Film for packaging of fresh or fermentation food, packaging material and container

A technology for fermented food and packaging film, applied in transportation and packaging, product, thin material handling, etc., can solve problems such as odor leakage, film is not optimal, inorganic compounds leak food, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

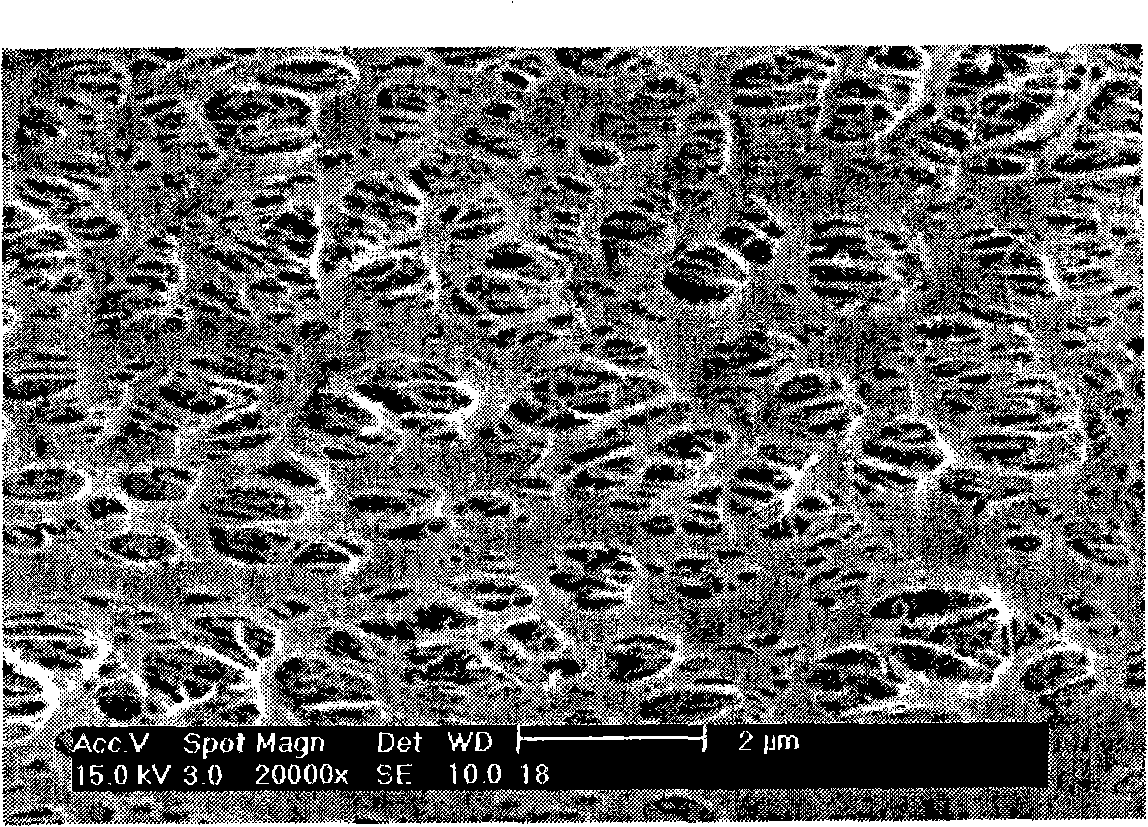

[0061]Using an inflation molding machine having an outer diameter of a mold of 150 mm, a polypropylene (trademark is UBE-PP-F109K, Ube Industries, Ltd.; melt Flow index = 9 g / 10 min) Inflated film was prepared. The obtained polypropylene film was heated at 145° C. for 30 minutes to obtain a non-stretched film with a crystallinity of 70%.

[0062] The non-stretched film was stretched in liquid nitrogen (-196°C) so that its length was increased by 20% from its original length. Next, the film was heated and cured at 145° C. for 2 minutes while maintaining the tension.

[0063] Thereafter, the film was subjected to 300% thermal stretch processing at 130°C. In addition, the film was heat-cured at 145° C. for 30 minutes to obtain a polypropylene microporous film.

[0064] The average pore diameter, porosity, thickness, air permeability, tensile strength, thermal shrinkage and pore closure temperature of the obtained film were measured, as shown in Table 1.

[0065] Here, the por...

