Impact tool

A technology of impact tools and tools, applied in the field of impact tools

Active Publication Date: 2008-11-19

MAKITA CORP

View PDF0 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the existing electric hammer needs to set a complicated mechanism for reducing vibration, so there is room for improvement in terms of structural rationalization

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

no. 1 approach

no. 2 approach

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

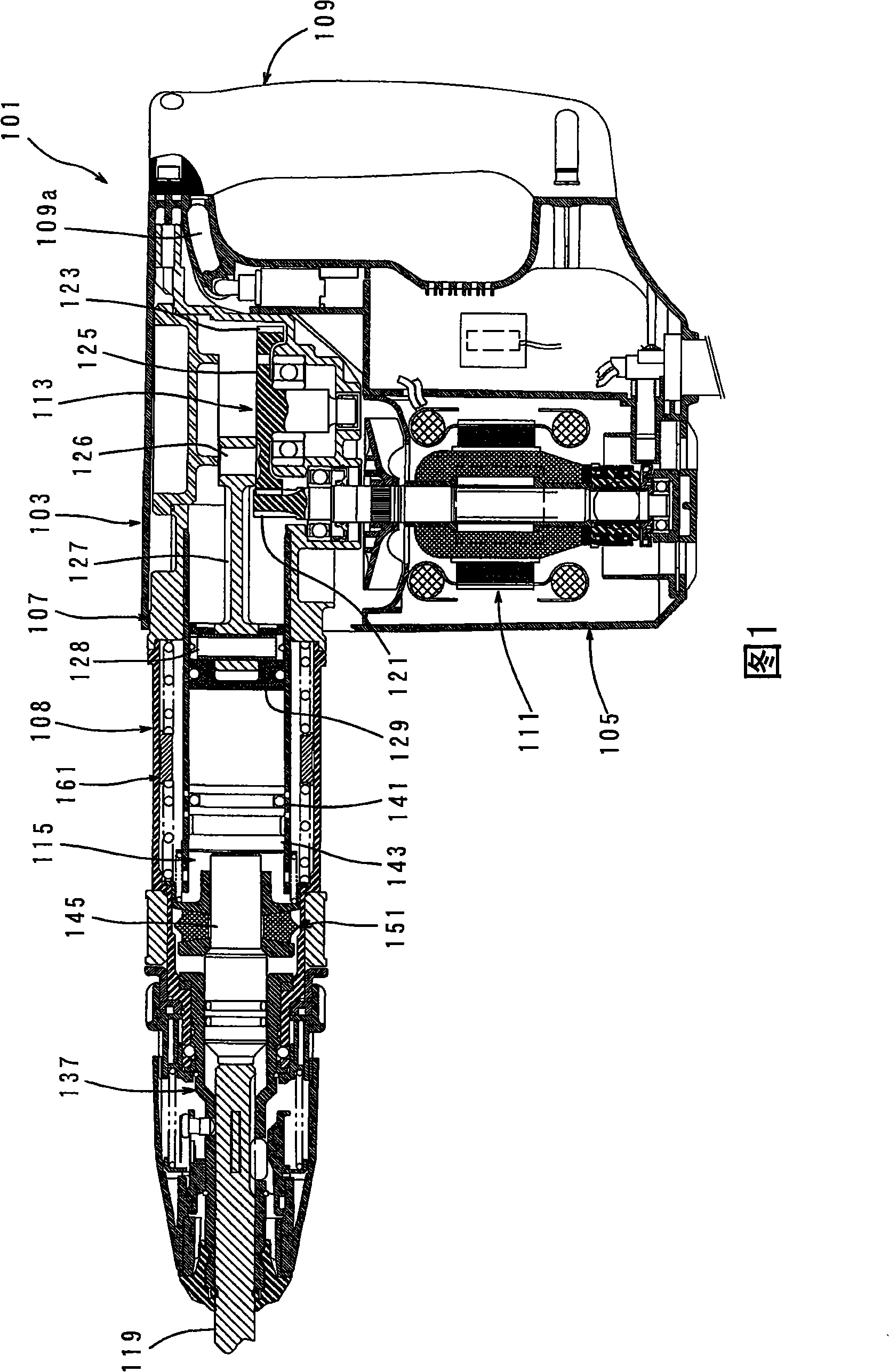

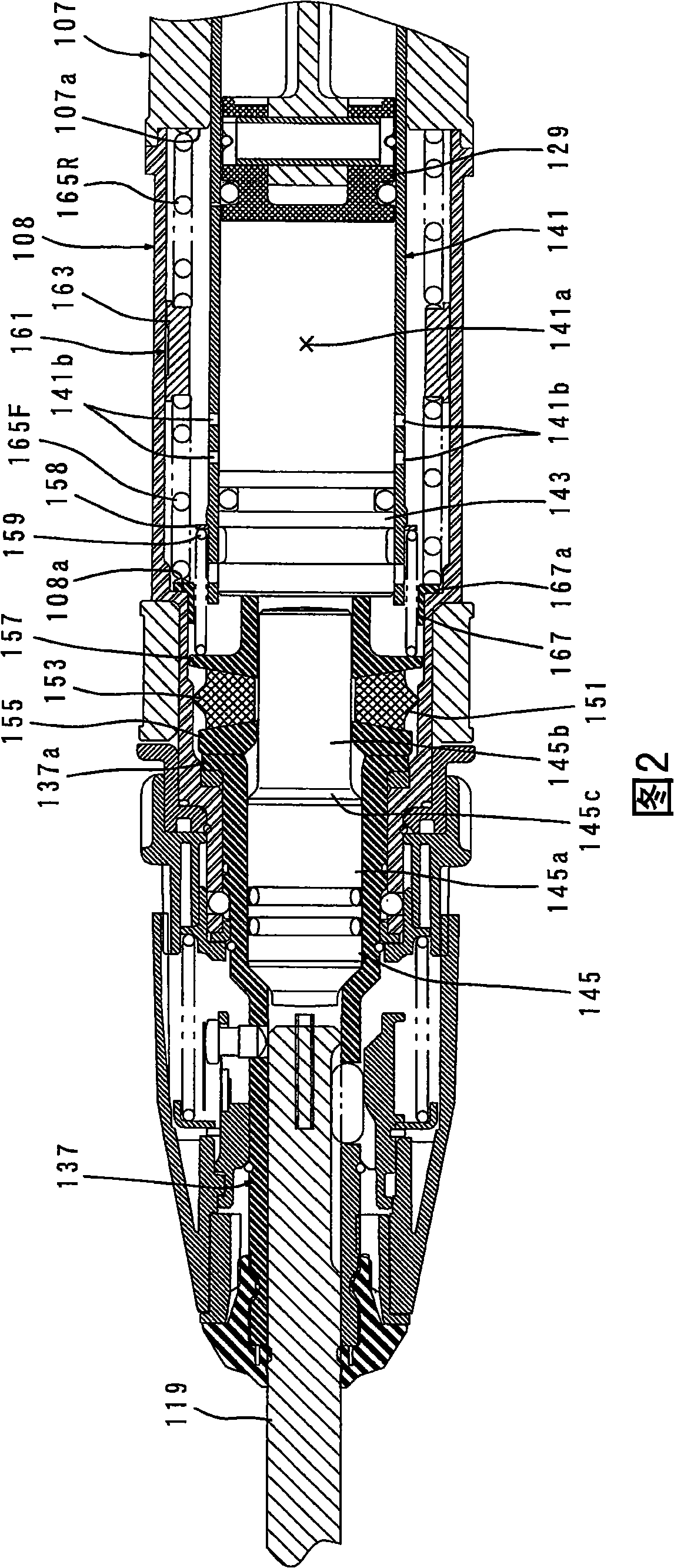

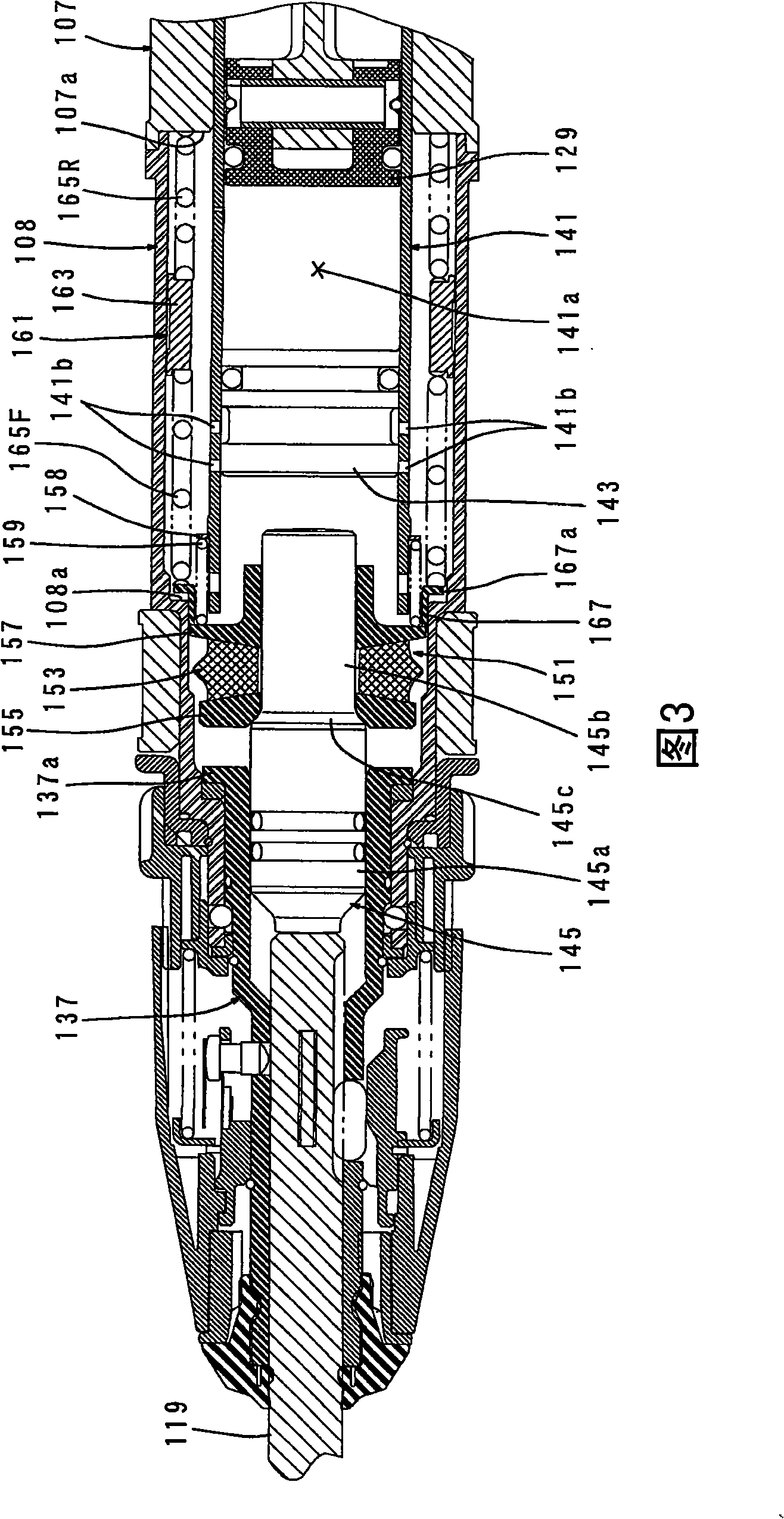

The invention provides an impact tool capable of inhibiting vibration of a tool body generated while hammering process, lessening counterforce to the processed material after impact motions and rationalizing structure of the device. The impact tool includes a tool body (103); a dynamic