Spinning machine with maintenance unit

A technology for maintaining a device and a spinning machine, which is applied to spinning machines, continuous winding spinning machines, open-end spinning machines, etc., and can solve the problem of unusable, inaccessible auxiliary yarn bobbins, and use of installation space. Narrow and other problems, to achieve the effect of preventing dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

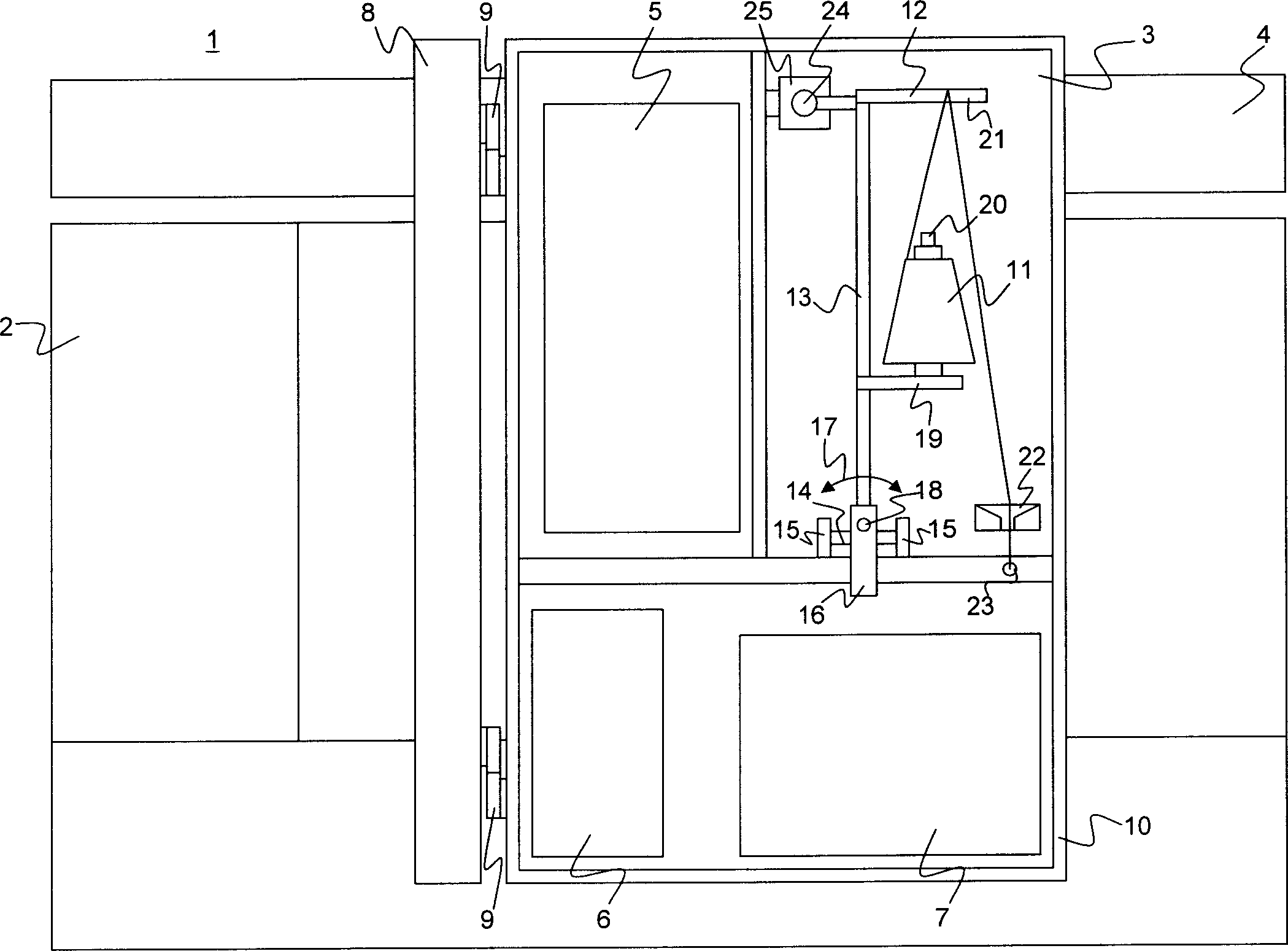

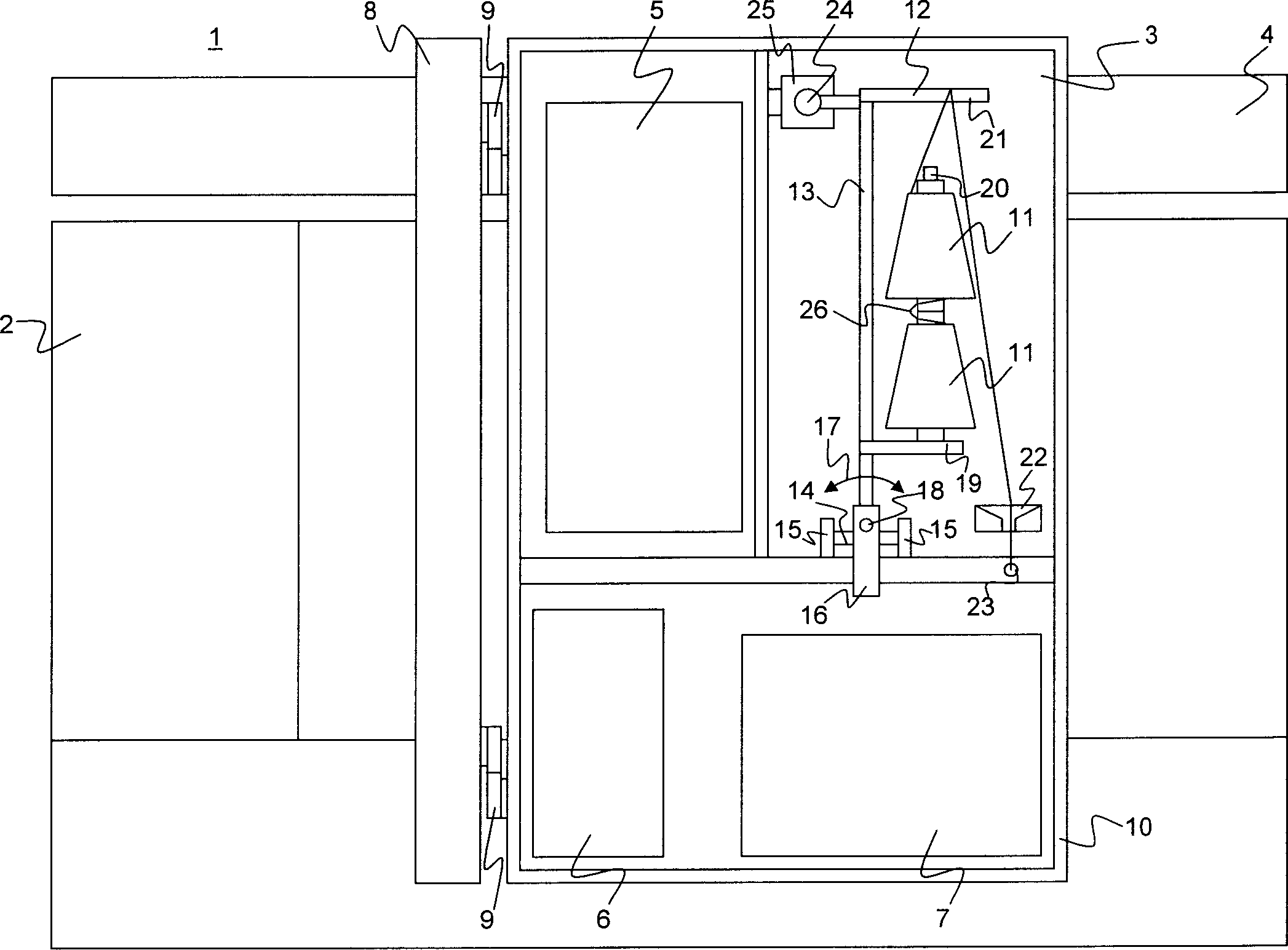

