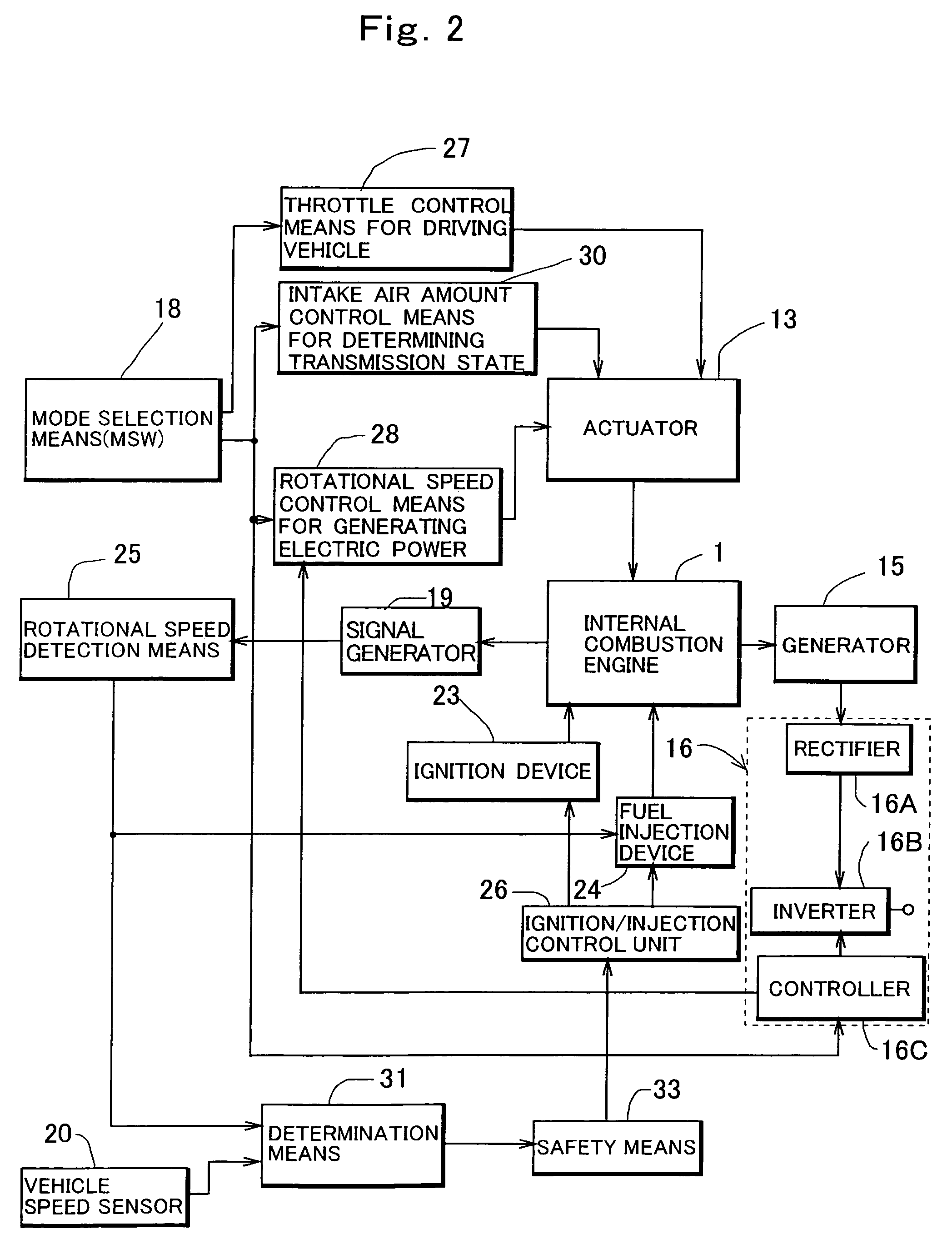

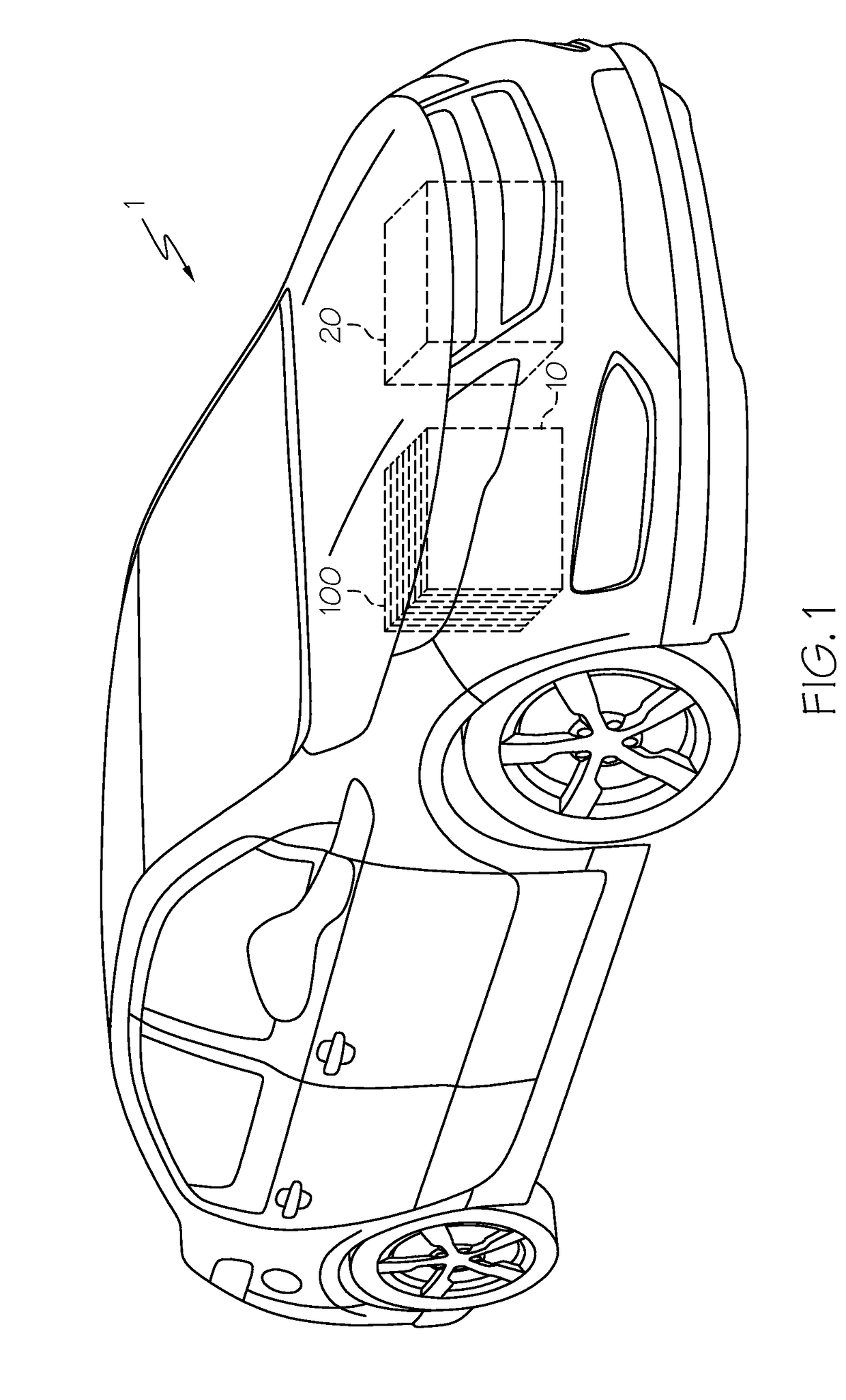

Method and device for determining transmission state of power transmission device for internal combustion engine driven vehicle

InactiveUS6971969B2Accurately determineAccurately determinedHybrid vehiclesElectrical controlTransmitted powerExternal combustion engine

A transmission state determination method of a power transmission device for an internal combustion engine driven vehicle including steps of: driving a generator by an internal combustion engine with a vehicle driven by the internal combustion engine stopped; performing an intake air amount gradually increasing process for gradually increasing the intake air amount of the internal combustion engine when the internal combustion engine is controlled so as to generate predetermined power from the generator; determining that the power transmission device for transmitting the output of the internal combustion engine to wheels of the vehicle is in a state of transmitting power when slight movement of a vehicle body is detected in the intake air amount gradually increasing process; and determining that the power transmission device is in a state of cutting power transmission when movement of the vehicle body is not detected in the intake air amount gradually increasing process.

Owner:KOKUSAN DENKI CO LTD

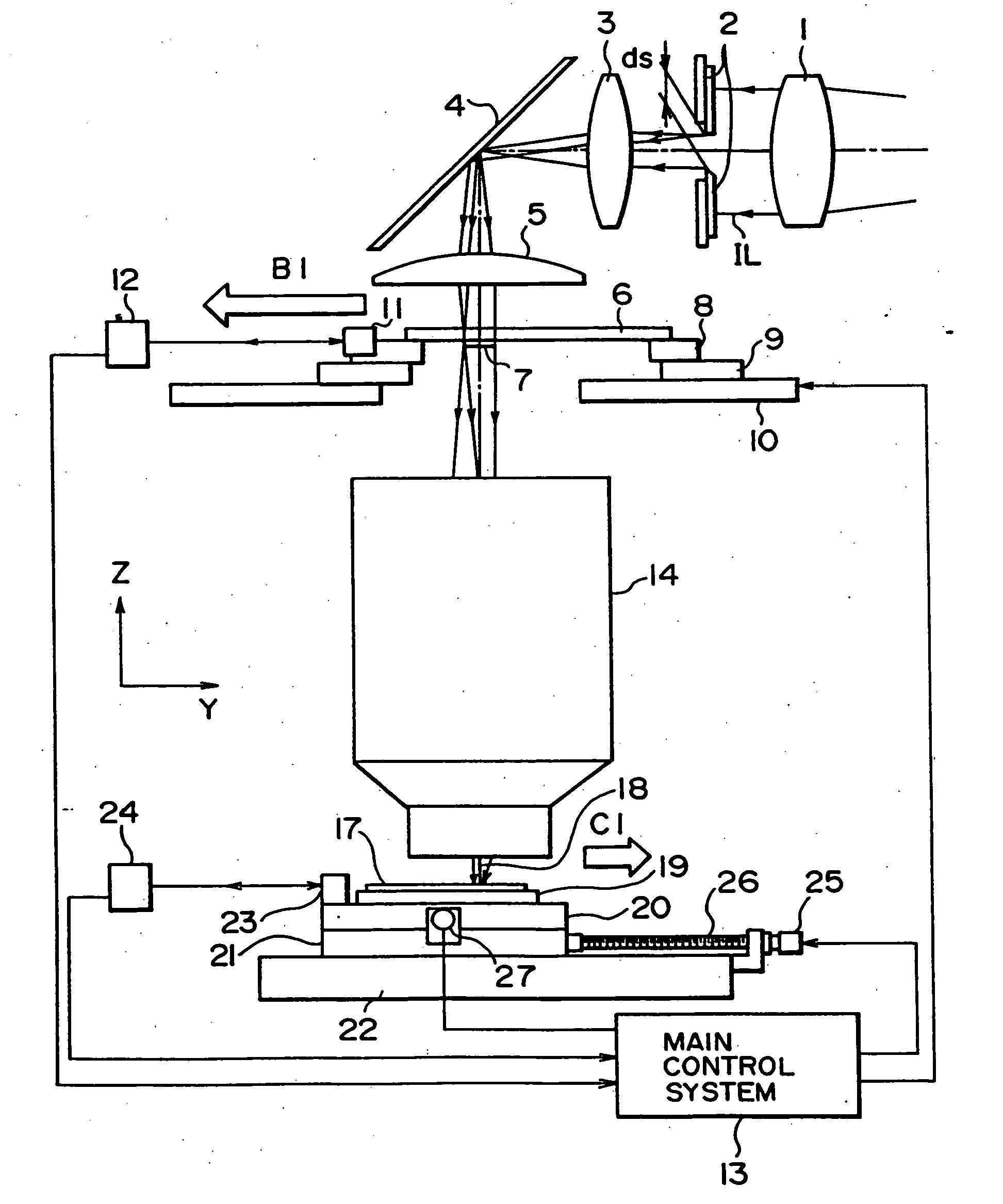

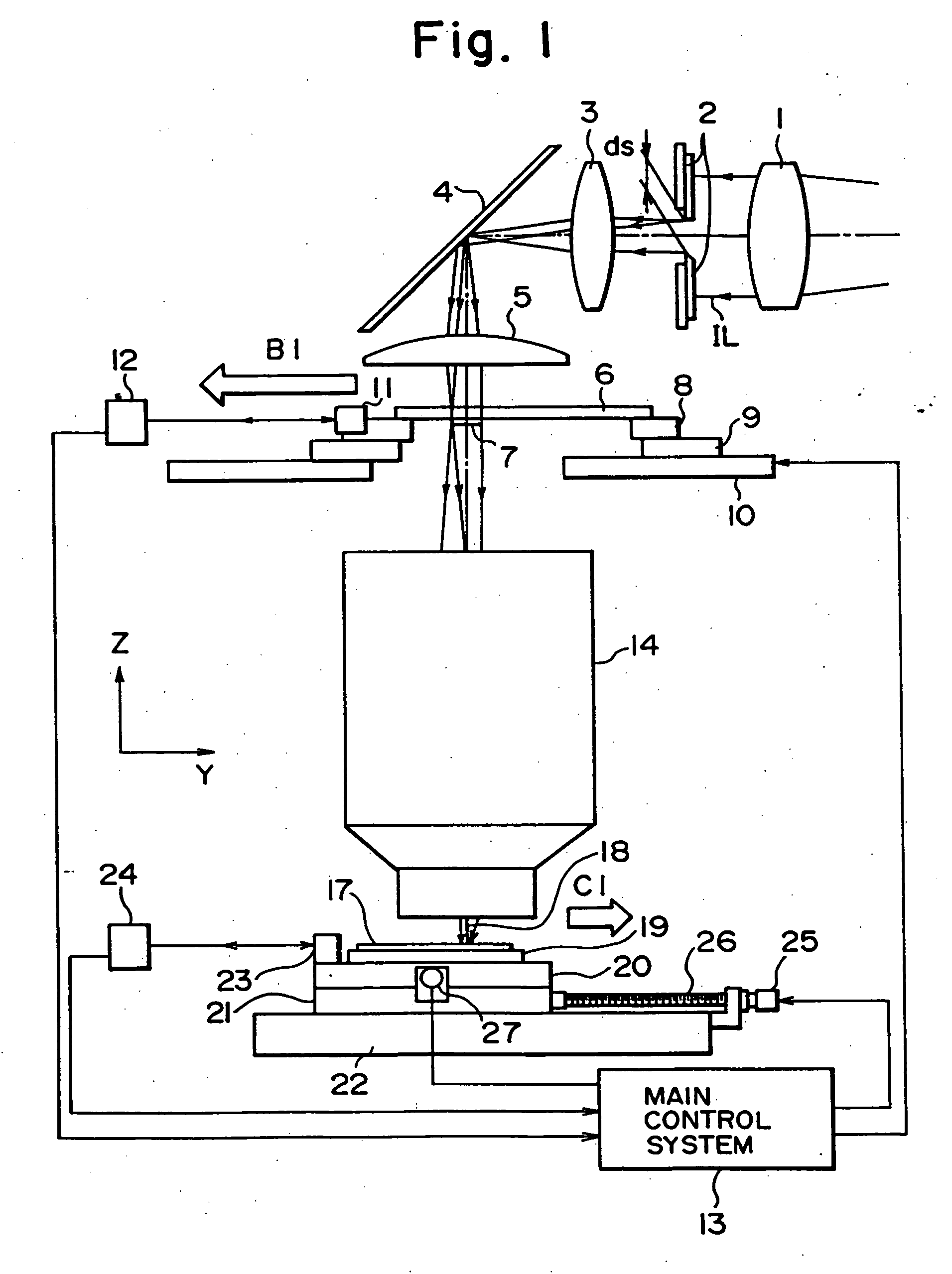

Stage unit, drive table, and scanning exposure apparatus using same

InactiveUS20050133732A1Minimize amount of heat generatedHigh measurement accuracyMaterial analysis using wave/particle radiationPhotomechanical exposure apparatusLiquid-crystal displayEngineering

An exposure method for manufacturing a liquid crystal display utilizes a scanning exposure apparatus to expose a pattern of a mask onto a glass plate. The exposure method includes a step of moving a mask stage that holds the mask in a scanning direction by a first electromagnetic actuator. The first electromagnetic actuator moves the mask stage associating with a guide member that extends in the scanning direction. The method also includes the step of moving the mask stage in a non-scanning direction different from the scanning direction by a second electromagnetic actuator. The second electromagnetic actuator moves the mask stage associating with no guide member, and a moving distance in the non-scanning direction by the second electromagnetic actuator is shorter than a moving distance in the scanning direction by the first electromagnetic actuator.

Owner:NIKON CORP

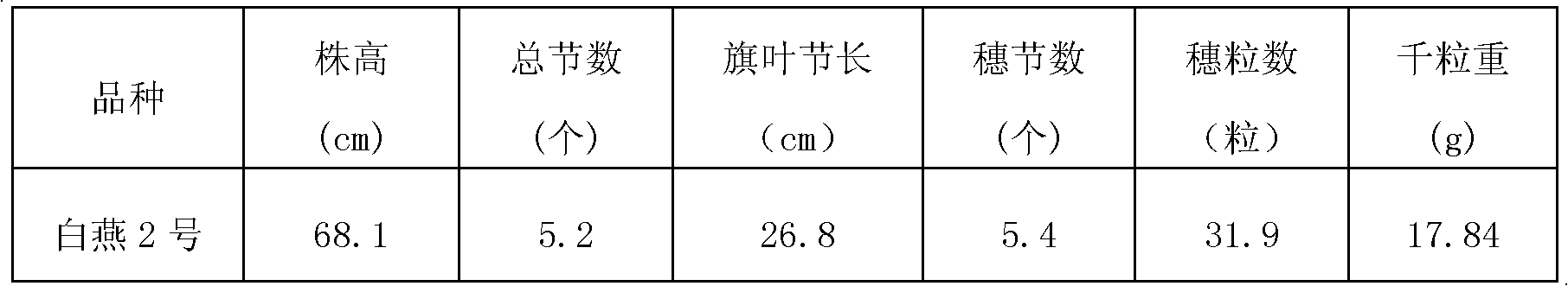

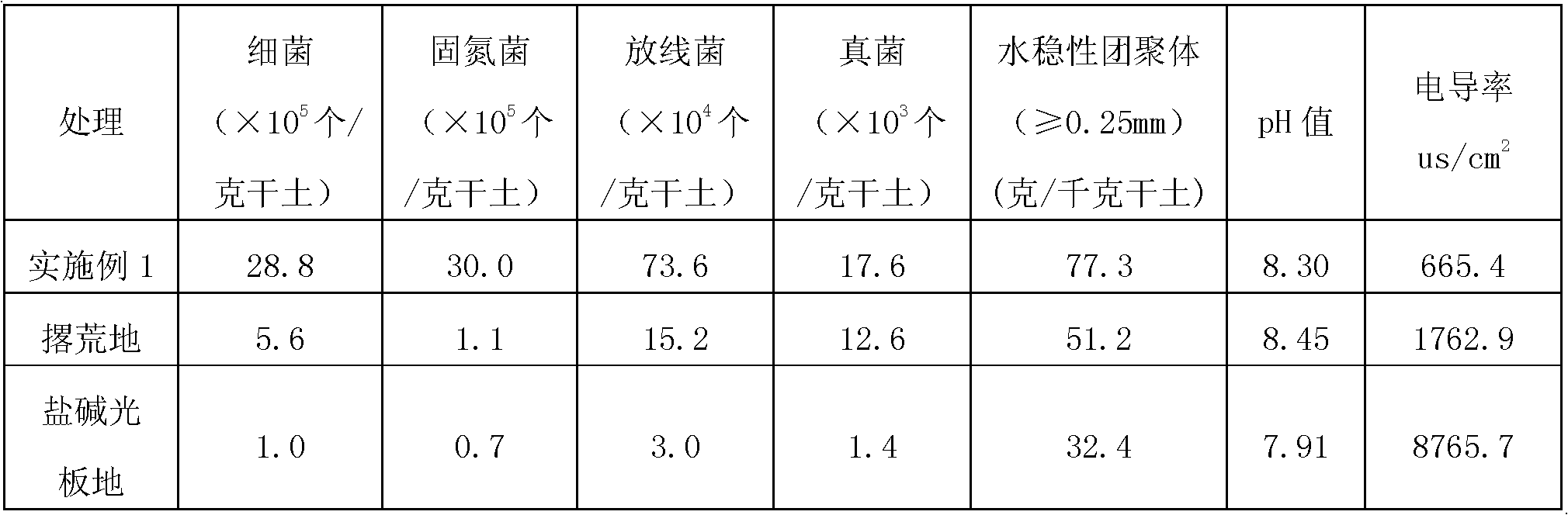

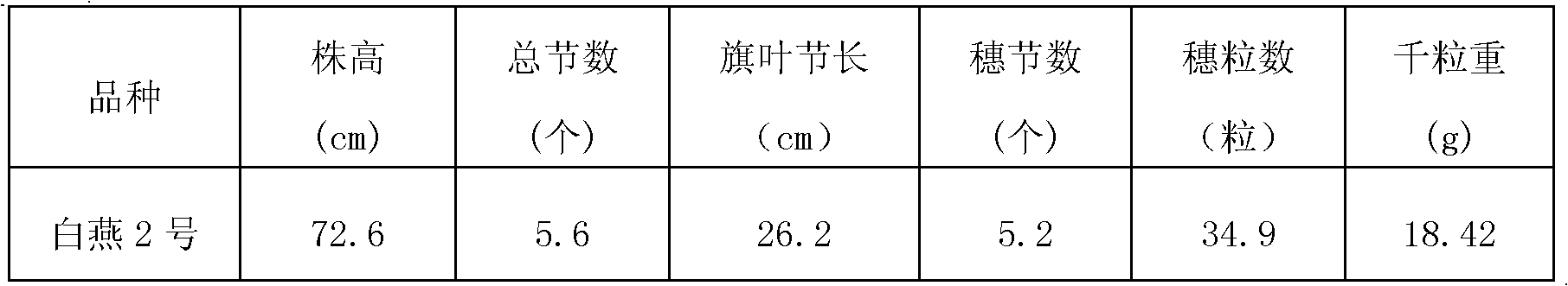

Method for planting oat by utilizing yellow river delta coast salinized soil

InactiveCN102630458AGood biological foundationHigh organic contentHorticultureEconomic benefitsPest control

The invention relates to a method for planting oat by utilizing yellow river delta coast salinized soil. The method comprises the following steps of: (1) applying crop straws and thoroughly decomposed farm manure onto the surface of the yellow river delta coast salinized soil, deeply ploughing and leveling; (2) irrigating deeply land ploughed and leveled in the step (1) before seeding; (3) uniformly spreading a soil ecological modifying agent and the compound fertilizer at the same time after all surface water permeates into soil, and carrying out rotary tillage; and (4) ridging after rotary tillage, seeding oat from the last ten days of March to the beginning of April, and compacting after seeding; and (5) carrying out childbearing period irrigation, fertilization, pest control, weed control and harvesting. The method disclosed by the invention has the advantages of low investment, can continuously improving the soil structure and can realize certain economic benefit.

