Investment casting shell molding process

A molding process and investment technology, applied in the directions of casting mold components, casting molding equipment, casting molds, etc., can solve the problems of increased cracking tendency of castings, scrapped products, and increased casting costs, so as to reduce the cracking tendency and improve the surface quality. , the effect of reducing the number of shell layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

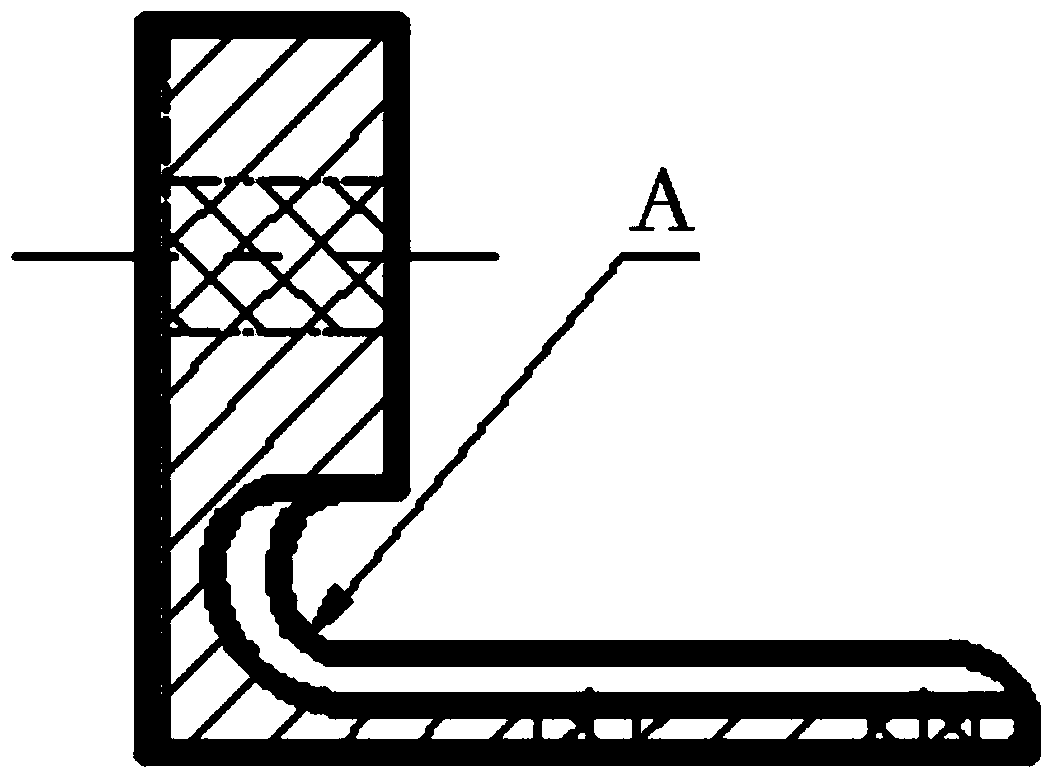

[0048] Such as figure 1 As shown, the "bracket" casting produced by our company is a small thin-walled part with a minimum wall thickness of only 1.5mm. Shell strength, after the workpiece is processed, a fluorescent inspection is performed, and it is found that a large number of workpieces have crack defects at A, which leads to the scrapping of the casting, and the total scrapping rate is as high as 78.6%.

[0049] In view of the causes of the defect rate, our company has adopted the following new technology:

[0050] An investment casting mold shell molding process, comprising the following steps:

[0051] (1) Material preparation: prepare 80-100 mesh white corundum sand, 260-320 mesh white corundum powder, 75 mesh mullite sand, 260~320 mesh mullite powder, 30~60 mesh mullite sand, Prepare a sufficient amount of silica sol and surface coating additives;

[0052] (2) Preparation of surface coatings in separate piles

[0053] a. Preparation of surface coating: white corundu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com