High-doping-amount furnace slag aerated concrete building block and preparation method thereof

An air-entrained concrete and high-volume technology, which is applied to ceramic products, climate sustainability, and other household appliances, etc., can solve the problem of insufficient stimulation of high-temperature activity of slag, failure to realize the application of high-volume slag, and environmental damage caused by stacking and other problems, to achieve the effect of low density, good thermal insulation performance, high strength and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

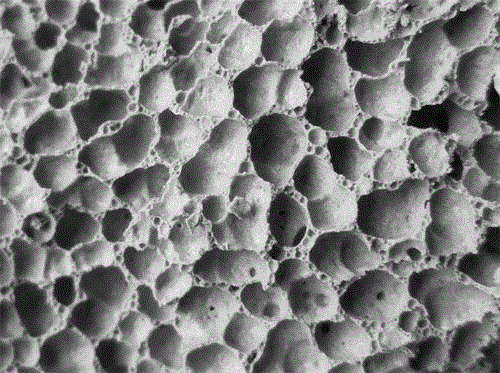

Image

Examples

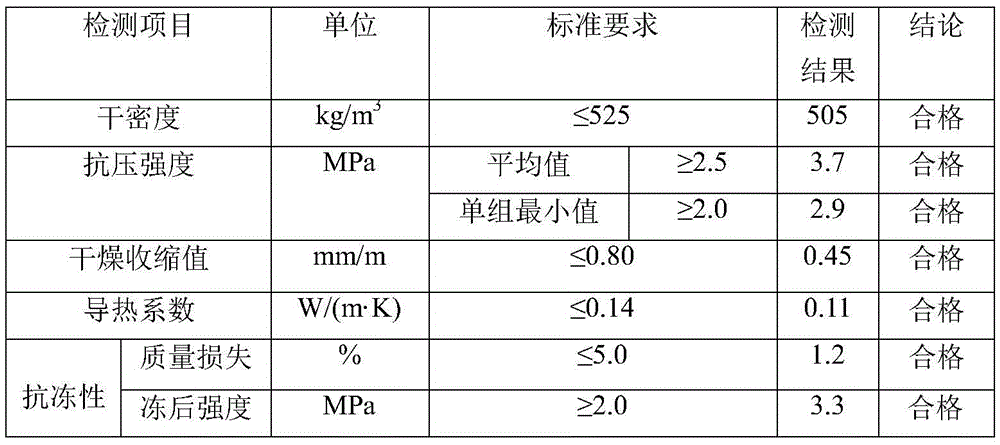

Embodiment 1

[0024] The invention provides an autoclaved aerated concrete block prepared with high-volume slag, which comprises the following components by weight: 125 parts of slag, 30 parts of quicklime, 10 parts of cement, 7 parts of slaked lime, 1 part of desulfurized gypsum, and aluminum powder 0.2 parts of paste, 0.005 parts of thickener, 0.03 parts of foam stabilizer and 175 to 225 parts of water. The amount of water can be adjusted freely within this range without affecting the quality of the final product. Among them, SiO in the slag 2 Content is 20%, Al 2 o 3 Content is 50%, Fe 2 o 3 The content of CaO is 12%, the content of CaO is 3%, the content of MgO is 2.0%, the others are impurities, the PAI index of slag is 56%, the cement is conventional P·O42.5 cement; the aluminum powder paste is water-based aluminum powder paste, model Be GLS-65, 4min gas generation rate 54%, 15min gas generation rate 96%, foam stabilizer is tea saponin, thickener is polypropylene sodium nitrate, h...

Embodiment 2

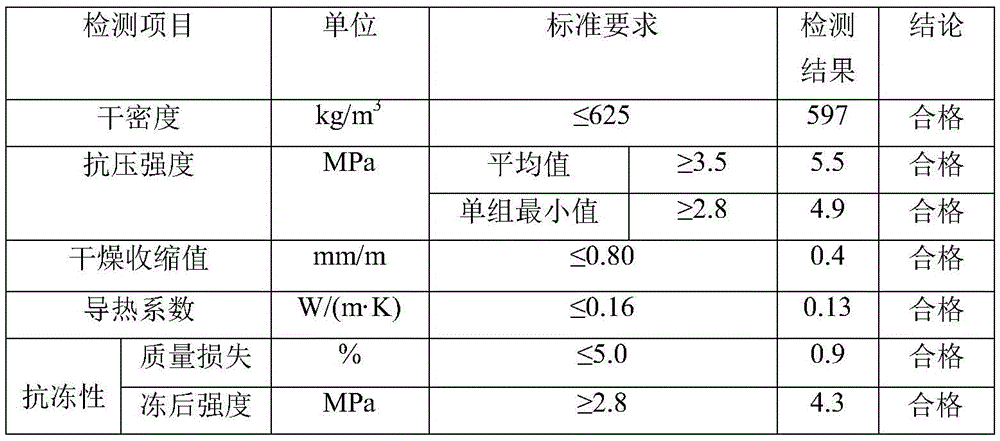

[0035] Provide another autoclaved aerated concrete block prepared by using slag, which includes the following weight components: 130 parts of slag, 38 parts of quicklime, 12 parts of cement, 5 parts of slaked lime, 3 parts of desulfurized gypsum, and 0.27 parts of aluminum powder paste , 0.008 parts of thickener, 0.05 parts of foam stabilizer and 175 to 225 parts of water, the amount of water can be adjusted freely within this range without affecting the quality of the final product. Among them, SiO in the slag 2 The content is 22%, Al 2 o 3 The content is 45%, Fe 2 o 3 The content of CaO is 15%, the content of CaO is 4%, the content of MgO is 1.0%, the others are impurities, the PAI index of slag is 60%, the cement is conventional P·O42.5 cement; the aluminum powder paste is water-based aluminum powder paste, 4min The gas generation rate is 56%, and the gas generation rate is 90% in 15 minutes. The foam stabilizer is acacia powder or pulled apart powder, and the thickener...

Embodiment 3

[0046] An autoclaved aerated concrete block prepared by utilizing slag, which comprises the following components by weight: 140 parts of slag, 46 parts of quicklime, 15 parts of cement, 4 parts of slaked lime, 2 parts of desulfurized gypsum, 0.2 part of aluminum powder paste, 0.01 part of thickener, 0.08 part of foam stabilizer and 175-225 parts of water, the amount of water can be adjusted freely within this range without affecting the quality of the final product. Among them, SiO in the slag 2 The content is 22%, Al 2 o 3 The content is 45%, Fe 2 o 3 The content of CaO is 15%, the content of CaO is 4%, the content of MgO is 1.0%, the others are impurities, the PAI index of slag is 58%, the cement is conventional P·O42.5 cement; the aluminum powder paste is water-based aluminum powder paste, 4min The gas generation rate is 60%, and the gas generation rate is 94% in 15 minutes. The foam stabilizer is acacia powder, and the thickener is clay. Here, 1 part by weight represen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com