Owner:INST OF AGRO FOOD SCI & TECH SHANDONG ACAD OF AGRI SCI

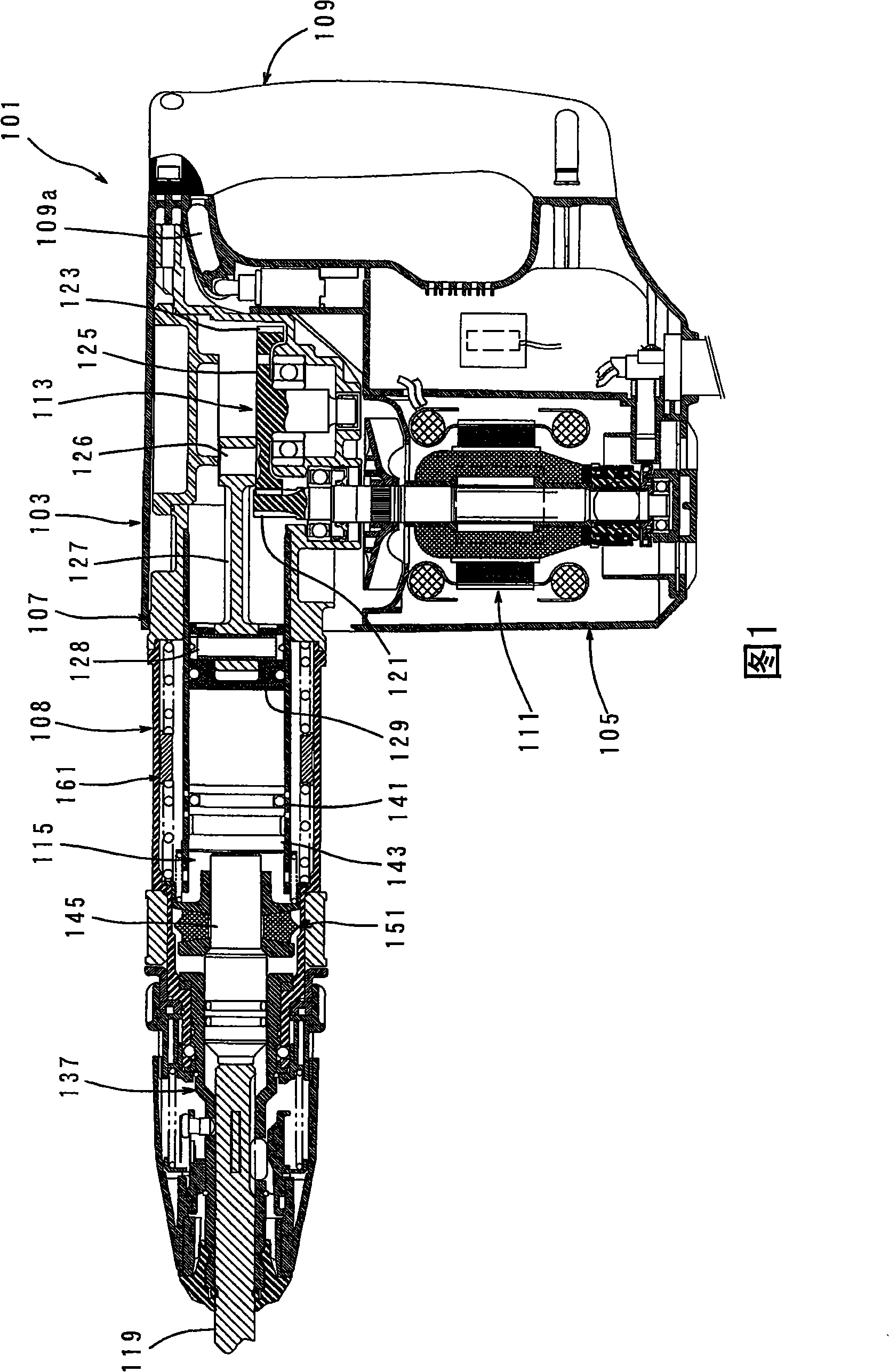

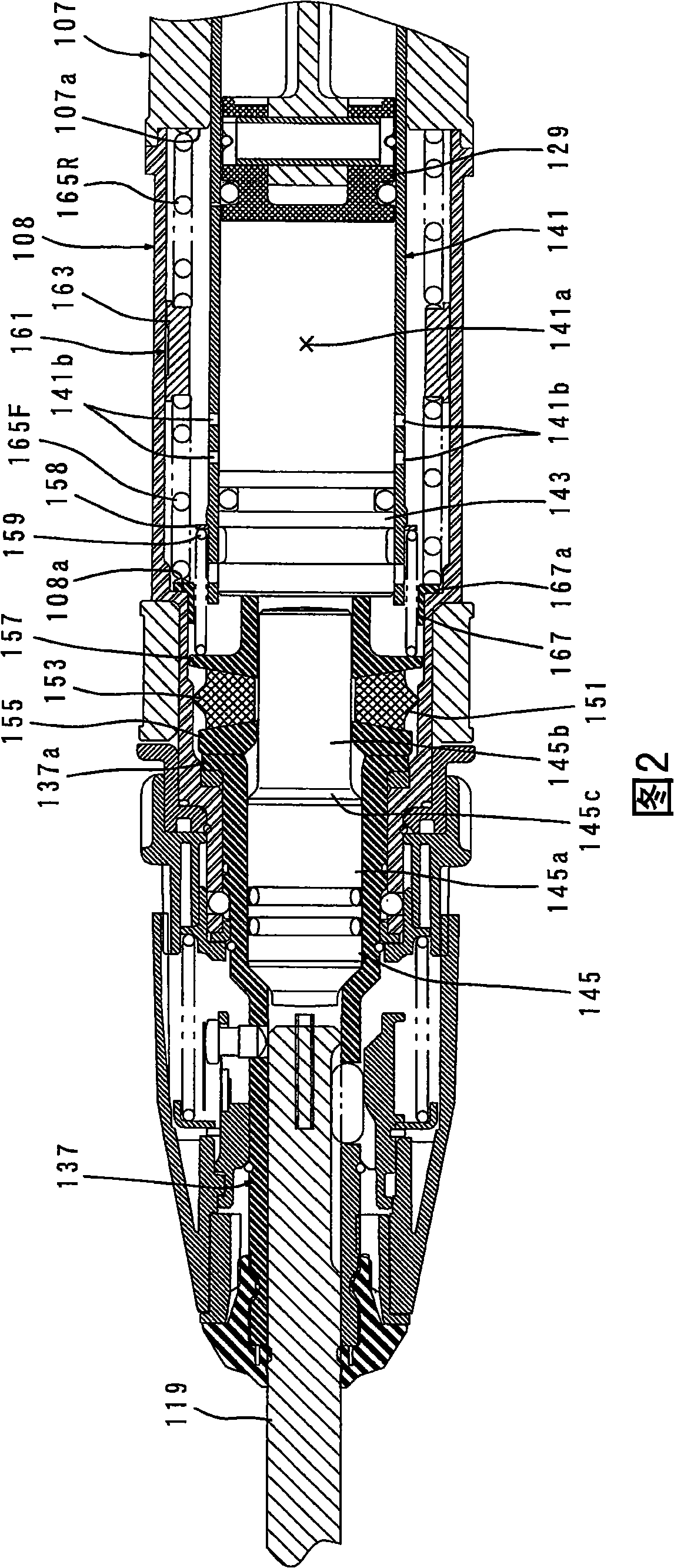

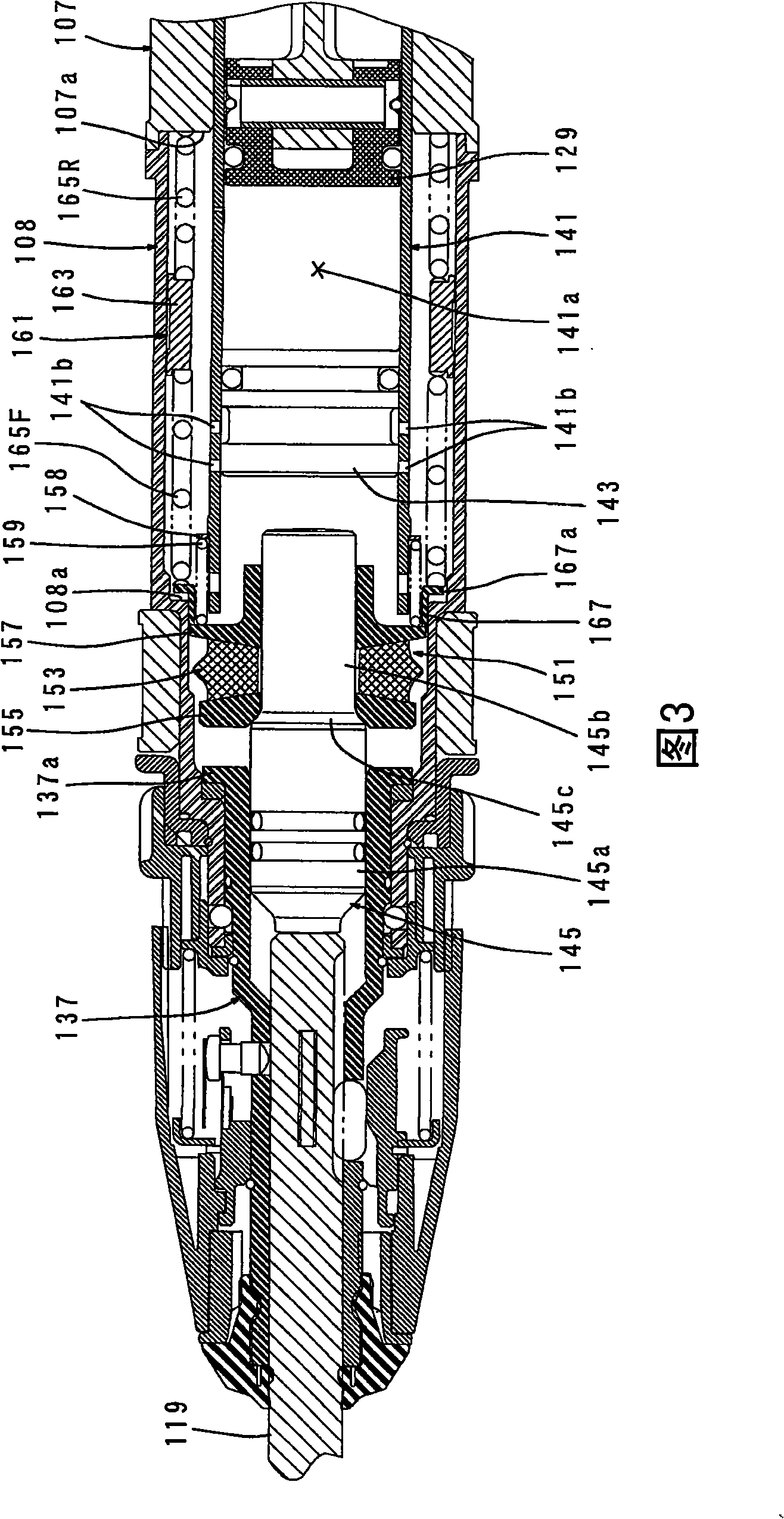

Impact tool

ActiveCN101306530AChange pressureAvoid straight line motionPortable percussive toolsElastomerElastic component

The invention provides an impact tool capable of inhibiting vibration of a tool body generated while hammering process, lessening counterforce to the processed material after impact motions and rationalizing structure of the device. The impact tool includes a tool body (103); a dynamic vibration reducer (161) having a heavy block (163) and elastic components (165F, 165R) and inhibiting vibration while the hammering process; a positioning elastic element which positions the tool body (101) with respect to the processed material prior to the hammering process, so as to, under the positioning state, absorb a counterforce caused by rebound from the processed material and acting on the hammer actuating members (119, 145) when the hammer actuating member (119, 145) perform the hammering process on the processed material. The positioning elastic element includes the elastic elements (165F, 165R) formed as component parts of the dynamic vibration reducer (161).

