Two stage treatment method for distillation concentration and incineration of diffusion liquid from refuse burying site

A technology of evaporation concentration and treatment method, which is applied in the direction of combustion method, oxidation treatment sludge, incinerator, etc., which can solve the problems of high cost and poor treatment effect, and achieve the effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

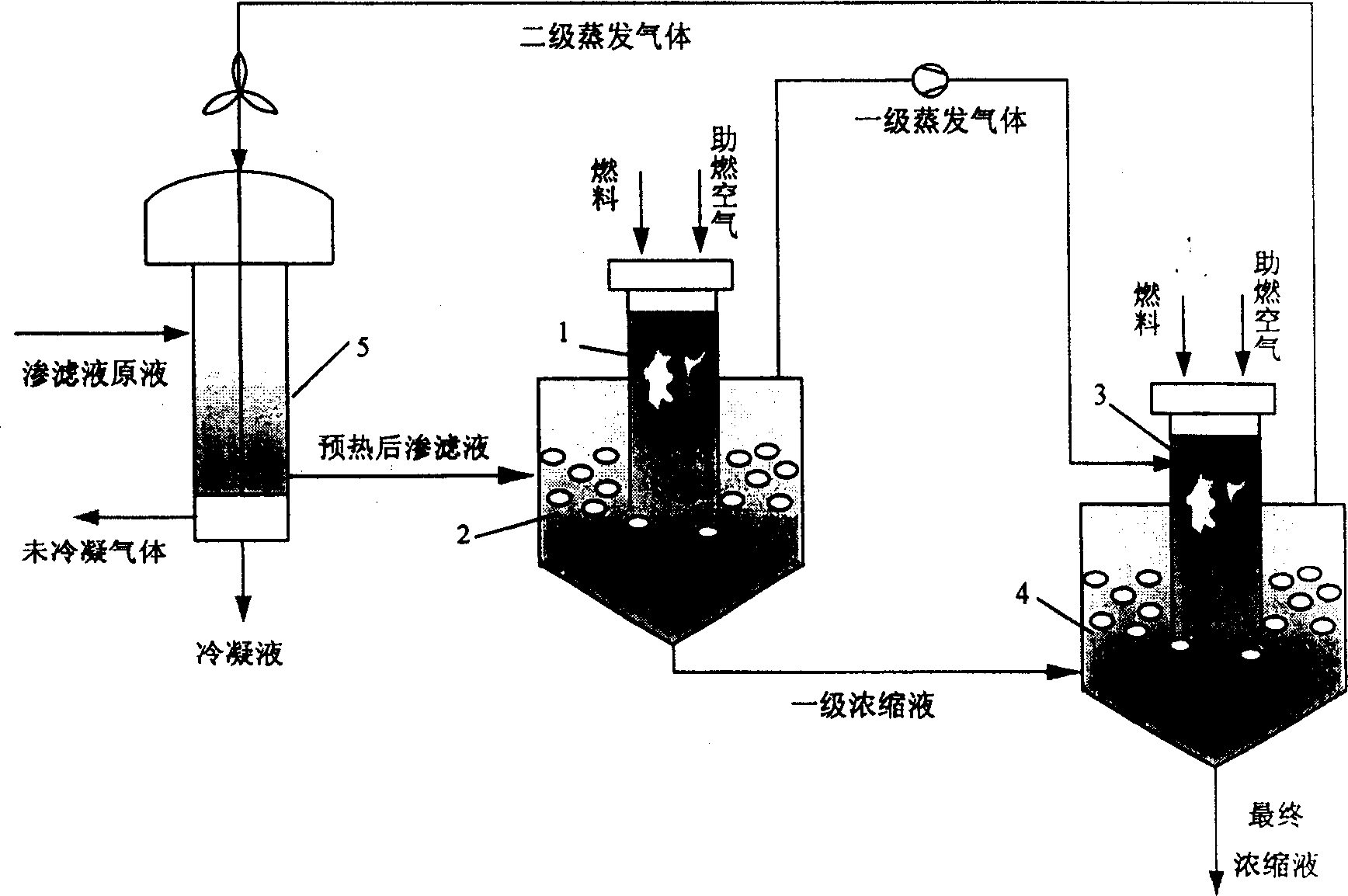

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

[0014] The two-stage treatment method described in the present invention uses landfill gas or other commercial fuels as fuel, adopts submerged combustion evaporation technology, and is divided into two stages: evaporative incineration and evaporative concentration, which are respectively realized by a primary evaporator and a secondary evaporator , The two-stage evaporator each includes a fuel combustion chamber, an evaporation chamber and an air distribution system. The purpose of the primary evaporator is to evaporate as much volatile organic compounds as possible from the leachate and then burn them for destruction. The purpose of the secondary evaporator is to evaporate water from the leachate and concentrate the leachate. The flue gas containing a large amount of volatile organic compounds produced in the evaporative incineration stage (primary evaporator) is inci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com