Processing method of scallion

A processing method and onion technology, which is applied in food preservation, fruit and vegetable preservation, food science, etc., can solve problems such as too simple cleaning methods, failure to meet hygienic standards, and excessive number of microorganisms, so as to reduce odor loss and microbial infection. chance, quick freezing time, good quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A processing method for green onions, comprising the following steps:

[0036] (1) Selection and inspection of raw materials: The requirements for raw materials are 1) the onion should contain less soil, the leaves should be large, and there should be no disease spots (white spots, purple leaves), yellow leaves, weeds, etc.; 2) the white part of the onion and the blue color The proportion requirements of the part: white: blue = 25%: 75%; 3) The diameter of the white part of the onion is φ≤10mm;

[0037] (2) Pretreatment: remove yellow leaves, diseased spots, onion leaf tips, sundries, etc.;

[0038] (3) Cut the head: cut off 10-15mm, depending on the size of the onion;

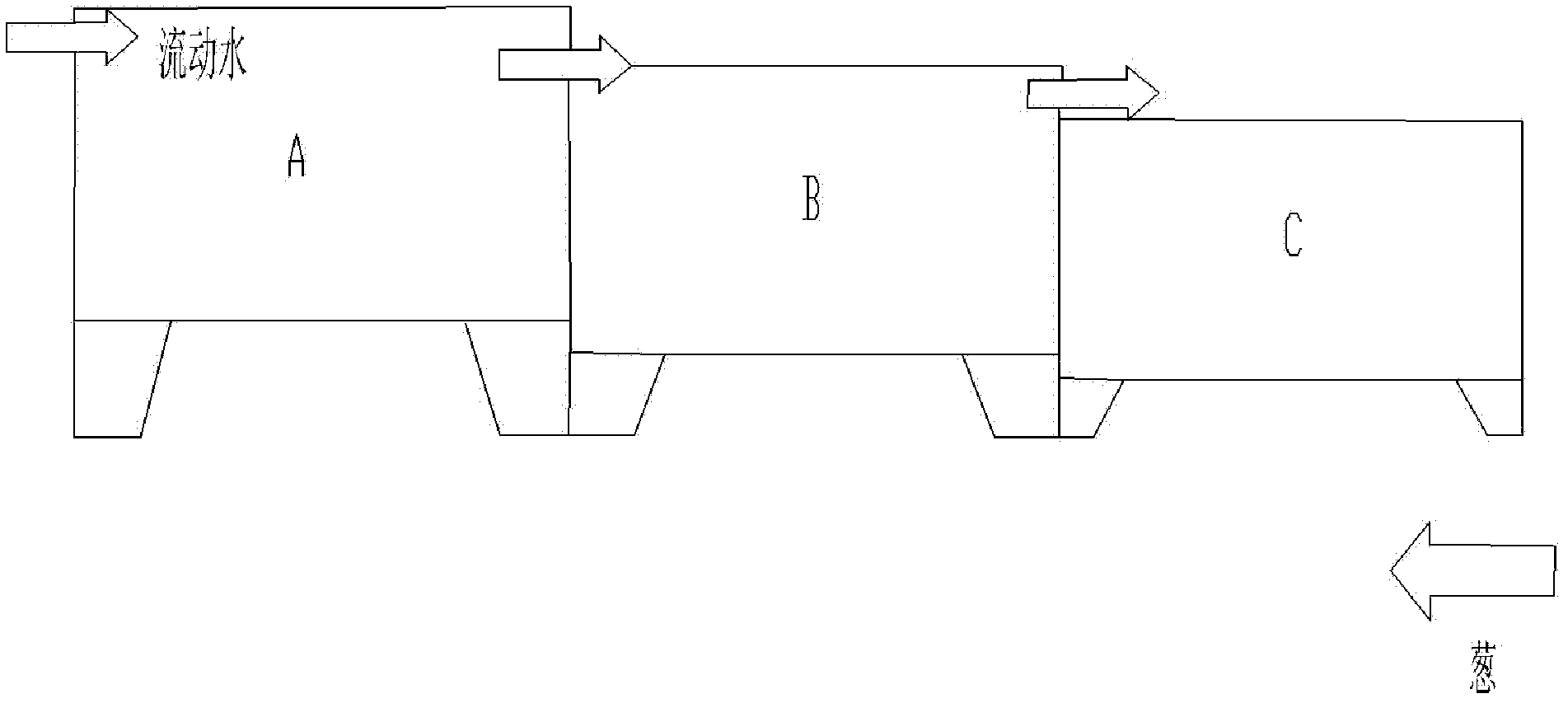

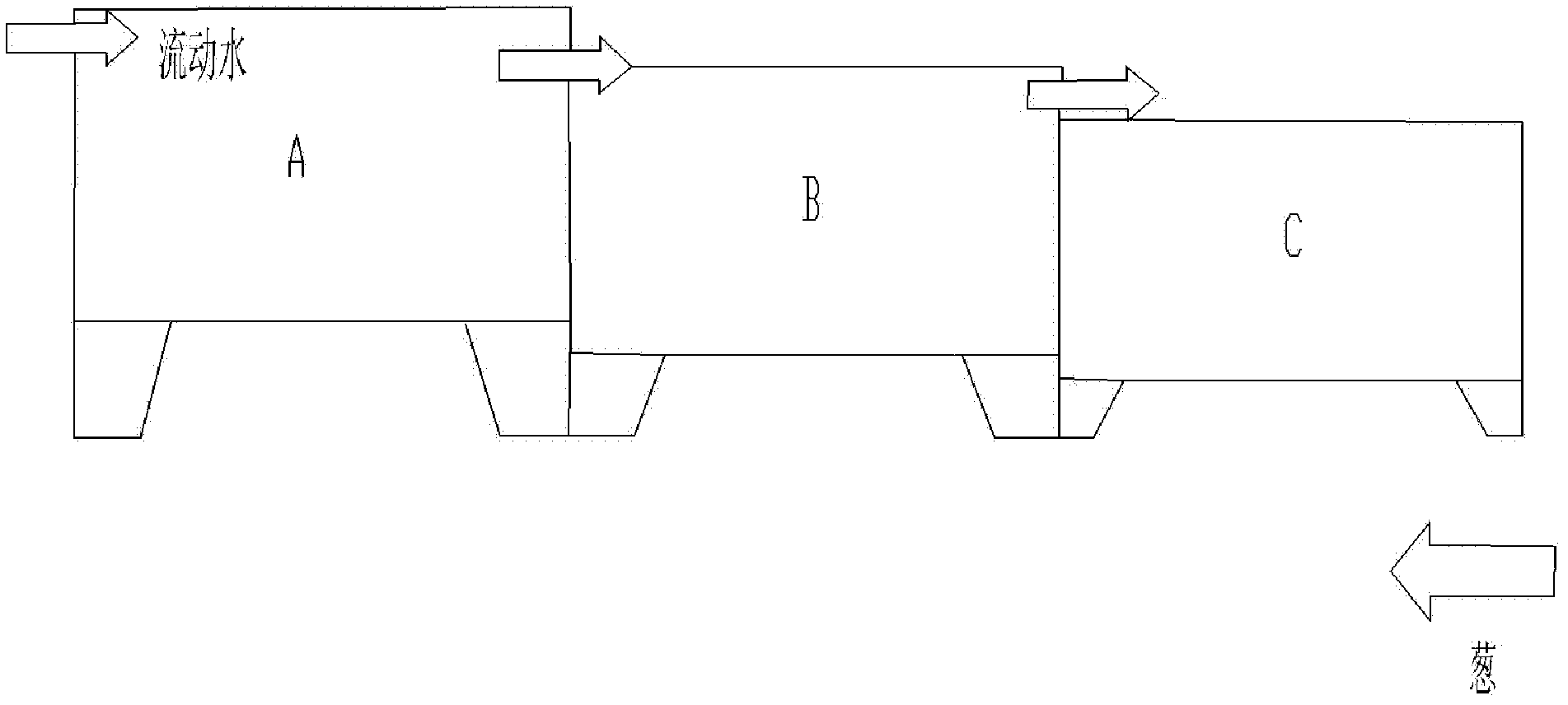

[0039] (4) Pre-cleaning: wash away the sediment, etc. in the bucket with running water;

[0040] (5) One-time immersion disinfection: soak and disinfect in 100ppm sodium hypochlorite disinfectant for 10 minutes, and change the water once an hour;

[0041] (6) Fine cleaning and impurity removal: use r...

Embodiment 2

[0053] A processing method for green onions, comprising the following steps:

[0054](1) Selection and inspection of raw materials: The requirements for raw materials are 1) the onion should contain less soil, the leaves should be large, and there should be no disease spots (white spots, purple leaves), yellow leaves, weeds, etc.; 2) the white part of the onion and the blue color The proportion requirements of the part: white: blue = 20%: 80%; 3) The diameter of the white part of the onion is φ≤10mm;

[0055] (2) Pretreatment: remove yellow leaves, diseased spots, onion leaf tips, sundries, etc.;

[0056] (3) Cut the head: cut off 10-15mm, depending on the size of the onion;

[0057] (4) Pre-cleaning: wash away the sediment, etc. in the bucket with running water;

[0058] (5) One-time immersion disinfection: soak and disinfect in 50ppm sodium hypochlorite disinfectant for 10 minutes, and change the water once an hour;

[0059] (6) Fine cleaning and impurity removal: use run...

Embodiment 3

[0071] A processing method for green onions, comprising the following steps:

[0072] (1) Selection and inspection of raw materials: The requirements for raw materials are 1) the onion should contain less soil, the leaves should be large, and there should be no disease spots (white spots, purple leaves), yellow leaves, weeds, etc.; 2) the white part of the onion and the blue color Requirements for the proportion of the part: white: blue = 22%: 78%; 3) The diameter of the white part of the onion is φ≤10mm;

[0073] (2) Pretreatment: remove yellow leaves, diseased spots, onion leaf tips, sundries, etc.;

[0074] (3) Cut the head: cut off 10-15mm, depending on the size of the onion;

[0075] (4) Pre-cleaning: wash away the sediment, etc. in the bucket with running water;

[0076] (5) One-time immersion disinfection: soak and disinfect in 75ppm sodium hypochlorite disinfectant for 10 minutes, and change the water once an hour;

[0077] (6) Fine cleaning and impurity removal: us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com