Owner:MAKITA CORP

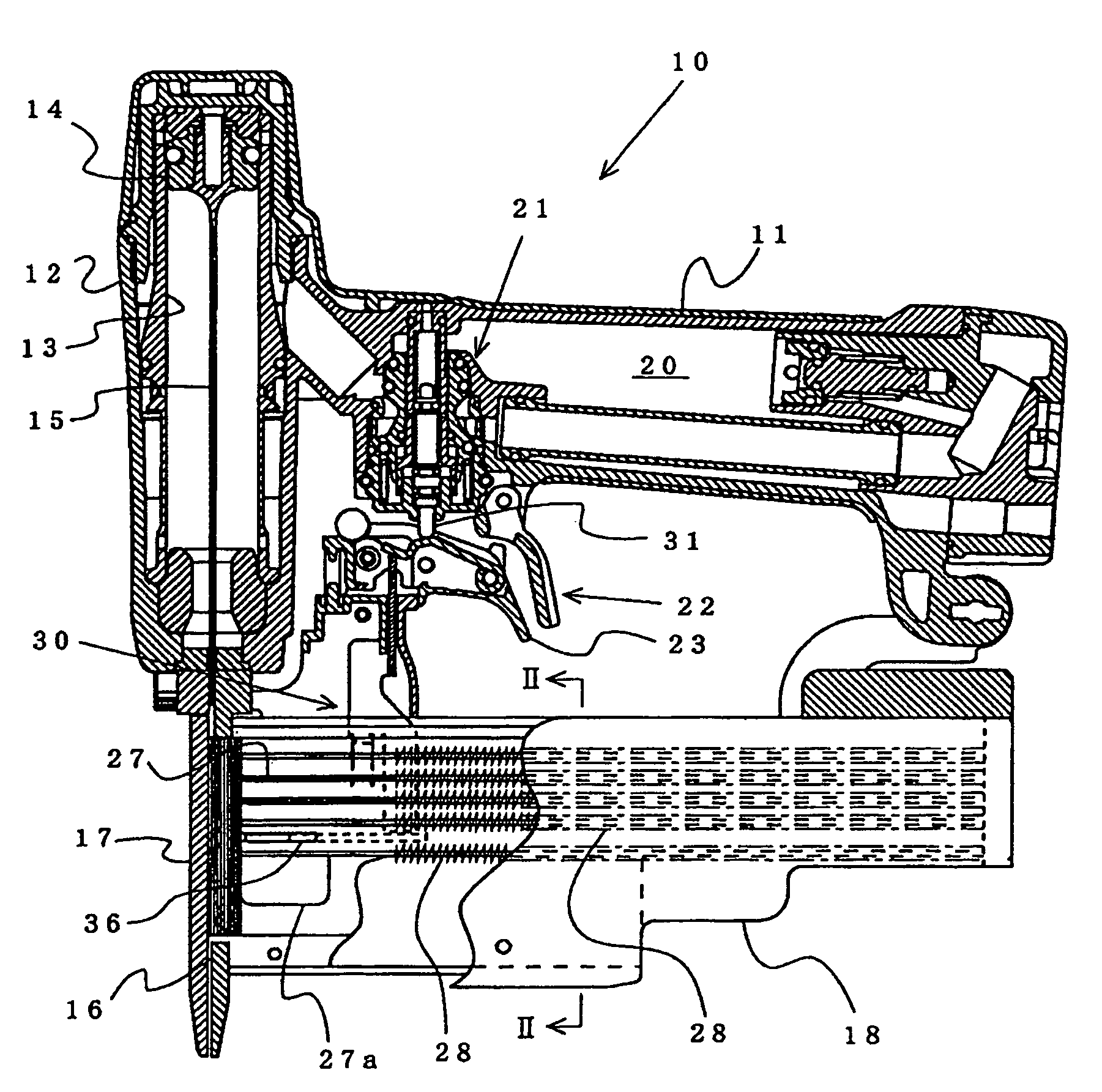

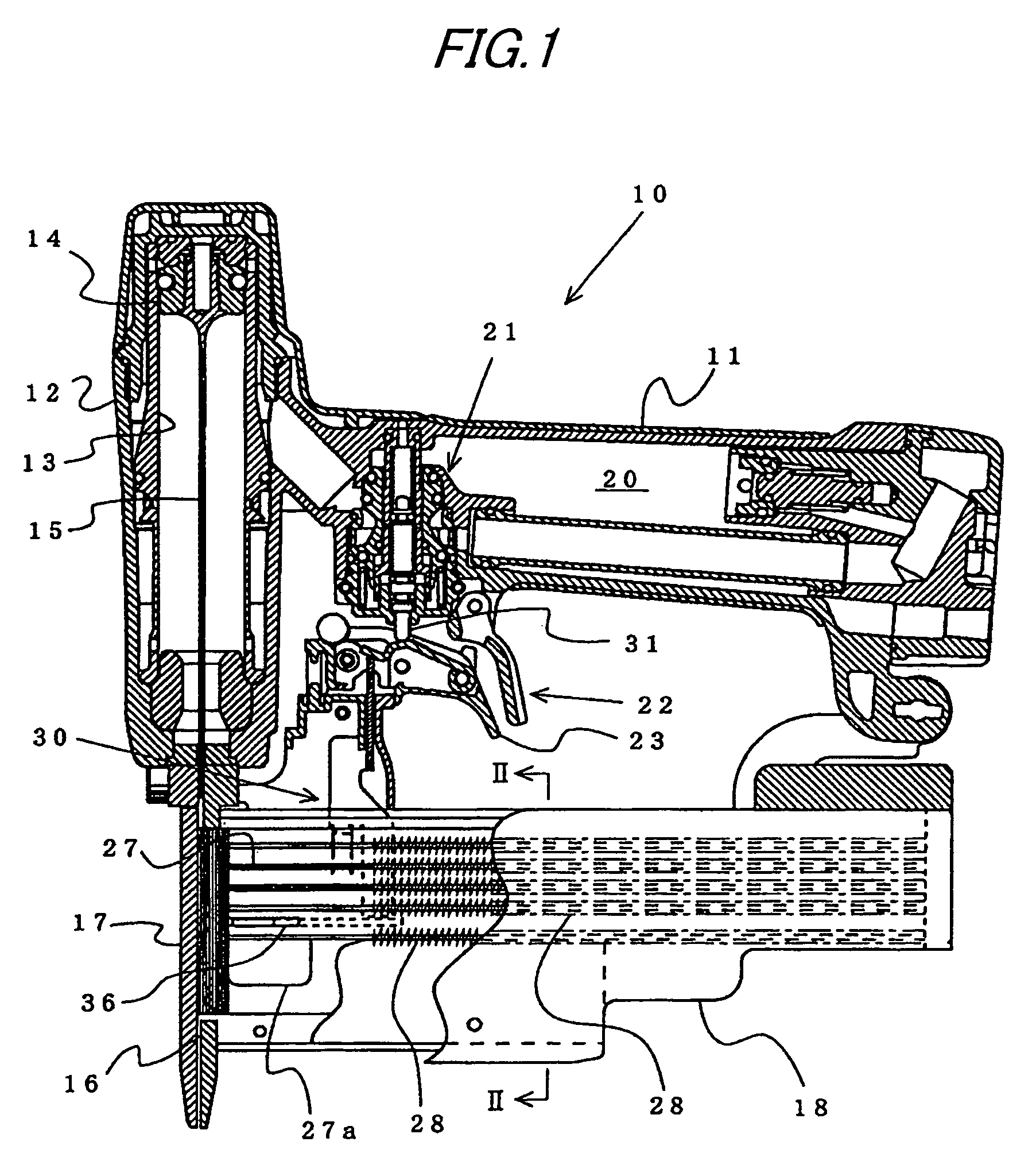

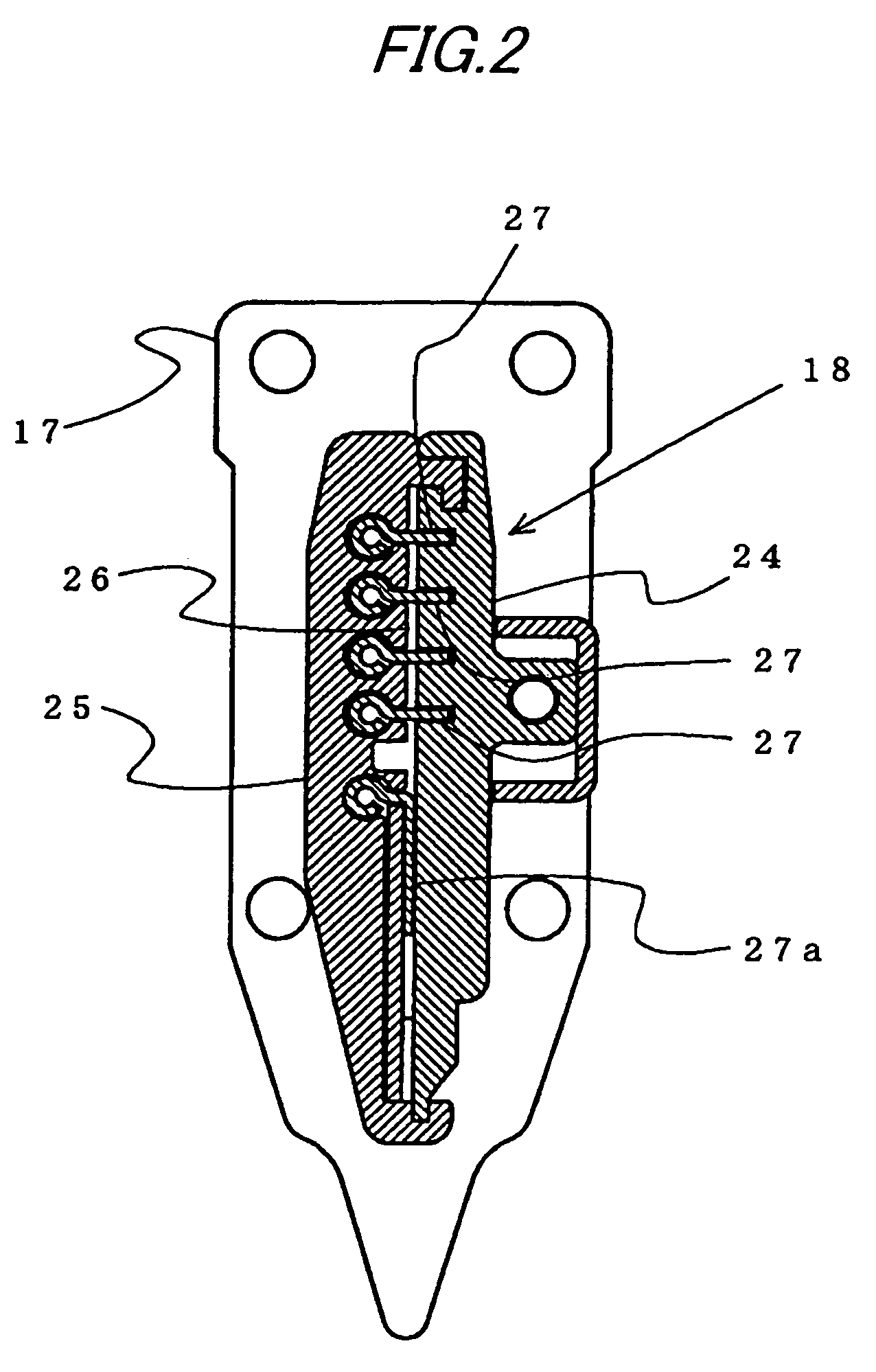

Nailing machine and magazine

A nailing machine includes a magazine for storing nails, an injection port, a drive mechanism, and a nail detecting lever. The nail detecting lever formed with a detecting end capable of advancing to inside of a nail containing portion is rotatably arranged between a downwardmost pusher and a pusher thereabove on one side of the magazine. An idle striking preventing arm has an upper end arranged at a vicinity of a starter, and a lower end arranged to be opposed to an end portion on a side opposed to a detecting end of the detecting lever and which is operated to start a nailing machine in cooperation with the starter. Further, the other side of the magazine is formed with a detecting end containing portion for containing the detecting end of the nail detecting lever.

Owner:MAX CO LTD

PROCESS FOR PREPARING A Ni/Sn SUPPORTED CATALYST FOR THE SELECTIVE HYDROGENATION OF POLYUNSATURATED HYDROCARBONS

InactiveUS20110166398A1Improve catalytic performancePrevent runawayHydrocarbon by hydrogenationCatalystsGas phaseUnsaturated hydrocarbon

A process is described for preparing a catalyst comprising at least one porous support and at least one metallic phase containing nickel and tin in a proportion such that the Sn / Ni molar ratio is in the range 0.01 to 0.2, said process comprising at least the following steps in succession:a) depositing nickel on at least said support in order to obtain a supported nickel-based monometallic catalyst;b) reducing said monometallic catalyst in the presence of at least one reducing gas;c) depositing, in the gas phase and in the presence of at least one reducing gas, at least one organometallic tin compound onto said reduced monometallic catalyst; andd) activating the solid derived from said step c) in the presence of at least one reducing gas.

Owner:IFP NEW ENERGIES

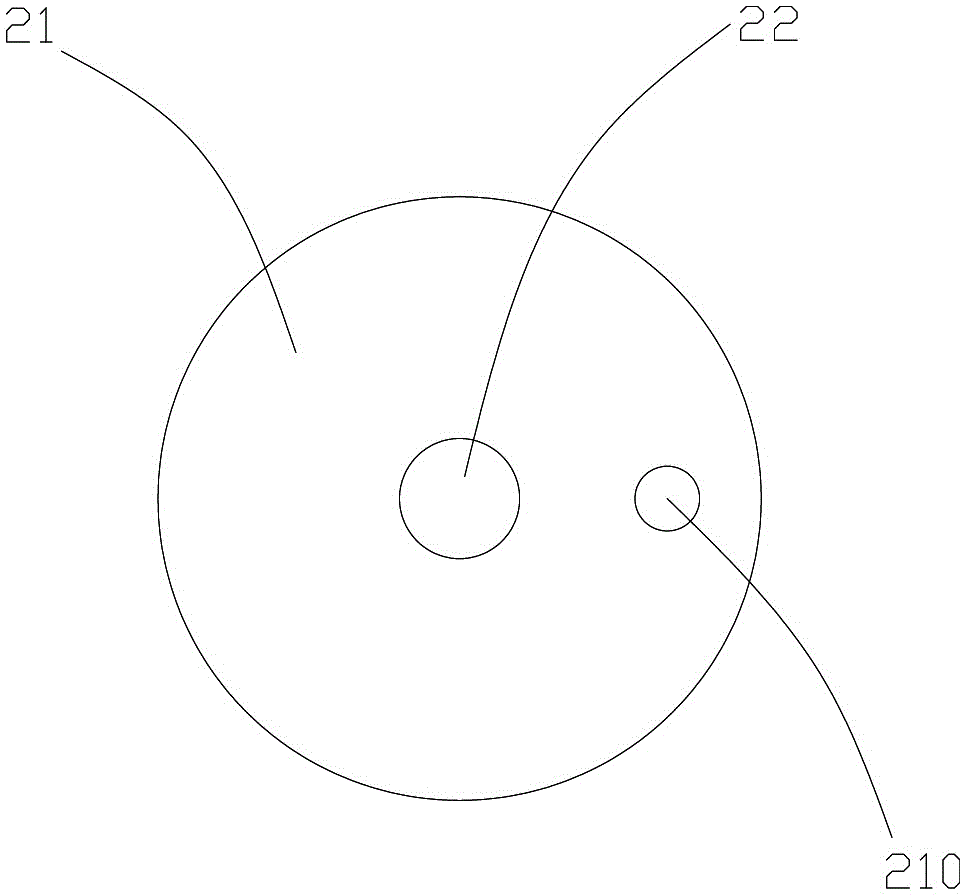

Color wheel

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

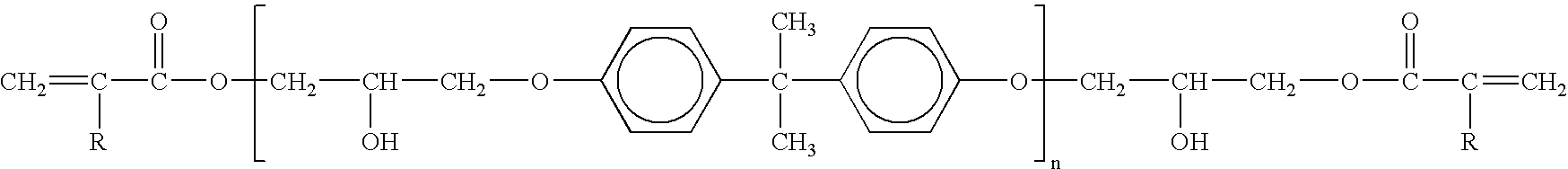

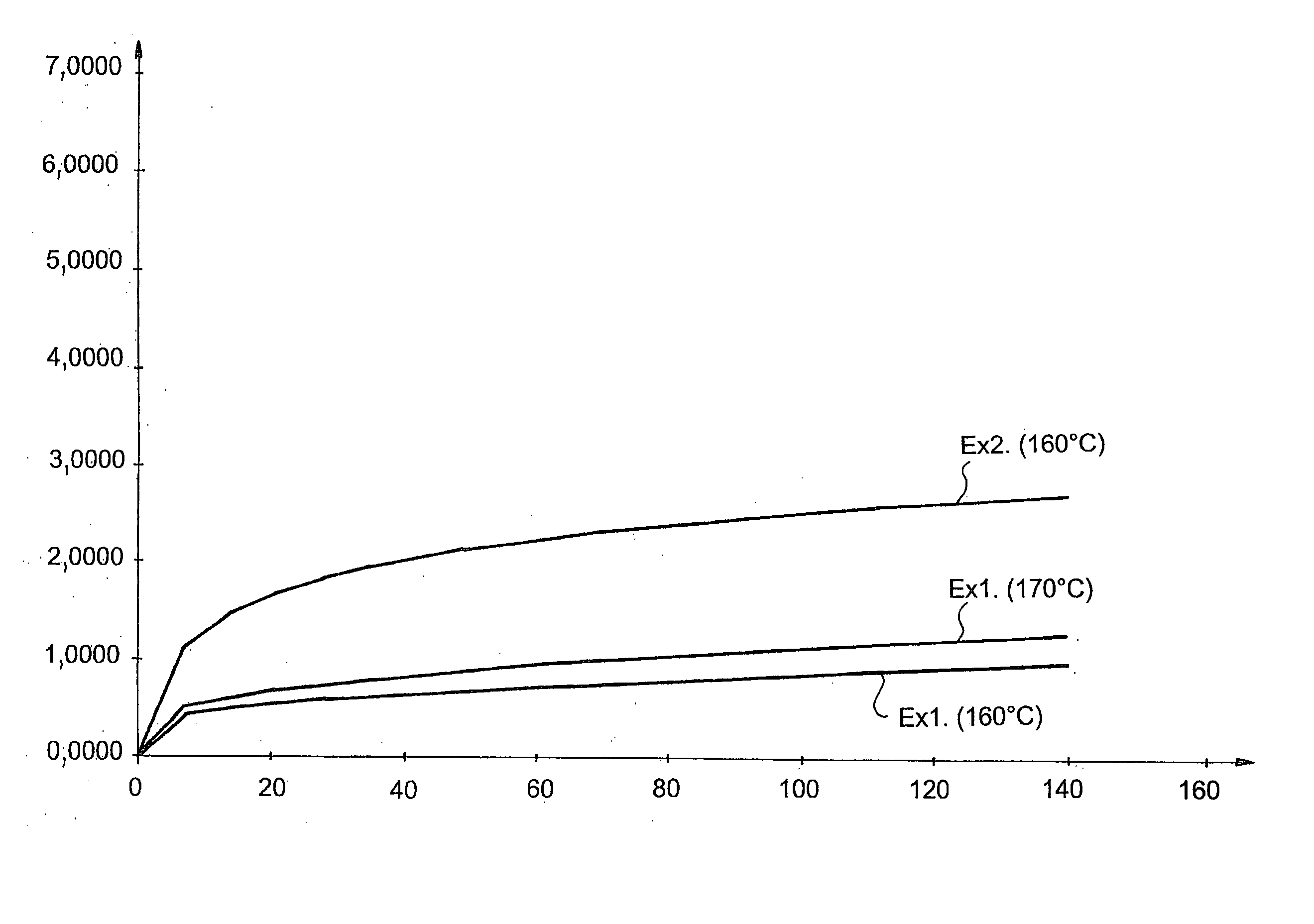

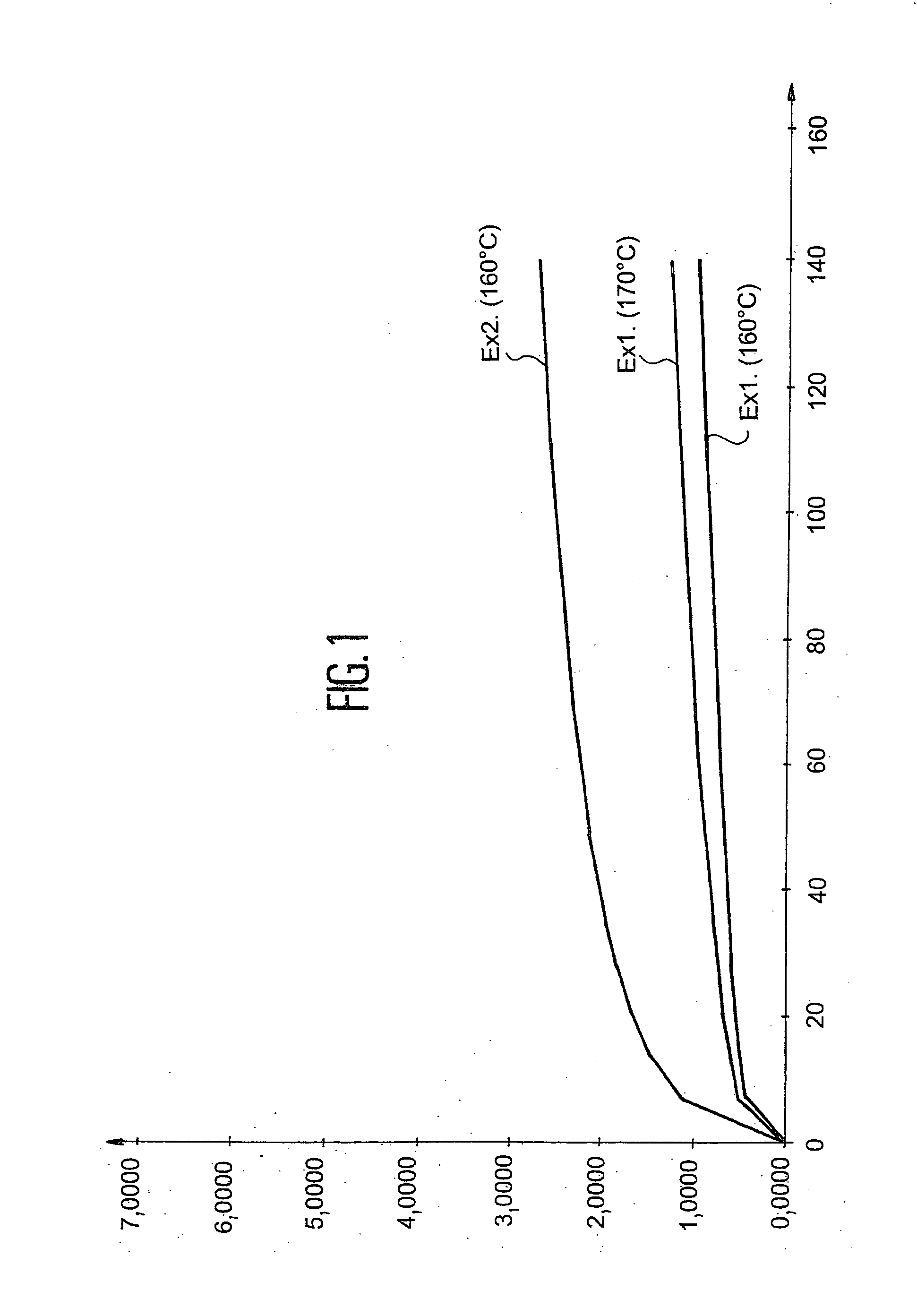

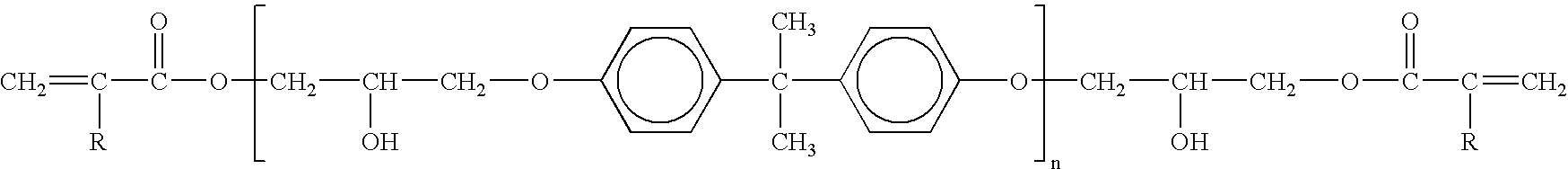

Material based on vinylester resin for neutron shielding and maintenance of sub-criticality

InactiveUS7160486B2Prevent runawayOther chemical processesNuclear engineering problemsZinc borateAlumina hydrate

This invention relates to a composite material for neutron shielding and maintenance of sub-criticality comprising a matrix based on vinylester resin and an inorganic filler capable of slowing and absorbing neutrons.The vinylester resin may be an epoxymethacrylate resin and the inorganic filler may contain a zinc borate and an alumina hydrate or magnesium hydroxide.