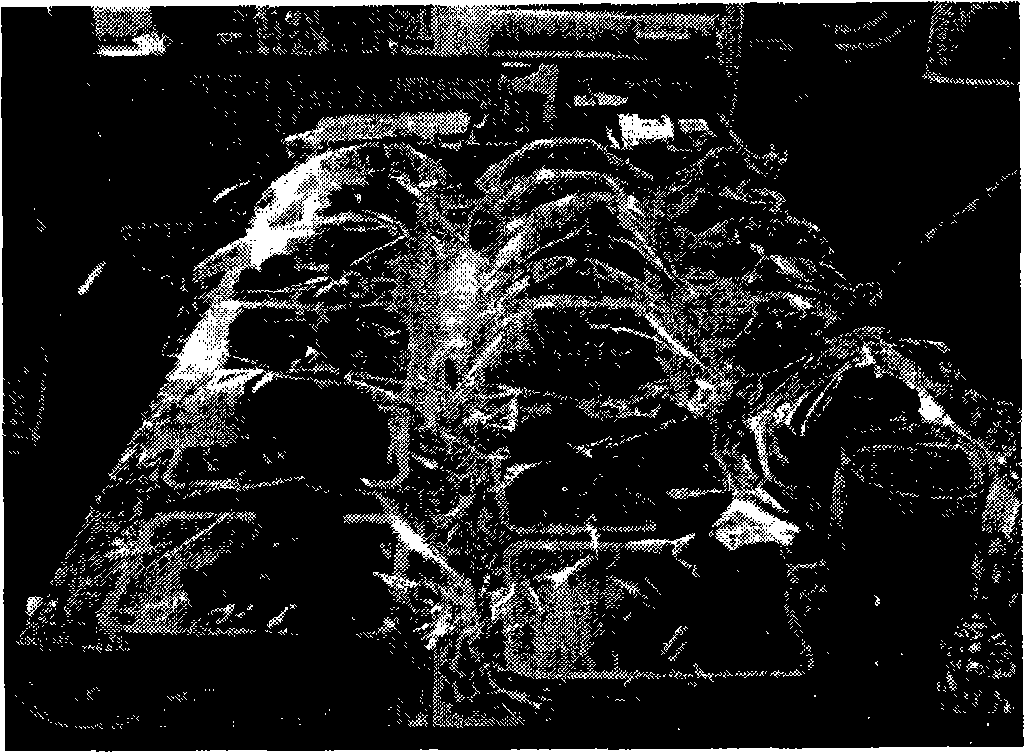

Embodiment 2

[0069] Crystalline polypropylene having a density of 0.92 and a melt flow index of 0.6 g / 10 min was melted and extruded through a 4 inch die with a discharge hole diameter of 0.04 inches. Afterwards, the extruded product was cooled to obtain a non-stretched film.

[0070] The extruded film was stretched 10% at room temperature and then 10% at -20°C. Next, the resulting product was processed by thermal stretching at 140°C. Afterwards, the film was heated and cured at 140° C. for 10 minutes.

[0071] The obtained membrane was tested by the method carried out in Example 1, and various properties shown in Table 1 were obtained.

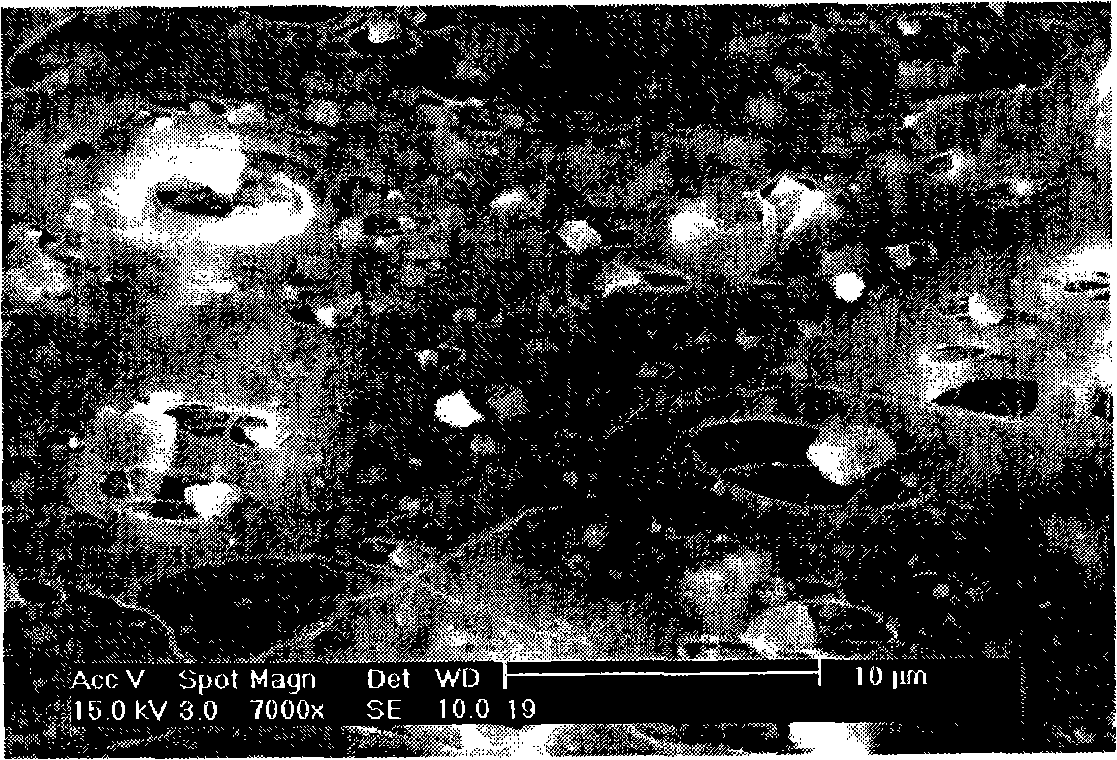

Embodiment 3

[0073] Crystalline polyethylene with a density of 0.93-0.96 and a melt flow index of 0.5-1.2 g / 10 min was melted and extruded through a 4 inch die with a discharge hole diameter of 0.04 inches.

[0074] The extruded film was subjected to a cold stretching process at 25° C. so that the length of the film was increased by 50% from the original length. Next, the resulting product was processed by thermal stretching at 115°C. Afterwards, the film was heat-cured at 120° C. for 5 min.

[0075] The obtained membrane was tested by the method carried out in Example 1, and various properties shown in Table 1 were obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com