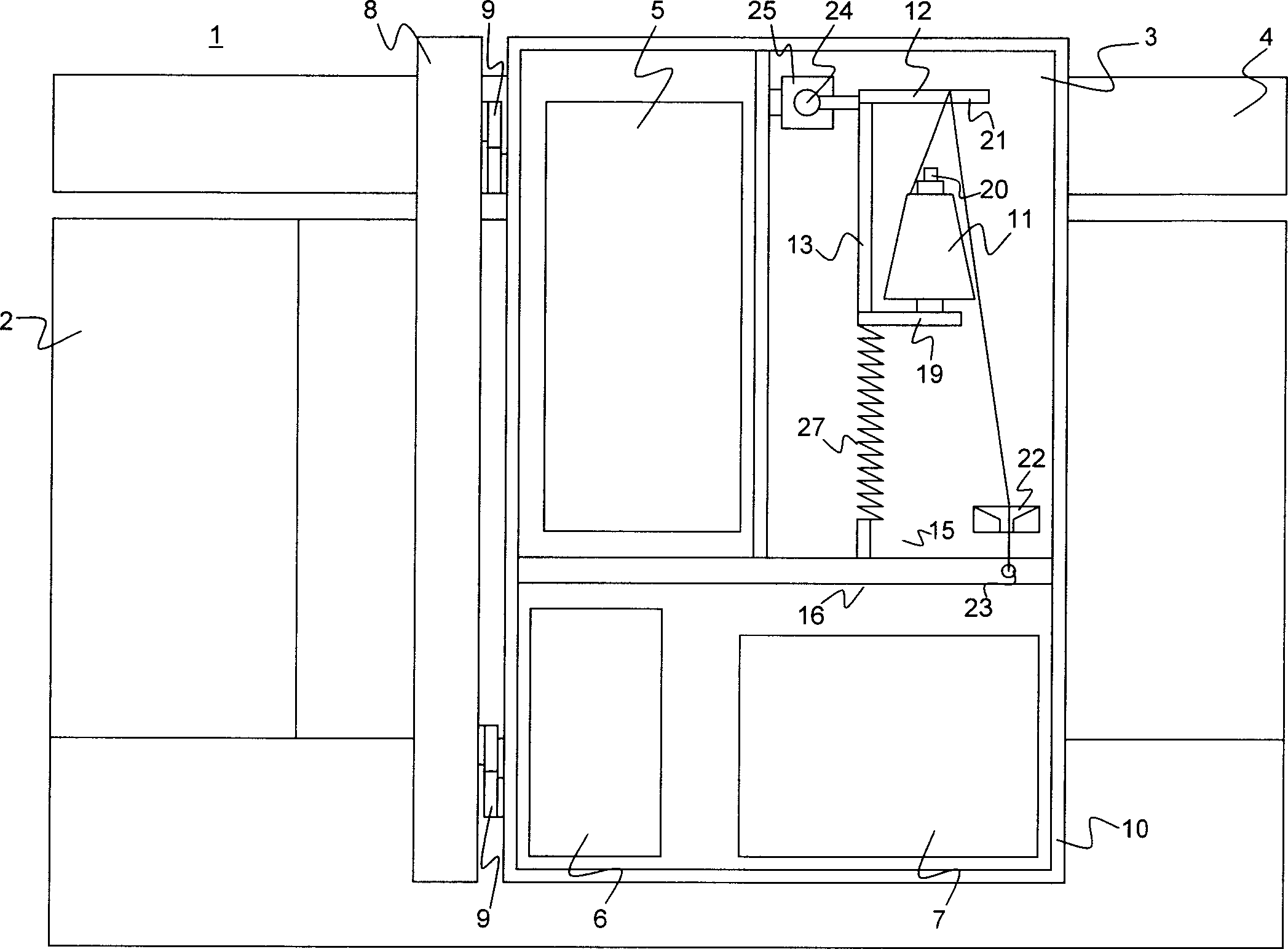

[0042] exist figure 1 The rotor spinning machine 1 according to the invention is shown in side view. For the sake of clarity, only two of the many parallel working positions 2 are shown. The maintenance device 3 is moved along the working position 2 , the maintenance device 3 being guided on a movement channel 4 above the working position 2 . Several units 5, 6 and 7 are installed in the maintenance unit 3. These groups 5 , 6 and 7 are used to perform different functions within the scope of the maintenance work carried out by the maintenance device 3 .

[0043] There is a door 8 installed on the casing 10 through the hinge 9 on the left side of the maintenance device 3 . Under normal working conditions, the door 8 is closed to prevent stolen goods from entering the inside of the maintenance device 3 . In this embodiment, in the upper right part of the maintenance device 3 there is an empty installation space for arranging a bobbin 11 according to the invention. For this p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com