Owner:COGEMA LOGISTICS

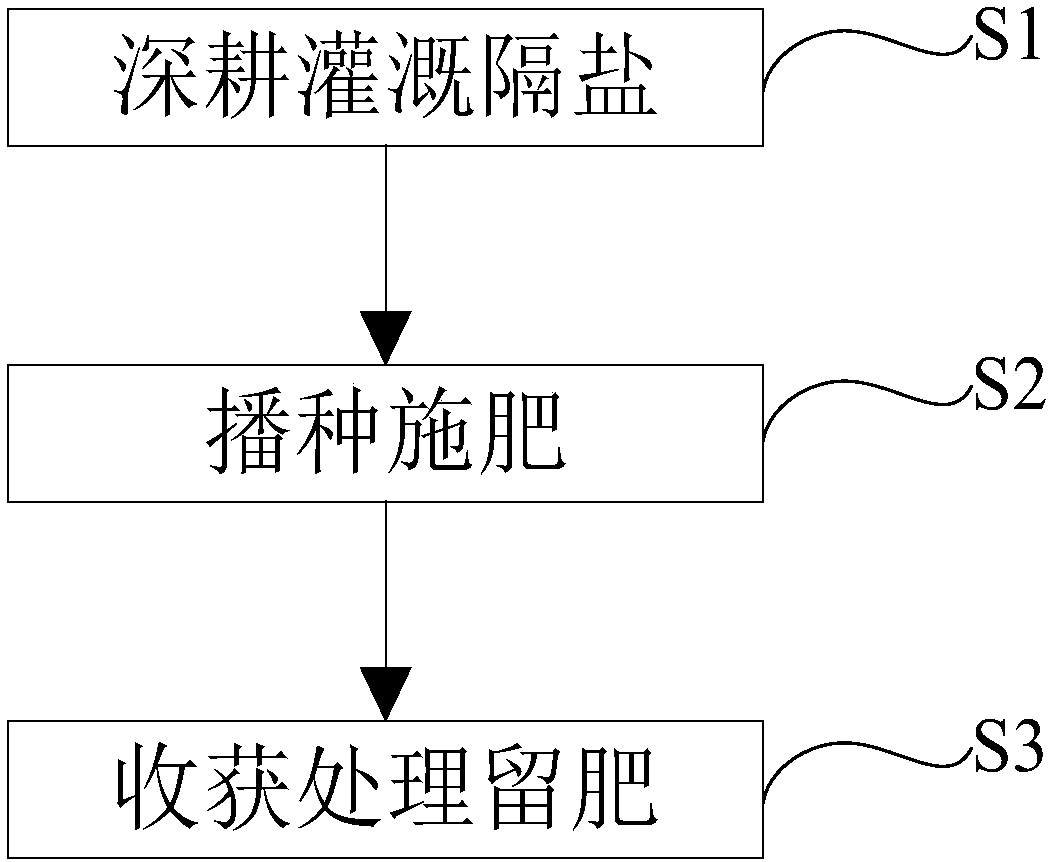

Method for improving soil fertility of saline-alkali soil by planting sesbania

InactiveCN108012610AImprove fertilityHigh seed yieldFabaceae cultivationSoil-working methodsPorosityAlkali soil

The invention is suitable for the technical field of saline-alkali soil improvement, and provides a method for improving the soil fertility of saline-alkali soil by planting sesbania. The method is characterized by comprising the steps of deep ploughing, irrigation and salt separation, wherein soil turning is carried out, weeds of the saline-alkali soil are removed, a compact soil layer is formedbelow the earth surface, and underground water high in salt content is prevented from moving upwards; sowing and fertilizing, wherein seeds need to be soaked or sand is added for wiping the seeds before sesbania sowing, a single sowing mode is used, phosphorus fertilizer is applied, the yield of sesbania is increased, and the content of nitrogen and phosphorus in sesbania is increased; harvestingand fertilizer retention, wherein after the sesbania is ripe, direct ploughing is conducted, straw and livestock manure can be heaped and applied to serve as base fertilizer or conduct topdressing, stalks need to be cut off, chopped and completely buried in the soil layer to prevent moisture evaporation, after sesbania is turned, the total quantity of water-stable aggregates of soil is increased,the soil volume weight is reduced, the porosity is improved, and the soil can be prevented against salt return. Therefore, the fertility of the saline-alkali soil can be improved, and conditions of the saline-alkali soil for planting crops are improved.

Owner:SHANDONG SHENGJING TOURISM DEV CO LTD

Method for mitigating thermal propagation of batteries using heat pipes

ActiveUS9689624B2Control damageProlong lifeElectric devicesSafety devices for heat exchange apparatusEngineeringPhase change

A battery module with one or more battery cells and a heat exchange member placed in thermal communication with the battery cell, and a method of making a heat pipe system from the heat exchange member. The heat exchange member includes a container with a heat transfer fluid disposed therein. In one form, the heat transfer fluid is capable of going through a phase change as a way to absorb at least a portion of heat present in or generated by battery cell. A pressure control device cooperates with the container and heat transfer fluid such that upon attainment of a predetermined thermal event within the battery cell, the pressure control device permits liberation of at least a portion of the heat transfer fluid to an ambient environment, thereby relieving pressure on the container and removing some of the excess heat caused by the thermal event.

Owner:GM GLOBAL TECH OPERATIONS LLC

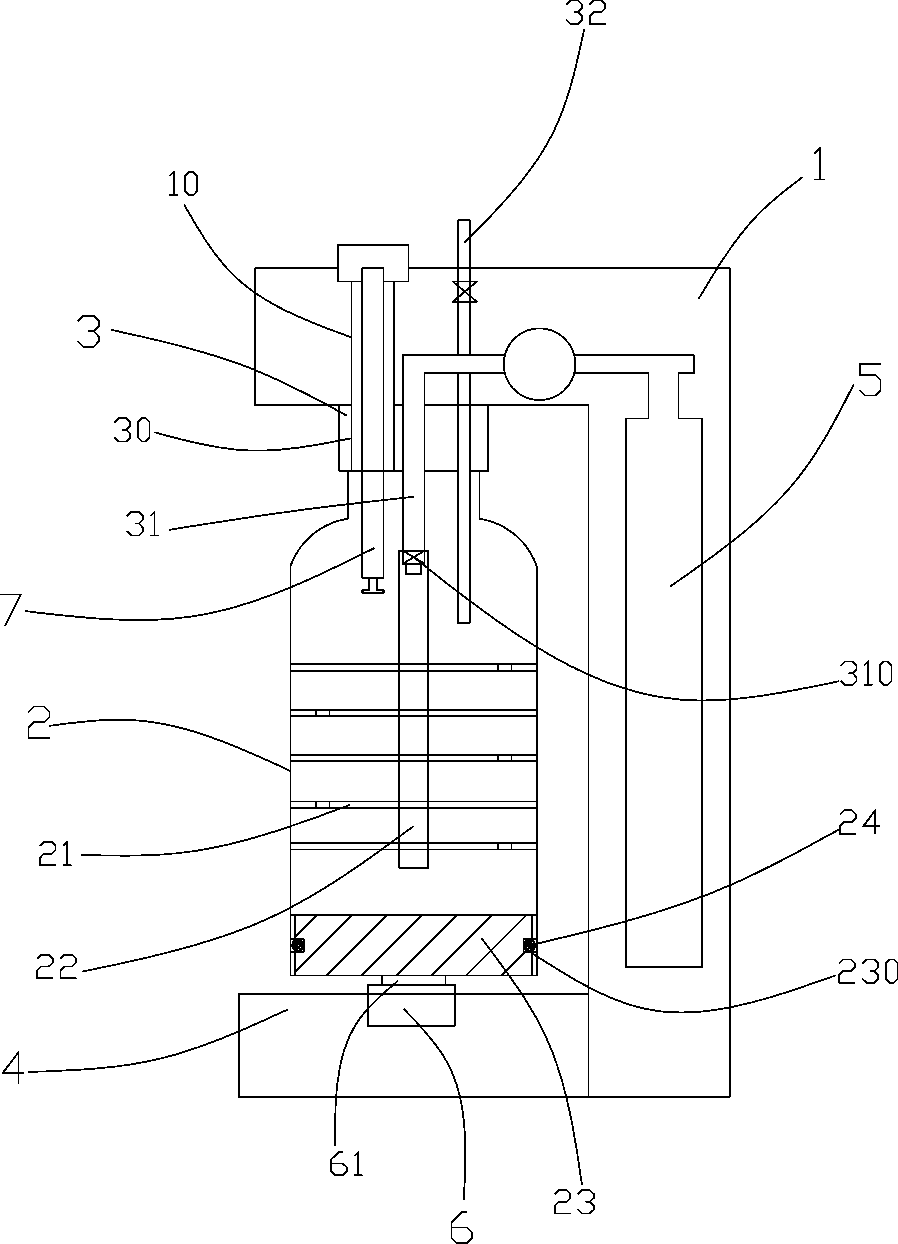

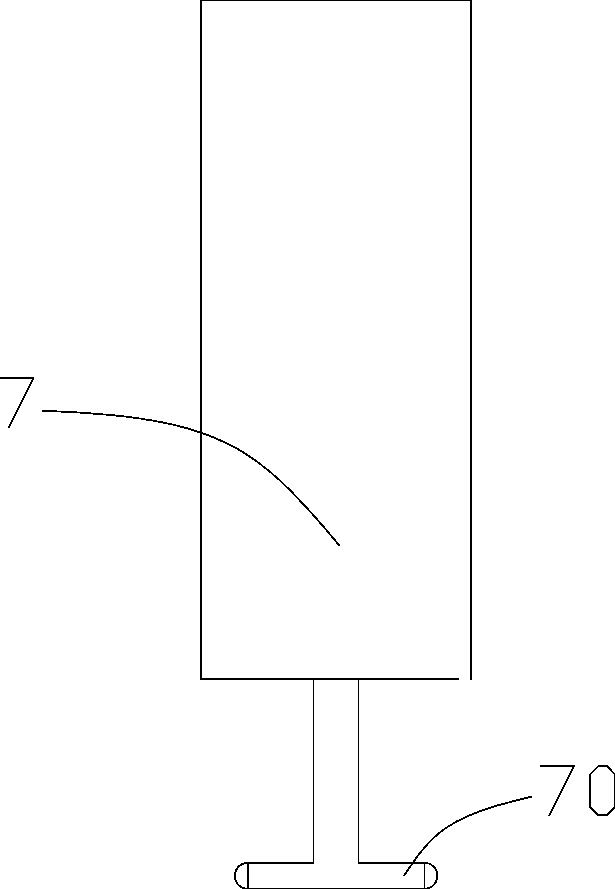

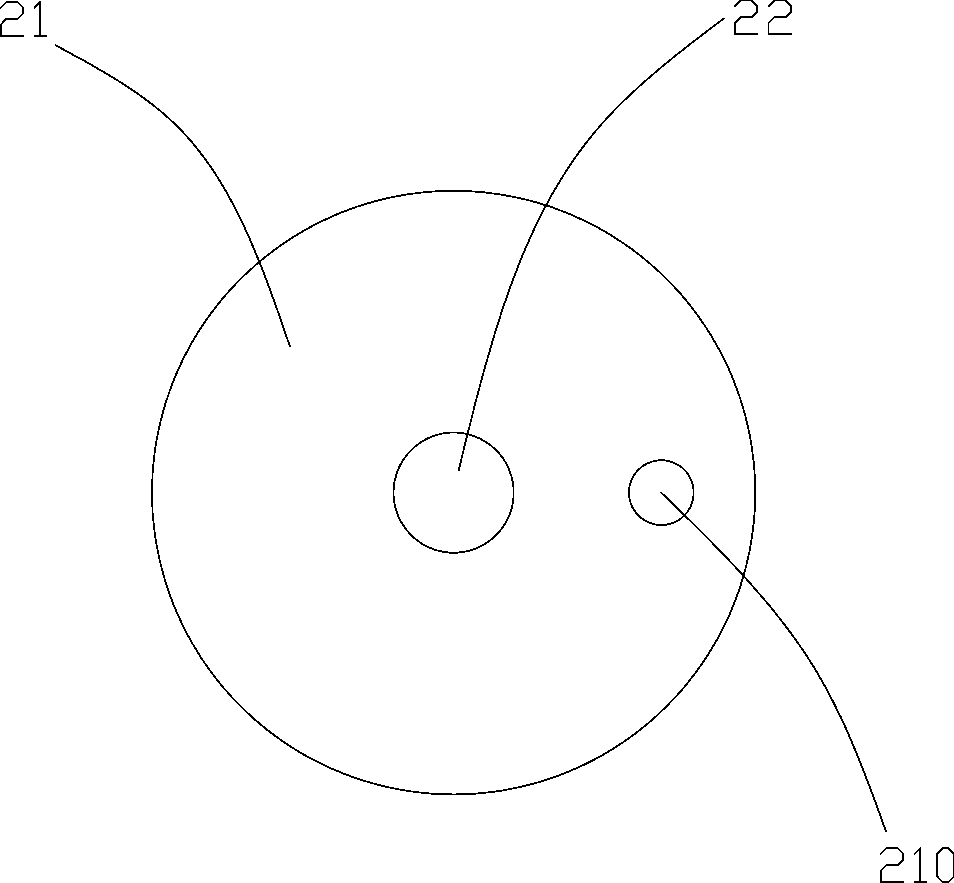

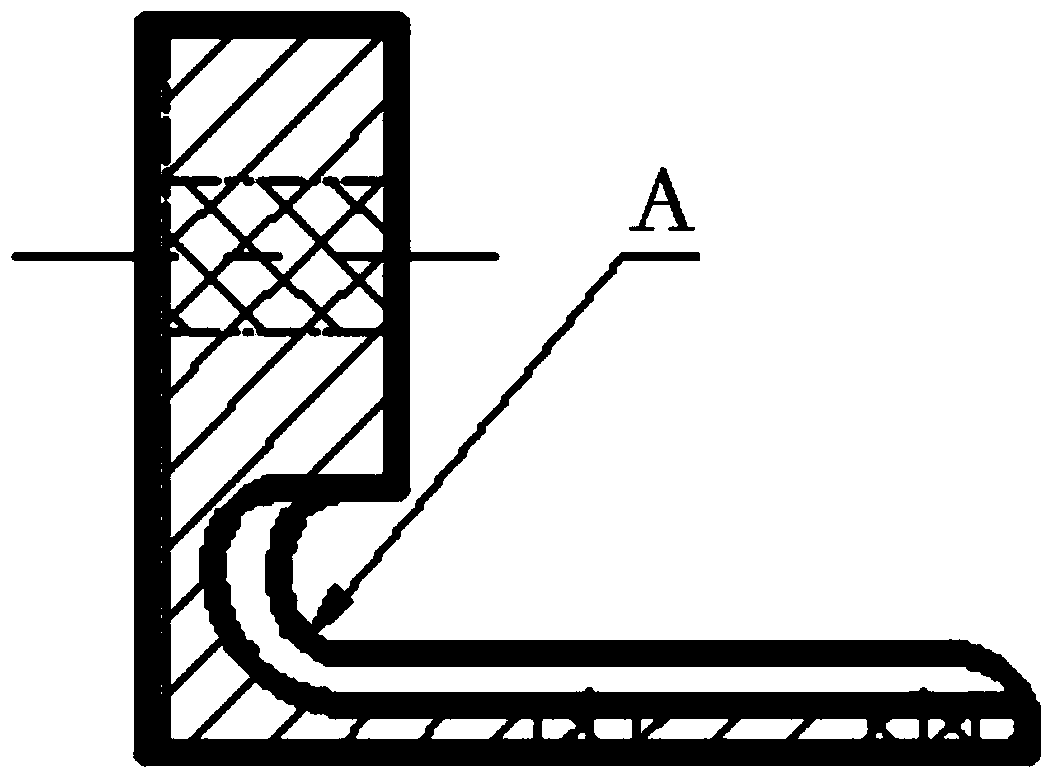

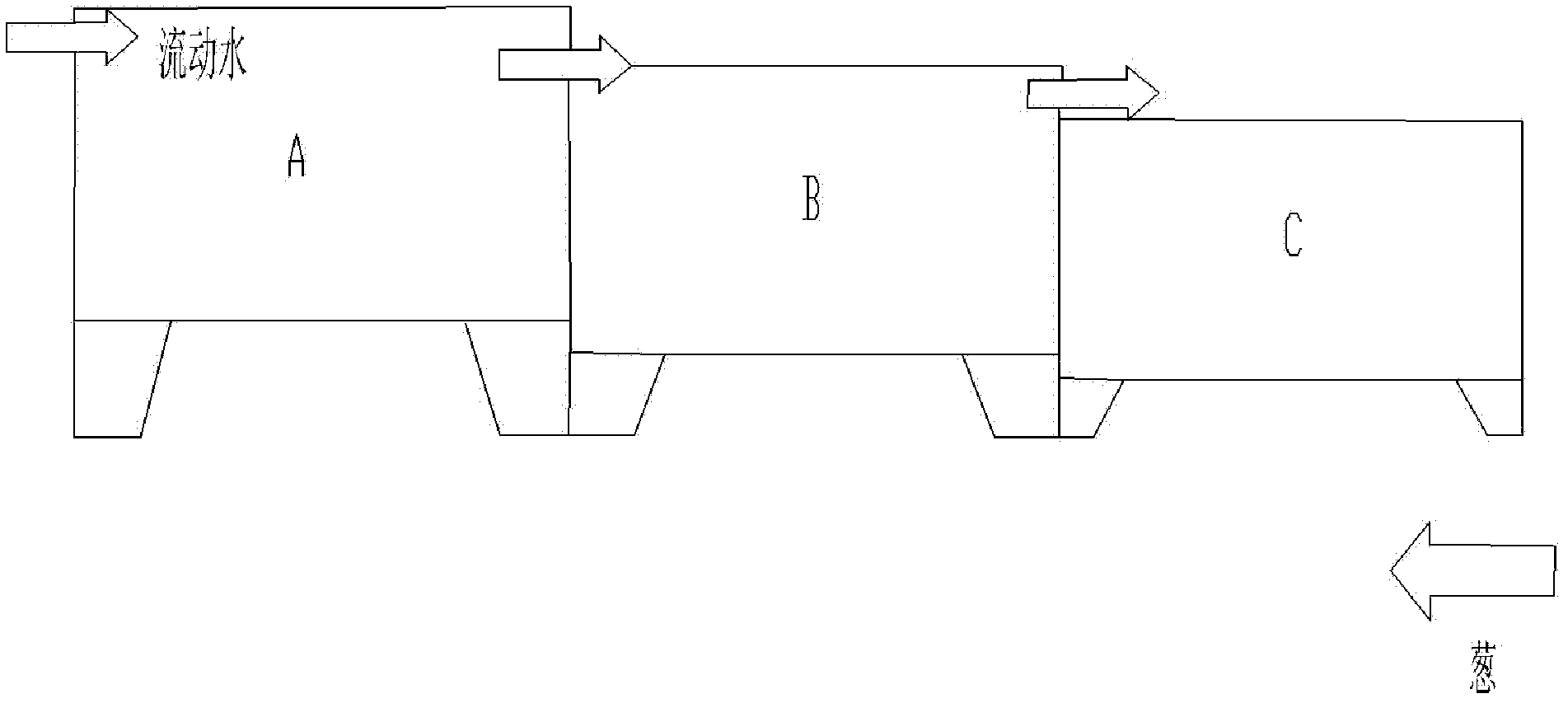

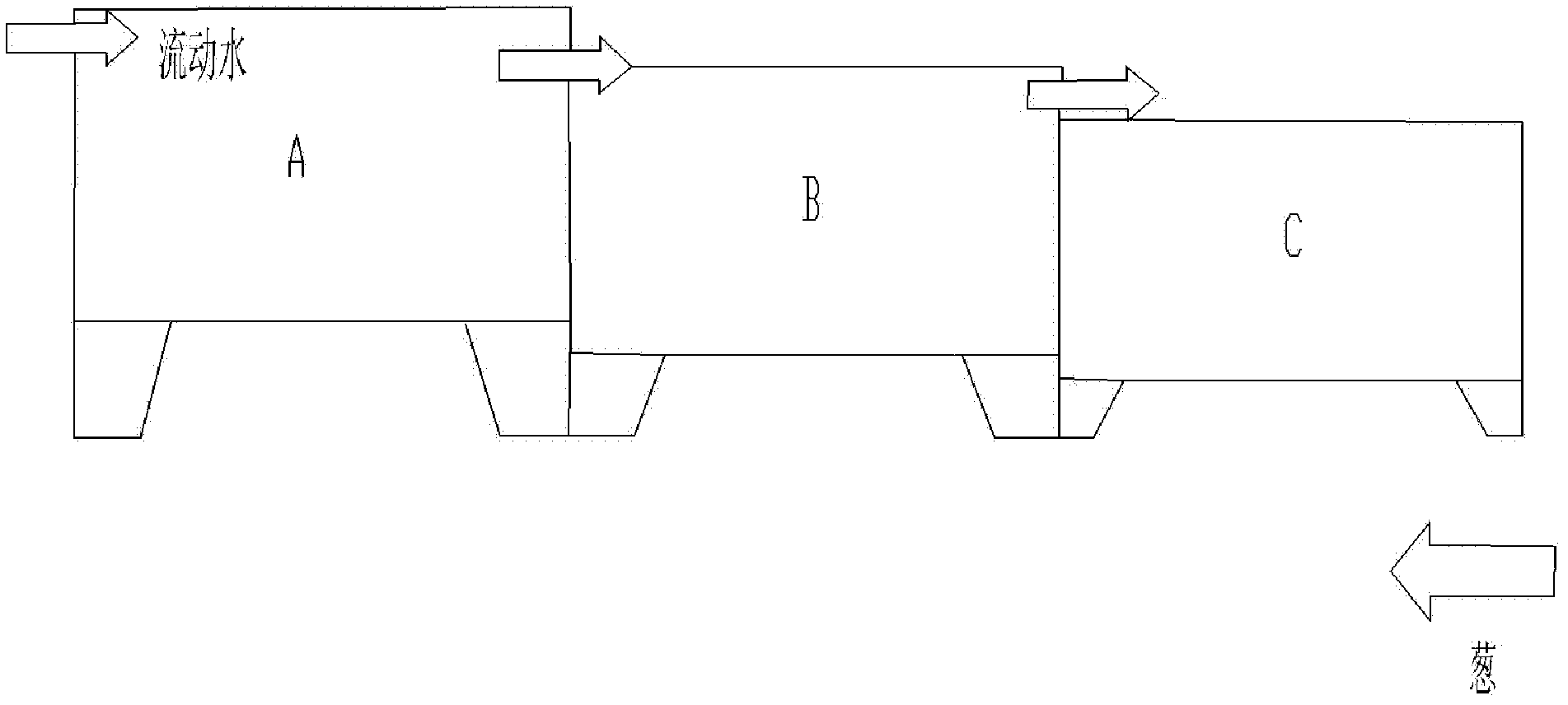

Soda water machine with concentrated juice powder spraying device

ActiveCN103720363APrevent runawayIncrease carbon dioxide concentrationBeverage vesselsFruit juiceSprayer

The invention discloses a soda water machine with a concentrated juice powder spraying device and belongs to technology of beverage preparation equipment. The soda water machine comprises a main body, a pressure water bottle and the concentrated juice powder spraying device, an air injection port and a base are arranged on the main body, an air injection pipe and a depressurization pipe are arranged on the air injection port, a partition and a venting pipe are arranged in the pressure water bottle, the venting pipe penetrates the center of the partition and is matched with the air injection pipe, the venting pipe and the partition are connected in a sealed manner, a through hole is arranged on the partition, a plunger is further arranged in the pressure water bottle, a lifting mechanism is arranged on the base, a connecting column is arranged on the lifting mechanism, and two sprayers are arranged on the concentrated juice powder spraying device. Compared with the prior art, the soda water machine has the advantages that soda water higher in carbon dioxide concentration can be prepared, concentration of carbo dioxide in the soda water is enabled to be close to be saturated, and taste is pure; during preparation of the soda water, concentrated juice powder is released in the soda water by the two sprayers of the spraying device, so that area of the concentrated juice powder and the soda water is increased, and the soda water is enabled to be uniform in taste.

