Residual heat utilization and simultaneous desulfurization and denitrification system for tower type coke oven flue gas

A coke oven flue gas, desulfurization and denitrification technology, applied in the direction of ammonium nitrate, ammonium sulfate, water/sludge/sewage treatment, etc. Low efficiency and other problems, to achieve the effect of improving internal energy utilization, broad prospects for promotion and application, and low construction and operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

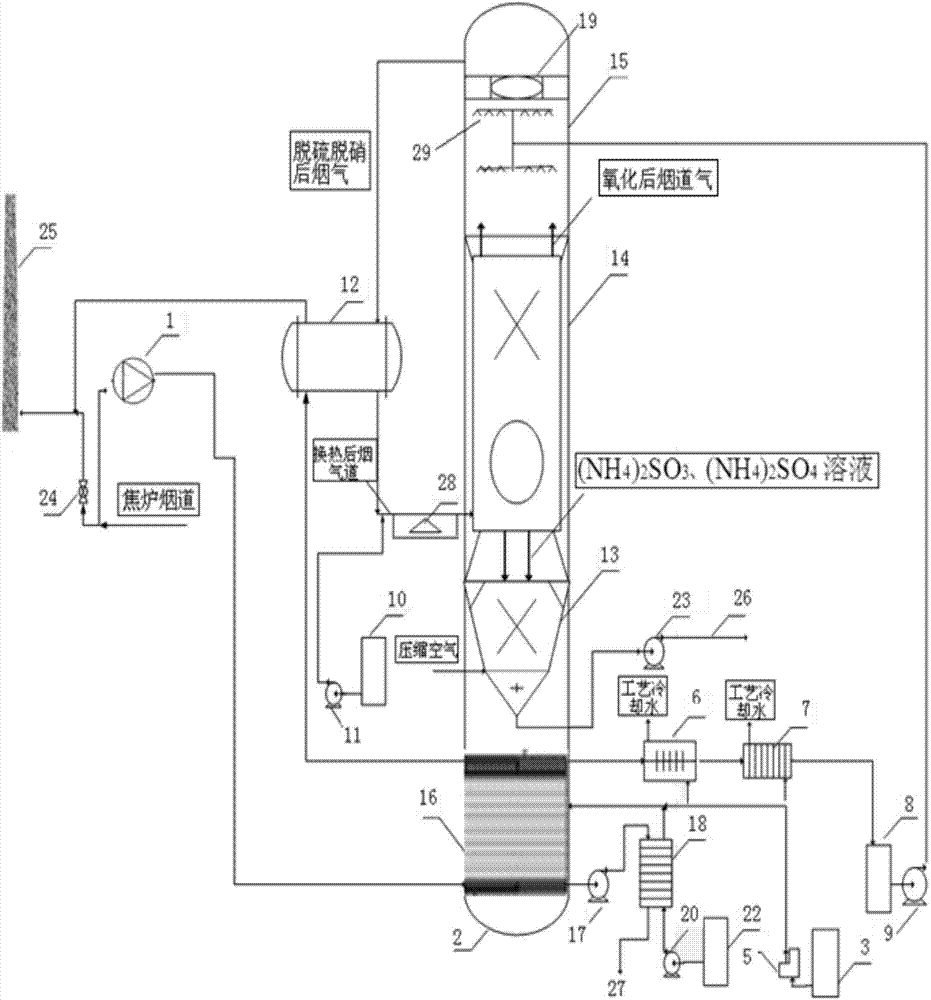

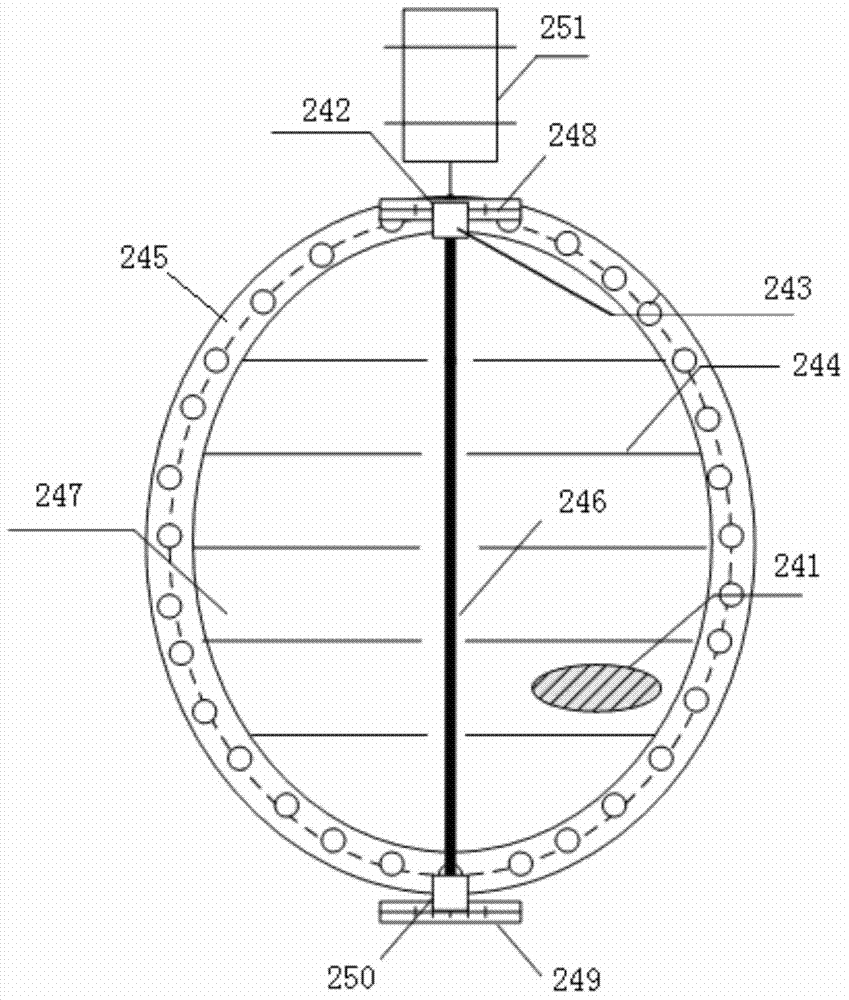

[0021] like figure 1 , figure 2 As shown, a tower type coke oven flue gas waste heat utilization and simultaneous desulfurization and denitrification system includes an induced draft fan 1 and a flue gas purification tower 2, and the air inlet of the induced draft fan 1 is connected to the main coke oven flue in the coke oven basement. The coke oven flue is provided with a flap valve 24, the air inlet of the induced draft fan 1 is connected to the coke oven flue at the front of the flap valve, and the main flue at the front of the flap valve 24 is connected to the exhaust outlet of the coke oven , the air outlet of the induced draft fan 1 is connected to the flue gas purification tower 2, and the flue gas purification tower 2 includes a heat pipe type waste water evaporator 16, a crys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com