Method for preparing calcium carbonate and co-producing sulfate by utilizing industrial desulfurization gypsum

A desulfurization gypsum and sulfate technology, which is applied in the preparation of ammonium sulfate, calcium carbonate/strontium/barium, urea derivatives, etc., can solve problems such as undeveloped, and achieve the goal of avoiding carbon emissions, protecting the ecological environment, and reducing mining Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

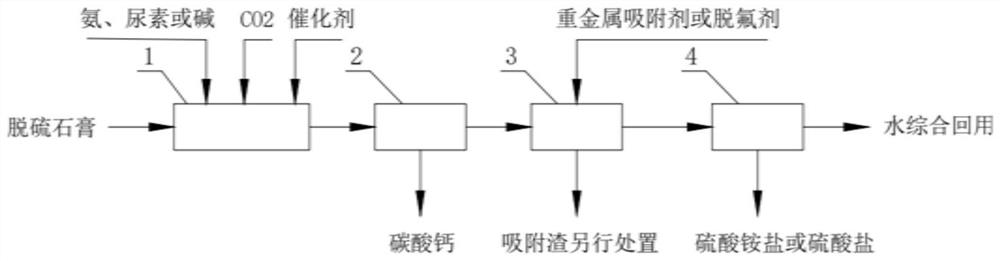

Method used

Image

Examples

Embodiment 1

[0040] (1) Pretreat the zinc-containing heavy metal desulfurization gypsum to make a gypsum slurry with a mass concentration of 35%, wherein the zinc concentration is 10.7mg / L;

[0041] (2) The gypsum slurry is sent to the desulfurization gypsum reactor with a pump, and the concentration of 1.8 equivalents is sent into the desulfurization gypsum reactor by a pump with a concentration of 15%, so that the pH value of the slurry is controlled between 8 and 10, fully stirred, Feed sufficient carbon dioxide gas simultaneously, control reaction time 1.5 hours, obtain the mixed solution containing calcium carbonate solid precipitate and ammonium sulfate salt, total reaction formula is:

[0042] CaSO 4 2H 2 O+CO 2 +2NH 3 ·H 2 O=CaCO 3 ↓+(NH 4 ) 2 SO 4 +3H 2 o

[0043] (3) The mixed solution is washed by pressure filtration to obtain calcium carbonate slag and a mass concentration of about 7.4% ammonium sulfate aqueous solution, with a zinc concentration of 10.5 mg / L;

[004...

Embodiment 2

[0049] (1) Pretreat the zinc-containing heavy metal desulfurization gypsum to make a gypsum slurry with a mass concentration of 35%, wherein the zinc concentration is 10.7mg / L;

[0050] (2) Send the gypsum slurry to the desulfurization gypsum reactor with a pump, and send 1.8 equivalents of ammonia water with a concentration of 15% into the desulfurization gypsum reactor to control the pH value of the slurry between 8 and 10, and add 0.15 The triethanolamine of % gypsum slurry quality is as catalyzer, fully stirs, feeds sufficient carbon dioxide gas simultaneously, controls reaction time 0.7 hour, obtains the mixed solution containing calcium carbonate solid precipitate and ammonium sulfate salt, and total reaction formula is:

[0051] CaSO 4 2H 2 O+CO 2 +2NH 3 ·H 2 O=CaCO 3 ↓+(NH 4 ) 2 SO 4 +3H 2 o

[0052] (3) The mixed solution is washed by pressure filtration to obtain calcium carbonate slag and a mass concentration of about 7.8% ammonium sulfate aqueous solution...

Embodiment 3

[0058] (1) Pretreating fluorine-containing desulfurized gypsum to make gypsum slurry with a mass concentration of 15%;

[0059] (2) Send the gypsum slurry to the desulfurization gypsum reactor with a pump, and send 2 equivalents of 10% ammonia water into the desulfurization gypsum reactor with a pump to control the pH value of the slurry between 8 and 10, fully stir, and simultaneously Feed a sufficient amount of carbon dioxide gas, and the reaction time is 1.5 hours to obtain a mixed solution containing calcium carbonate solid precipitate and ammonium sulfate salt, and the total reaction formula is:

[0060] CaSO 4 2H 2 O+CO 2 +2NH 3 ·H 2 O=CaCO 3 ↓+(NH 4 ) 2 SO 4 +3H 2 o

[0061] (3) The mixed solution is filtered and washed to obtain calcium carbonate slag and a mass concentration of about 8.2% ammonium sulfate aqueous solution, and the fluorine concentration is 51 mg / L;

[0062] (4) After drying the calcium carbonate slag, collect and obtain a calcium carbonate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com