Owner:NINGBO RDWORKS ELECTRIC TECH DEV

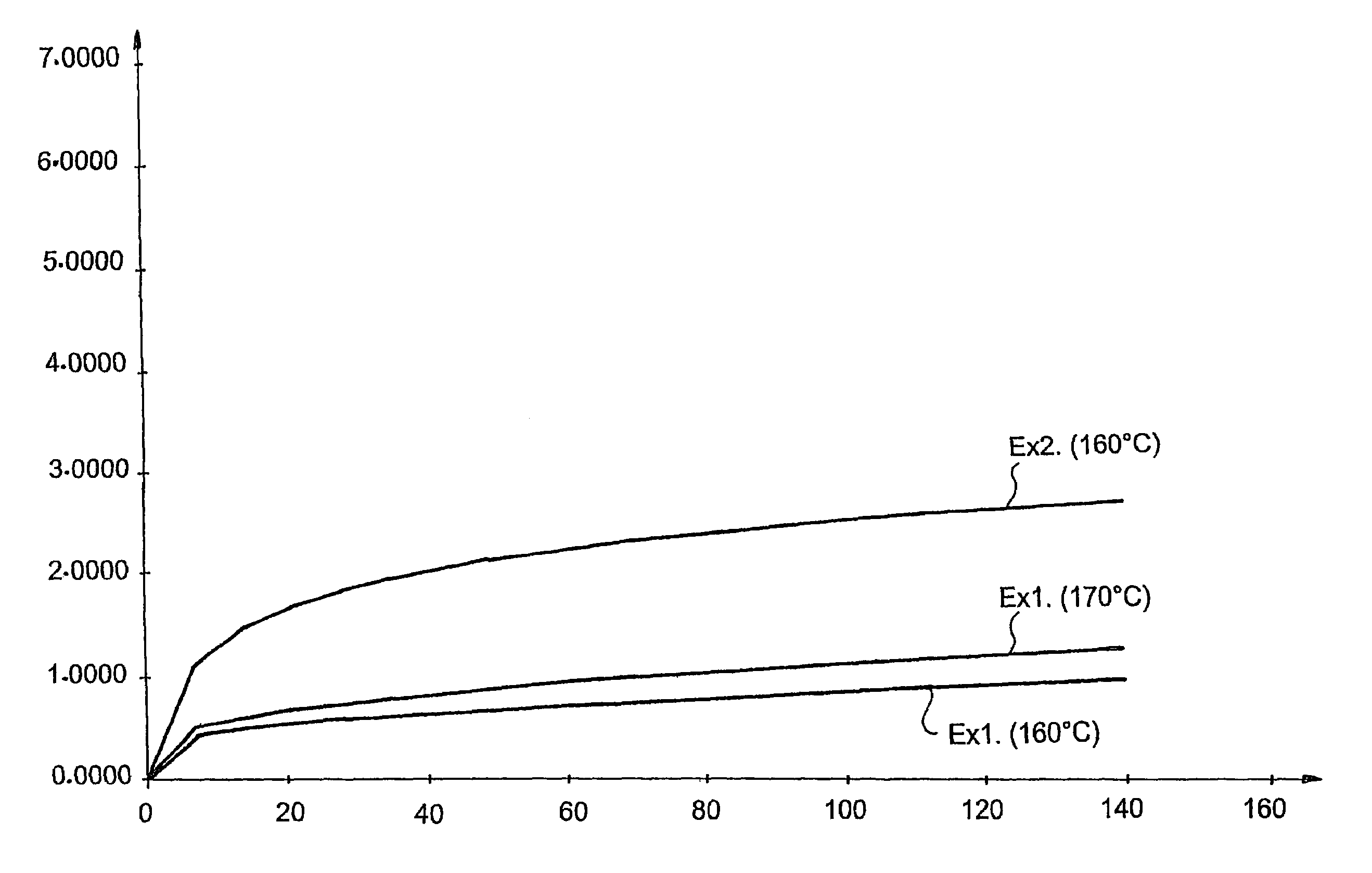

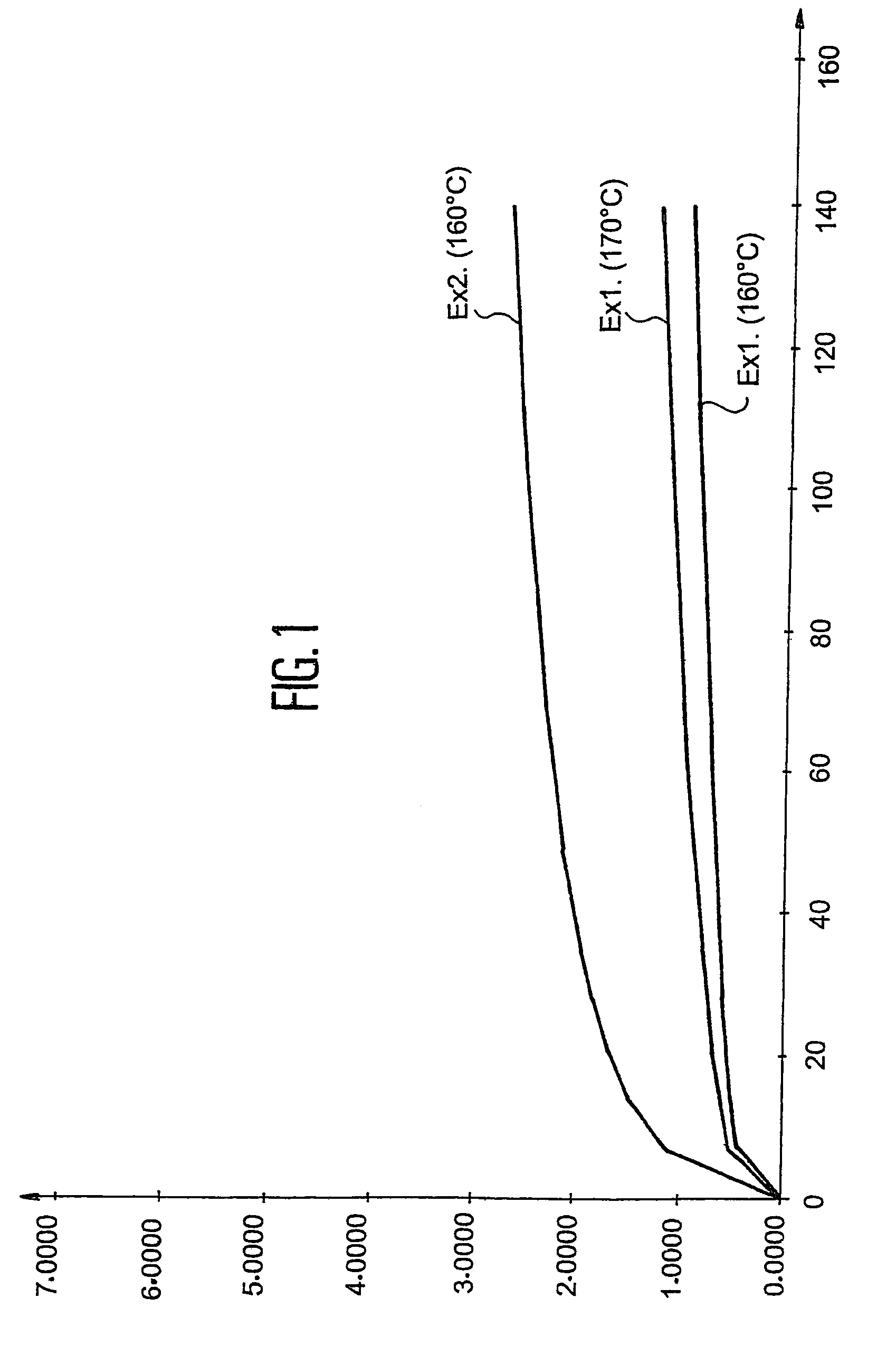

Process for producing acrylic polymer

Owner:SOKEN CHEM & ENG CO LTD

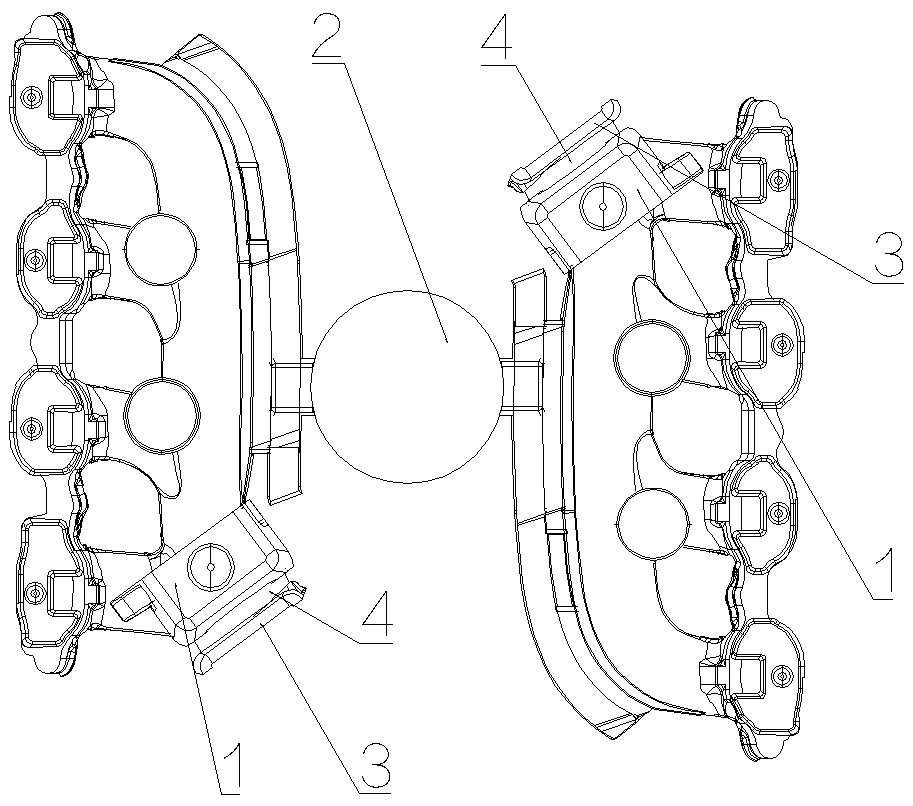

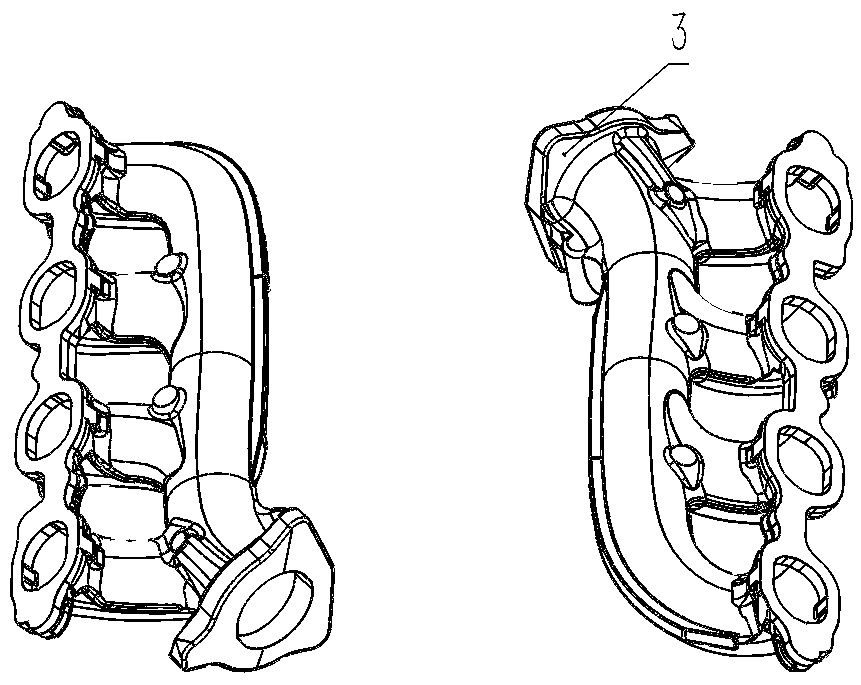

Investment casting shell molding process

The invention discloses an investment casting shell molding process, belonging to the technical field of material molding. The process comprises the following steps: preparing materials, piling and preparing surface coatings, assembling and cleaning a wax module, coating, hardening, drying and dewaxing. According to the technical scheme, different mold layers are made of different coatings, and due to long-term stirring, the coatings are fully and uniformly mixed. Moreover, the amount of silica sol is increased in the surface coating, the surface quality of the shell surface layer is improved, the number of the mold shell layers is reduced under the conditions that the shell strength is guaranteed and run-out is avoided, the avoiding performance of the shell is improved, and the effect of reducing cracking tendency of the casting is achieved.

