Quenching furnace flue gas reusing device and reusing method based on quenching furnace flue gas reusing device

A quenching furnace and flue gas technology, which is applied in the direction of quenching devices, furnaces, furnace components, etc., can solve problems such as long furnace switching time, and achieve the effects of economical project implementation costs, saving consumption, and reducing flue gas emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

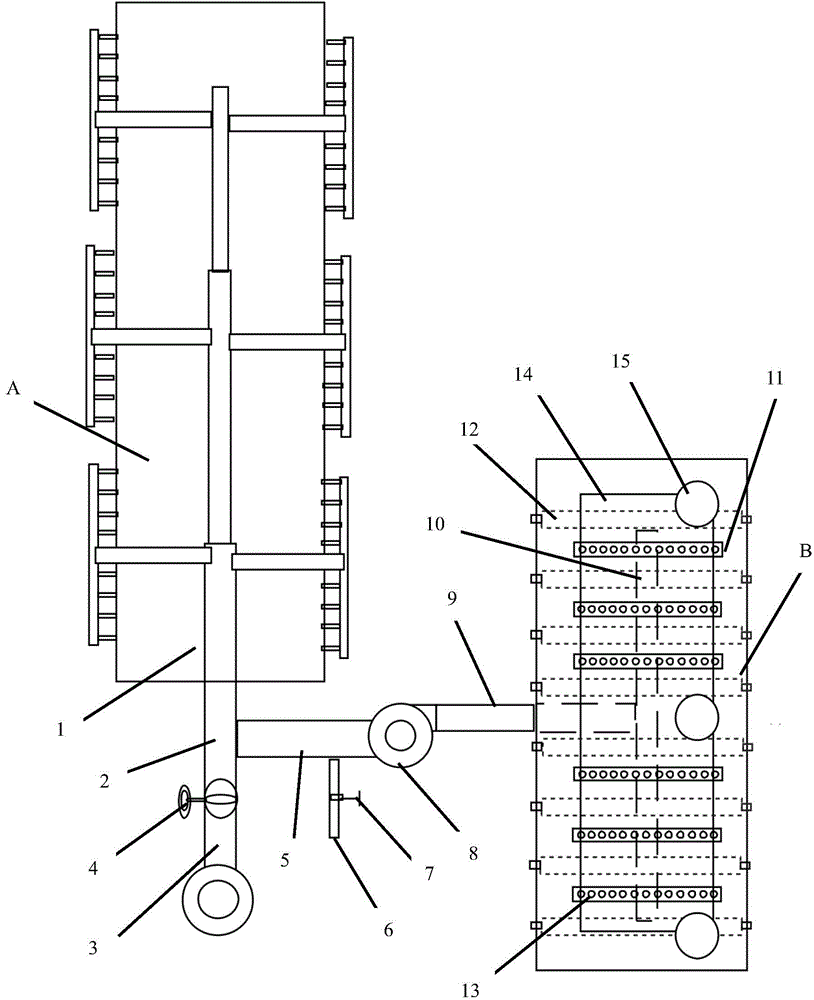

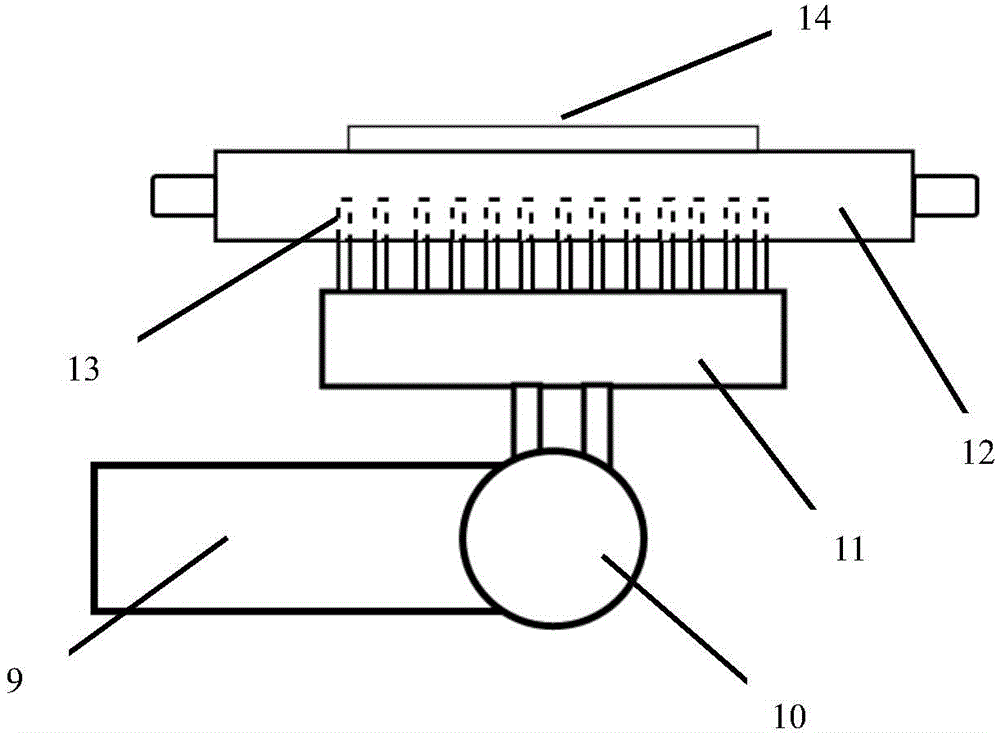

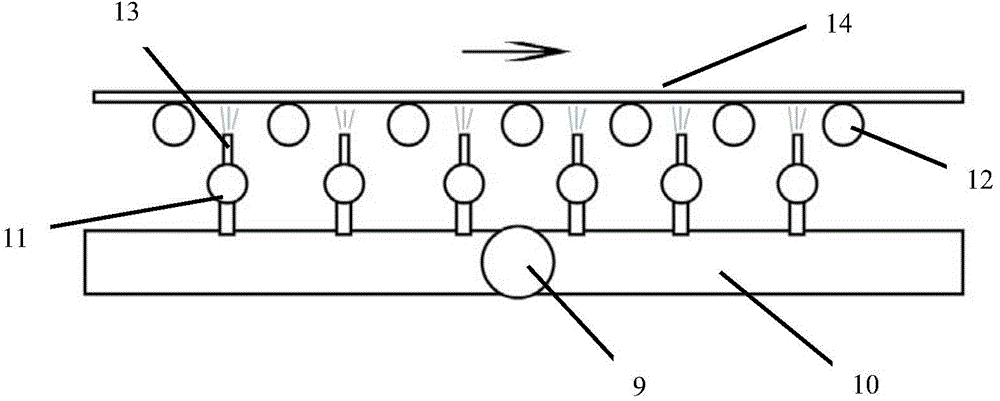

[0026] The structure of the quenching furnace flue gas reuse device provided by the invention is as follows: figure 1 , figure 2 and image 3 As shown, it includes: quenching furnace A and tempering furnace B arranged side by side, the quenching furnace A is provided with a flue gas pipe 1, the bottom of the tempering furnace B is provided with a horizontal flue gas main pipe 9 extending out of the tempering furnace B, the flue gas pipe One end of 1 is provided with a tee pipe 2, and the tee pipe 2 is provided with a connecting pipe 5 and a quenching furnace chimney 3 with an adjustable butterfly valve 4. The air mixing pipe 6 of the regulating valve 7, the end of the connecting pipe 5 is provided with a high-temperature suction fan 8, and the high-temperature suction fan 8 is connected with one end of the horizontal flue gas main pipe 9, and the other end of the horizontal flue gas main pipe 9 is connected with a longitudinal The flue gas main pipe 10, the longitudinal flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com