Fuel gas thermal desorption-steam enhanced vapor extraction in-situ coupling repair method for composite organic contaminated site

A technology of organic pollution and remediation methods, applied in the restoration of polluted soil and other directions, can solve the problems of true coupling and no mention, and achieve the effect of improving the remediation efficiency and realizing the utilization of waste heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

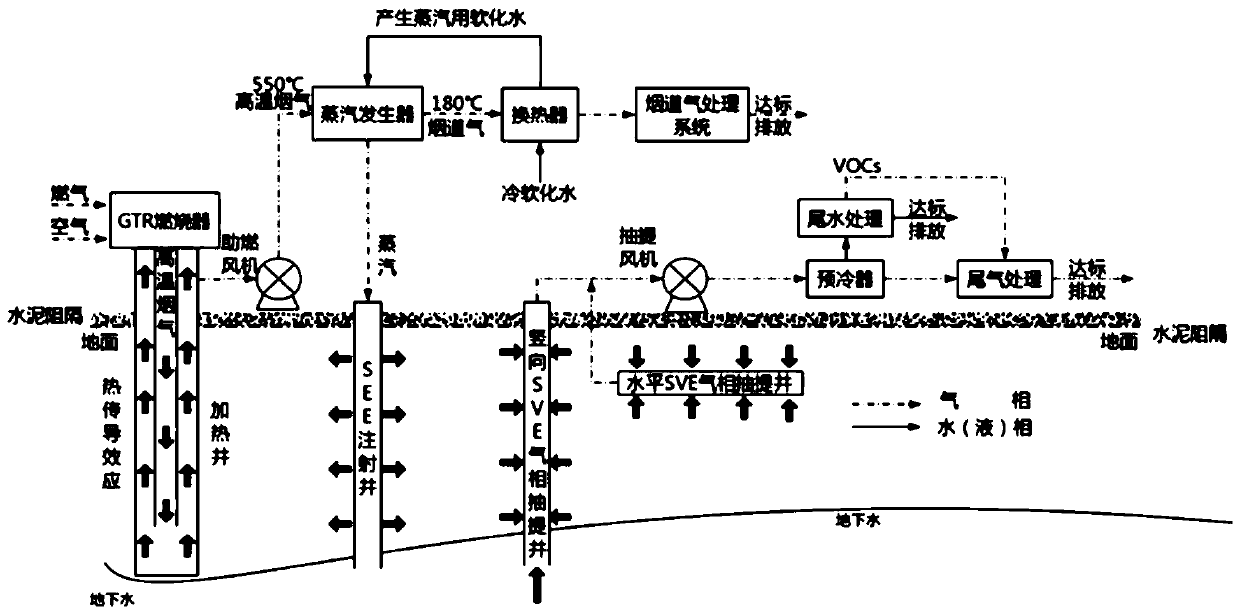

[0011] The gas thermal desorption-steam enhanced gas phase extraction in-situ coupling repair method for complex organic pollution sites of the present invention, its preferred specific implementation is:

[0012] Including high-temperature flue gas heating wells, steam injection wells, and vapor phase extraction wells;

[0013] The high-temperature flue gas produced by the burner conducts heat transfer through the high-temperature flue gas heating well for soil restoration;

[0014] The flue gas returned from the high-temperature flue gas heating well is introduced into the steam generator, and the steam generator is fed with demineralized water for generating steam at the same time, and the heat of the flue gas is used to generate steam and inject it into the steam injection well for steam enhanced gas phase extraction. carry.

[0015] Before coupling restoration, first determine the coupling mode and coupling ratio that adapt to different site characteristics and restorati...

specific Embodiment

[0023] Specific examples, such as figure 1 Shown:

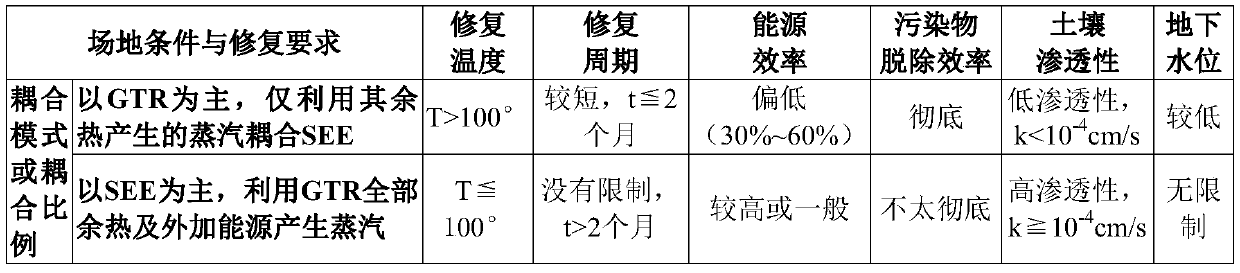

[0024] For complex organic pollution sites of benzene series, petroleum hydrocarbons, polycyclic aromatic hydrocarbons and halogenated hydrocarbons, from the perspectives of remediation temperature, remediation period, energy efficiency, pollutant removal efficiency, low-permeability soil adaptability, and groundwater level adaptability, etc., To couple the respective technical advantages of GTR and SEE, first determine the coupling mode and coupling ratio (the contribution ratio of GTR and SEE to the remediation soil) that adapt to different site characteristics and remediation requirements, as shown in Table 1.

[0025] Table 1 Corresponding matrix of GTR-SEE coupling mode and related parameters

[0026]

[0027] For the GTR-based coupling mode, GTR heating wells, steam injection wells and polluted gas extraction wells are alternately distributed, the depth of various wells and the spacing between wells (including the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com