Owner:GUIZHOU ANJI AVIATION PRECISION CASTING

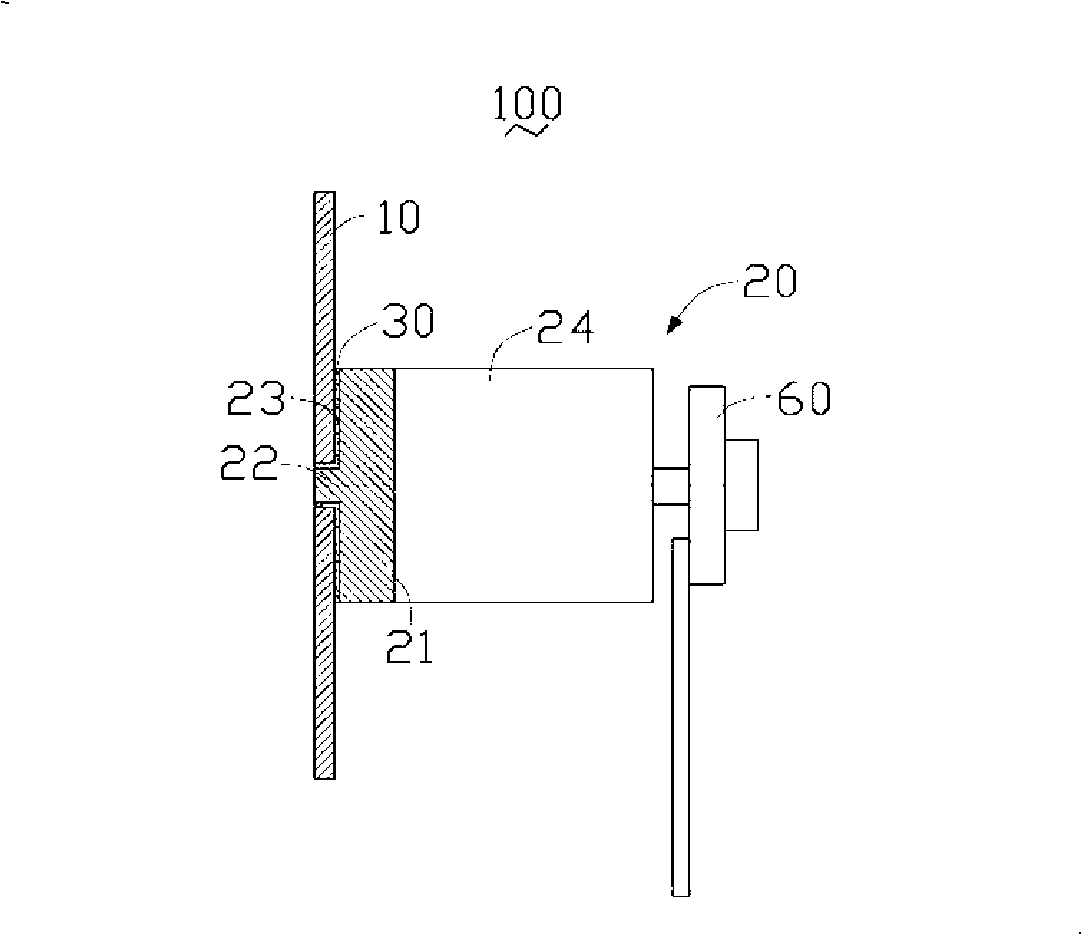

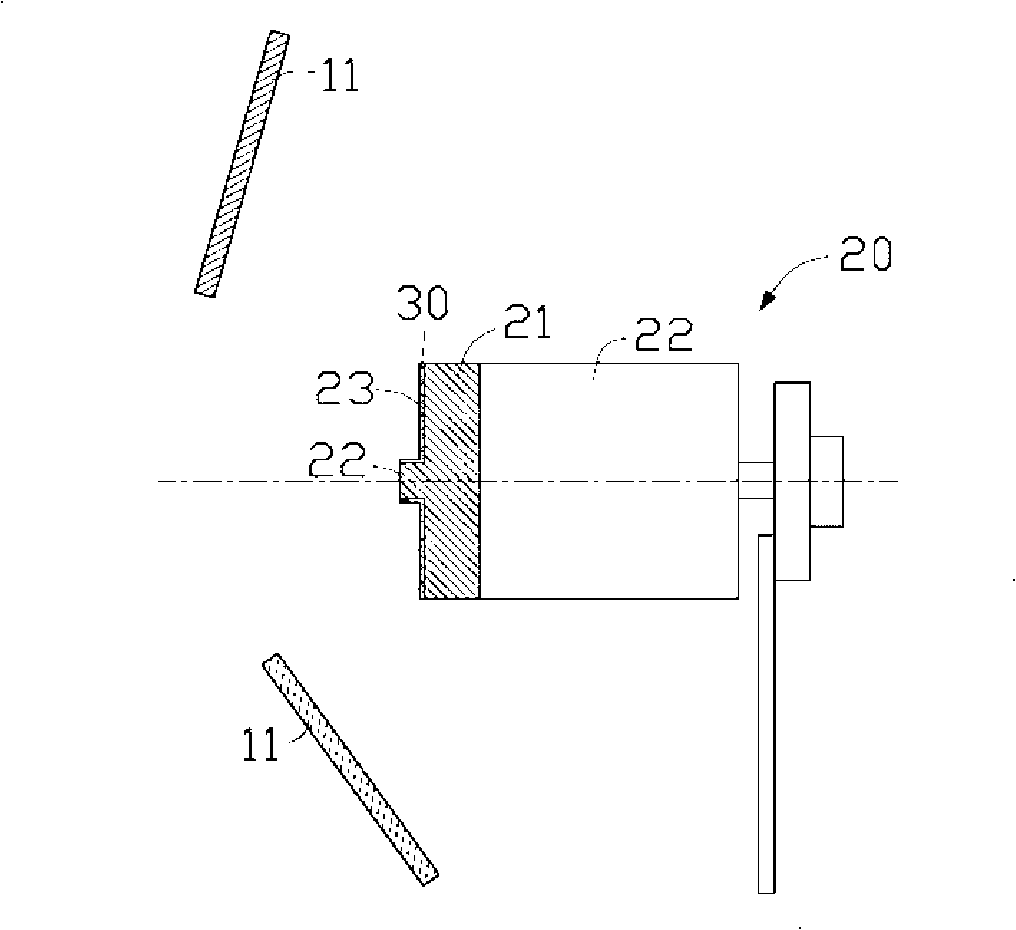

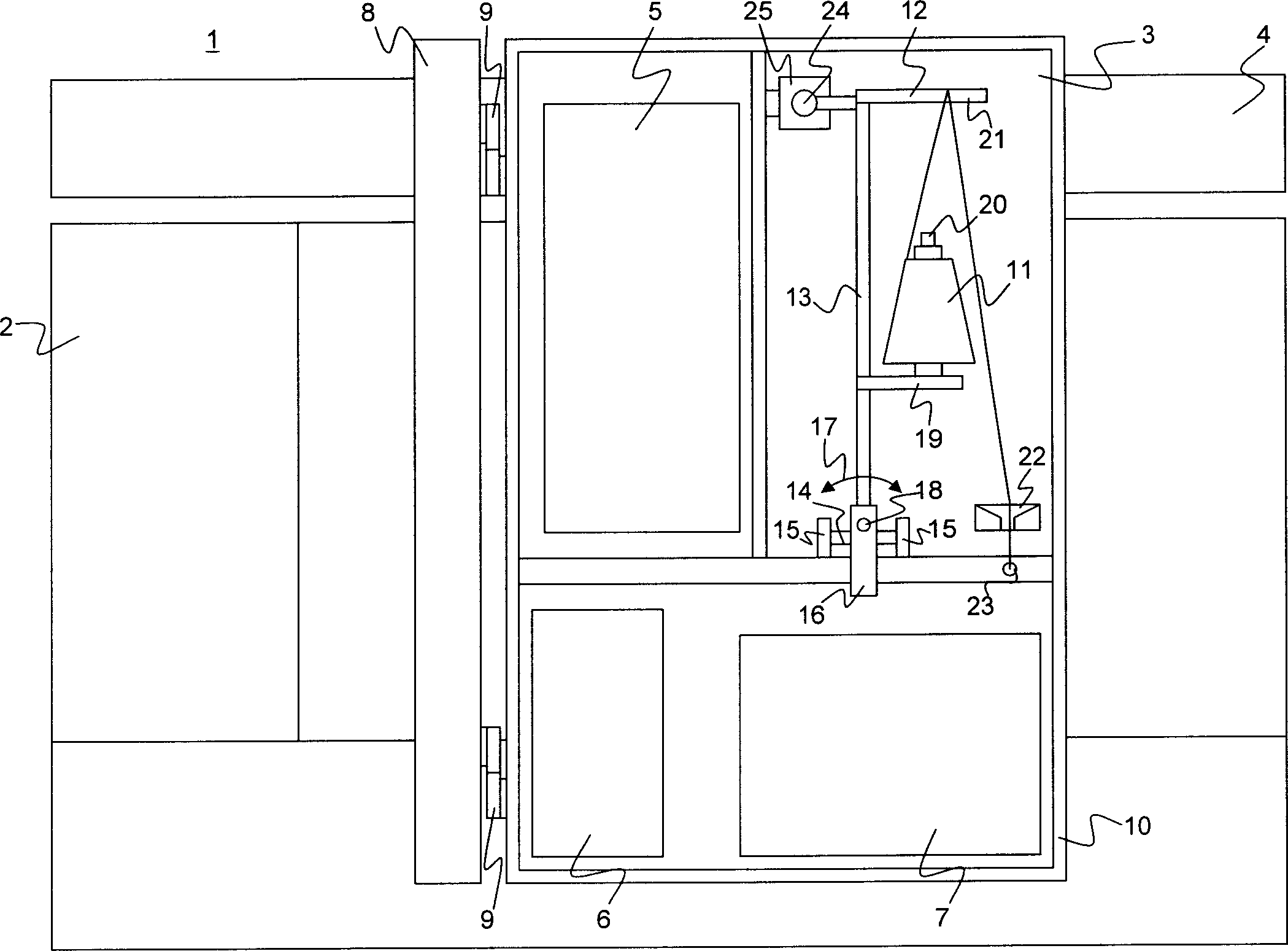

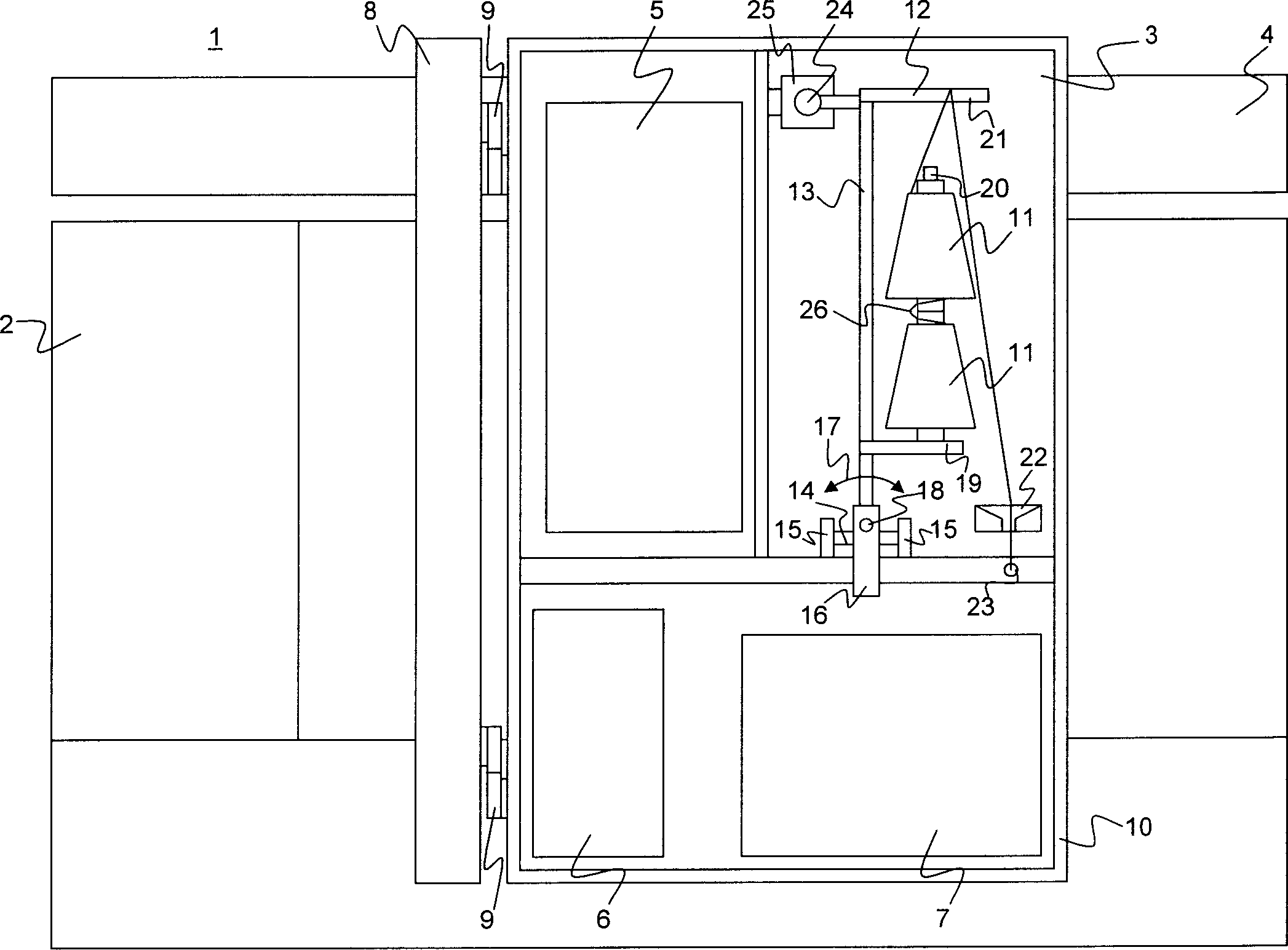

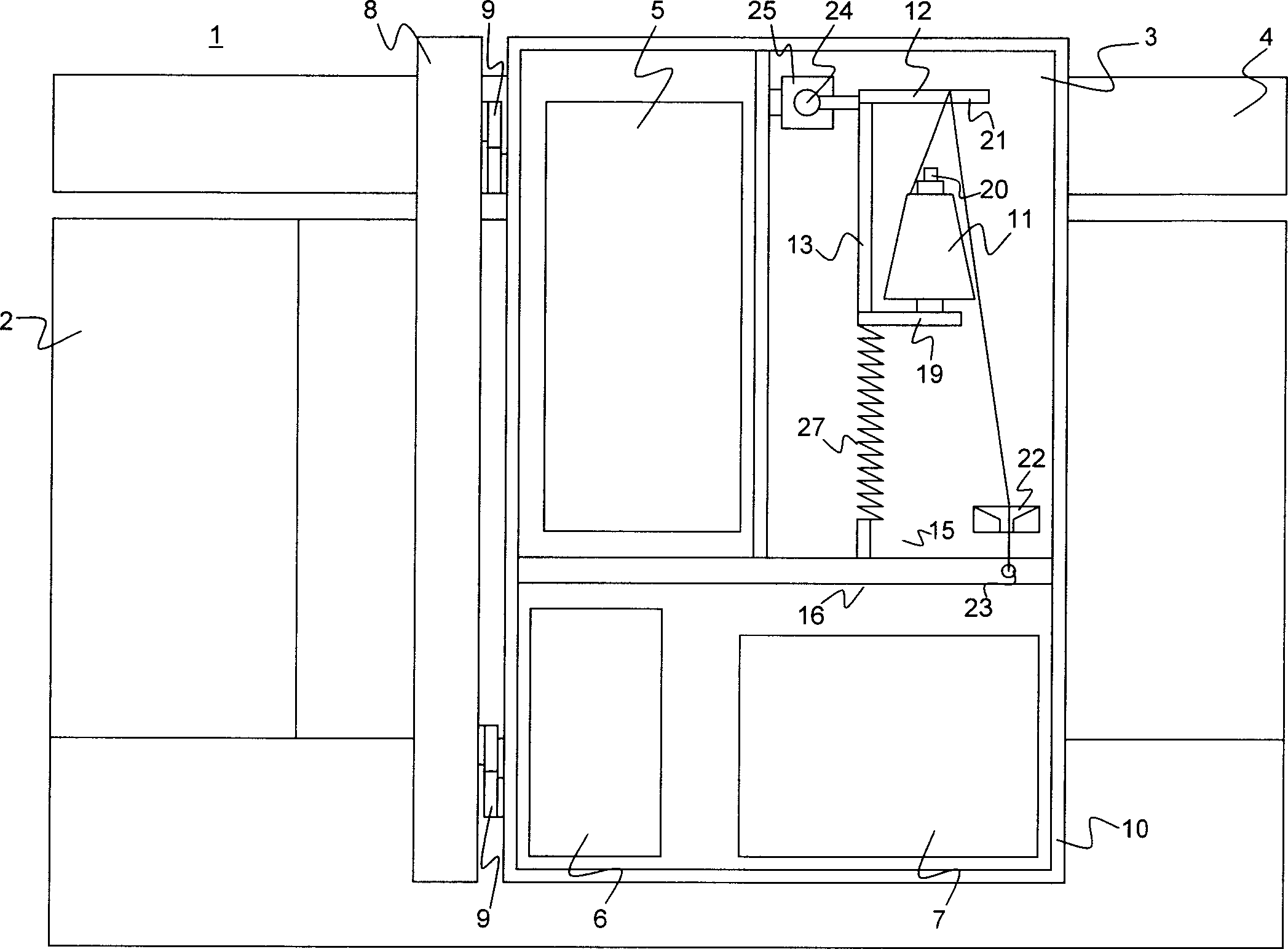

Spinning machine with maintenance unit

InactiveCN1763279AFree from pollutionAvoid pollutionContinuous wound-up machinesOpen-end spinning machinesBobbinMachine maintenance

The invention relates to a method for storing and changing bobbins (11) on a maintenance device (3) of a spinning machine, in particular a rotor spinning machine or a ring spinning machine. The method according to the invention is characterized in that at least one cartridge (11) is stored in a first position and replaced in a second position.

