Incinerator flue gas multi-pollutant dry-type purification process and device

A purification process, purification device technology, applied in incinerators, climate change adaptation, combustion methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

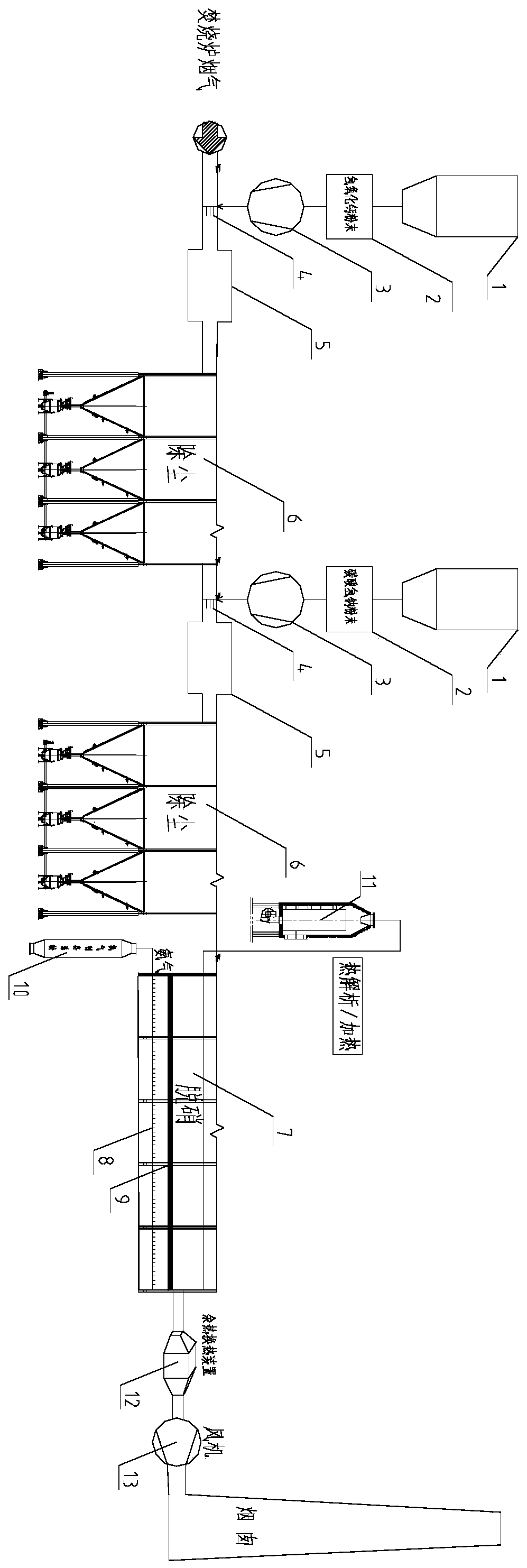

[0031] In order to set forth the specific implementation steps of the present invention more vividly, it will be further described as follows in conjunction with the accompanying drawings:

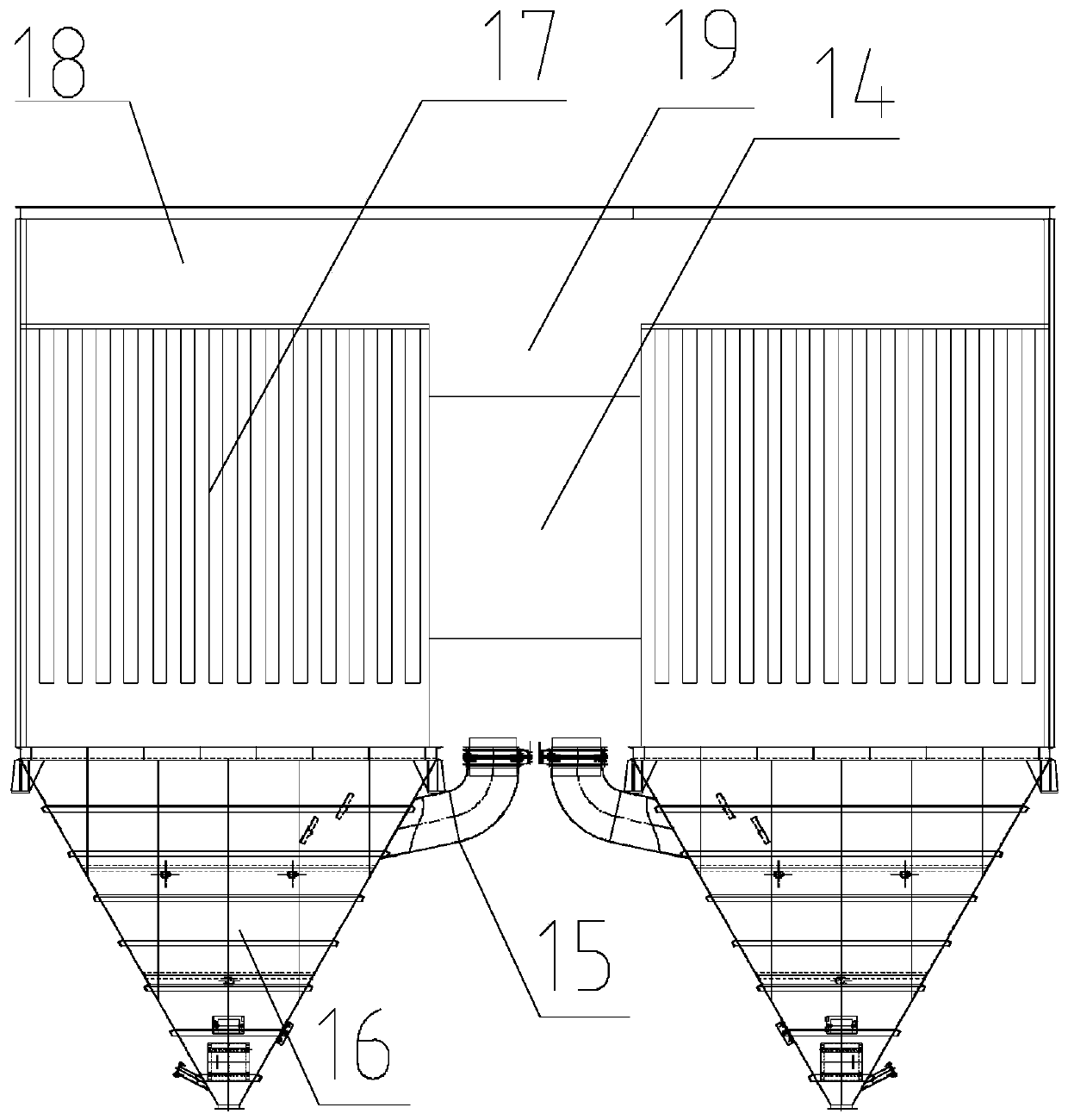

[0032] Referring to the accompanying drawings, an incinerator flue gas multi-pollutant dry purification device includes a desulfurizing agent powder bin 1, a desulfurizing agent mill 2, a Roots blower 3, a desulfurizing agent dosing device 4, a desulfurizing tower 5, and a cloth bag Dust collector 6, medium and low temperature SCR reactor 7, ammonia injection grid 8, static mixer 9, ammonia gas preparation system 10, thermal analysis / heating system 11, waste heat heat exchange device 12, induced draft fan 13; the bag dust removal The device 6 includes an air inlet flue 14 , a flue gas uniform distribution device 15 , an ash hopper 16 , a filter bag 17 , a clean air chamber 18 , and an air outlet flue 19 . The flue gas of the incinerator is desulfurized by two stages (calcium hydroxide + so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com