vibration reducer (161) having a heavy block (163) and elastic components (165F, 165R) and inhibiting vibration while the hammering process; a positioning elastic element which positions the tool body (101) with respect to the processed material prior to the hammering process, so as to, under the positioning state, absorb a counterforce caused by rebound from the processed material and acting on the hammer actuating members (119, 145) when the hammer actuating member (119, 145) perform the hammering process on the processed material. The positioning elastic element includes the elastic elements (165F, 165R) formed as component parts of the dynamic vibration reducer (161).

Description

impact tool technical field The present invention relates to a technique capable of alleviating a reaction force received from a workpiece during the hammering operation in an impact tool for linearly hammering the workpiece. Background technique JP Unexamined Patent Publication No. 52-109673 discloses an electric hammer structure provided with a vibration damping device. In this conventional rotary hammer, an anti-vibration chamber integral with the main body cover (and the motor case) is formed on the lower side of the main body cover in front of the motor case, and a dynamic vibration absorber is housed in the anti-vibration chamber. Therefore, the vibration generated in the direction of the long axis of the hammer bit when the hammer bit is driven is absorbed by the dynamic vibration absorber. However, the conventional electric hammer requires a complicated mechanism for reducing vibration, and thus there is room for improvement in terms of structural rationalization...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B25D17/24B25D9/00

Inventor 生田洋规龟谷光

Owner MAKITA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com