Owner:RIETER INGOLSTADT SPINNEREI

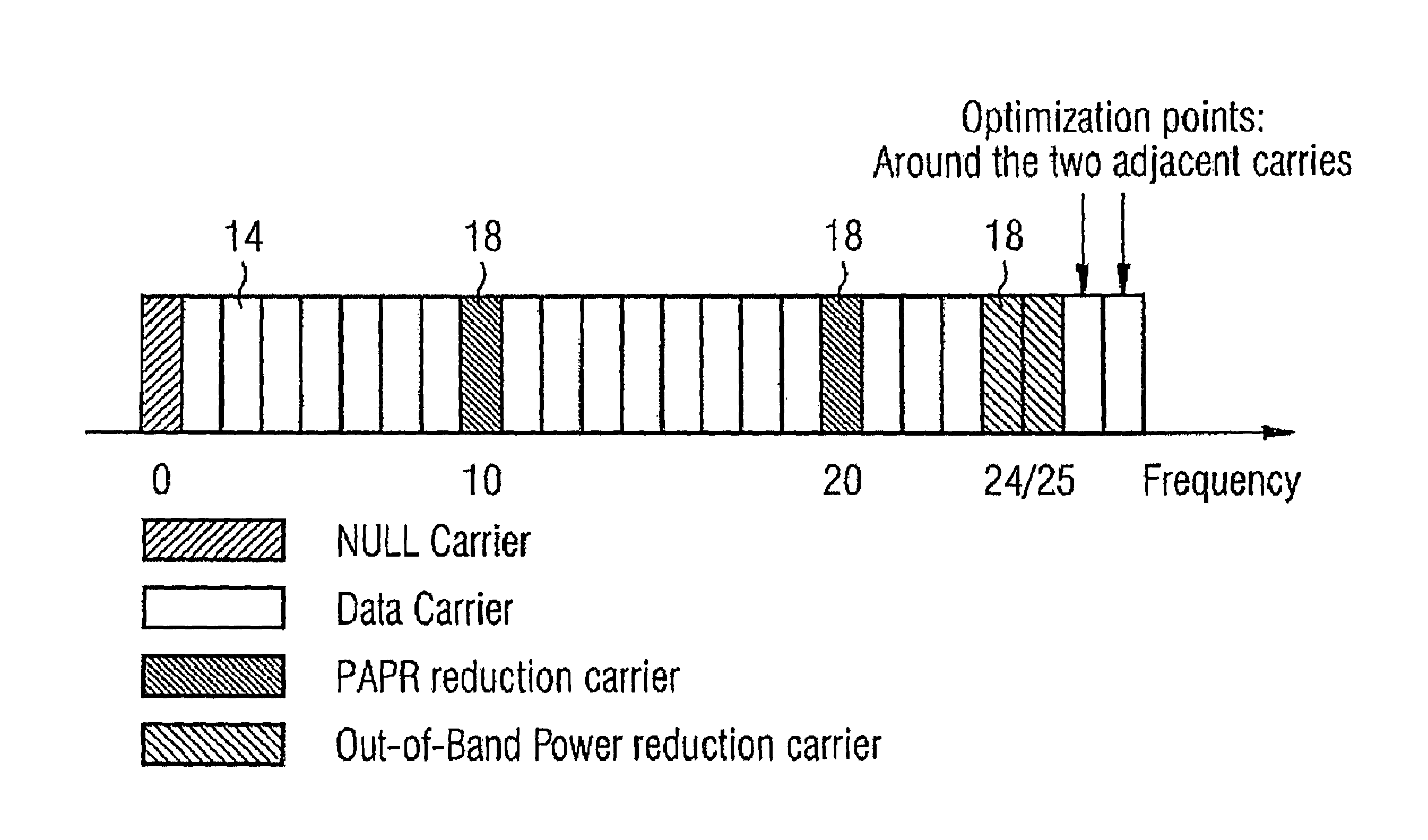

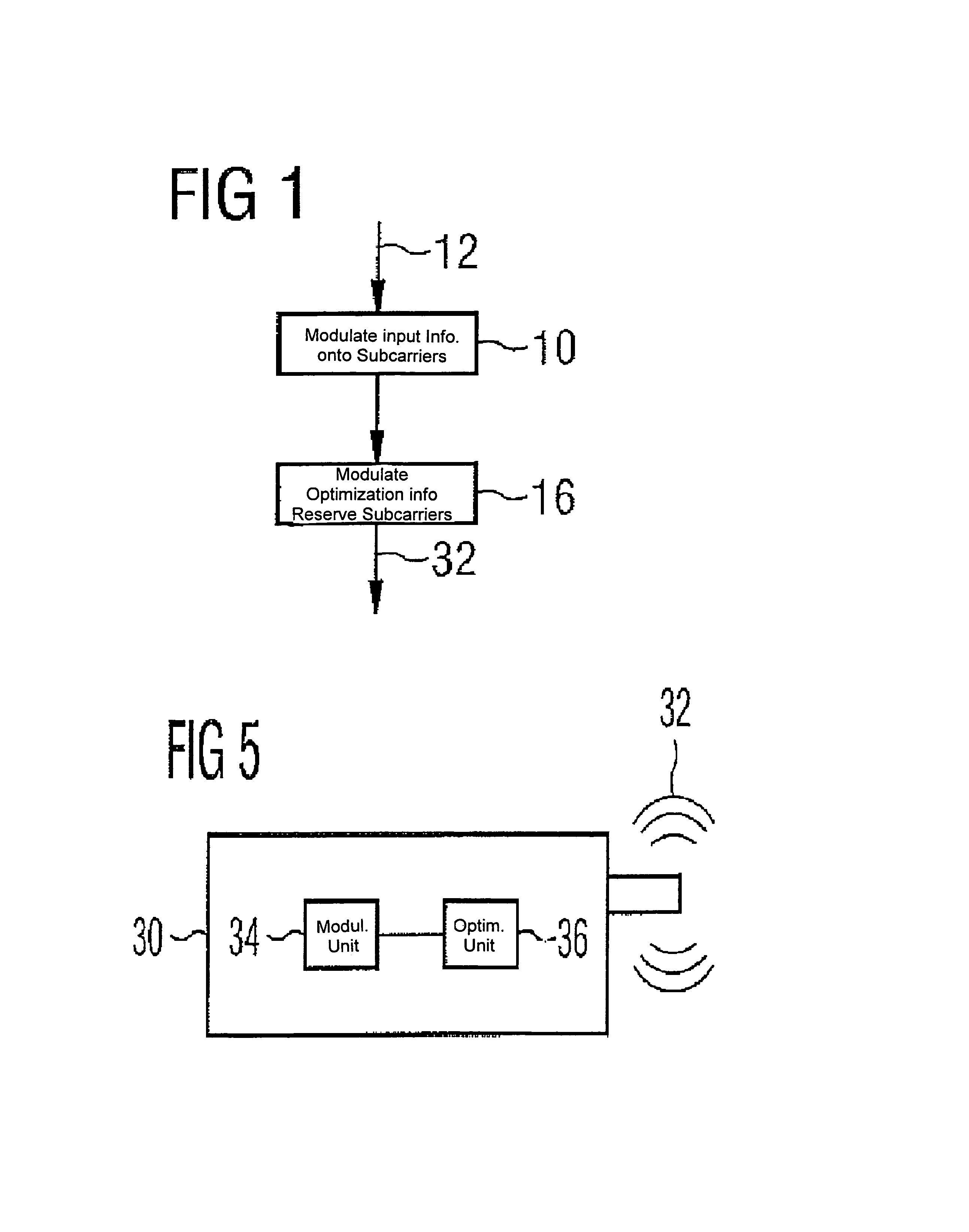

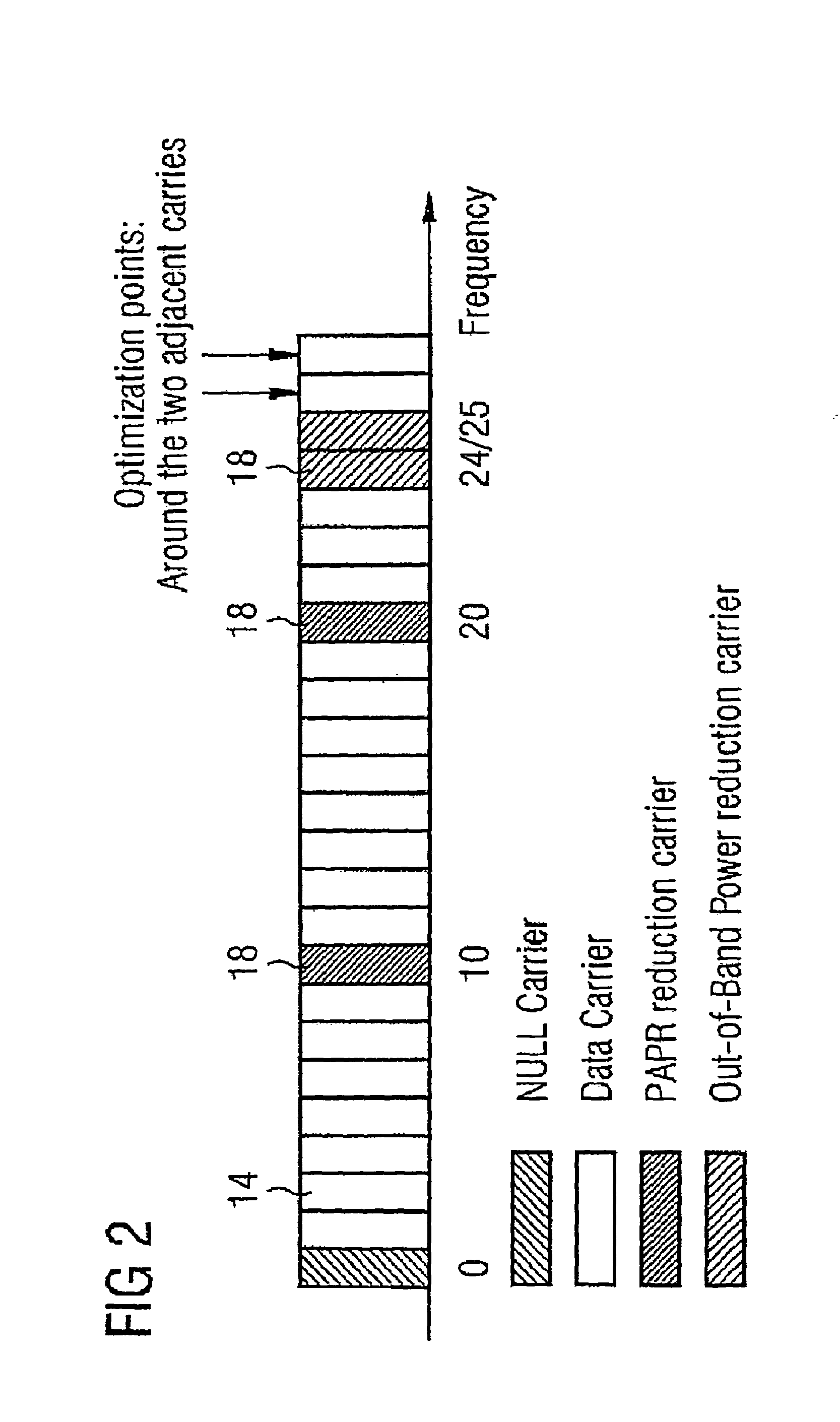

Method for optimizing signals with multiple subcarriers

ActiveUS8442148B2Improve spectral efficiencyPrevent runawaySecret communicationMulti-frequency code systemsCarrier signalPeak value

A method codes data in a transmitted signal. The transmitted signal comprises multiple subcarriers with orthogonal frequencies. The signals are modulated corresponding to a given subset of the subcarriers of the transmitted signal in order to encode information. The signal is modulated corresponding to least one reserved subcarrier depending on at least one optimization criterion relating to a quality of the overall transmitted signal. In order to enhance the quality of the transmitted signal, the optimization criterion depends on at least one first quantity relating to a peak-to-average-power ratio of the transmitted signal and on at least one second quantity relating to an out-of-band power of the transmitted signal.

Owner:RPX CORP +1

Soda machine with juice concentrate powder inkjet unit

ActiveCN103720363BPrevent runawayIncrease carbon dioxide concentrationBeverage vesselsEngineeringInjection air

The invention discloses a soda water machine with a concentrated juice powder spraying device and belongs to technology of beverage preparation equipment. The soda water machine comprises a main body, a pressure water bottle and the concentrated juice powder spraying device, an air injection port and a base are arranged on the main body, an air injection pipe and a depressurization pipe are arranged on the air injection port, a partition and a venting pipe are arranged in the pressure water bottle, the venting pipe penetrates the center of the partition and is matched with the air injection pipe, the venting pipe and the partition are connected in a sealed manner, a through hole is arranged on the partition, a plunger is further arranged in the pressure water bottle, a lifting mechanism is arranged on the base, a connecting column is arranged on the lifting mechanism, and two sprayers are arranged on the concentrated juice powder spraying device. Compared with the prior art, the soda water machine has the advantages that soda water higher in carbon dioxide concentration can be prepared, concentration of carbo dioxide in the soda water is enabled to be close to be saturated, and taste is pure; during preparation of the soda water, concentrated juice powder is released in the soda water by the two sprayers of the spraying device, so that area of the concentrated juice powder and the soda water is increased, and the soda water is enabled to be uniform in taste.

Owner:NINGBO RDWORKS ELECTRIC TECH DEV

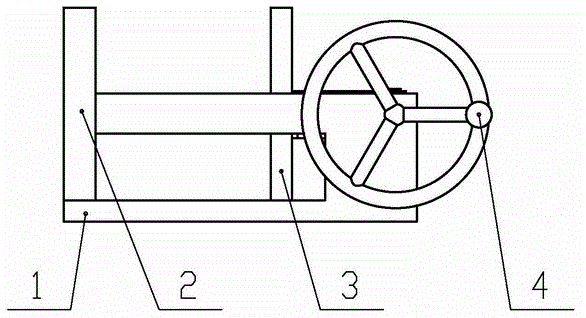

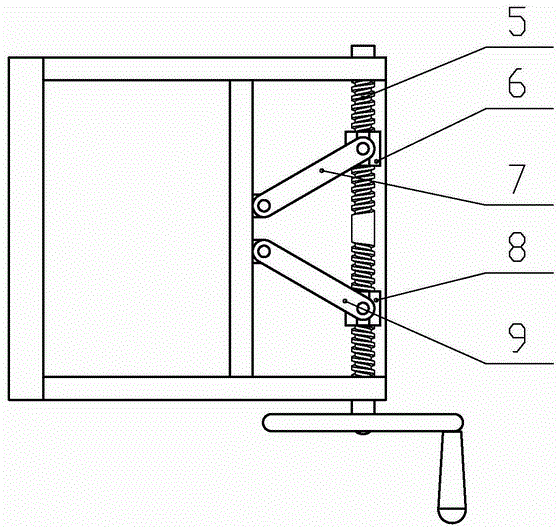

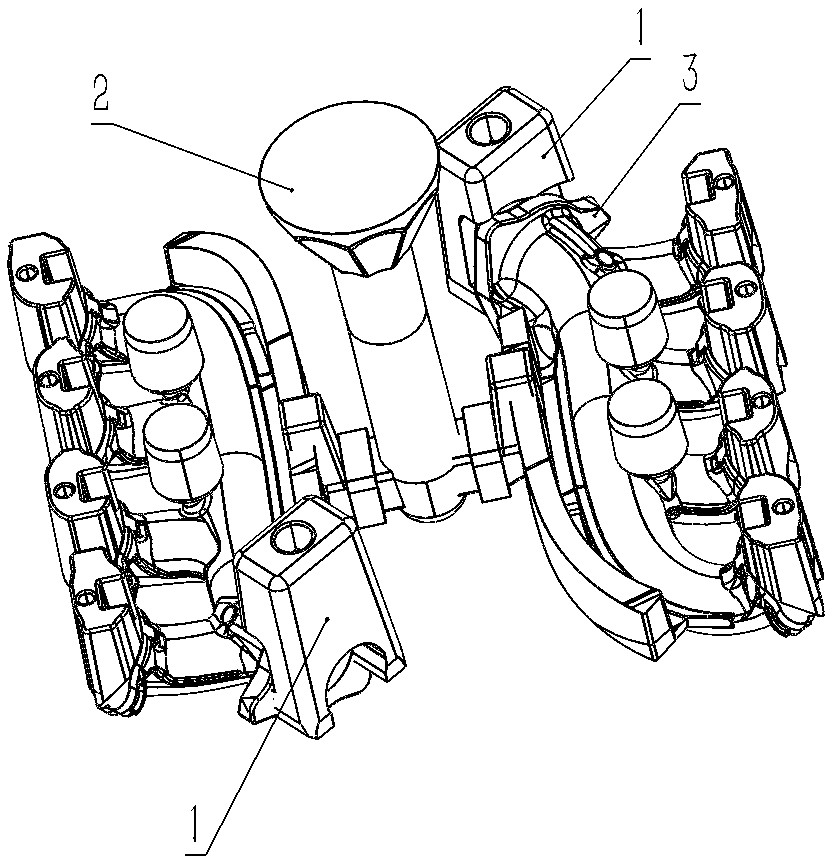

Mold opening mechanism with mechanical advantage

ActiveCN105397072AMovement precisionSports reliableMould handling equipmentsEngineeringMechanical advantage

The invention discloses a mold opening mechanism with a mechanical advantage. The mold opening mechanism comprises a base, a still mold installing plate, a moving mold installing plate and a transmission mechanism, wherein the still mold installing plate is arranged on the base, the moving mold installing plate is matched with the sill mold installing plate, and the transmission mechanism is used for driving the moving mold installing plate to move front and back so as to achieve the action of mold opening / closing. The transmission comprises a bolt, a nut, a connecting rod and a hand wheel, wherein the bolt is sleeved with the nut, the hand wheel is installed on the end portion of the bolt, and the connecting rod is movably hinged between the moving mold installing plate and the nut. Compared with the prior art, according to the mold opening mechanism with the mechanical advantage, the phenomena that mold shifting and mold damaging are prone to occurring when a mold is opened and closed manually are overcome. The mold opening mechanism is simple in structure, low in manufacturing cost and wide in application range; by means of threaded transmission, operating of the mechanism is precise and reliable, the mold closing force is large, and mole swelling and leak out are avoided; operation is convenient, the process of mold opening and closing can be achieved just by shaking the hand wheel manually, the labor intensity is reduced, and the service life of the mold is prolonged; the operation time of mold opening and closing is short, and the production efficiency of products is improved.

Owner:襄阳新兴精密制造有限公司

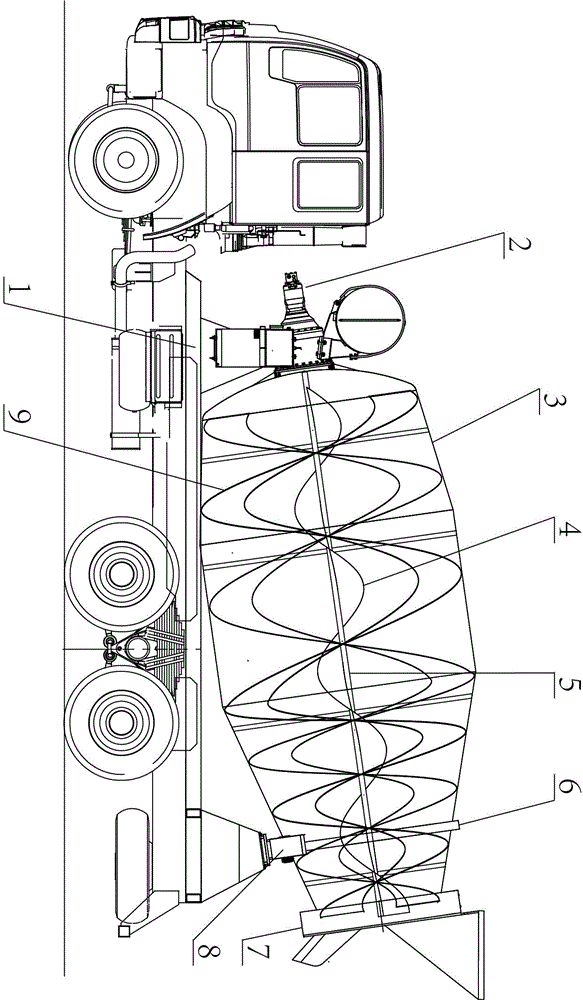

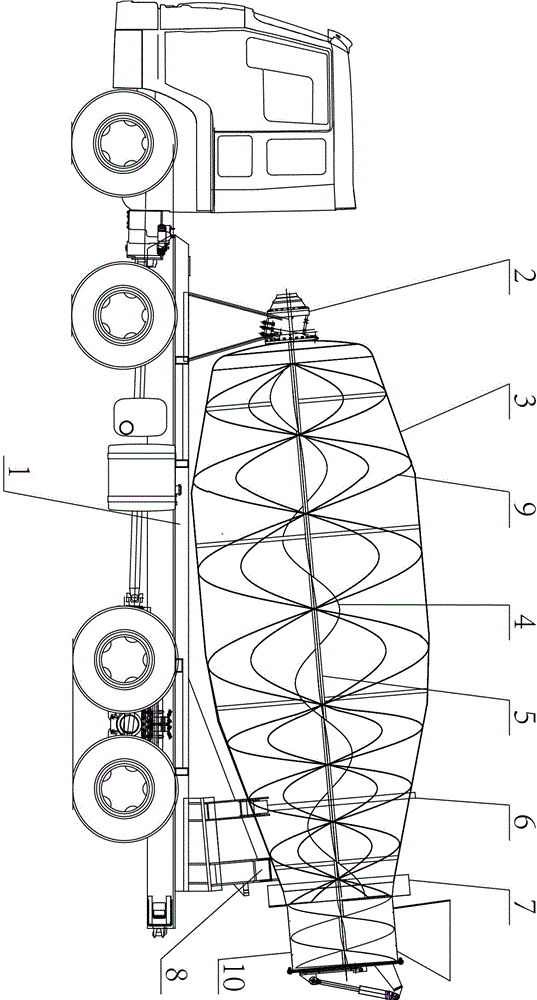

Composite screw transporting vehicle

ActiveCN104385462AStir wellImprove mixing uniformityDischarging apparatusCement mixing apparatusSludgeEngineering

The invention discloses a composite screw transporting vehicle. The rear end of a rotary material cylinder is connected with a rotary sealing mechanism, wherein a main screw blade is spirally mounted on the inner wall of the rotary material cylinder; a center shaft is arranged inside the rotary material cylinder; a secondary screw blade is mounted on the center shaft. The secondary blade and the main blade have synergistic effects. When the composite screw transporting vehicle is used as a high-viscosity concrete transporting vehicle or a sludge transporting vehicle, the loading and unloading rate is relatively high, and the utilization rate of the material cylinder is relatively high; when the composite screw transporting vehicle is used as a concrete transporting vehicle, the concrete is relatively uniformly stirred; the delamination is alleviated; the quality of the high-quality concrete is not influenced.

