Triple-generation system for utilizing slag-washing water afterheat by using blast furnace drum method

A technology for slag flushing water and triple supply, which is applied in the field of triple-supply system for the utilization of waste heat of blast furnace slag flushing water, can solve the problems of blockage of heat exchangers and terminal equipment, failure of heating system, failure of filtration system, etc. Insufficient water source, high utilization efficiency of waste heat, and the effect of improving water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

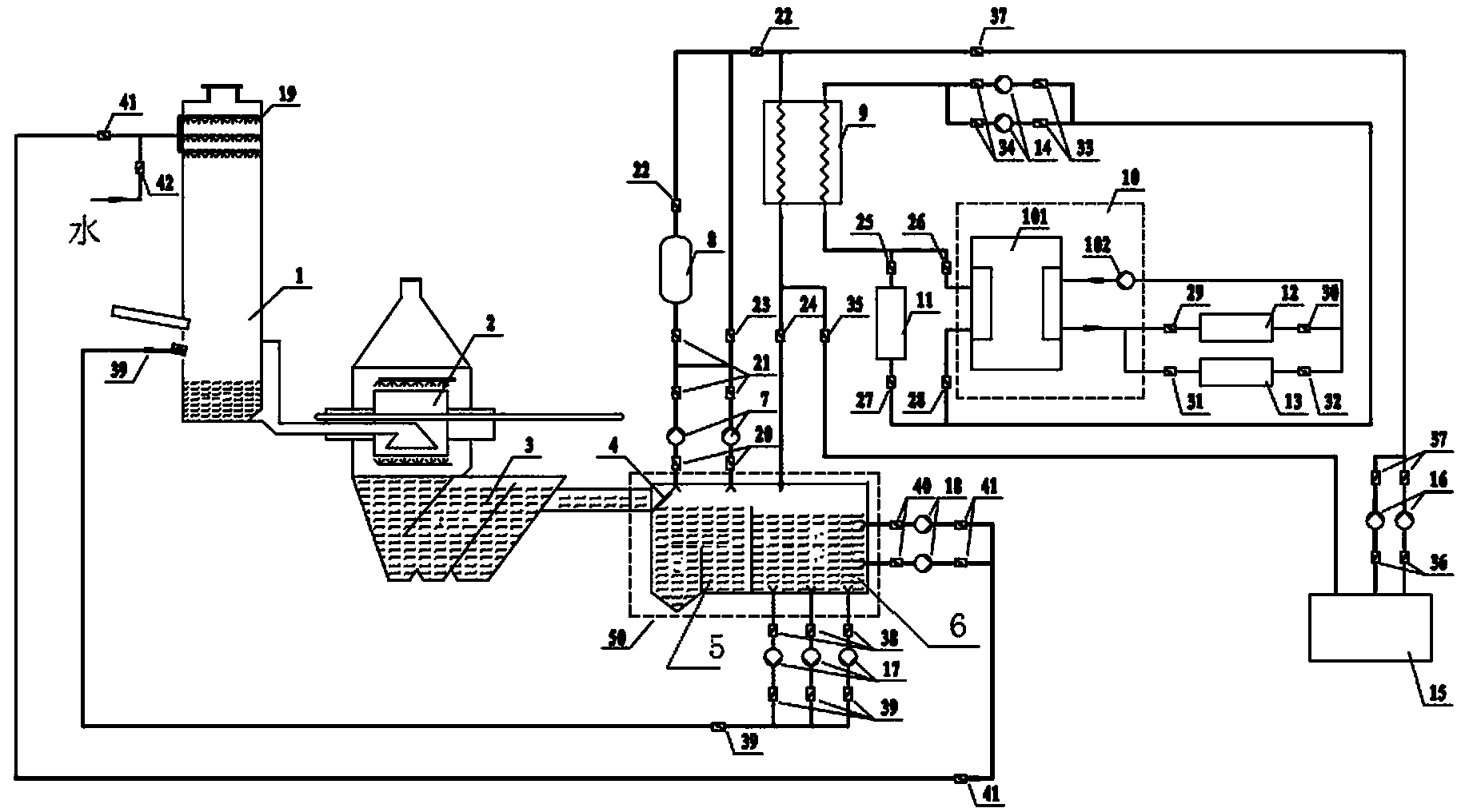

[0024] see figure 1 , a triple supply system for utilization of residual heat from blast furnace drum method slag flushing water, which includes a granulation tower 1 matched with the blast furnace, and the granulation tower 1 is sequentially connected with a drum 2, a hot water tank 3, and a heat storage adjustment pool 50 The heat storage regulating tank 50 includes a sedimentation heat storage tank 5 and a granulation water storage tank 6, and the precipitation heat storage tank 5 and the granulation water storage tank 6 are connected by a partition wall, and the precipitation heat storage tank 5 communicates with the upper part of the granulation storage tank 6; the outlet of the sedimentation heat storage tank 5 is connected to the first inlet of the heat exchange device 9 through the waste heat water supply pump group 7 and the filter device 8, and the first inlet of the heat exchange device 9 One inlet is communicated with the outlet of the chemical cleaning device 15 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com