Owner:YANTAI SHENGLIDA ENG TECH

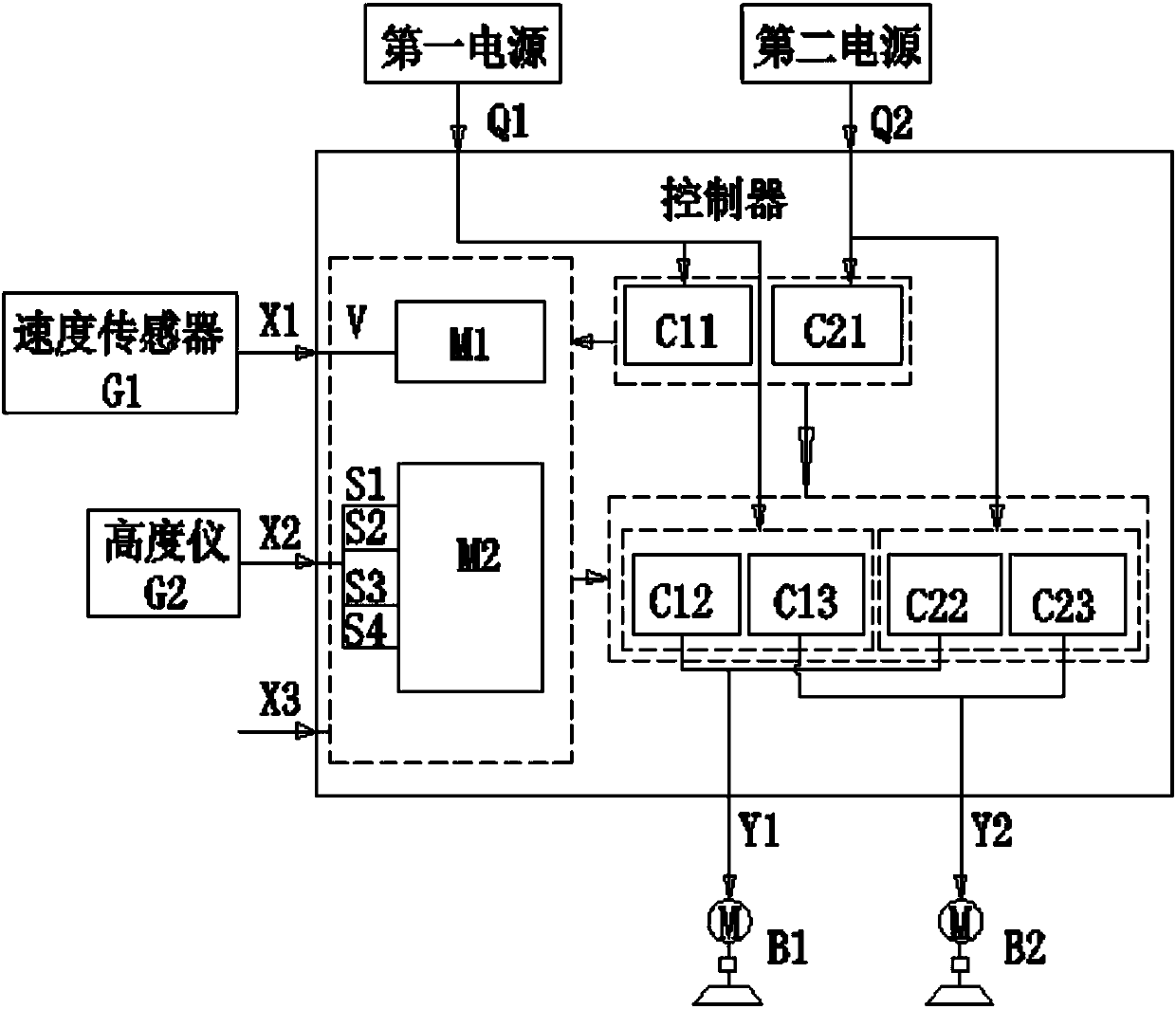

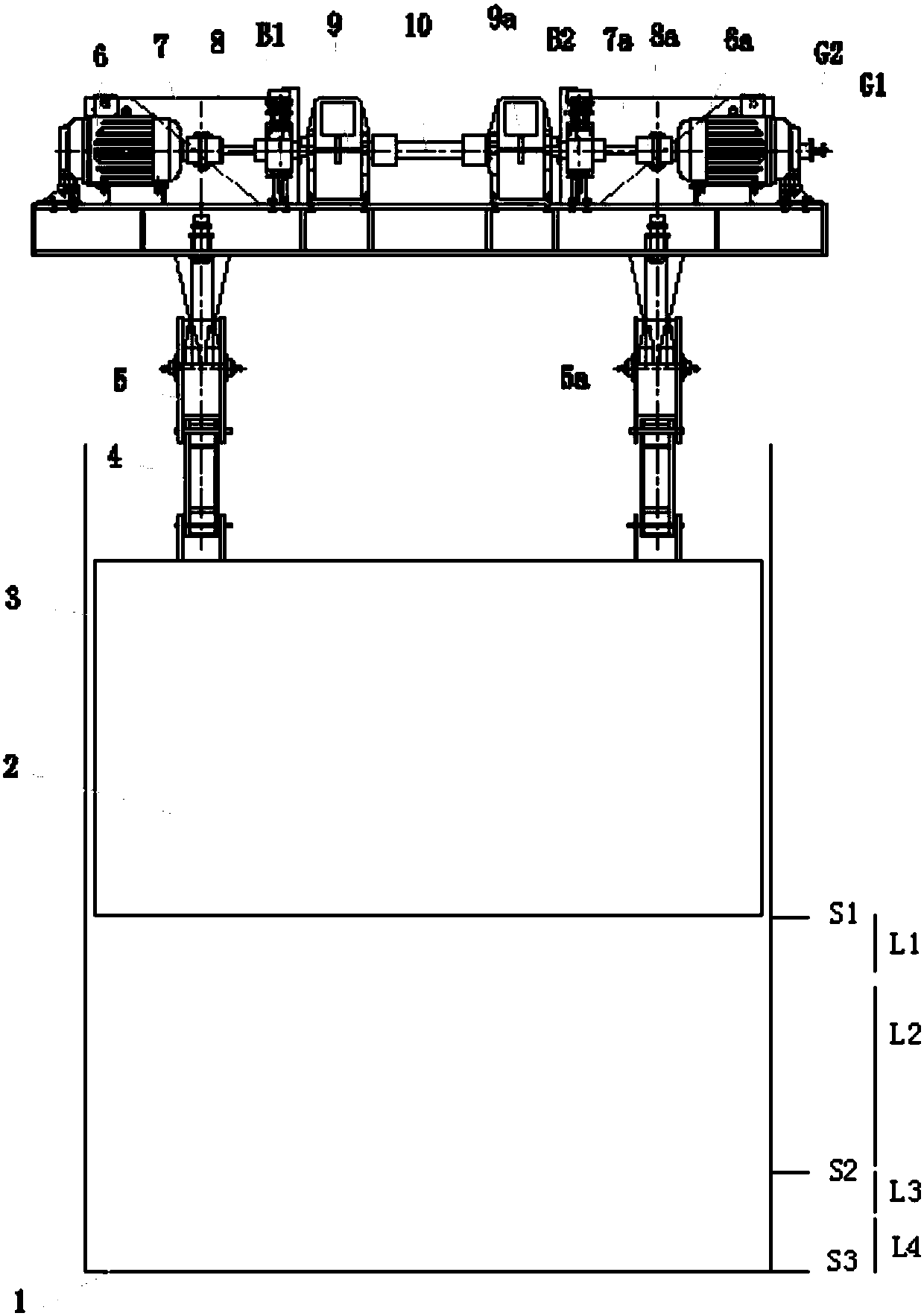

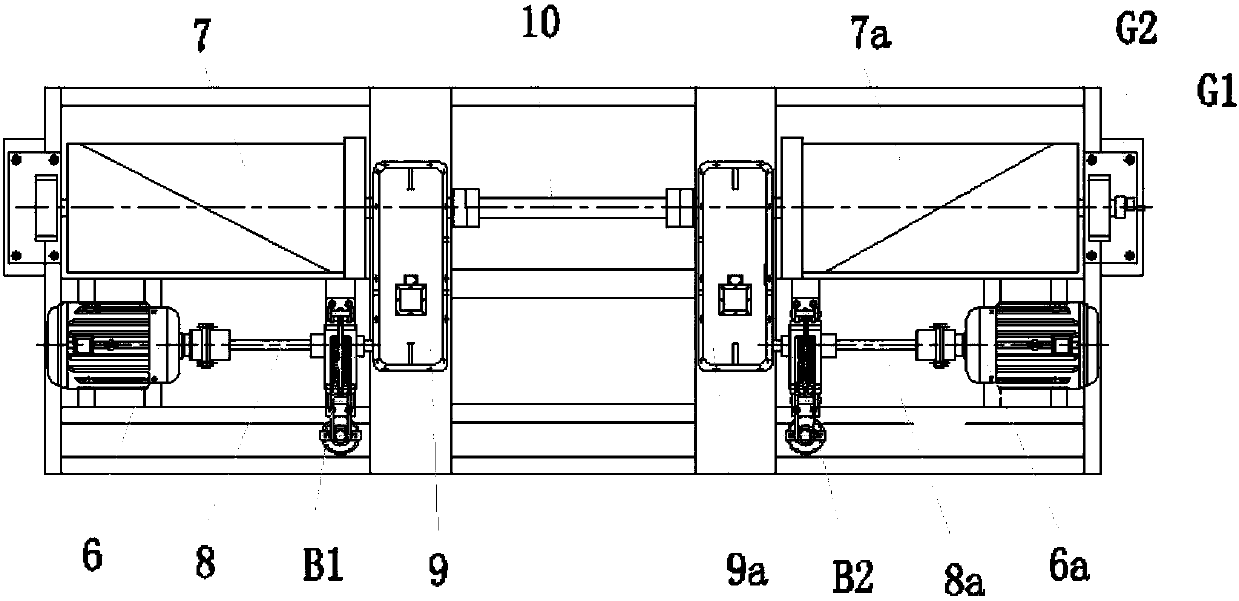

Accident quick gate falling speed regulation device for wind hoist and control method

ActiveCN107558446ASolve problems with complex dynamics that are difficult to controlPrevent runawayBarrages/weirsHydro energy generationEngineeringDamping torque

The invention discloses an accident quick gate falling speed regulation device for a wind hoist and a control method. The accident quick gate falling speed regulation device comprises a brake, a height gauge, a speed sensor and a controller. The balancing magnitude relation of damping torque and holding force of the brake is controlled by acquiring the comparison value of the gate falling speed and the predetermined speed, and the purpose that a gate falls down at the predetermined speed is achieved; by acquiring the gate falling speed and the position signal, control is conducted according toa sequence closing method, quick falling of the gate and timely water flowing speed reduction are achieved, a hydraulic turbine set is prevented from operating in a runaway manner, the gate slowly falls into a bottom sill, the impact is reduced, and the gate and the bottom sill are protected from being damaged due to impact. According to the accident quick gate falling speed regulation device forthe wind hoist and the control method, the full-closed-loop automatic redundancy design is adopted, it is guaranteed that the gate is quickly, stably and safely closed in time under the accident state.

Owner:湖南联诚能源发展有限公司

Processing method of scallion

InactiveCN102578212AEasy to controlImprove securityFruits/vegetable preservation by freezing/coolingQuick FreezeIce water

The invention discloses a processing method of scallion, which comprises the following steps that: prewashing; first-time dipping sterilization; fine washing; second-time dipping sterilization; segmentizing; third-time dipping sterilization; pre-cooling in ice water; and quick freeze, so a finished product is obtained. Due to adoption of the processing method, the hygiene and safety problem of the scallion can be well solved, thorough removal of impurities, thorough decontamination and thorough removal of residual sterilizing agent of raw materials can be guaranteed; and pollution of microorganisms on the scallion can be maximally reduced, and the taste of the scallion can be maximally maintained.

Owner:龙海龙贤果蔬速冻食品有限公司

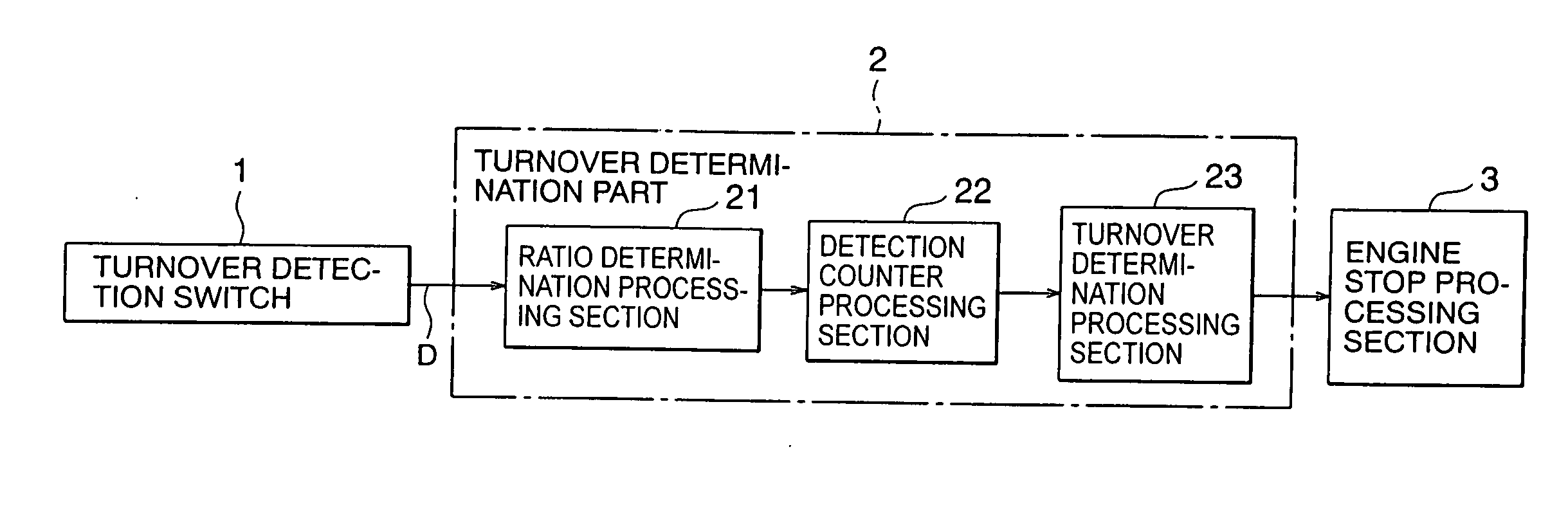

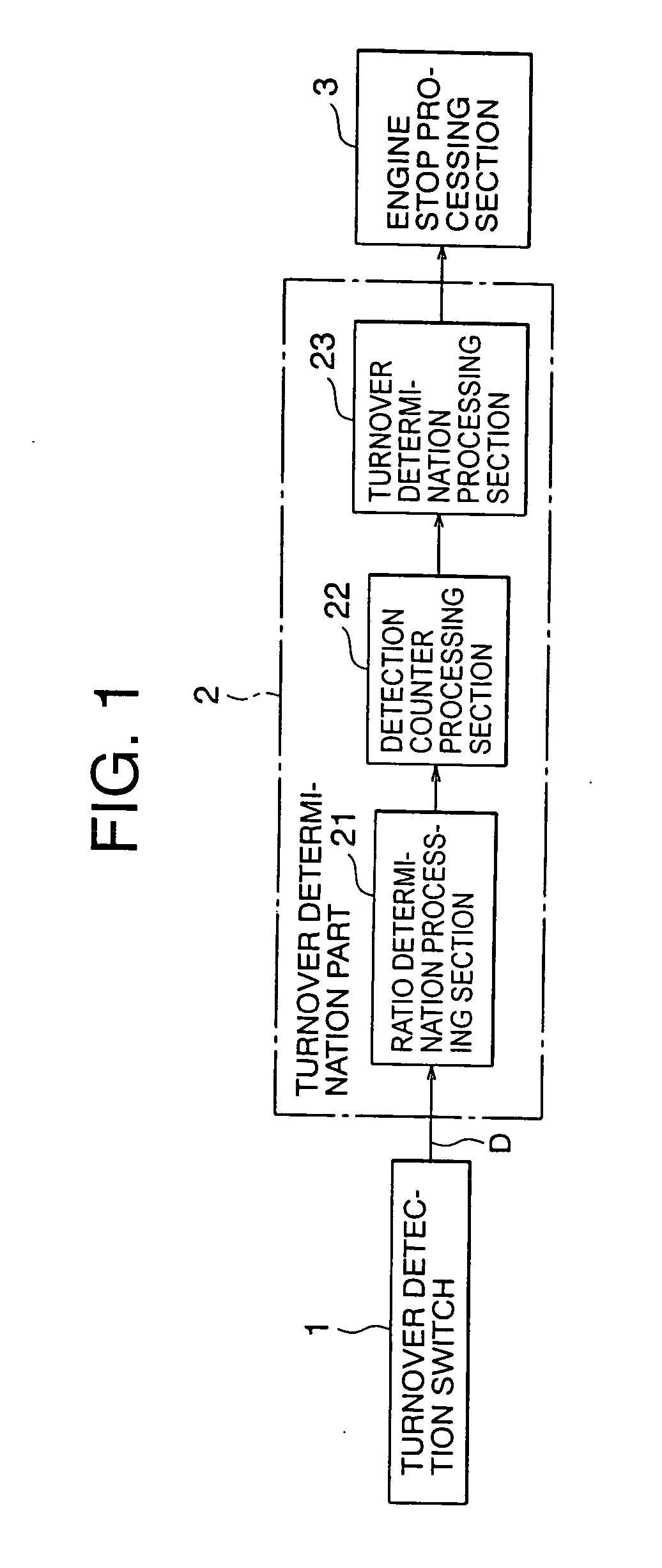

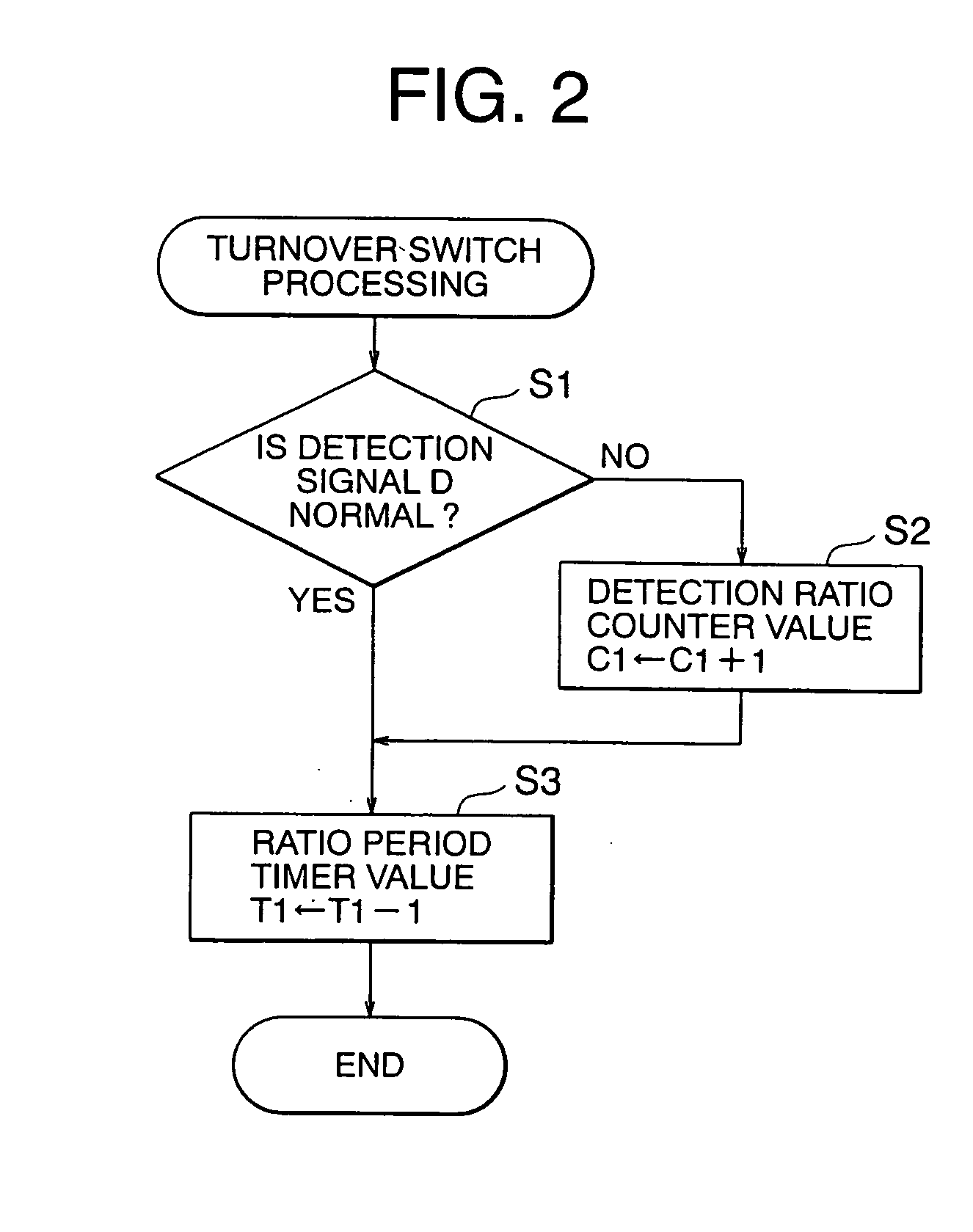

Control apparatus for a hull with a four-cycle engine installed thereon

InactiveUS20060089762A1Quick fixSuppression delayDigital data processing detailsLarge containersMarine engineeringFour-stroke engine

A control apparatus for a hull with a four-cycle engine installed thereon can perform engine stop processing by quickly detecting a turnover state of the hull while suppressing a turnover determination delay due to noise superposition. The apparatus includes a turnover determination part that determines, based on a detection signal from a turnover detection switch, whether the hull is in a turnover state, and an engine stop part that stops the engine upon determination of a final hull turnover state. The turnover determination part increments a detection ratio counter each time a detection signal indicative of a hull turnover state is input thereto, counts up a continuous turnover counter each time the detection ratio counter value indicates a predetermined determination ratio value or above. When the continuous turnover counter value reaches the predetermined determination value or above, the turnover determination part determines that the hull is in the final turnover state.

Owner:MITSUBISHI ELECTRIC CORP

Material for neutron shielding and for maintaining sub-criticality based on vinylester resin

InactiveUS20050012054A1Prevent runawayElectrode and associated part arrangementsDischarge tube/lamp detailsAlumina hydrateZinc borate

This invention relates to a composite material for neutron shielding and maintenance of sub-criticality comprising a matrix based on vinylester resin and an inorganic filler capable of slowing and absorbing neutrons. The vinylester resin may be an epoxymethacrylate resin and the inorganic filler may contain a zinc borate and an alumina hydrate or magnesium hydroxide.

Owner:COGEMA LOGISTICS

Bead rotating plate of beading machine

ActiveCN104179045AImprove beading efficiencyFast transmissionTextile decorationState of artMechanical engineering

The invention discloses a bead rotating plate of a beading machine. The bead rotating plate comprises a rotating plate main body, a rotating blade and bead outlet parts, wherein the rotating plate main body is provided with a groove for containing the beads; the rotating blade is installed in the groove of the rotating plate main body; the bottom of the groove of the rotating plate main body is provided with fixed holes, the bead outlet parts are nested in the fixed holes, and the bead outlet parts are provided with bead outlet holes. Compared with the prior art, the bead rotating plate of the beading machine can accelerate the transferring speed of the beads, so that the transferring speed of the beads can keep up with the beading transferring speed, the transferring efficiency of the beads can be increased, and the beading efficiency of the beading machine can be improved.

Owner:林尧宇

Film for packaging of fresh or fermentation food, packaging material and container

A fresh or fermentation food packaging film, a packaging material and a packaging container which use the film, are disclosed. The fiesh or fermentation food packaging film whose average pore size is 0.01 to 2[mu]m and whose porosity is 10^80%, wherein the film is manufactured from pure crystalline polymer without addition of inorganic compounds or organic compounds for pore formation, so as to impart rnicroporousness thereto by a dry stretching method which does not use an organic solvent and solvent. The packaging film which can pack fermentation food, such as Kimchi, etc., and fresh food, such as vegetables, etc., in which the packaging film can allow the food some operations, such as breathing and transpiration, etc., but restrain penetration of liquid, such as, water, etc., and can also effectively prevent leakage of smell, such that the food can be kept fiesh, through a simple handling process.

Owner:INTERPORE

Casting mold for increasing mold thickness

InactiveCN109570440AIncrease profitThere will be no escapeFoundry mouldsFoundry coresCasting moldHot joints

The invention discloses a casting mold for increasing mold thickness. The casting mold comprises a sand box, molding sand, a pouring cup and a riser, wherein the riser is arranged at the rear side ofthe hot joint position at the edge of the sand box, so that an original mold with one cavity is changed into a mold with two cavities, or the mold with two cavities is changed into a mold with four cavities; the safe mold thickness is sufficiently ensured; the running-out phenomenon of a casting during casting process will not occur; and the safe pouring without running-out is ensured while the utilization of the sand box is improved.

Owner:西峡飞龙特种铸造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com